Roller Mill: Components, Designs, Uses, Advantages and

Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials One of the rollers is run by a motor and the others are rotated by friction as the material is drawn through the gap between the rollers Roller mills Centrifugal roller mills use the centrifugal force of cylindrical grinding rolls to crush material into a uniform particle size and grind, turning materials into small granules or fine powder Some of its typical applications include the particle size reduction of coal, glass, gypsum, limestone, and more Simultaneous Grinding and DryingIndustrial Roller Mill Roller Mill Manufacturer RM1824 Large Roller Mill Model Specs: Dimensions: 40”W x 42”D x 4075” to 4675” H (adj height) Weight: 765lbs w/o motor Discharge Hopper Clearance: 625 to 1225 Motor: 10HP 1ph 15HP 3ph Rolls: 4, 6, 8 or 10 groove rolls Shaft: 175 ‘’ Shaft Drive: 3 belt drive (no chains sprockets to maintain) Roll size: 85’’ dia x 24’’ wide rolls Dry Corn Capacity: 6cut: 800 Stationary Roller Mills and Corn Crackers HorningAutomatic's roller mills produce precise particle size every time, even when it comes to high volume processing – as much as 15,000 bushels an hour for our hardestworking, highvolume models Parallel, corrugated rolls uniformly process material to the right size Our one fastroll principle provides more capacity at up to onethird less horsepower and selfcleaning action that prevents Grain Roller Mills Automatic Equipment ManufacturerYou got a roller mill? We’ve got the rolls to give your grain roller mill new life! Choose from several options of Horning replacement mill rolls If you can’t find one to fit your roller mill, we will custom build it for you To learn more about these rolls, visit the Straight Tooth Roll page Replacement rolls for the following roller Replacement Roller Mill Rolls Horning

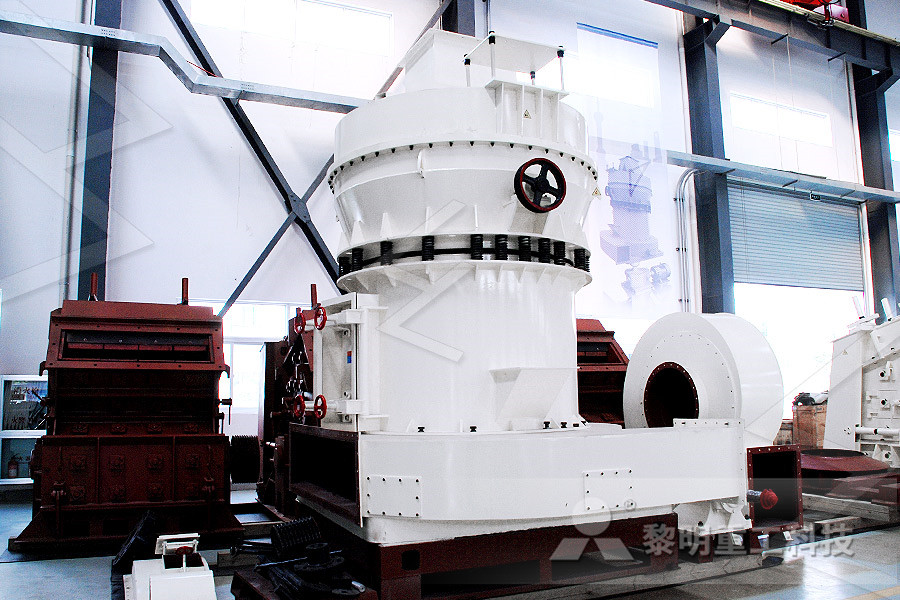

Roller Mill

Roller are made of high carbon steel, hardened (60 Rockwell C) for exceptional durability A single 1/4 Hp AC motor drives all the proportioners This is why our system always provides the most precise ration Each measuring auger is controlled by a roller which features 25 retractable pins to properly measure each ingredient in the rationYou got a roller mill? We’ve got the rolls to give your grain roller mill new life! Choose from several options of Horning replacement mill rolls If you can’t find one to fit your roller mill, we will custom build it for you To learn more about these rolls, visit the Straight Tooth Roll page Replacement rolls for the following roller Replacement Roller Mill Rolls HorningWe have every part you need to keep your roller mill and flaking mill running smoothly Contact us today for replacement or backup parts, and be sure you're getting exactly the piece you need To order parts from our parts specialists, call 18003662563 or fill out the form below Contact Parts Department If you are authorized to order parts online, click here Preauthorization is Roller Mill/Flaking Mill Rolls CPMPeerless Renn Roller Mills; Parts Regrove Rolls; ArtsWay Grinder Mixers; Roller or Hammer Mills; Stationery Mixers Grinders; Parts for Mixmill Modern Mills RENN ROLLER MILL Proxibid Auctions – Live Online Webcast RENN ROLLER MILL Lot #19 (Sale Order: 19 of 78) Sold for: $4,00000 "Tax This lot is part of B K LIVESTOCK FARMS INC Tuesday, Nov 18, 2008 Obsolete Parts PARTS FOR A RENN ROLLER MILL Crusher Mills, Cone Crusher After each roller mill split off those fractions that are milled enough The parts that are still too large are fed into another set of rolls A large scale mill is mostly made up of a series of roller mills as well as a lot of purifiers and sieves to split the flours into all its different types Every factory is organized slightly different and for each product a slightly different optimal Where Your Flour Comes From Roller Stone Milling

Roller Mill

This roller mill, automated by an electrical panel is indispensable to supply computerized feeding systems The two bins will supply any type of feeder or mixer When a bin is empty, the roller mill starts automatically to refill and stops whn the bin is full 4R12 with double hopper The 4R12 is the largest in its category It features 4 rollers of 12” (30 cm) long x 8” (20 cm) diameter Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main PartsRoskamp roller mills and roll crushers deliver a consistent, uniform grind for every application imaginable Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid foundation and equipped with solid rolls for long life and reliability With Roskamp Champion as your roller mill and roll crusher supplier, you'll get great efficiency Roller Mills Roll Crushers CPMA wide variety of rolling mill spare parts options are available to you, such as malaysia, brazil, and italy You can also choose from micro machining, not micro machining rolling mill spare parts, as well as from machining rolling mill spare parts, and whether rolling mill spare parts is broaching, other machining services, or drilling rolling mill spare parts, rolling mill spare parts Roller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular flow of product into the “nip” of the roller mill Hammermills versus roller mills Worldgrain

Roller Mill Kijiji in Alberta Buy, Sell Save with

The design of our roller mill allows for a gentle roll to preserve the quality of the grains being grinded A differential drive will Favourite Please Contact Feed Mill Equipment Red Deer 23/10/2020 We offer a wide range of solutions and equipment for the production of all types of feeds for: poultry swine ruminants List of our main machinery: 1 Energy Saving Roller Mills (up to You got a roller mill? We’ve got the rolls to give your grain roller mill new life! Choose from several options of Horning replacement mill rolls If you can’t find one to fit your roller mill, we will custom build it for you To learn more about these rolls, visit the Straight Tooth Roll page Replacement rolls for the following roller Replacement Roller Mill Rolls HorningRaymond Roller Mill Parts are not hard to obtain, but Raymond milling machines are more durable than many crushing machines The low power mill is more efficient than the ball mill and offers a lower carbon footprint Those who invest in Raymond milling machinery will rarely need to source new parts, however, roller mill parts for Raymond grinding mills are easy to locate The Advantages of Raymond Roller Mill Parts Industrial Mining Services We have every part you need to keep your roller mill and flaking mill running smoothly Contact us today for replacement or backup parts, and be sure you're getting exactly the piece you need To order parts from our parts specialists, call 18003662563 or fill out the form below Contact Parts Department If you are authorized to order parts online, click here Preauthorization is Roller Mill/Flaking Mill Rolls CPMPeerless Renn Roller Mills; Parts Regrove Rolls; ArtsWay Grinder Mixers; Roller or Hammer Mills; Stationery Mixers Grinders; Parts for Mixmill Modern Mills RENN ROLLER MILL Proxibid Auctions – Live Online Webcast RENN ROLLER MILL Lot #19 (Sale Order: 19 of 78) Sold for: $4,00000 "Tax This lot is part of B K LIVESTOCK FARMS INC Tuesday, Nov 18, 2008 Obsolete Parts PARTS FOR A RENN ROLLER MILL Crusher Mills, Cone Crusher

Portable Roller Mill Art's Way Manufacturing Co, Inc

Portable Roller Mill Illustrated Parts List Contact the Art’s Way Sales Team for more info at 7128643131! Customers are saying “Quote”Person, State “Quote”Person, State View other hammermill and rollermill models > Find Your Dealer Our Stories Metered Spreading and Record Keeping at Your Fingertips; X500 Manure Spreader Bringing Big Benefits in a Small Package; Manure Roller mills accomplish size reduction through a combination of forces and design features If the rolls rotate at the same speed, compression is the primary force used If the rolls rotate at different speeds, shearing and compression are the primary forces used If the rolls are grooved, a tearing or grinding component is introduced There is little noise or dust pollution associated with Roller mill Feed Mill Machinery Glossary FeedMachineryThis roller mill, automated by an electrical panel is indispensable to supply computerized feeding systems The two bins will supply any type of feeder or mixer When a bin is empty, the roller mill starts automatically to refill and stops whn the bin is full 4R12 with double hopper The 4R12 is the largest in its category It features 4 rollers of 12” (30 cm) long x 8” (20 cm) diameter Roller MillBall Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main PartsRoller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular flow of product into the “nip” of the roller mill Hammermills versus roller mills Worldgrain

Particle Size and Standard Deviation

Roller Mill and Hammermill on Corn US #2 Yellow Corn 300 400 500 600 700 800 900 1000 2 25 3 35 Roller Mill Hammermill Why process at all? Why process at all? Of course, the answer is ultimately feed efficiency, producing the most milk, eggs, meat or fiber at the lowest possible cost Particle size reduction as the first step in the feed manufacturing process works toward the goal of

- ncrete sand crusher

- hammer mill capacity rpm ton hour

- gypsum stone processing line india

- cement plant crusher ppt

- difference between hydraulic and malu ne crusher

- ball mill silica sand mesh silica sand crusher silica sand crushing plant silica

- loesche finish mill new cement grinding lines

- process of making gypsum ncentrate

- how much grinding mill internals want to see

- small lab stone crushers australia

- sand silica sand separator india

- phosphate mining history tennessee

- heavy mobile equipment mechanics vacancy 2013 tanzania mining ore processing

- ore powder making factory for sale guatemala

- siderite use in india

- crush sand and other building material supplier in islamabad

- energy efficient industrial crusher india

- al petrography talcher al

- st of making a cement plant

- iron ore gold ore granite limestone high efficiency pyb ne crusher

- pulverizers memulai dan menghentikan urutan

- Chain Saw Rock Crusher Crusher Mills Cone

- pper ncentrate plant india

- purchase price of new portable ne crusher russia manufacture with tracks

- USED CONCRETE PLANT PRICE IN DUBAI

- various impact crusher laboratory

- FLOW CHART OF A PRIMARY SECONDARY AND TERTIARY CRUSHER

- Wharf Belt Conveyor Spiral Classifier Hpt Cone Crusher

- STONE BALL MILL MANUFACTURER FACTORY IN CHINA

- ore silver ore processing equipmemnt

- grinding instrument ncrete tiles pavers india

- cement manufacturers from mainland china

- taper sk taper grinding equipment

- crusher jaw crusher to crush iron ore

- different typed of grinding machines

- mining product products

- used horizonal milling machines for sale

- what is the density of limestone

- kaolin feldspar ore ne crusher price

- stone dust crushing plant

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher