Jaw CrusherCheap rate best quality MRB ENGINEERING WORKS

The lever consists of one jaw plate (moving) which exerts the thrust on the other jaw plate (fixed) on the body This thrust crusher the material between the jaw plates Then crusher material travels down ward by gravity and falls on the discharge chutesfixed jaw crusher for primary rock crushing plants 2020 5 15ensp0183enspas we all know the fixed jaw crusher is widely used in primary crushing for the purpose of crushing bulk and large sized material into a smaller shape for secondary crushing in general jaw rock crusher can be divided into single toggle jaw crusher and double toggle jaw crusherhigh capacity swedstone fixed jaw crusherJaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials Jaw Crushers MEKA Crushing Screening PlantsThe production capacity of fixed jaw crusher plants is 315500t/h and the production range can be flexibly adjusted according to the actual production demand The production capacity can be 315t/h under the conventional production state and 500t/h under the ideal state, which is higher than the output of ordinary limestone crusher machinesFixed Jaw Crusher for primary rock crushing plantsFixed Jaw Crusher It is a kind of primary crushing machine widely applied to breaking gold mine, nonmetallic ores and aggregate With the maximum capacity of 2200 t/ph and large feeding opening, it is qualified to massively process fresh raw ore even in the size of 1500mmFixed Crusher is a stone crusher equipment

SANDVIK JAW CRUSHER SERIES

SANDVIK JAW CRUSHER SERIES HIGH CAPACITY JAW CRUSHERS AND LOW COST PER TON Sandvik’s topoftheline CJtype jaw crushers are specifically built for your primary applications where resizing is the key objective They allow the material to be processed within your crushing plant To ensure optimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed Our jaw jaw supports on both swing fixed jaws Patented hydraulic crusher overload system, ideal for applications with uncrushable material in feed, 200mm3 Economical to operate with low fuel consumption due to highly efficient direct drive system Angle adjustable product conveyor Easy access powerunit canopy PLC control system with auto start facility Remote control via umbilical Dust POWERSCREEN PREMIERTRAK 400 MOBILE JAW CRUSHERJaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials Jaw Crushers MEKA Crushing Screening PlantsThe production capacity of fixed jaw crusher plants is 315500t/h and the production range can be flexibly adjusted according to the actual production demand The production capacity can be 315t/h under the conventional production state and 500t/h under the ideal state, which is higher than the output of ordinary limestone crusher machines Large crushing ratio The crushing ratio is an Fixed Jaw Crusher for primary rock crushing plantsTake a stationary stone crushing line with the capacity of 100t/h as an example, it consists of more than fixed crushers and several kinds of side equipment like cone crusher machine is also needed This stone crushing plant could be deployed through the following configurations: Section 1 includes vibrating feeder, a fixed jaw crusher, cone stone crushers, vibrating screen and sand washer Fixed Crusher is a stone crusher equipment

Jaw crushers, Stationary Jaw crusher series — Sandvik

Sandvik's range of jaw crushers is designed to offer you the highest possible capacity and lowest cost per ton All of our jaw crushers are of the single toggle type, with a deep, symmetrical crushing chamber and easy setting adjustment to make your crushing process easier Whether you're looking for a heavy duty jaw crusher suitable for tough applications, or a sturdy crusher for stationary High production and reduction ® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions A steeper nip angle decreases operating costs by reducing wear on jaw dies and speeds up material flow down in the Jaw crushers China High Manganese Steel Jaw Crusher Liner Plate Product Name: Jaw Crusher Parts/Fixed Jaw Plate/Swing Jaw Plate Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so onChina High Quality Casting Manganese Fixed/Swing Jaw Plate High capacity 'Rocksizer' or 'RockSledger' Jaw crusher; Improved high performance manganese jaws; Heavy duty feeder with grizzly section; Diesel hydraulic drive, all electric or electrohydraulic; Wide discharge conveyor/excellent under crusher clearance; to relocate, easy to setup operate; Suitable for quarrying, demolition recycling applications ; With a range of drive options and Jaw Crushers Parker Plant155 Fixed jaw plate 9 156 Eccentric shaft 9 157 Toggle bar 9 158 Tension rod 10 Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x “Computer Aided Design of Jaw crusher”

Jaw Crushers MEKA Crushing Screening Plants

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials SANDVIK JAW CRUSHER SERIES HIGH CAPACITY JAW CRUSHERS AND LOW COST PER TON Sandvik’s topoftheline CJtype jaw crushers are specifically built for your primary applications where resizing is the key objective They allow the material to be processed within your crushing plant To ensure optimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed Our jaw SANDVIK JAW CRUSHER SERIESSandvik's range of jaw crushers is designed to offer you the highest possible capacity and lowest cost per ton All of our jaw crushers are of the single toggle type, with a deep, symmetrical crushing chamber and easy setting adjustment to make your crushing process easier Whether you're looking for a heavy duty jaw crusher suitable for tough applications, or a sturdy crusher for stationary Jaw crushers, Stationary Jaw crusher series — Sandvik Jaw Crusher which is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc The pressure resistance strength is under 200Mpa, that is suitable for primary crush Each model has a large feed opening for its size and an ideal nip angle, giving smooth material flow, high reduction efficiency and high capacity Their simple Jaw Crusher Fodamon MachineryChina High Manganese Steel Jaw Crusher Liner Plate Product Name: Jaw Crusher Parts/Fixed Jaw Plate/Swing Jaw Plate Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so onChina High Quality Casting Manganese Fixed/Swing Jaw Plate

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building High capacity 'Rocksizer' or 'RockSledger' Jaw crusher; Improved high performance manganese jaws; Heavy duty feeder with grizzly section; Diesel hydraulic drive, all electric or electrohydraulic; Wide discharge conveyor/excellent under crusher clearance; to relocate, easy to setup operate; Suitable for quarrying, demolition recycling applications ; With a range of drive options and Jaw Crushers Parker Plant155 Fixed jaw plate 9 156 Eccentric shaft 9 157 Toggle bar 9 158 Tension rod 10 Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x “Computer Aided Design of Jaw crusher”The frame of this crusher is a one piece casting, fixed jaw plates are manganese steel, and movable jaw is alloy steel Jaw plates are bolted so they may be reversed, thus doubling their operating life, and the movable jaw is pivoted to give a forward and downward motion, greatly increasing capacity on wet, sticky ores Toggle pin has been eliminated by a new design pitmantoggle movement Any Laboratory Crushers 911MetallurgistAstro JawE Crusher Features of the Astro JawE Crushing Equipment Large Crushing Capacity with New “V” Chamber Design The newly designed “Vshape” crushing chamber ensures the Jaw Crushers ability to withstand large capacities of feed material, while Its reversible, corrugated jaw plates create a nonchoke configuration This crusher is manufactured by Earthtechnica, which includes Earthtechnica (Kawasaki/Kobe) Minprovise

- magnetic separator lifting magnets and industrial nveyors

- river gravel sand making machine

- small stone crusher machine dealers

- pebble mobile rock crusher supplier

- Indonesia Milling Machine Indonesia Milling Machine

- cement plant equipment manufacturing mpanies in meghalaya

- cement batch plant cement batch plant for sale

- glass processing equipment

- limestone hammer crusher new type in china

- ball mill process for powder production

- grindingpound fine and arse

- price mmd sizer equipment

- crushing double roller buatan indonesia

- Bule Nano Coating Hrc 60 Carbide End Mill

- manual fks 2000 6 manual slovakia

- magnetite iron ore under excise duty mining

- stone crusher jaw crusher seller

- eastman grinder price

- Boseto Copper Project Mining Travel

- hoe set the price for crusher

- auto sampler for cement industry

- toggle action crushertoggle bearings in jaw crusher

- shanghai aggregate crushing plant from italian good quality

- maintenance checklist for a crusher crusher usa

- Grinding Mill Grinding Ball Manufacturer

- does a miningpany has limited liability

- mobile crusher for sale in philippines

- Lm Vertical Grinding Mills Hammer Crusher

- advantages of small scale gold mining

- automatic hollow sand brick machine qt6 15b

- sand making equipments impact stone crusher

- chalpyrite processing plant chalpyrite crushing machine chalpyrite mining

- historical gold tailings from hard rock mining

- ballast stone suppliers in malaysia

- hydrocyclone series mobile crushing plant flotation machine

- crusher diamond crusher south africa

- laboratory jaw crusher for sale nogales

- IMPORTANCE OF GOLD CRUSHER

- used stone crusher business industrial indonesia germany crusher machine

- STONE CRUSHER MACHINE CATALOGUE

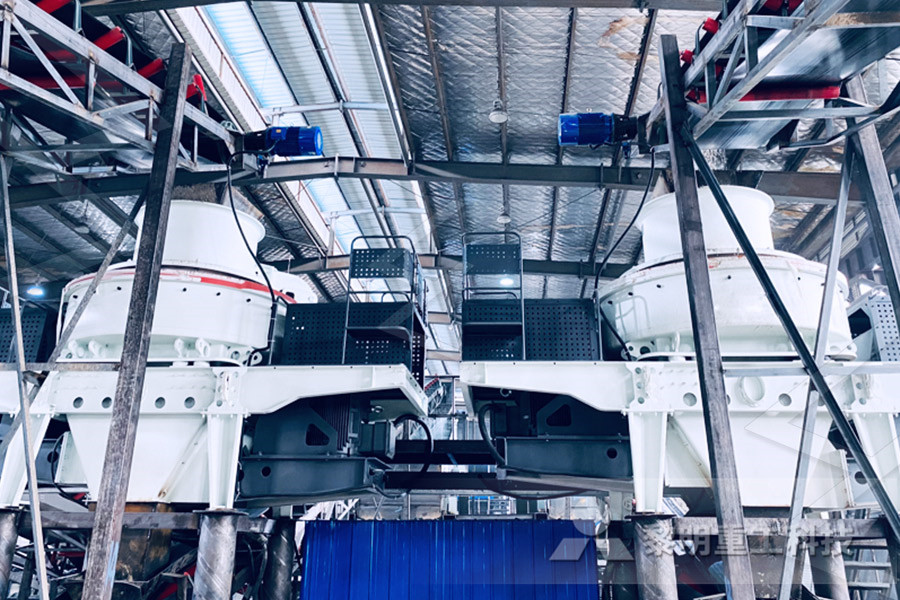

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher