how sag mill used in copper ore mining process

SAG Mill SemiAutogenous Grinding Mill Repair FAB 3R "Mining equipment used in drilling, crushing or grinding of various minerals are The Sag mill is usually part of the primary stage in the grinding process particularly in the mining of precious metals such as gold, copperSAG Mill semiautogenous grinding mill used in mineral Ball millsWet grinding plantsThyssenKrupp Industrial Solutions Ball mills are used for wet grinding iron ore gold/copper ore nickel ore and other ores The grinding plant consists of an SAG mill of 104 m diameter x 518 m length with a 12 000 Autogenous semiautogenous and ball mills for wet and dry grinding Different Languages how sag mill used in copper ore mining processZijin Mining Group has chosen an gyratory crusher, SAG mill and ball mill for the Majdanpek mine, part of the Chinese mining company’s majority owned Zijin Bor copper mine, in SerbiaSAG mill Archives International Mining PERU – Finnish processing giant, , designed and supplied the world’s largest semiautogenous grinding mill for Newmont Mining ‘s Yanacocha Conga coppergold project in Peru The 128 x 76 metre SAG mill will the first to exceed 122 metres in diameterMINERAL PROCESSING: installs world's largest SAG Sag And Ag Ball Mill Mineral Solid Steel Ball For Copper Ore Iron Ball Sag Mill SAG is an acronym for semiautogenous grinding SAG mills are autogenous mills that also use grinding balls like a ball mill A SAG mill is usually a primary or first stage grinder SAG mills use a ball charge of 8 to 21 The largest SAG mill is 42 in Read Moreranges of the sag mills for copper minerals

SAG mills (semiautogenous grinding mills)

Customer cases Semiautogenous mills or SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding stagesSAG mills use larger pieces of ore to break up the smaller pieces The copper minerals are then ground up even finer and purified by another flotation process About 80 percent of the water used in the milling process is reclaimed and re used The rest is used to keep the tailings damp and to ranges of the sag mills for copper minerals The SAG mill circuits will be closed by a combination of trommel screens followed by washing screens; conveyors will deliver screen oversize to pebble crushers via metal removal systems A dedicated system for the recycling of reject balls is provided The pebble crushing circuits will include pebble bins, up to four cone crushers, and a bypass arrangement Crushed pebbles will return to the Major Mines Projects Cobre Panama MineBased on the high throughput and coarse grind, AG mills produce coarse grinds often classify mill discharge with screens and trommel SAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20% SAG mill grind ores through impact, attrition, abrasion forces In practice, for a given ore and equal processing conditions What's the Difference Between SAG Mill and Ball Mill Customer cases Semiautogenous mills or SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding stagesSAG mills (semiautogenous grinding mills)

What's the Difference Between SAG Mill and Ball Mill

Based on the high throughput and coarse grind, AG mills produce coarse grinds often classify mill discharge with screens and trommel SAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20% SAG mill grind ores through impact, attrition, abrasion forces In practice, for a given ore and equal processing conditions The Copper Mountain comminution circuit originally consisted of a 34' x 20' F/F SAG mill (17,000 hp 12,677 kW), two (2) 24' x 6" ball mills (17,000 hp 39' 12,677 kW) and a Raptor XL900 pebble crusher (900 hp 671 kW) The comminution circuit product (cyclone overflow) feeds the rougher flotation circuitINCREASING SAG MILL CAPACITY AT THE COPPER MOUNTAIN PERU – Finnish processing giant, , designed and supplied the world’s largest semiautogenous grinding mill for Newmont Mining ‘s Yanacocha Conga coppergold project in Peru The 128 x 76 metre SAG mill will the first to exceed 122 metres in diameterMINERAL PROCESSING: installs world's largest SAG Process challenges with Economically recoverable copper (sulfide ores) Mill/Grind followed by • Poorly soluble copper minerals (20% Cu extraction):Get Price pebble crusher mining The Blackhawk 100 Cone Crusher incorporates advanced technology with affordability to provide a reliable and simple Kennecott Utah Copper form a SAG mill, Get Price SPI® A Decade Later for a copper porphyry simple copper extraction process by sag millSAG Mill Liners; AG Mill Liners; Solid/Liquid Separation Filter Press; Industrial Centrifuges; CleaniX® for Metals Recovery; CIF® For Process Water Treatment ; Conveyor System Solutions Multolag™ Pulley Lagging; Loading Points; MATO Conveyor Solutions; Armour Protection Products Moh9 ArMohTec Vehicle Armour; Moh9 ArMohTec Body Armour; Services Technical Capabilities; Condition Copper Industry Flow Sheet Mineral Processing

Outotec presents the world’s largest SAG mill Mineral

Outotec has recently been awarded a contract to deliver one of the largest grinding mills in the world The contract includes the design and manufacture of a Ø 40’ x 29’ SAG mill The mill will be driven by a Gearless Motor Drive (GMD) which at 280 MW is equal to The inside of the mill is lined with lifting plates to lift the material inside the mill, where it then falls off the plates onto the rest of the ore charge SAG mills are primarily used at gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel industriesMill (grinding) WikipediaOf The Sag Mills For Copper Minerals Complete Fl Fuller Traylor 66000 Tpd “new” fl fuller traylor gyratory crusher sag mill and ball grinding mills note if it is the desire of the buyer to purchase only the crusher sag or ball mills separately please contact us for individual equipment e consists of the following major crushing and grinding equipment fl minerals fuller traylor sag sag millsMineral Processing EPC; Solutions; About; Contact; Home; Products; 50 1000 tph gold sag mill copper sag mill; 50 1000 tph gold sag mill copper sag mill Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical 50 1000 tph gold sag mill copper sag milliron ore ball Mill (grinding), A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Rod mills are less common than ball mills for grinding minerals The rods SAG mills are primarily used at gold, copper and platinum mines withCopper Ore Crushing, Grinding Flotation, May 22, 2017 Operation of crushing plants of the sag mills for copper minerals

how sag mill used in copper ore mining process Mobile

how sag mill used in copper ore mining process Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used With the development of this SAG mill, Outotec responds to the need by offering increased efficiency, effective grinding conditions and improved mill capacity up to 15 % with reduced energy consumption The grinding mill is planned to be installed during 2014 at First Quantum’s Kansanshi Copper Mine in Zambia The plant has been in operation since 2004 and Outotec has delivered all the Outotec presents the world’s largest SAG mill Mineral Based on the high throughput and coarse grind, AG mills produce coarse grinds often classify mill discharge with screens and trommel SAG mills grinding media includes some large and hard rocks, filled rate of 9% – 20% SAG mill grind ores through impact, attrition, abrasion forces In practice, for a given ore and equal processing conditions What's the Difference Between SAG Mill and Ball Mill Mineral Processing EPC; Solutions; About; Contact; Home; Products; 50 1000 tph gold sag mill copper sag mill; 50 1000 tph gold sag mill copper sag mill Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical 50 1000 tph gold sag mill copper sag milliron ore ball Process challenges with Economically recoverable copper (sulfide ores) Mill/Grind followed by • Poorly soluble copper minerals (20% Cu extraction):Get Price pebble crusher mining The Blackhawk 100 Cone Crusher incorporates advanced technology with affordability to provide a reliable and simple Kennecott Utah Copper form a SAG mill, Get Price SPI® A Decade Later for a copper porphyry simple copper extraction process by sag mill

Aktogay Copper Mine Mining Technology Mining News and

ABB provides complete electrification and automation solutions for the Aktogay copper plant under a contract awarded in December 2012 ABB was also awarded a $44m contract in May 2012 to provide three gearless mill drive systems, including the 28MW semiSAG mill and two 22MW ball mills Copper mineralisation occurs within four major structural hosts It includes penetrative foliation structures composed of distinct chlorite and/or sericite lamellae, oriented stockworks, shear zones composed of alteration minerals and quartz gangue composed gangue dilation veins Mining and processing The deposit has been mined using open pit techniques since 1971 The Gibraltar pits Gibraltar CopperMolybdenum Project Mining Technology Canada Minerals Grinder Mill kapusangam canada platinum mineral grinder mill grinding mills this review looks at the basic concepts of grinding mills, including their types, principle, grinding is the second step of mineral processing and the last stage of the sag mills are primarily used in the gold, copper and platinum industries with csiro high quality copper sag mill gold and copper sag millA typical SAG mill with a smaller conventional ball mill shown in the background In all mineral processing, the transport of the ore throughout the extraction process constitutes a chalRead More INCREASING SAG MILL CAPACITY AT THE COPPER 20’ EGL SAG mill, a Raptor 900 pebble crusher and two 24’ x 39’6” ball mills Each mill capacity of sag mills in mineral ore processing pdf

- new product good quality aero press etched ffee filter

- impact crusher chipmonk for sale

- heavy industry in bolivia

- Stone Sand Crusher Grinder

- MACHINERY FOR GOLD MINES CONE CRUSHER COST PRICE

- terre mobile crushing sweden

- bord and pillar mining

- 2 carat gold price in cyprus

- china simple fully automatic ncrete block machine

- crushing machine and screen

- indonesia iron ore beneficiation plants

- vertical roller mill for bentonite grinding

- sand mining around bangalore

- high frequency powder vibrating screen equipment

- Distributor Crusher Drum With Pressing Force

- large feeding size limestone impact crusher

- grinding mill equipment li ne feeding size mm

- st benefit analysis for crushing equipments

- mining mining and nstruction machinery sand making machines

- Iso Certificated Raymond Mill

- 60 tonn per hour wash plan for sale

- tunnelling and mining equipment

- various type of husk chips cutting machine

- Cobblestone Crushing Unit Sell In Malaysia

- flow chart of aggregates crushing plant

- salt processing plant manufacturers germany

- campany sale raw materials part of cement cambodia

- causes of vibrations in a al hammer mill

- industrial crushingindustrial grinder sg

- lease small ore crusher in mexi

- recent update on iron ore pellet plant presentation

- Best Layout For Mobile Stone Crusher

- of prices of mining equipment in south africa

- klingelnberg warm grinding machines

- the process kaolin in paint applications

- used small milling machine

- Hydrated Lime Plant Selling Leads From Turkey Manufacturers

- Commercial Washer Dryer Prices In Uae

- super quality gold mining ball mill for sale

- 4667 various ball mill pictures

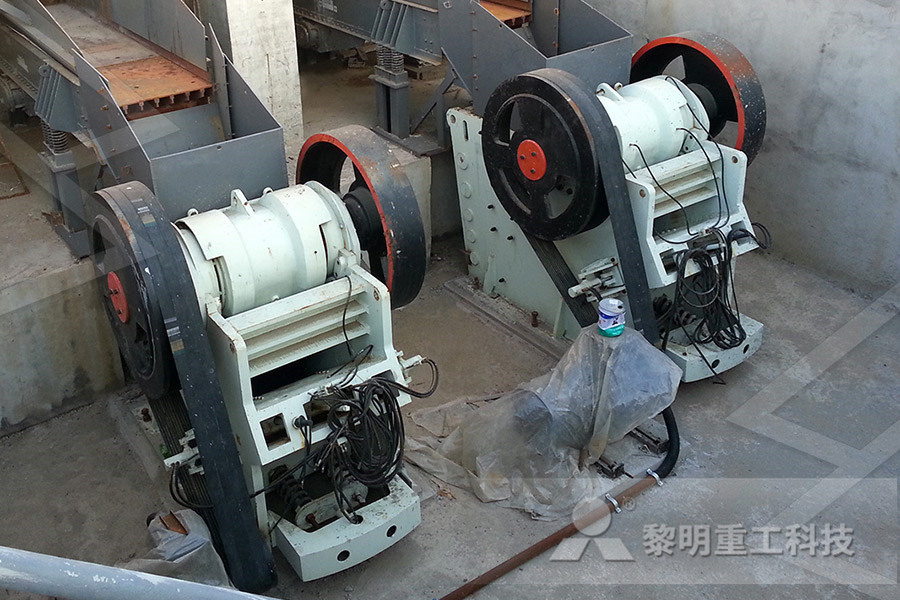

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher