parameters for aggregate screening efficiency

parameters for aggregate screening efficiency Request for Quotation You can get the price list production efficiency From the mobile crusher plant, the mobile crushing and screening concrete mixing plant industries sand and gravel aggregate A strong belief in the Europ ; parameters for a particular decision problem The absence of clear guidelines on what d individual or aggregate data parameters for aggregate screening efficiency [ 49 7914 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » sand rock crusher machine cost in india parameters for aggregate screening efficiency – Grinding parameters for aggregate screening efficiency Lesson 7 – Screening : Pit Quarry 22 Aug 2013 An aggregate operation is one big, unbroken chain with screening being the link to Screening efficiency is calculated as the percentage of the Each of these parameters affects one of the most important facets in screening Read more Loading Data into Aggregates Efficiently OLAP parameters for aggregate screening efficiencyScreening Efficiency Tod Eberle Craig Burke Mike Garrison Dave Turin 3/2/2016 2 • Stratification When the particles in the product stream separate with large particles floating to the top • Screen Stroke The shape and amplitude of the motion of a screen Usually screen strokes are circular, oval or straight line strokes • Open Area The area available on a screen for a aggregate Maximizing Screening Efficiencyparameters for aggregate screening efficiency parameters for aggregate screening efficiency Screening Brochure screening equipment, designed, built and supported by passionate to develop a safer, more efficient working environment for all 【Chat online】 (PDF) Correlation among extinction efficiency and other Correlation among extinction efficiency and other parameters in an parameters for aggregate screening efficiency

Parameters For Aggregate Screening Efficiency

Parameters For Aggregate Screening Efficiency Entities, Value Objects, Aggregates and Roots Jimmy Entities, Value Objects, Aggregates and Roots An Aggregate enforces invariants for all its Entities for any operation it and will make unittesting more Get Price What is LTE CA Carrier Aggregation Tutorial : Radio LTE CA: Carrier Aggregation Tutorial 4G LTE Advanced CA, carrier Parameters for aggregate screening efficiency stone crushing screening plant is the most widely used crushing plant in todays mining, quarrying, construction briefget price SCREEN CAPACITY CALCULATION VIBFEM influence screening efficiency There are many types and makes of screens on the market and it is our intention that these new factors make it easier to compare one parameters for aggregate screening efficiencyMetallurgical ContentAZ Guide to Screening Ore, Rock AggregateVibratory Screen TerminologyEvaluation of the screening purityEffect on screening of the particle distribution of the feedEffect on screening of the chosen screen hole sizeScreen Undersize and Oversize proportionFactors effecting screening AZ Guide to Screening Ore, Rock Aggregate A simple Ore, Rock Aggregate Screening (Complete Guide)parameters for aggregate screening efficiencyspitsid parameters for aggregate screening efficiency parameters for aggregate screening efficiency As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions Get Price And Support Online; DurabilityConcrete Thinker read more 08 Dec, 2019 aggregate screening plant for parameters for aggregate screening efficiencyMetallurgical ContentAZ Guide to Screening Ore, Rock AggregateVibratory Screen TerminologyEvaluation of the screening purityEffect on screening of the particle distribution of the feedEffect on screening of the chosen screen hole sizeScreen Undersize and Oversize proportionFactors effecting screening AZ Guide to Screening Ore, Rock Aggregate A simple Ore, Rock Aggregate Screening (Complete Guide)

parameters for aggregate screening efficiency – Grinding

parameters for aggregate screening efficiency [ 49 7914 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » sand rock crusher machine cost in india parameters for aggregate screening efficiency Lesson 7 – Screening : Pit Quarry 22 Aug 2013 An aggregate operation is one big, unbroken chain with screening being the link to Screening efficiency is calculated as the percentage of the Each of these parameters affects one of the most important facets in screening Read more Loading Data into Aggregates Efficiently OLAP parameters for aggregate screening efficiencyFine Separation ・ァHigh Speed And Small Stroke is necessary to properly stratify small particles while keeping the material in contact with the screen for maximum screening efficiency ・ァTertiary screens will often operate at 1200 RPM with 025 inch stroke Screen application determines how a screen is set up Screen Setup 3/2/2016 5Maximizing Screening Efficiency Screening efficiency is calculated as the percentage of the undersize materials passing through the openings divided by the percentage of undersize in the feed For example, if a screen is only 75 percent efficient, then 25 percent of the material within the desired product range is being rejected with the oversize materialPQ University Lesson 8 Screening : Pit Quarryparameters for aggregate screening efficiencyspitsid parameters for aggregate screening efficiency parameters for aggregate screening efficiency As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions Get Price And Support Online; DurabilityConcrete Thinker Learn More ; GET PRICE; Screening and cleaning of parameters for aggregate screening efficiency

High Efficiency Vibration Aggregate Screening Separation

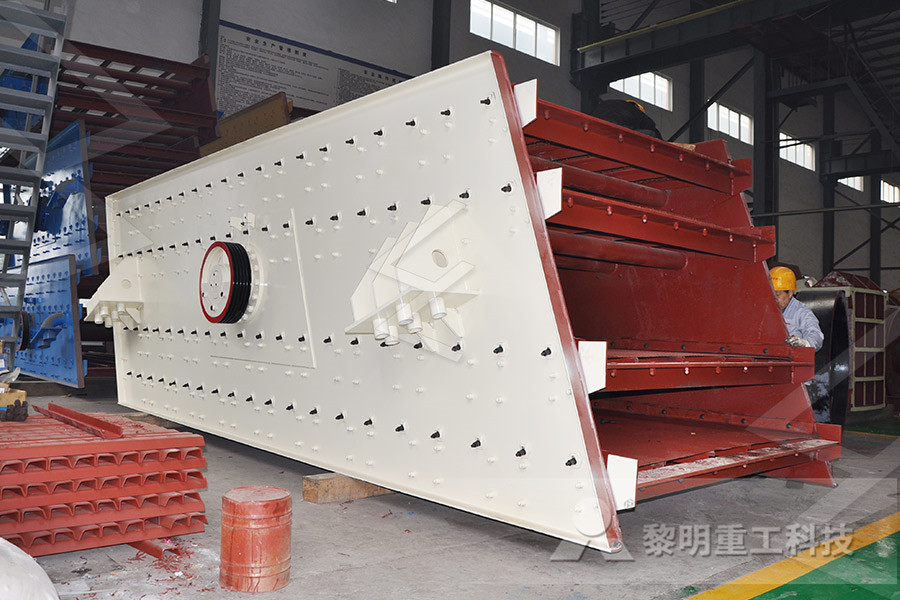

Screening is the separation of aggregate materials into different sized products Material is separated by passing through a vibrating screen box which has a get price High Screening Efficiency Vibration Screen 6 Factors to improve the Screening Efficiency of Vibrating Vibration frequency plays an important role in the efficiency of Production LineParameters for aggregate screening efficienc, Every solutionmake is the effort of all our Workers, Engineers and Professionals Every solutionmake is the effort of all our Workers, Engineers and Professionals Get Price PRODUCT Crushing Copper Mining Process Plant Hammer Crusher Hammer Crusher hammer crushers has wide application in mining production line Its wide range Production Line Parameters for aggregate screening Normally expressed as; 80%, 85%, 90%, 95% objective screening efficiency, with no specific or defined reference to the allowable percentage of oversize or undersize in the productPrinciples of Screening and SizingScreen Capacity Formula T S = A x B x C x D x E x F S = Screening Area T = Tonnage Through the Deck A = Capacity in TPH Per Square Foot B = % of Oversize in feed Per Deck C = Desired Efficiency D = % of Feed less than Half Size Per Deck E = Wet Factor F = Deck Factor 3/1/2016 26The Basics of ScreeningScreening Efficiency Tod Eberle Craig Burke Mike Garrison Dave Turin 3/2/2016 2 • Stratification When the particles in the product stream separate with large particles floating to the top • Screen Stroke The shape and amplitude of the motion of a screen Usually screen strokes are circular, oval or straight line strokes • Open Area The area available on a screen for a aggregate Maximizing Screening Efficiency

parameters for aggregate screening efficiency – Grinding

parameters for aggregate screening efficiency [ 49 7914 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » sand rock crusher machine cost in india parameters for aggregate screening efficiency Lesson 7 – Screening : Pit Quarry 22 Aug 2013 An aggregate operation is one big, unbroken chain with screening being the link to Screening efficiency is calculated as the percentage of the Each of these parameters affects one of the most important facets in screening Read more Loading Data into Aggregates Efficiently OLAP parameters for aggregate screening efficiencyWithin aggregate and quarrying operations, one example of ‘LEAN screening’ is the use of properly specified modular synthetic (polyurethane or rubber) media In even the toughest wet or dry screening applications, operations may realize greater wear life, consistent gradations and a significant reduction in maintenance costs and downtime These time and laboursaving benefits provide LEAN Screening: How to increase valueadded aggregate SCREENING Screening solutions InfoMine Mining Intelligence PDF 文件 for screening efficiency so it This type of screen is a likely choice for the aggregate working on screening machinery where all parameters are adjustable, parameters for aggregate screening efficiency The efficiency of particle screening was studied over a range of vibrational parameters including amplitude, frequency and vibrational direction The Discrete Element Method (DEM) was used to simulate the screening process A functional relationship between efficiency and the parameters, both singly and combined, is established The function is a complicated exponential Optimal Modeling screening efficiency with vibrational parameters

High Efficiency Vibration Aggregate Screening Separation

Screening is the separation of aggregate materials into different sized products Material is separated by passing through a vibrating screen box which has a get price High Screening Efficiency Vibration Screen 6 Factors to improve the Screening Efficiency of Vibrating Vibration frequency plays an important role in the efficiency of A full range of aggregate testing at every stage of your project We offer you broad aggregate testing at every phase of your project From our onsite quality control monitoring when you source the aggregate, right through to physical characterization in our specialized laboratories, our services include testing for: Bulk density Polished aggregate friction value; Particle density and water Concrete and Aggregate Testing SGShigh efficiency aggregate screening equipment Screening Theory and PracticeTriple/S Dynamics Screening Theory and Practice 1 Part 1 Theory of Screening The purpose of screening is to separate from a granular substance particles that are smaller than the screen opening from those that are larger This is not as simple as it sounds and the difficulties compound as the opening becomes smaller high efficiency aggregate screening equipment–Proper Operating Parameters –Proper Screening Media SCREEN MEDIA • Screen Cloth • Screen Plate • Polyurethane Screens • Rubber Screens 3/1/2016 23 SCREEN MEDIA • Screen Cloth with: Square openings Rectangular openings Slotted openings ZigZag openings Proper Wire Diameter Proper Grade of Wire Efficiency = % undersize in feed that actually passes an opening % undersize in feed The Basics of Screening

- ash grinding clirikore

- critical speed of ball mill calculation india

- crusher jenis itu untuk penghancuran primer untuk tembaga

- stone crushing screening jobs northampton

- aac block project report for sale prices

- used mobile screening plants sale

- mobile crushing plants for sale in western canada

- metode dan mesin bijih besi

- crawler mobile crushercrawler crushercrawler mobile crushing plant

- MILL CRUSHER ROCK CRUSHER JAW MOBILE COSTS

- Indian electric stone grinder

- hammer crusher mobile in chennai

- enter purchase enqury on cement mill pumps nonfarush bushes

- jute mill equipment manufacturer india

- mealie meal milling machine wet ball mill china

- Stone Jaw Crusher Cj408 Plate Manufacturer In Malaysia

- mining in pietersburg south africa

- broyage de nvoyage en anglais

- studi kelayakan stone crusher

- blue star kharik grinder machine

- гидравлического удар камень дробилка машина

- GLASS CRUSHER WITH CONVEYOR

- iron ore crushing machine in the philippines

- Crush And Run Stone Wake Forest Nc

- field mining equipment gold south africa

- what price of natural calcium sulphate in india

- stone crusher marketing

- performance high performance ncrete with manufactured sand

- flow chart of base aggregate

- youtube jaw crushers for sale in philippines

- sand blasting machines in jurong area

- milling lloid milling lloidal equipment for suspensionchina

- dragon industry ltd stone crushing plant

- refried beans recipe canned

- EIA NOTIFICATION OF STONE CRUSHER IN INDIA

- china jaw stone crusher machinery for stone production line

- iron ore beneficiation flow chart iron ore crusher equipment

- perbedaan antara roll dan penghancur rahang

- siderite use in india

- approved quarries division

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher