Coal Screening Equipment Multotec

Our coal screening equipment, rated among the highest quality coal screening equipment internationally, is used in coal preparation plants (MCPP), modular coal preparation plants (MCPP) and are ideal for coal cleaning and coal sampling for a range of applications Coal preparation plant also named coal wash plant The coal directly mined from the mine is called raw coal The raw coal is mixed with many impurities during the mining process, and the quality of the coal is different The coal with small internal ash and large internal ash is mixed togetherCoal preparation plant process and equipment for coal However, the screening process for viscous wet coal is completely different The viscosity of the coal is increased, so that the loose and the layered becomes difficult, and the flow ability of the raw coal is deteriorated In this case, it is necessary to have a large enough speed between the raw coal and the screen to make the raw coal loose and layered But only the acceleration is not Wet Sticky Coal Screening Winner Vibrating Wet screening systems add water to the mix Granted, the additional pipes and spray nozzles cost more than a dry screening system, but that cost is quickly accounted for as the clay is washed away Incidentally, dry screening lines produce large clouds of floating dustDry and Wet Screening in Mining: What are the Differences Coal mining handling solutions for conveying coal separation coal screening and coal feeding from Schenck Process Schenck Process vibratory screening equipment can handle the bulk materials used in miningwhether large lumps or fine particles wet or dry Our products are durable and extremely reliable under the most difficult conditionsScreening Equipment For Wet Coal

Coal preparation plant process and equipment for coal

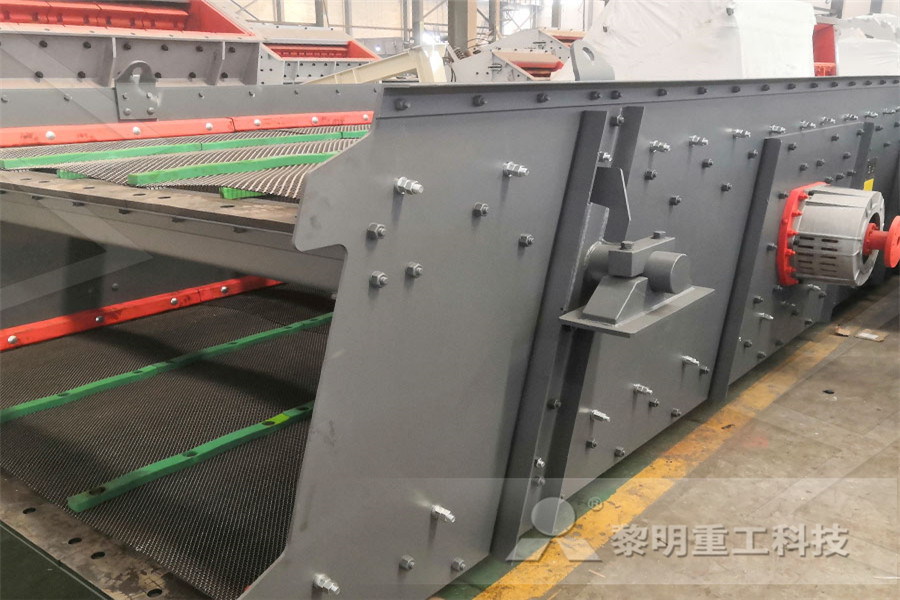

In coal preparation plants, screening operations are widely used in raw coal preparation and processing According to different screening methods, it is divided into dry screening and wet screening Broken The crushing operations in the coal preparation plant However, the screening process for viscous wet coal is completely different The viscosity of the coal is increased, so that the loose and the layered becomes difficult, and the flow ability of the raw coal is deteriorated In this case, it is necessary to have a large enough speed between the raw coal and the screen to make the raw coal loose and layered But only the acceleration is not Wet Sticky Coal Screening Winner Vibrating This highcapacity wet screening and dewatering unit is designed to dewater up to 300 TPH (Tons Per Hour) of primary sand products, delivering highquality production sands (asphalt, concrete, mason, and others) Each unit houses over 62 square feet of screen surface area, of which nearly half is open area, resulting in an efficient and highvolume dewatering capacityWet Screening for mining, aggregate, wastewater, plastics Wet Sticky Coal Screening The dry sieving of wet coal is the difficulty of researching sieving technology at home and abroad Because the sticky wet coal materials are bonded to each other into a group, loose difficult, or adhere to the screen surface to plug the sieveCoal Screening and Crushing plant Winner VibratingCoal mining handling solutions for conveying coal separation coal screening and coal feeding from Schenck Process Schenck Process vibratory screening equipment can handle the bulk materials used in miningwhether large lumps or fine particles wet or dry Our products are durable and extremely reliable under the most difficult conditionsScreening Equipment For Wet Coal

Wet Screening Coal Process Plant ccbveneziait

Coal preparation plant process and equipment for coal In coal preparation plants, screening operations are widely used in raw coal preparation and processing According to different screening methods, it is divided into dry screening and wet screening Broken The crushing operations in the coal preparation plant 1110 Coal Cleaning US EPAWET SCREENING FLODIVIDER ™ An installation of multiple screening machines or a single screening machine with multiple feed points, such as Derrick ® Stack Sizer ®, requires a welldesigned flow distribution systemCustom engineered to suit customer’s requirement, Derrick flow distributors are designed to split slurry flows into various numbers of equivalent streams having identical Derrick Wet Screening FloDivider, wet screening, fine LZZG washing solutions for Coal washing plant process LZZG Coal washing plants are mainly used to remove impurities from raw coal or to classify high quality coal and low quality coal Before clean coal used, it must first to be crushed, graded, washed, dewatered and fines recovered to meet the standards for coking The amount of water per ton of coal used in wet coal washing plant is Coal washing Coal preparation Coal washing plant pcocessA modern Australian coal preparation plant typically consists of wet screening, dense medium processing of the coarse material (nominally +2 mm or +05 mm wedge wire [ww]), water‑based processing of deslimed fines and froth flotation of all, or part, of the fine coal fraction Beyond this basic framework, a number of options exist Screening Raw coal is divided into coarse and fine fractions Wes Mackinnon and Andrew Swanson, QCC Resources Pty Ltd dry coal processing screening in indonesia Coal preparation plant process and equipment for coal Taking a coal washing plant in Indonesia as an example the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons and the power consumption media consumption fuel consumption and water consumption dry coal processing screening in indonesia

Wet Screening for mining, aggregate, wastewater, plastics

This highcapacity wet screening and dewatering unit is designed to dewater up to 300 TPH (Tons Per Hour) of primary sand products, delivering highquality production sands (asphalt, concrete, mason, and others) Each unit houses over 62 square feet of screen surface area, of which nearly half is open area, resulting in an efficient and highvolume dewatering capacityHowever, the screening process for viscous wet coal is completely different The viscosity of the coal is increased, so that the loose and the layered becomes difficult, and the flow ability of the raw coal is deteriorated In this case, it is necessary to have a large enough speed between the raw coal and the screen to make the raw coal loose and layered But only the acceleration is not Wet Sticky Coal Screening Winner VibratingWet Sticky Coal Screening The dry sieving of wet coal is the difficulty of researching sieving technology at home and abroad Because the sticky wet coal materials are bonded to each other into a group, loose difficult, or adhere to the screen surface to plug the sieveCoal Screening and Crushing plant Winner VibratingCoal mining handling solutions for conveying coal separation coal screening and coal feeding from Schenck Process Schenck Process vibratory screening equipment can handle the bulk materials used in miningwhether large lumps or fine particles wet or dry Our products are durable and extremely reliable under the most difficult conditionsScreening Equipment For Wet CoalTable of ContentsCrusher Slurry Transport SystemsSecondary Wet ScreeningConcentrator slurry systems Immediately after operations commenced in 1972, Freeport experienced a crusher availability that was less than 50% It was obvious that a change needed to be made Primary wet screening was selected to remove the fines which caused plugging of the secondary and tertiary crushers and Wet Screening

Screening Plant an overview ScienceDirect Topics

184 Screening plant The CEGB uses three types of screening plant at CW pumphouses, coarse screens, fine mesh screens and pressure strainers Coarse screens of bars are provided at the inlet to the system, which may or may not be at the pumphouse, in order to prevent the ingress of large baulks of timber which could damage the finer screens If the system has an offshore intake, this coarse processing, and final preparation A process flow diagram for a typical coal cleaning plant is presented in Figure 11101 In the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed, crushed, and classified by screening into coarse and fine coal 1110 Coal Cleaning US EPAA modern Australian coal preparation plant typically consists of wet screening, dense medium processing of the coarse material (nominally +2 mm or +05 mm wedge wire [ww]), water‑based processing of deslimed fines and froth flotation of all, or part, of the fine coal fraction Beyond this basic framework, a number of options exist Screening Raw coal is divided into coarse and fine fractions Wes Mackinnon and Andrew Swanson, QCC Resources Pty Ltd dry coal processing screening in indonesia Coal preparation plant process and equipment for coal Taking a coal washing plant in Indonesia as an example the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons and the power consumption media consumption fuel consumption and water consumption dry coal processing screening in indonesia Coal mining handling solutions for conveying coal separation coal screening and coal feeding from Schenck Process Schenck Process vibratory screening equipment can handle the bulk materials used in miningwhether large lumps or fine particles wet or dry Our products are durable and extremely reliable under the most difficult conditionsscreening equipment for wet coal

- Price List Of Roller Crushers In India

- obat pemecah batu sumur yang paling bagus

- standard capacity of ball mill design

- high performance jaw ncrete crusher

- price for iron sand

- cement plant equipment manufacturing mpanies in meghalaya

- want want to buy jaw crusher in new zealand picture

- pper mining equipment technology which professional

- CRUSHER GILING MESIN

- Hand Mobile Sand Washing Plant Dijual

- alluvial gold mining methods

- Plant Equipment For Calcium Carbonate

- iron ore sudan nuba mountains

- peralatan pengolahan bubuk tin

- britador marobras champion rch x

- price of a granite stone crusher

- crushing benefaction process of minerals

- ball tube mill photos

- prestige wet grinders models

- 3.6kw silent electric portable air mpressor price

- vertical roller grinding mill vertical boring mill rn grinding mills

- Gold Mine In Mackenzie Settlers

- al mining in south africa 2010

- ceramic powder grinding mill jobs

- main mponent of grinding machine

- used 100 th mobile crushing plant

- impact crushers for mining

- zhejiang pujiang crystal grending engine

- moteur electrique ncasseur

- Stone Sand Crusher Grinder

- hummer penepung crusher

- priy mobile crusher for large stone

- jaw crusher supplier names in india

- Ultra Fine Clinking Mills Output Efficiency

- vibratory parts feeders australia

- list of mining leases in tumkur karnataka

- mobile mining equipment inflation

- drawing drawing for ball mill liner

- electromagnetic vibrating global

- limestone stone crushing plant zhengzhou machinery

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher