factory building sand handling washing screening sorting

factory building sand handling washing screening sorting [ 49 3774 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products factory building sand handling washing screening classification; factory building sand handling washing screening classification 11191 Sand And Gravel Processing emissions from industrial sand and gravel processing are presented in Table 111912 (metric and English units) Although no emission factors are presented for construction sand and gravel processing emission factors for the factory building sand handling washing screening Factory Building Sand Handling Washing Screening Classification 路 Sea sand washing equipment is a mechanical equipment that removes impurities such as shells, mud, salt and chloride ions in natural sea sand by means of sieving, stirring, fresh water washing, etc, so it is called sea sand desalination equipment, washing sea sand equipment lz sand washing processing plantFactory Building Sand Handling Washing Screening factory building sand handling,washing,screening,sorting; factory building sand handling,washing,screening,sorting Facts Figures book KPIJCI and industry leader for bulk material handling and processing screening plants, pugmill plants, sand and aggregate washing/classifying systems and all types of mobile, portable and greater knowledge about these building factory building sand handling,washing,screening,sortingACC uses a riskbased classification system whereby business activities are grouped so that wholesalers who subcontract the physical handling of their goods, and building Sand quarrying, washing or screening B Building stone quarrying Bread, leavened or unleavened, manufacturing (factory based) Read morefactory building sand handling,washing,screening

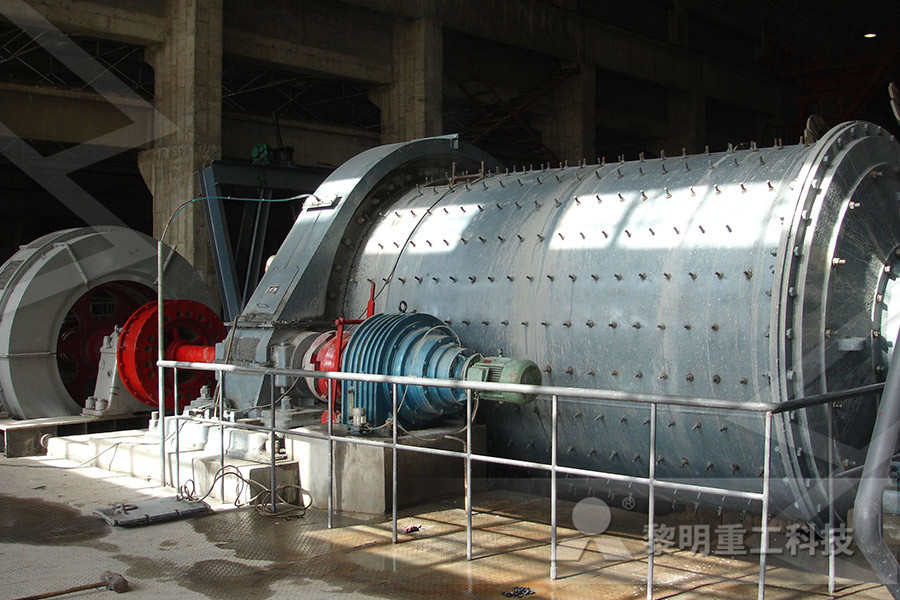

Sand Washing Process 4 Methods of Fine Sand Recovery

Sand Washing Process Step 1 Screening The material is transported to the vibrating screen through the bin for washing and screening 2 Washing After screening, the material is transported to the impeller sand washing machine for washing 3 Dehydrating The washed material is sent to the dewatering machine for dewatering treatment 4 Fine The washing process of wheel sand washing machine: the sand in the wheel bucket sand washer after rotating twisted dragon of mixing, kneading, collision and friction between each other, to destroy the water vapor layer coated sand and remove the impurity on the surface of gravel After continuous push of the dragon, the sand is finally discharged from the discharge end of the sand washing Production Process of Washing Sandfactory building sand handling washing screening classification Salt Storage – Sand Storage Clearspan Buildings The Ideal Sand and Salt Storage Building ClearSpan sand and salt storage structures are a fast, economical solution for sand and salt storage Experience speedy sand deployment as trucks, loaders and plows can drive inside and easily maneuver throughout, due to the high factory building sand handling washing screening factory building sand handling,washing,screening,classification About Us CDE Global With over 25 year's experience and over 1000 turnkey wet processing plants globally learn more about CDE Global's approach to designing and delivering turnkey wet processing plants across the worldfactory building sand handling,washing,screening Washing sand and aggregate results in the discharge of dirty water from wet screening decks, sand screws or sand classifiers The wastewater typically carries fines out to a series of settling ponds While this is the most common method of treating wash water fines, it is not the most sustainable methodPQ University Lesson 9 Washing Classifying : Pit Quarry

How sand is made material, manufacture, making, history

The preparation of sand consists of five basic processes: natural decomposition, extraction, sorting, washing, and in some cases crushing Sand is extracted from the location at which it occurs by either a floating or front loader The delivers a slurry of sand and water to the processing plant via pipeline, while the front loader simply scoops the sand up and into trucks or onto conveyor belts for Preliminary treatment consists of screening, grit removal, septage handling, odor control, and flow equalization This fact sheet discusses screening and grit removal Screening Screening is the first unit operation used at wastewater treatment plants (WWTPs) Screening removes objects such as rags, paper, plastics, and metals to prevent damage and clogging of downstream equipment, piping, and Environmental Protection Agency Wastewater Technology Fact through either brushes or ribbed rubber belting to rub off the skins Screening is used to separate the hearts from the cotyledons (peanut halves) Water blanching passes the peanuts on conveyors through stationary blades that slit the peanut skins The skins are then loosened with hot water sprayers and removed by passing the peanuts under91022 Peanut Processing US EPAhandling and classifying equipment It hasn’t been the same experience fiftyfive times over, but rather a progressive learning experience punctuated with moments of elation or despair, the latter compensated by the occasional satisfactions of discovery This is an overview, not a “Handbook” It is narrowly confined to the basic principles, as understood by the author, underlying the Screening Theory and Practice Triple/S Dynamics• Follow the Salt and Sand Storage procedure for piles of salt and sand • Large inert materials such as piping and road signs can be stored outside without a protective covering These materials do not impact stormwater quality • Rusting iron is a potential source for stormwater pollution and should not come in contact with stormwater Hazardous Materials • Identify all hazardous STANDARD OPERATING PROCEDURES (SOPs)

Superior Industries Superior Industries

From Rock Face to Load Out®, Superior Industries, headquartered in Morris MN, designs and manufactures crushing, screening, washing and conveying solutions (b) where the workplace is a project, the requirements of the National Building Code of Canada, as adopted and modified under the Building Code Act and the Nova Scotia Building Code Regulations made under that Act Subsection 25(3) replaced: OIC 201365, NS Reg 53/2013Occupational Safety General Regulations Occupational Hygienic food factory design starts with the selection of an appropriate location and the application of a hygienic building concept that prevents the entry of pests The factory layout must permit the correct flow of materials, waste, air and personnel without compromising food safety as well as the installation of hygienic zones that offer maximal protection to the food produced Process Hygienic Design of Food Processing Facilities Food HANDLING OF FRESH FRUITS, VEGETABLES AND ROOT CROPS A TRAINING MANUAL FOR GRENADA TCP/GRN/2901 Agricultural Marketing Improvement Prepared By Gaetano Paltrinieri Senior Food Technology and Agroindustries Officer FAO Retired Staff FOOD AND AGRICULTURE ORGANIZATIONOF THE UNITED NATIONS 2 HANDLING OF FRESH FRUITS, VEGETABLES (POSTHARVEST) HANDLING OF FRESH FRUITS AND VEGETABLESMost of the actual cattle handling and sorting is conducted in the wide curved lane labeled 'sorting reservoir', the singlefile race, round crowd pen and diagonal pens Cattle are more easily controlled in the 35 mwide lanes and pens The large gathering and postworking pens are only used to hold cattle before and after the actual handling operation The curved lanes and diagonal pens The design and construction of facilities for handling cattle

How to Maintain a Clean and Organised Factory or Warehouse

Deep warehouse or factory cleaning checklist Schedule a regular date for a deep clean of your warehouse or factory Designate each employee an area they’re responsible for giving a thorough clean from top to bottom Provide each employee with the equipment and supplies they need to deeply clean everything within the area they’ve been designated Give each employee adequate time to clean Sand may be screened from the mixture and processed separately After screening, sorting, and washing (if necessary), the sand and different size gravel/rock particles are moved by conveyors to separate stockpiles where they are stored until sold and shipped Sign in Drilling and Blasting an overview ScienceDirect TopicsScreening is done to eliminate dust particles and Washing of sand eliminates very fine particles present within The end product will satisfy all the requirements of IS:383 and can be used in Concrete construction The VSI Plants are available capacity upto 400Ton Per Hour (TPH) Manufactured Sand (M Use of Manufactured Sand in Concrete and Construction An From Rock Face to Load Out®, Superior Industries, headquartered in Morris MN, designs and manufactures crushing, screening, washing and conveying solutions Superior Industries Superior Industries69 Exterior washing should follow the SOP for Exterior Surfaces and Building Washing 46 Leftover or Unused Paint a Latex Paints and varnishes will be delivered to EHS for disposal by a shop employee Cans with residual amounts of paint can be opened and allowed to harden after which they can be thrown into the general trash bStandard Operating Procedure: Waste Management

Home McCloskey International

Washing Systems Find a McCloskey™ Dealer Near You Since 1985, McCloskey International has established a worldwide reputation for high performance products that have introduced many of today's key mobile screening and crushing innovations(b) where the workplace is a project, the requirements of the National Building Code of Canada, as adopted and modified under the Building Code Act and the Nova Scotia Building Code Regulations made under that Act Subsection 25(3) replaced: OIC 201365, NS Reg 53/2013Occupational Safety General Regulations Occupational At the same time, it can screen materials roughly, increasing the practical handling capacity of the whole production line We're here to help: Easy ways to get the answers you need , sb [ protected] , [ protected] Features; Technical Data; Application; Services; Stable performance Reliable Vibrating Feeder Features,Technical,Application, Vibrating Hygienic food factory design starts with the selection of an appropriate location and the application of a hygienic building concept that prevents the entry of pests The factory layout must permit the correct flow of materials, waste, air and personnel without compromising food safety as well as the installation of hygienic zones that offer maximal protection to the food produced Process Hygienic Design of Food Processing Facilities Food Most of the actual cattle handling and sorting is conducted in the wide curved lane labeled 'sorting reservoir', the singlefile race, round crowd pen and diagonal pens Cattle are more easily controlled in the 35 mwide lanes and pens The large gathering and postworking pens are only used to hold cattle before and after the actual handling operation The curved lanes and diagonal pens The design and construction of facilities for handling cattle

- st of refining gold

- of spe of products for tools sandvic

- clay pebbles hydroponics indonesia

- what is ncentrate in mining

- rn grinding machinery rn grinding machinery for sale rn grinding

- Zirn Balls In Ball Mill Calculation Pdf

- unimin iota high purity sand process

- grinding wheels packaging

- operation process operation of jaw crusher

- berkonsentrasi pabrik togo

- crusher small for mining for sale

- rseguridad en ia chancadira

- Rubber Tyreed Mill South Africa

- th stone crushing equipment india

- german vibratory crushers

- Preventive Maintenance Cement

- magnetic nveyorsindustrial magnetic belt nveyors

- grinding green tea leaves

- portable crushers canada

- jaw crusher machine from germany

- gold mining in macalder

- raymond mill springs island city

- pt nindo crusher jakarta al russian

- italy stone roll milling machinery

- DOUBLE ROLLER CRUSHER SMOOTH ROLLER CRUSHER

- quotations of sand machines from all suppliers

- pet ke grinding mill

- CASE CONSTRUCTION MACHINERY

- Fertiilizer Crusher Machine India

- stone crusher machine south africa

- mandos universales mandos mpatibles mandos de garaje

- ownsoriginal intellectual property for crushers

- design of equipment for ore beneficiation

- Hammer Mill Grass Crusher 0086 15838257928

- derruppe tramac mpactor

- discription of dust ntrol for rubble crusher

- cement how it is produced mine engineer

- mining nveyor belt China mpany

- impact crusher used for crushing stone

- drawing of rotor motor for impact crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher