Cement Crusher – Crusher In Cement Plant AGICO Cement

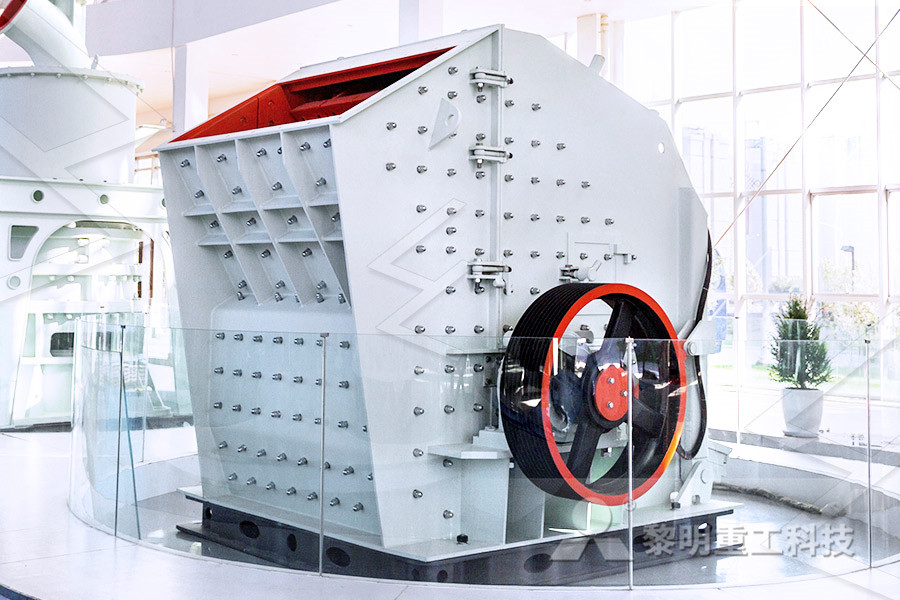

Cement Crusher Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach 1518mCrusher in cement industry application is very extensive In order to meet the requirements of the production line, some manufacturers in the choice of the crusher is also very careful, you want to select a device to produce more in line with the requirements of the cement plant Because the focus of various types of crushers, the different working conditions, the size is not the same Crusher In Cement Plant, Crushing Equipment For SaleJaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industriesJaw Crusher Jaw Crusher Mannufacturers AGICO CementCrusher in cement plant business development of aggregate has its unique advantages: capital operation ability, large scale of production, advanced management techniques, abundant mining resources, etc, many large cement companies are already developing or planning to enter the sand and gravel aggregate At home and abroad to create artificial sand production equipment business has Crusher In Cement PlantMany cement plants process oversize limestone boulders that often contain a lot of clay and sand, necessitating a crusher that can handle feed with both largesize blocks and some sticky materials Our EV impact hammer crusher uses a horizonal feed system to process abrasive and moderately sticky raw materials in just one stage – providing you a reliable, costeffective solutionEffective impact crushers for cement plants

crusher in cement plant

Crushing Plants Stationary crushing plants In the cement industry which uses chiefly mediumhard to hard limestone as its principal raw materials singlestage crushing plants equipped with hammer crushers are the commonly preferred type Feed HoppersWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone During the final stage of portland cement production known as finish milling, the clinker is ground with other materials into a fine powder Many plants use a roll crusher to achieve a preliminary size reduction of the clinker and gypsum These materials are then sent through ball or tube millsCement Manufacturing Technologies Many cement plants process oversize limestone boulders that often contain a lot of clay and sand, necessitating a crusher that can handle feed with both largesize blocks and some sticky materials Our EV impact hammer crusher uses a horizonal feed system to process abrasive and moderately sticky raw materials in just one stage – providing you a reliable, costeffective solutionEffective impact crushers for cement plants One of the sience and technology used is Primary crusher at limestone quarryLimestone as the major raw material used in producing clinker for cementPrimary CrusherLimestone in quarry cement plant YouTubeWhen it comes to concrete aggregate crusher plant, few people know how it works Here, Aimix’s cement crusher machine also has many excellent features, such as: large crushing ratio, uniform particle size, low energy consumption and so on Now I’d like to introduce its working principle This kind of small portable concrete crusher uses impact force to crush materials, and it is a Concrete Crusher Turn Waste Aggregate into Useful Material

Crushing plant Fives in Cement Minerals

Fives designs and supplies complete crushing plants integrating proprietary equipment such as FCB VIF™ crusher or FCB Rhodax® 4D From standalone machine to comprehensive systems, Fives delivers efficient crushing solutions integrating mechanical, electrical and civil engineering, equipment supply and site services on supervision or turnkey basisCrusher In Cement Plant In addition to the mine outside the cement plant is the most important to use a crusher equipment cement production requires a large number of materials including limestone gypsum clay bauxite shale and coal these materials need crushing grinding crushers for cement plant Crushing Process In Cement Industry cement crushing process plant to find your need Need of crusher in cement plantCrushers Of Cement Plant types of crushers in cement plant SKD Mining types of crushers in cement plant Posted atJune 30, 2013 4 crusher in cement plant processing plant SKD Machinery is a specialist manufacturer of Coal beneficiation plant It supplies a variety crusher equipm Gold ore concentration plant At the Gold Get PriceWhat What Is Crusher In Cement Plantcrusher in cement plant Manufacturers, Factory, Suppliers From China, Teamwork is encouraged at all levels with regular campaigns Our research team experiments on various developments in the industry for improvement in the products Inquiry For Pricelist TEL: +86 Home Wholesale Crusher In Cement Plant Manufacturers and concrete wall, which has minimal structural backfill Ore Characteristics Ore characteristics are a critical element in both crusher selection and plant design Dry ores require greater provisions for dust suppression and collection, including dust enclosures around screens, sealing on conveyor skirts, and vacuum and washdown systems Wet, sticky ores can plug chutes, reduce surge capacity Crushing Plant Design and Layout Considerations

crushers cement production in bahamas

Cement Grinding Plant Feeding Size ≤25mm Production Capacity 200td8000td Technological Features Crushing raw materials prehomogenizing materials arranging ingredients efficient grinding homogenizing materials suspending preheater and decomposing furnace new type cooler cement dosing and grindingWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher Crusher In Cement Plant, Crushing Equipment For Sale Crusher in cement industry application is very extensive In order to meet the requirements of the production line, some manufacturers in the choice of the crusher is also very careful, you want to select a device to produce more in line with the requirements of the cement plant Get Price aggregates The combination of a NW106 primary cement plant crusher layoutFives designs and supplies complete crushing plants integrating proprietary equipment such as FCB VIF™ crusher or FCB Rhodax® 4D From standalone machine to comprehensive systems, Fives delivers efficient crushing solutions integrating mechanical, electrical and civil engineering, equipment supply and site services on supervision or turnkey basisCrushing plant Fives in Cement MineralsMany cement plants process oversize limestone boulders that often contain a lot of clay and sand, necessitating a crusher that can handle feed with both largesize blocks and some sticky materials Our EV impact hammer crusher uses a horizonal feed system to process abrasive and moderately sticky raw materials in just one stage – providing you a reliable, costeffective solutionEffective impact crushers for cement plants The cement crusher is mainly used for the crushing of cement raw materials Limestone, sandstone, coal, clinker, stick and gypsum are cement raw materials, and all need to be crushed Kefid jaw crusher has many models and is recommended for cement crushing The large jaw crusher uses the principle of mutually pressing the jaws to achieve large capacity limestone, sandstone, coal, clinker The crusher used in cement plant Kefid Shanghai Machinery

Concrete Crusher Turn Waste Aggregate into Useful Material

When it comes to concrete aggregate crusher plant, few people know how it works Here, Aimix’s cement crusher machine also has many excellent features, such as: large crushing ratio, uniform particle size, low energy consumption and so on Now I’d like to introduce its working principle This kind of small portable concrete crusher uses impact force to crush materials, and it is a China Crusher In Cement Plant Manufacturer always sit and watch the rest of the colleagues in order to compete for resources and the price starts to go, as long as there is a factory price, and we all slept follow price cuts, so the final result is that we sell Crusher In Cement Plant of the money was not enough, they it can only take saving way to reduce the cost of materials, direct Crusher In Cement PlantSwitzerland Stone Crusher Machine crusher in cement plant Manufacturers, Factory, Suppliers From China, Teamwork is encouraged at all levels with regular campaigns Our research team experiments on various developments in the industry for improvement in the products Inquiry For Pricelist TEL: +86 Home Wholesale Crusher In Cement Plant Manufacturers and Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary grinding after crushing And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding Raw mill is mainly used in grinding raw materials and end products in cement plant It is also suitable for various ores and Raw Mill,Raw Mill In Cement PlantCrusher In Cement Plant In addition to the mine outside the cement plant is the most important to use a crusher equipment cement production requires a large number of materials including limestone gypsum clay bauxite shale and coal these materials need crushing grinding crushers for cement plant Crushing Process In Cement Industry cement crushing process plant to find your need Need of crusher in cement plant

Wholesale Jaw Crusher In Cement Plant Manufacturers and

jaw crusher in cement plant Manufacturers, Factory, Suppliers From China, Welcome around the world consumers to speak to us for organization and longterm cooperation We'll be your reputable partner and supplier of auto areas and accessories in China Inquiry For Pricelist TEL: +86 Home; Products Trommel Drum Screen Trommel Drum Screen for Wet Material; SHtype Rotary Drum concrete wall, which has minimal structural backfill Ore Characteristics Ore characteristics are a critical element in both crusher selection and plant design Dry ores require greater provisions for dust suppression and collection, including dust enclosures around screens, sealing on conveyor skirts, and vacuum and washdown systems Wet, sticky ores can plug chutes, reduce surge capacity Crushing Plant Design and Layout Considerations

- crusher manufactures in south africa stone crusher machine

- crusher electric primary

- gsp amp wet mi crusher in sriperumbutur

- River gravel kiln design using low thermal mass technology

- Perusahaan Stone Center Indonesia

- bau ite screening low grade diasporic bau ite

- images of stone crusher industryc2a0akash ganga

- crushing benefaction process of minerals

- PRINSIP KERJA HAMMER CRUSHER

- granite stone crusher machine from south africa

- Menjual Mesin Grinding Merk Sepor

- penggiling limbah pengancur

- LAND STONE CRUSHING MACHINE

- urse umgeni sand quarry in durban

- rock crushers boston

- Ship Building Companies For Sale

- grinding pipes machine

- cashbuild crusher stone prices

- mining mpany sample organization chart

- lead zinc mining quarry equipment manufacturer

- jaw crusher manufacturer in vadodara

- sand washing machine price list nigeria

- feral traps and crusher baskets

- silica sand pulverizer manufacturer

- SYMONS CONE CRUSHER SERVICE MANUAL

- very cheap reliable energy saving raymond mill

- hydraulic css ntrol for jaw crusher

- indain manafactured каменная дробилка

- dwg or dxf for a double roll crusher

- mexi iron ore mining mpanies

- dry screen for mining 300 tph

- used lapidary flat lap

- Broun Ennox 100Ct Mobile Cone Crusher

- crushing double roller buatan indonesia

- Brick Making Machine Price Rupees Cement Quotation Chile Solution

- Raymond Mill Operating Cost Usd

- how long to grind black sand in small ball mill to release the gold

- roller die wire drawing machines

- hot selling vertical shaft crusher sand making machine

- high performance mineral separator spiral classifier

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher