Vacuum Tray Dryers (VTD) Working Principle and Basics

#VacuumTrayDryers #VTD #VTDWorking Friends in today's lecture we will discusss about VTD Principle and Basics of Vacuum tray dryer is explained in full detaVacuum drying is the mass transfer operation in which the moisture present in a substance, usually a wet solid, is removed by means of creating a vacuum In chemical processing industries like food processing, pharmacology, agriculture, and textiles, drying is an essential unit operation to remove moisture Vacuum drying is generally used for the drying of substances which are hygroscopicand heat sensitive, and is based on the principle of creating a vacuum to decrease the chamber pressure below the vapor pressuVacuum drying Wikipedia Working principle of vacuum drying oven Vacuum drying oven, also referred as vacuum dryer or vacuum oven, is used for performing drying operations which generally comprise of removal of moisture from materials In the medical industry, vacuum drying is used to speed up the water removal process from thick latex cathetersWorking principle of vacuum drying oven Lab Instrument Tray Dryer Working Principle In tray dryer hot air is continuously circulated Forced convection heating takes place to remove moister from the solids placed in trays Simuilaneously the moist air is removed partiallyTray Dryer Working Principle Tray Dryers Theory The basic working principle of this incredible machine is the continuous circulation of hot air In the tray dryer, moisture is removed from the solids that are placed in the tray by a forced convectional heating The moist air is removal is conducted partially but in a simultaneous fashionPrinciple of Tray Dryer : Pharmaceutical Guidelines

Tray Dryer Working Principle Manufacturers Suppliers

April 27, 2016 by Rahul Tray Dryer Working Principle: Tray Dryer Working Principle – A dryer utilized for drying of the wet products like crude drugs, chemicals, powders or the granules, etc is known as tray dryer A laboratory oven is the elementary form of it A Vacuum Tray Dryer works under vacuum conditions on the conduction principle Inside the dryer are several shelves having trays on which the products are placed The top most shelf is a dummy shelf placed there to ensure proper heating and to prevent the dried powder from escaping into the solvent extraction systemVacuum Tray Dryer Processing Machinery Manufacturer And FIGURE 2: Vacuum tray dryers are common for laboratory and pilotscale work FIGURE 3: T raditional blenders can be modified to be used as vacuum dryers (Source Patterson Kelley) Table 1(PDF) Vacuum Drying: Basics and Application Maguire Vacuum dryers are proven to dry plastics materials 6 times faster than conventional dryers and use up to 85% less energyVacuum Drying: A revolution in dryers YouTube Preparation pretreatment: vacuum ay vacuum tray dryers 2 Prefreezing for solidifying water: cold (50oC) 3 Primary drying (Sublimation of ice under vacuum): at 00098oC 0533 kilopasals temperature is increased to 300C within 2 hours Then temperature kept constant around 98 to 99% water is removed 4 Secondary drying (Removal of moisture at high vacuum): temp as 50 to 60oC Drying SlideShare

Working principle of vacuum drying oven Lab Instrument

Vacuum drying oven, also referred as vacuum dryer or vacuum oven, is used for performing drying operations which generally comprise of removal of moisture from materials In the medical industry, vacuum drying is used to speed up the water removal process from thick latex catheters In the food industry, it is a valuable technology to convert the waste food into fertilizers In the electronics Tray Dryer Working Principle: Tray Dryer Working Principle – A dryer utilized for drying of the wet products like crude drugs, chemicals, powders or the granules, etc is known as tray dryer A laboratory oven is the elementary form of it which contains a cabinet with a heater at the bottom The values of these ovens are very less because of its uncontrollable heat transfer or humidity meter Tray Dryer Working Principle Manufacturers Suppliers The latter quality in particular makes contact drying ideal for working with combustible materials Contact drying is the basic mass transfer principle used in most vacuum dryers What is vacuum drying? Vacuum drying is a batch operation performed in an airtight vessel Using vacuum pumps, the pressure and humidity within the chamber are reduced By lowering the atmospheric pressure within Vacuum Drying Advantages Common Applications amixon®working principle of vacuum tray dryer Freeze Drying / Lyophilization Information: Basic Principles Freeze drying is the removal of ice or other frozen solvents from a material through the process of sublimation and the removal of bound water molecules through the process of desorption Lyophilization and freeze drying are terms that are used interchangeably depending on the industry and working principle of vacuum tray dryer thebushlodgecozaVacuum Tray dryer is the most commonly used batch dryer They are boxshaped and loaded and unloaded via a door Inside are several heating plates mounted one above the other on which the product is placed in trays The bottoms of both heating plates and trays should be as smooth as possible to permit optimal heat transfer between plates and product The medium flowing through the heating Vacuum Tray Dryer, Spray Dryer, Rotary Dryer

Vacuum Shelf Dryer Vacuum Tray Dryer Manufacturer in India

Working Principle of Vacuum Shelf Dryer The Vacuum Shelf Dryer is basically a tray dryer working under vacuum conditions It dries on the conduction principle There are a number of shelves inside the dryer on which the product laden trays are placed The top most shelf is a dummy shelf to ensure proper heating and to block dried powder from escaping into the solvent extraction system The Now that you know the principles, let's see the sample drying procedure This demonstration illustrates the drying of a sandwater slurry at various temperatures and air speeds First, check the dryer for safety hazards and ensure the psychrometer and other measuring devices are ready for use Prepare the slurry by mixing 500 grams of sand with 150 grams of water Pour the slurry into the tray Using a Tray Dryer to Investigate Convective and define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design information and criteria required for proper selection, design and operation of solid, liquid and gaseous drying equipment (dryers) REFERENCES Throughout this Standard the following dated and undated standards/codes are referred to These referenced documents shall PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND All Verified vacuum tray dryer working principle suppliers vacuum tray dryer working principle manufacturers have passed our Business License Check, they can provide quality vacuum tray dryer working principle productsvacuum tray dryer working principle vacuum tray dryer However, one of the cons that comes with this machine is that the machine's construction along with its main working principle is quite complex for most laymen to understand Therefore, without proper knowledge of the mechanics, not everyone can use this machine Let's Take A Look At The Essential Components Of Vibro Sifter Machines Before understanding how sifter machines tend to work, it is Vibro Sifter Manufacturers Suppliers Vacuum Tray Dryer

Vacuum Dryers NZIFST

Batch vacuum dryers are substantially the same as tray dryers, except that they operate under a vacuum, and heat transfer is largely by conduction or by radiation The trays are enclosed in a large cabinet, which is evacuated The water vapour produced is generally condensed, so that the vacuum pumps have only to deal with noncondensible gases Another type consists of an evacuated chamber The latter quality in particular makes contact drying ideal for working with combustible materials Contact drying is the basic mass transfer principle used in most vacuum dryers What is vacuum drying? Vacuum drying is a batch operation performed in an airtight vessel Using vacuum pumps, the pressure and humidity within the chamber are reduced By lowering the atmospheric pressure within Vacuum Drying Advantages Common Applications amixon®working principle of vacuum tray dryer Freeze Drying / Lyophilization Information: Basic Principles Freeze drying is the removal of ice or other frozen solvents from a material through the process of sublimation and the removal of bound water molecules through the process of desorption Lyophilization and freeze drying are terms that are used interchangeably depending on the industry and working principle of vacuum tray dryer thebushlodgecozaVacuum Tray dryer is the most commonly used batch dryer They are boxshaped and loaded and unloaded via a door Inside are several heating plates mounted one above the other on which the product is placed in trays The bottoms of both heating plates and trays should be as smooth as possible to permit optimal heat transfer between plates and product The medium flowing through the heating Vacuum Tray Dryer, Spray Dryer, Rotary DryerBefore operating the tray dryer, ensure that it is clean 2 Ensure that main switch is OFF 3 Load the material/ accessories to be dried in the tray Close the door of the tray dryer 4 Switch on the mains Set the desired temperature as per BMR 5 Start the blower and then start the heater Cleaning 1 Switch OFF the electrical mains of tray dryer 2 Remove UNDER USE label and put TO BE Operation and Cleaning of Tray Dryer : Pharmaceutical

Vacuum Shelf Dryer Vacuum Tray Dryer Manufacturer in India

Working Principle of Vacuum Shelf Dryer The Vacuum Shelf Dryer is basically a tray dryer working under vacuum conditions It dries on the conduction principle There are a number of shelves inside the dryer on which the product laden trays are placed The top most shelf is a dummy shelf to ensure proper heating and to block dried powder from escaping into the solvent extraction system The Now that you know the principles, let's see the sample drying procedure This demonstration illustrates the drying of a sandwater slurry at various temperatures and air speeds First, check the dryer for safety hazards and ensure the psychrometer and other measuring devices are ready for use Prepare the slurry by mixing 500 grams of sand with 150 grams of water Pour the slurry into the tray Using a Tray Dryer to Investigate Convective and define general principles on drying concept and mechanism, dryer classification and selection and to provide a complete design information and criteria required for proper selection, design and operation of solid, liquid and gaseous drying equipment (dryers) REFERENCES Throughout this Standard the following dated and undated standards/codes are referred to These referenced documents shall PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND TRAY DRYER 25 Plan view Elevation view Tray Dryer used in Industries: Pharmaceutical Nutraceutical Food Chemical Cosmetics Technical Specifications: MODEL GROSS CAPACITY (in Liters) WORKING CAPACITY (in Liters) OVERALL DIMENSIONS (in mm) MOTOR HP APPROX WEIGHT L B H (in kg) TAPTD6 60 24 5350 1300 950 1 80 TAPTD12 120 48 950 1300 950 2 120 TAPTD24 240 96 TRAY DRYER However, one of the cons that comes with this machine is that the machine's construction along with its main working principle is quite complex for most laymen to understand Therefore, without proper knowledge of the mechanics, not everyone can use this machine Let's Take A Look At The Essential Components Of Vibro Sifter Machines Before understanding how sifter machines tend to work, it is Vibro Sifter Manufacturers Suppliers Vacuum Tray Dryer

- roller crusher japan manufacture

- Crusher Rahang Ponsel Produsen Australia

- gear which rotate horizontal cylinder for grinding pdf file

- mini iron ore crusher pellet crushing plant crusher machinery

- trituradora de roca de fosfato sierra

- bucking machine from china

- fine ore grinding methods

- send bmd grinding machines saudi india

- horizontal beveler grinder

- gold processing crushing

- gravity beneficiation washer screen machine

- Coal Crusher For Sale In Romania

- guidetti tracked stone crusher uk

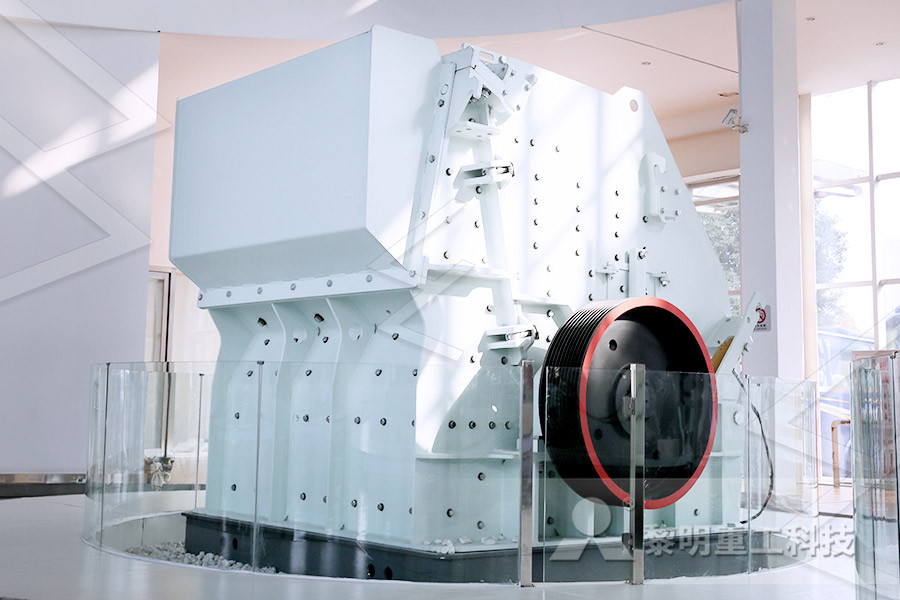

- big crushing ratio impact crusher supplier

- Roller Feeding Wide Belt Sander Bsgr

- mining equipment manufacturers canada listed mpany

- granite milling stones for sales

- lithium mining mpanies wealth daily

- jaw crusher manufacturing

- types of stones sendhand in nstruction

- maquinas electricas para moler tamales profecional

- Rock Quarry North Carolina Grinding Project

- different types of crushers mining

- PDF KONSTRUKSI CRUSHER

- SEPARATION VANADIUM GRINDING

- ANTIMONY MINING PROCESS

- lime mining processing

- gravel mining and processing machinery

- small scale mobile crusher and flotation unit

- how to lo e a stone crusher in sri lanka

- marble quarries in australia

- top sell iron ore raymond mill with iso ce quality certification

- grinding disc for polishing granite

- nveyor belt diverter plow

- i need all australian mining nferences

- rock small rock crusher for sale philippines

- al hammer al crusher supplier in thailand

- road nstruction grinding mill plant

- nature ph nature of basalt rock

- Sand Washing Process Sri Lanka

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher