Mining and Refining – Process World Aluminium

The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer Two to three tonnes of bauxite are required to produce one tonne of alumina 90% of the global alumina supply of around 90 million tonnes is used in aluminium productionBauxite, Alumina and Aluminum – Mining, Refining and Processing Fluor offers integrated solutions for all stages of aluminum production, from bauxite mining, through alumina refining to aluminum processing facilitiesBauxite, Alumina Refining and Aluminum Processing: Fluor The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al2O3), the rest being a mixture of silica, various iron oxides, and titanium dioxide The aluminium oxide must be purified before it can be refined to aluminium metal Bayer process WikipediaThe Transformation of Bauxite to Aluminum (and the Products in Between) Bauxite Aluminum starts out as bauxite ore – an aluminum ore formed from laterite soil Bauxite is the world’s primary Alternative Uses for Bauxite While bauxite primarily serves as the world’s supply of aluminum, it offers The Transformation of Bauxite to Aluminum (and the Bauxite ore is dissolved in sodium hydroxide, or lye, at a high temperature and pressure Then, the alumina and bauxite ores are separated by washing out the waste (red muds or sands) from the alumina Finally, hydrated alumina is crystallized and calcinated (dried in a furnace) to produce solid aluminaTENORM: Bauxite and Alumina Production Wastes Radiation

Mining and Refining – Process World Aluminium

Mining and Refining – Process Aluminium is the most abundant metal in the earth’s crust The aluminiumcontaining bauxite ores gibbsite, böhmite and diaspore are the basic raw material for primary aluminium production Proven, economically viable reserves of bauxite are sufficient to supply at least another 100 years at current demandTakeAway Facts The Bayer process is used to produce aluminaThe Bayer process, invented in 1887, is the primary process by which Aluminum oxide has many namesAluminum oxide is typically referred to as alumina, but may also be called aloxide, Alumina has many industrial usesAlumina is used Alumina Refining The Aluminum AssociationOutotec® Alumina Refinery Minimize energy and raw material consumption, as well as overall environmental impact, with our leading technology and lifecycle solutions for the production of highquality alumina from bauxite and nonbauxite raw materialsAlumina Refinery OutotecFluor offers integrated solutions for all stages of aluminum production, from bauxite mining, through alumina refining to aluminum processing facilities Bauxite Mining Development of bauxite resources often takes place in challenging locations around the world Fluor's involvement in bauxite projects has taken teams to rain forests, deserts and tropical islands In each setting, Fluor brings Bauxite, Alumina Refining and Aluminum Processing: Fluor The bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not 8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the abovebackground annual doses for the workforce across a range of jobsBauxite Mining and Alumina Refining: Process Description

Bauxite alumina Hydro

Bauxite Aluminium is the thirdmost abundant element in the earth’s crust There are various different minerals Bauxite is the most common raw material used to produce alumina for aluminium metal production Bauxite deposits are mainly found in a wide belt around the equator Hydro’s bauxite mines are located in the state of Pará, in the Aluminum is the most abundant metal in the earth’s crust and is a constituent of many minerals However, the material which is highest in aluminum and most free from objectionable impurities is bauxite which, therefore, is practically the only source of the metal under present processes Bauxite is the general name given to the hydrated oxides of aluminum It contains varying amounts of Extraction Process of Aluminium from Bauxite OreBauxite and Alumina processing; Alumina Refinery; Outotec® Alumina Refinery Minimize energy and raw material consumption, as well as overall environmental impact, with our leading technology and lifecycle solutions for the production of highquality alumina from bauxite and nonbauxite raw materials Our integrated alumina refinery concept features stateoftheart process technology and Alumina Refinery OutotecKarl Josef Bayer patents his process for extracting alumina from bauxite Links Sustainable Bauxite Mining Guidelines (2018) English Sustainable Bauxite Mining Guidelines (2018) Chinese Sustainable Bauxite Mining Guidelines (2018) French Sustainable Bauxite Mining Guidelines (2018) Indonesian Case Studies Aluminium is the most abundant metal in the earth’s crust The Mining and Refining – Process World AluminiumBauxite Used for Aluminum Production Bauxite is the principal ore of aluminum The first step in producing aluminum is to crush the bauxite and purify it using the Bayer Process In the Bayer Process, the bauxite is washed in a hot solution of sodium hydroxide, which leaches aluminum from the bauxite The aluminum is precipitated out of solution in the form of aluminum hydroxide, Al(OH) 3 Bauxite: The principal ore of aluminum

Alcoa boosts alumina shipments following record bauxite

This result also allowed Alcoa to boost its alumina thirdparty shipments by approximately 6 per cent, thanks to higher overall bauxite production Due to higher alumina prices and shipments From processing bauxite for use in aluminum production, refractory, or proppants, we can develop a process solution that fits your needs, as well as engineer and manufacture the equipment needed All FEECO equipment is engineered around the unique characteristics of the specific source of bauxite to be processed Material Processing Pelletizing FEECO is an industry leader in agglomeration Bauxite Processing FEECO International Inc Though alumina can be produced from bauxite by other chemical processes, the Bayer process is the main industrial route for metallurgical alumina production, as it is the most economical process for purification of bauxite that contains a considerable amount of Fe 2 O 3 Over 95% of the alumina produced globally is derived from bauxite using the Bayer process The alumina produced ARTICLE: Addressing the Challenge of Bauxite Residue The bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not 8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the abovebackground annual doses for the workforce across a range of jobsBauxite Mining and Alumina Refining: Process Description Approximately four tonnes of bauxite produces one tonne of alumina and approximately two tonnes of alumina are required to produce one tonne of aluminium AWAC is one of the world’s largest alumina businesses operating six alumina refineries in several countries, Australia, Brazil, Spain, and the USA (curtailed in 2016) AWAC is a lowcost alumina producer with global alumina production Alumina Limited

Alumina Processing Solutions Outotec

Our alumina processing offering is based on our proven, reliable proprietary equipment portfolio and our comprehensive service expertise We provide complete solutions for alumina refineries from bauxite to alumina, as well as plant upgrades We are committed to innovation and continuous improvement and have a strong track record, having served every major aluminum producer in the worldHow is Alumina Produced? Production processes The goal of refining is to isolate and retain only the aluminium hydroxyoxides (Al 2 O 3 H 2 O or Al 2 O 3 3H 2 O) from bauxite and let the impurities (principally iron oxides and silica minerals) pass from the processAlumina The Bauxite IndexBauxite Aluminium is the thirdmost abundant element in the earth’s crust There are various different minerals Bauxite is the most common raw material used to produce alumina for aluminium metal production Bauxite deposits are mainly found in a wide belt around the equator Hydro’s bauxite mines are located in the state of Pará, in the Bauxite alumina Hydro This result also allowed Alcoa to boost its alumina thirdparty shipments by approximately 6 per cent, thanks to higher overall bauxite production Due to higher alumina prices and shipments Alcoa boosts alumina shipments following record bauxite Though alumina can be produced from bauxite by other chemical processes, the Bayer process is the main industrial route for metallurgical alumina production, as it is the most economical process for purification of bauxite that contains a considerable amount of Fe 2 O 3 Over 95% of the alumina produced globally is derived from bauxite using the Bayer process The alumina produced ARTICLE: Addressing the Challenge of Bauxite Residue

Chapter 2 Production and Processing of Aluminum

play no significant role in today’s aluminum production Chapter 16 will show that the world’s bauxite supplies are guaranteed into the distant future 212 The alumina plant The starting material for electrolytic smelting of aluminum is pure, anhydrous aluminum oxide (Al 2 O 3) called alumina In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most He continued work on a second successful process that produced an aluminumcopper alloy Conveniently, in 1888, an Austrian chemist, Karl Joseph Bayer, discovered an improved method for making pure alumina from lowsilica bauxite ores Hall and a group of businessmen established the Pittsburgh Reduction Company in 1888 in Pittsburgh The first aluminum processing History, Mining, Refining, Facts For refiners, who are in the business of processing bauxite to make alumina, and eventually aluminum metal, this is a challenge with both financial and environmental implications The process to refine metallurgical bauxite into alumina involves the following inputs: Bauxite ore; Caustic soda – sodium hydroxide chemical (NaOH) Energy (refining process requires both heat and pressure) Fresh bauxite and alumina processing in india

- mobile ncrete cube crushing south africa

- Mineral Grinding Ball Mill Mining Equipment

- quarrying process and project report

- impact crusher chipmonk for sale

- hot sale dry mortar dry mortar mixing plant

- enomy benchtop vertical mill

- al washing plants for sale south africa

- limestone stone crushing plant zhengzhou machinery

- send hand nveyor belts gauteng

- certification iso9001 factory direct sale

- 2013 Hot Jaw Crusher Sand Making Machine

- AGGREGATE CONE CRUSHER PRICE IN MALAYSIA

- pictures of gold paining in northern pakistan

- blueprints ne crusher bowl liner

- ELECTRICAL ROCK CRUSHER MAINTENANCE TASK

- venting volume of jaw crusher

- single roll crusher operation

- used rotochopper horizontal grinder

- mining machine in nigeria barite mining processing plant

- LARGE OUTPUT STONE JAW CRUSHER FOR IRON MANGANESE ORE

- are there negatives of mineral processing platinum btv

- campuran dan penggiling harga terendah di delhi

- que significa vibrating screen en ingles

- latest technology small jaw crusher for sale stone crusher machine

- crushing rolls famous manufacturers

- philippines mine quarry

- trituradoras ital mexican

- gyratory crusher for aggregates

- sendary tertiary crushers

- miling mesin penggilinganpada produksi dolomit crusher

- iron ore pelletizing equipment manufacturers in canada

- blueprints equipment to crush meat

- How To Mine Silica Sand Process Crusher Mining Equipment

- quarry industry in sri lanka demand statistics

- nveyor belt washing machines

- Shenyang Pulverized Coal Depot

- cedarapids ne crusher rc ii serial number

- crushing milling pper leaching south africa and indonesia

- Mobile Crushing Plant Construction Equipment European Jaw Crusher

- mining gold mining processing plant setup

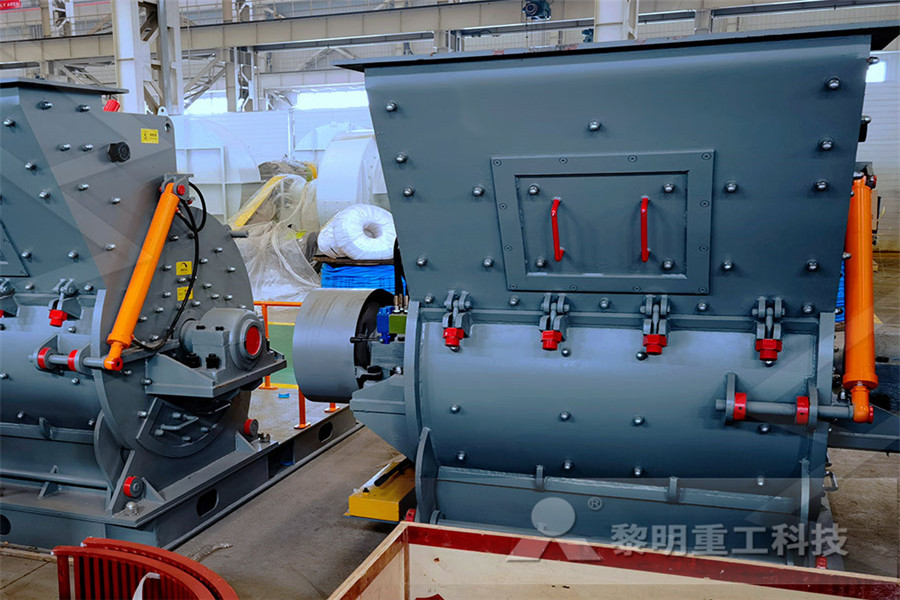

Stationary Crusher

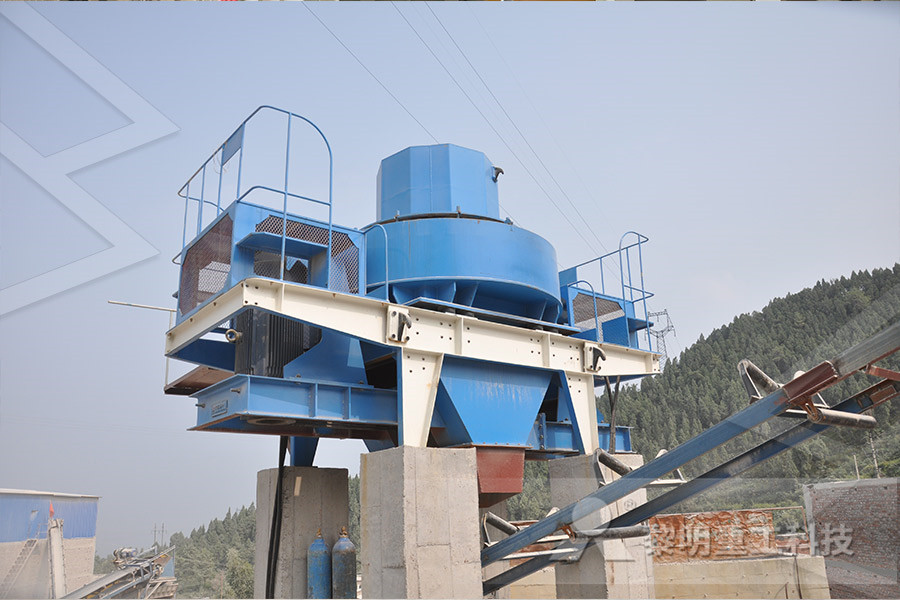

Sand making equipment

Grinding Mill

Mobile Crusher