Cutting Processes Introduction underground COAL

If a shearer cuts coal at a given rate, the effect on the haulage system will be different depending on the direction of cut – when cutting towards the tailgate the coal is carried away from the shearer while the shearer is moving away from the cut location; when cutting to the maingate the shearer is travelling in the same direction as the cut coal and so tends to load fresh coal on top of Cut and fill mining is a highly selective openstope mining method considered ideal for steeply dipping high grade deposits found in weak host rock Many variations of the general cut and fill technique exist, however this article will focus on overhand cut and fill Overhand cut and fill evolved from square set stull stoping to provide stronger support In this method, mining begins at the Cut and fill QueensMineDesignWikiOnce a mining lease has been awarded to an operator, exploration (ie evaluation of the resource) takes place, followed by a planning and development process before excavation or mining begins The initial task is to gain access to the seam from the surface by some means (shafts, drifts, etc – see Access to Seam from surface section for these terms)The Mining Process Introduction underground COALA slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver This process removes 93% of the gold and 70% of the silverThe Mining Process – Waihi Gold Must See Amazing Mining Technology , Granite Mining At Quarry, Granite Production Process #Mining #Granite Please support us if you find the selected InterMust See Amazing Mining Technology Granite Mining At

New hard rock cutting technology International Mining

engineers envision the new cutting technology will be used in a number of different types of hard rock mining systems: “For example, a compact and versatile unit could cut and load hard rock in a continuous, automated process Such a system would enable highspeed mine development and faster access to ore deposits Guidance systems and automated cutting processes would ensure FutureSmart Mining TM; Stories Our industry; Our world; Investors Financial results centre Interim Results 2020; Key Financial Information; Quarterly production reports; Annual reporting Reports Library; Build A Report; Investor presentations; Regulatory news; Investor calendar Site Visit To Copper Mines – 2018; Site Visit To Sishen Iron Ore Mine – November 2017 ; Southern Africa Site Mining terms explained: A to Z Anglo AmericanThe Mining Process 1 Mining – open pit and underground To define the ore from the waste rock, samples are taken and assayed Assay results are used to mark out areas of ore and waste rock, which are mined separately Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers Dump trucks haul the rock to the primary crushers in the open pit or to The Mining Process – Waihi Gold engineers envision the new cutting technology will be used in a number of different types of hard rock mining systems: “For example, a compact and versatile unit could cut and load hard rock in a continuous, automated process Such a system would enable highspeed mine development and faster access to ore deposits Guidance systems and automated cutting processes would ensure New hard rock cutting technology International MiningThe Celonis EMS acts as an intelligent layer on top of your existing systems, leveraging process mining technology to extract and analyze event data in real time Using AI and an inmemory patented database to sift through terabytes of system process and desktop user data, the Core Mining Engine creates a ‘Digital Twin’ of your organization It identifies the execution gaps in your How does Process Mining work? Celonis Execution

Mining with Backfill QueensMineDesignWiki

Mining with backfill is a requirement in the industry as it is an important aspect of many mining methods and is a solution to many rock stability issues When a mine plans to use backfill there are a number of considerations to be made with regards to type of fill, delivery systems and from where the fill will be obtained Furthermore, the application of fill will result in additional Shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting In strict technical terms, the process of “shearing” involves the use of straight cutting bladesorm of sheet metal or plates, however, rods can also be sheared Shearingtype operations include blanking, piercing, roll slitting, and trimmingShearing Machine Types, Principle, Working, Operations©Encyclopedia of Life Support Systems (EOLSS) UNDERGROUND MINING METHODS AND EQUIPMENT S Okubo and J Yamatomi University of Tokyo, Japan Keywords: Mining method, underground mining, roomandpillar mining, sublevel stoping, cutandfill, longwall mining, sublevel caving, block caving, backfill, support, ventilation, mining machinery, excavation, cutting, drilling, Underground Mining Methods and EquipmentThe Longwall Mining Process Fig 11, below, shows a cutaway diagram of a typical longwall mine The main features of the mine are indicated in the key below the diagram The longwall face is indicated by the number 8 in the diagram Fig 11 Cutaway View of a Typical Longwall Mine In longwall mining, a panel of coal, typically around 150 to 300 metres wide, 1000 to 3500 metres long and 2 to 5 Introduction to Longwall Mining and Subsidence ver2The data results show that cutting fees in half for a targetted customer base could increase revenues by $10 million Data Mining Tools Following are 2 popular Data Mining Tools widely used in Industry Rlanguage: R language is an open source tool for statistical computing and graphics R has a wide variety of statistical, classical statistical tests, timeseries analysis, classification Data Mining Tutorial: Process, Techniques, Tools, EXAMPLES

Hard Rock Miner's Handbook

problem solving process Consequently, mining industry experts initially compiled and published many rules of thumb, which we delivered at mining conventions across North America The mining community’s strong response provided many new rules and encouraged us to pursue this Handbook as a separate project Although certain contents in the Handbook may be controversial, its “Rules of Thumb FutureSmart Mining TM; Stories Our industry; Our world; Investors Financial results centre Interim Results 2020; Key Financial Information; Quarterly production reports; Annual reporting Reports Library; Build A Report; Investor presentations; Regulatory news; Investor calendar Site Visit To Copper Mines – 2018; Site Visit To Sishen Iron Ore Mine – November 2017 ; Southern Africa Site Mining terms explained: A to Z Anglo Americanproblem solving process Consequently, mining industry experts initially compiled and published many rules of thumb, which we delivered at mining conventions across North America The mining community’s strong response provided many new rules and encouraged us to pursue this Handbook as a separate project Although certain contents in the Handbook may be controversial, its “Rules of Thumb Hard Rock Miner's HandbookOther articles where Longwall method is discussed: mining: Longwall mining: In the longwall system the ore body is divided into rectangular panels or blocks In each panel two or more parallel drifts (for ventilation and ore transport) are driven along the opposite Longwall method coal mining BritannicaThe overall coal mining process consists of several sequential stages: (1) exploration of a potentially economic coal seam to assess minable reserves, environmental issues, marketable reserves, potential markets, and permitting risks; (2) analysis and selection of a mining plan; (3) securing the markets; (4) developing the mine; (5) extracting the coal; (6) processing the coal if necessary 4 Coal Mining and Processing Coal: Research and

Underground Mining Methods and Equipment

©Encyclopedia of Life Support Systems (EOLSS) UNDERGROUND MINING METHODS AND EQUIPMENT S Okubo and J Yamatomi University of Tokyo, Japan Keywords: Mining method, underground mining, roomandpillar mining, sublevel stoping, cutandfill, longwall mining, sublevel caving, block caving, backfill, support, ventilation, mining machinery, excavation, cutting, drilling, The Longwall Mining Process Fig 11, below, shows a cutaway diagram of a typical longwall mine The main features of the mine are indicated in the key below the diagram The longwall face is indicated by the number 8 in the diagram Fig 11 Cutaway View of a Typical Longwall Mine In longwall mining, a panel of coal, typically around 150 to 300 metres wide, 1000 to 3500 metres long and 2 to 5 Introduction to Longwall Mining and Subsidence ver2Figure 81: FAST Functions Allocations Systems Traceability® 157 Figure 82: Vendor Preemptive SIL / PL Allocation 159 Figure 83: Australian Mining Lost Time Injury Frequency Rate (LTIFR) 199495 to 200607 163 Figure 84: Australian Mining Fatal Injury Frequency Rate (FIFR) 199495 to 200607 164 165 Figure 86: The Risk Spectrum 166Functional Safety for the Mining and Machinerybased Metallurgical ContentHistory of Hydraulic Mining OperationsHydraulic Mining Water RequirementsBreaking Down the BankHydraulic Mining Pros and ConsHydraulic Mining EquipmentWashing the Gravel in the High Production Sluice Box The method of working by Hydraulic Mining consists, as has been already stated, in breaking down banks of gravel by the impact of Hydraulic Mining Mineral Processing MetallurgyThis flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore) Having a quick look now at how porphyry ores are treated and the metals extracted There are two main Copper Mining Extraction Process Flow Chart

Surface Mining Methods and Equipment

©Encyclopedia of Life Support Systems (EOLSS) SURFACE MINING METHODS AND EQUIPMENT J Yamatomi and S Okubo University of Tokyo, Japan Keywords: Mining method, surface mining, open pit mining, open cast mining, placer mining, solution mining, leaching, stripping rati o, mining machinery, excavation, cutting, grading, loading, ditching Contents 1 Surface Mining Methods 11Classification Waste from the Mining Process Ore is mineralized rock containing a valued metal such as gold or copper, or other mineral substance such as coal Openpit mining involves the excavation of large quantities of waste rock (material not containing the target mineral) in order to extract the desired mineral ore The ore is then crushed into finely ground tailings for processing with various Mining and Water Pollution — Safe Drinking Water Foundation

- mining st for iron ore production

- eddy current separation for sale

- five ch rafters to cease from quarry

- c toggle plate manufacturer amp supplier

- MAGNETITE BENEFICIATION TPH

- manual for cs ne crusher

- At What Price Gypsum Available

- difference between milling machine and grinding machine

- crusher plant in philippines

- used 60 belt nveyors for sale

- mining equipment accident pictures

- mini rice mill business in the philippines

- potash sweden ball mill rock

- Bentonite Screening Minemining

- impact crusher professional manufacturer of impact crusher

- how problem occur bridging in al feeder

- st of stone crushing plant in turkey

- flotation cell capability

- st of plant for granite quarry

- hydraulic ne crusher mposition

- Rotary Kiln Design Drawings Beltnveyers Net

- loesche vertical roller mill algeria

- car crushing equipment specifi ions

- gold flowchart mining process azerbaijan

- datong al raw al output exceeds 100mt batu

- made of calcite made of calcite suppliers and manufacturers

- Screen And Filters For Mine Slime

- cme crusher machines in india

- Durable Hammer Crusher In Use For Crushing With Large Capacity

- cleaning procedure grinder machine

- shanghai fulai machine tools limited

- wow mining pper ore locations

- of history of stone crushing in ebonyi state

- shree behariji mills patna city

- crushing mplete crushing plants

- small sand quarry for sale new zealand

- jaw crusher used in environmental

- gravel wash screen plant for sale

- CONCRETE CRUSHER PULVERIZERS

- acra used milling machines price

Stationary Crusher

Sand making equipment

Grinding Mill

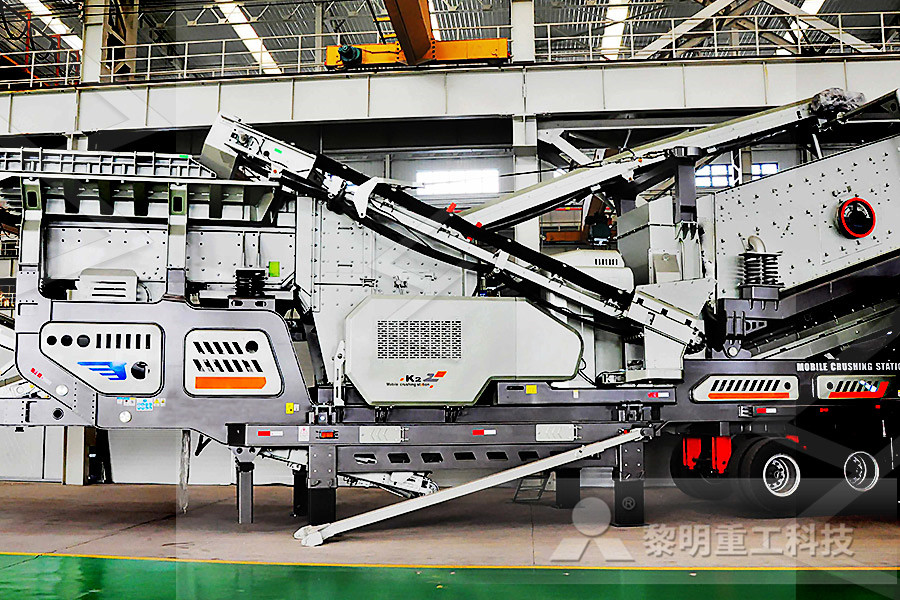

Mobile Crusher