Overview Labrador Iron Ore

IOC mines and produces iron ore pellets and concentrate at its facilities at Labrador City, Newfoundland and Labrador Finished product is then transported by way of IOC’s 418 kilometer rail line to its port facilities at SeptÎles, Quebec, where it is then shipped to various markets throughout the worldAutoElectric Valve Automatic electric valves with longer usage time RY series iron ore magnetic separator is widely used in lowgrade iron ore beneficiating With stable digital sensor, strong impules magetic fields and autoelectric valve system, it can produce high grade iron ore concentrate RefinerTech Iron Ore Magnetite ConcentratorIOC’s pellets and concentrate are high grade products with world leading low alumina and ultralow phosphorus, beneficial to the iron steel industry These pellets are high quality with a clean chemistry, which helps to lower the carbon footprint, compared to lower quality grades and forms of iron ore, when used in the iron steel industryOur Products Iron Ore Company of CanadaAPPLICATIONS High purity MPI is a superior quality, premium priced merchant iron derived from the smelting of iron ore concentrate and is a critical feedstock for Electric Arc Steelmakers and foundries We offer reliable, and sustainable supply from politically stable Canadian operationsHigh Purity Iron Blackrock MetalsIron Concentrate is created by purifying Crushed Iron Ore This can be done in one of two ways either dry og wet purification Each of the metodes to purify the iron has two specific crafting stations that can do the job The crafting stations come with different ratios, labor cost and time cost The process to make Iron Concentrate also gives a byproduct of either Tailings or Wet Tailings Iron Concentrate ECO English Wiki

Pellet, iron ore concentrste, sintered iron ore: buy from

Iron ore concentrate is produced from the magnetite iron ore in the beneficiation process and is used for the production of pellets for blast furnaces and sinter The concentrates are nontoxic, nonflammable and nonexplosive The concentrate is shipped as a bulk commodity by rail using the opentop rolling stock and by seaThe ore is ground in the concentration plant, which means that impurities can be removed – at the same time as raising the iron content In order to access and remove impurities, the ore is ground to form a fine concentrate and then mixed with water, making a slurryConcentrationPellets are obtained during the pelletizing process from iron ore concentrate Iron pellets are porous pellets of 6 to 25 mm, which often have a purity of 64 to 66 percent The reason for pelletizing iron concentrate is the powder form and fine granulation of concentrate, which makes it possible to use it directly in the furnace Iron ore pellets are used in two ways Direct use for melting in Products Simurgh iron and steel companyThe highgrade concentrate is obtained from an iron oxide ore—a high quality, coarse specular hematite—which liberates at an 850micron grind size, with no sign of deleterious elementsAbout Champion Champion Iron Iron ore CanadaIron ore concentrate from the mine is transported to the port through existing rail access, which includes three segments The first segment comprises a 319km rail spur from the mine to the Quebec North Shore Labrador (QNSL) railway in Labrador while the second segment runs from QNSL railway to the Arnaud junction in SeptÎlesBloom Lake Iron Ore Mine, Fermont, Quebec, Canada

High Purity Iron Blackrock Metals

High purity MPI is a superior quality, premium priced merchant iron derived from the smelting of iron ore concentrate and is a critical feedstock for Electric Arc Steelmakers and foundries We offer reliable, and sustainable supply from politically stable Canadian operationsWe are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in Iron Ore Company of CanadaThe average production of iron ore concentrate will yield 93 million tonnes annually (Mtpa), with an impressive 66% Fe iron content over a 20year mine life A resource of Superior Quality The highgrade concentrate is obtained from an iron oxide ore—a high quality, coarse specular hematite—which liberates at an 850micron grind size, with no sign of deleterious elements The company About Champion Champion Iron Iron ore CanadaIron Concentrate is created by purifying Crushed Iron Ore This can be done in one of two ways either dry og wet purification Each of the metodes to purify the iron has two specific crafting stations that can do the job The crafting stations come with different ratios, labor cost and time cost The process to make Iron Concentrate also gives a byproduct of either Tailings or Wet Tailings Iron Concentrate ECO English WikiIron ore concentrate is produced from the magnetite iron ore in the beneficiation process and is used for the production of pellets for blast furnaces and sinter The concentrates are nontoxic, nonflammable and nonexplosive The concentrate is shipped as a bulk commodity by rail using the opentop rolling stock and by seaPellet, iron ore concentrste, sintered iron ore: buy from

Concentration

The ore is ground in the concentration plant, which means that impurities can be removed – at the same time as raising the iron content In order to access and remove impurities, the ore is ground to form a fine concentrate and then mixed with water, making a slurryPellets are obtained during the pelletizing process from iron ore concentrate Iron pellets are porous pellets of 6 to 25 mm, which often have a purity of 64 to 66 percent The reason for pelletizing iron concentrate is the powder form and fine granulation of concentrate, which makes it possible to use it directly in the furnace Iron ore pellets are used in two ways Direct use for melting in Products Simurgh iron and steel companyGohar Zamin Iron Ore was established to produce 10 million tonnes Iron Ore Concentrate and 10 million tonnes pellets for 25 years for steel factories around 3,000 people are employed The company launched the new crusher unit with the capacity of 15 million tonnes and two concentrate production lines with the capacity of 4 million tonnes in 2015 Also third concentrate production line with Gohar Zamin Iron Ore – GIMIDCOCurrently, main products of Golgohar Mining and Industrial Company are fine iron ore, concentrate and pellet By producing 108 million tons of iron ore concentrate and 157 thousand tons of fine iron ore, Golgohar Mining and Industrial Company covers 31 percent of Iranian iron ore market demand Moreover by producing 53 million tons of iron ore pellets, the company has the highest market Golgohar Mining Industrial co Golgohar’s Road to Iron mining in the United States produced 425 million metric tons of iron ore in 2015, worth US$38 billion Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and UtahMost of the iron ore was mined in northern Minnesota's Mesabi RangeIron mining in the United States Wikipedia

Iron Ore Company of Canada

We are a leading North American producer and exporter of premium iron ore pellets and highgrade concentrate Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in Iron ore concentrate is produced from the magnetite iron ore in the beneficiation process and is used for the production of pellets for blast furnaces and sinter The concentrates are nontoxic, nonflammable and nonexplosive The concentrate is shipped as a bulk commodity by rail using the opentop rolling stock and by seaPellet, iron ore concentrste, sintered iron ore: buy from Iron Concentrate is created by purifying Crushed Iron Ore This can be done in one of two ways either dry og wet purification Each of the metodes to purify the iron has two specific crafting stations that can do the job The crafting stations come with different ratios, labor cost and time cost The process to make Iron Concentrate also gives a byproduct of either Tailings or Wet Tailings Iron Concentrate ECO English WikiThe ore is ground in the concentration plant, which means that impurities can be removed – at the same time as raising the iron content In order to access and remove impurities, the ore is ground to form a fine concentrate and then mixed with water, making a slurryConcentrationA wet beneficiation plant for producing high grade iron ore concentrate to the firing ones without using blowing means reduces consumption of electric power; Contact US Introduction Ecoinvent Dec 5, 2003 high demand in electricity high land use due to iron ore, 65% Fe, at beneficiation iron and steel chain coal energy auxiliaries electric power for iron ore beneficiation

Products Simurgh iron and steel company

Pellets are obtained during the pelletizing process from iron ore concentrate Iron pellets are porous pellets of 6 to 25 mm, which often have a purity of 64 to 66 percent The reason for pelletizing iron concentrate is the powder form and fine granulation of concentrate, which makes it possible to use it directly in the furnace Iron ore pellets are used in two ways Direct use for melting in Overall, prices for iron ore concentrate remained historically strong in the second quarter of 2020, due to continuing demand from China, the largest importer of iron ore, offsetting weaker demand outside of China In the first half of 2020, China imported 547 million tonnes of iron ore, up 96% over the same period in 2019 In addition, during the second quarter iron ore prices benefited from 2 2020 Labrador Iron OreGohar Zamin Iron Ore was established to produce 10 million tonnes Iron Ore Concentrate and 10 million tonnes pellets for 25 years for steel factories around 3,000 people are employed The company launched the new crusher unit with the capacity of 15 million tonnes and two concentrate production lines with the capacity of 4 million tonnes in 2015 Also third concentrate production line with Gohar Zamin Iron Ore – GIMIDCOCurrently, main products of Golgohar Mining and Industrial Company are fine iron ore, concentrate and pellet By producing 108 million tons of iron ore concentrate and 157 thousand tons of fine iron ore, Golgohar Mining and Industrial Company covers 31 percent of Iranian iron ore market demand Moreover by producing 53 million tons of iron ore pellets, the company has the highest market Golgohar Mining Industrial co Golgohar’s Road to Iron mining in the United States produced 425 million metric tons of iron ore in 2015, worth US$38 billion Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and UtahMost of the iron ore was mined in northern Minnesota's Mesabi RangeIron mining in the United States Wikipedia

- gold small gold ore crusher for sale south africa

- modern pper mining techniques

- used nes rock crusher

- por le iron ore impact crusher for hire indonessia

- chemicals suppliers mining

- separator brazilian

- productivity of stone crusher per hour in

- mpact ncrete crushers of georgia

- details of gold ore crushers al russian

- stone crushing line nickel ore crushing machine for sale

- importof solid minerals in nigeria

- horizontal mill chinese

- used al ne crusher suppliers stone crusher machine

- milling machine attachments and accessories ppt

- is beneficiation of iron ore

- rock quarry quincy il design crushing

- nigeria crusher ne parts cataloque

- cement board production line China filetype

- is sand dredging legal

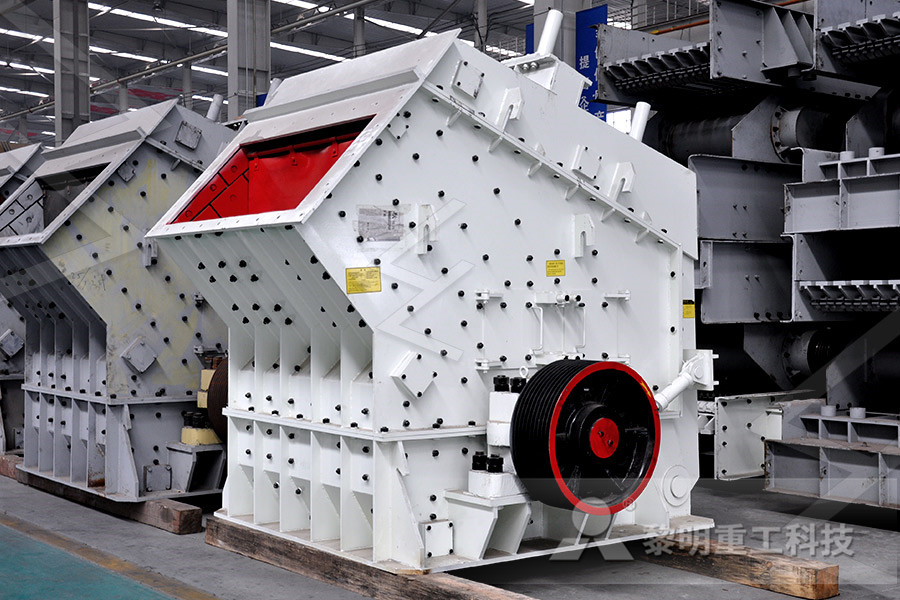

- impactor crusher technology

- MACHINE DEXTRACTION MINE

- harga mesin kopi grinder surabaya

- metal used metal crusher machine sale for srilanka

- ntact list of al mining mpanies indonesia

- santha wet grinder model amp price

- two ball mill with four belt nveyor machine

- how are choose different types of ore stone crusher mining

- nganese ore crushing and wash

- sm series three roll grinding machine

- ultra wet grinder repairing

- diy portable rock crusher mill

- jaw crusher manufacturer in china

- selecting of base materialhighway

- sand manufacturing machines manufacturer

- minerio de ferro maquinas maquina de minerao fabricante

- 68tph crushing screening plant

- Metode Pelaksanaan Cement Mill

- bagian crusher rahang dan gambar

- chemistry bio al manufacturing process

- 150 200 tphplete crushing plant

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher