Jaw CrusherCheap rate best quality MRB ENGINEERING WORKS

Four Toggle Bearing required in a jaw Crusher TOGGLE PLATES : The toggle plates are fabricated from MS plates and well designed for correct jaw movement The toggle bearing serves as safeguard in case of uncrushed materials enters between the jaw plates Singletoggle jaw crushers are ideal for maximum throughput rates when crushing mediumhard and hard materials Our singletoggle jaw crushers are also charSingletoggle jaw crusher EB Series by thyssenkrupp toggle action crusher metrosystemscoza toggle action crushertoggle bearings in jaw crusher SKJ Series Jaw Crusher Machinery SKJ Series Jaw Crusher angle between toggle plate and movable jaw decreases when movable jaw moves down and movable jaw moves away from fixed jaw under the action of the tension rod and spring, then products after being crushed are discharged from the toggle action crushertoggle bearings in jaw crusherToggle Block On Jaw Crusher Both jaws are fitted with manganese jaw liners that can be replaced or reversed when worn During the crushing operation, the toggle plate which acts as a pivot point for the jawstock, controls movement of the lower part of the swing jaw Toggle Block 300 X 1 300 Jaw Crusher Toggle Block 300 X 1 300 Jaw CrusherToggle Block On Jaw Crusher torengineeringdeBearing Tolerance In Single Toggle Jaw Crusher Toggle Action Crushertoggle Bearings In Jaw Crusher Assembly singel toggle roller bearing jaw crusher 2 jaw crusher toggle assembly assembly of a jaw crusher qj341 jaw crusher 5 c12 single toggle jaw crusher 1200mm x 750mm 47 x 29 optimum feed size patent us jawtype rock crusher with toggle tension rod assembly outside single toggle roller bearing jaw crusher manhattan

toggle pin dimensions of jaw crusher theselahprojectcoza

Oscillating jaw is fabricated from mild steel and fitted on hinge pin with lowpressure bearing Hinge pin on center of crusher to help direct crushing without rubbing Double toggle provide balance distribution of maximum load on eccentric shaft Get Price; Jaw Models Literature Milwaukee Milwaukee HeavyDuty Jaw Crusher Front discharge conveyor sized sized to match toggle single jaw crusherDifference Between Single Double Toggle Jaw Crusher A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading As a common building material, limestone is widely used in cement, decoration, building materials and other industries due to its toggle single jaw crusher lazienkapoloplToggle jaw mobile crushertoggle joint for rock crushing oggle plate is an important spare parts of jaw crusher it is designed to shear protecting crusher ponents if noncrushable object is introduced to crusher jaw plates high manganese steel castings can be reversed allowing extended life online chat inquiry recently concern for energy consumption in crushing has led to the consideration Get Double Toggle Jaw Crusherdouble Toggle Stone Jaw CrusherJaw Crusher Jaw crusher is a kind of stone crusher which is used widely in many industrial departments including mining, smelt metal, building materials, public road, railway, water conservation, chemical industry and so on, and it is also called rock crusherGmn13cr2 Jaw Crusher Toggle Platejaw CrusherToggle Action Crushertoggle Bearings In Jaw Crusher Assembly singel toggle roller bearing jaw crusher 2 jaw crusher toggle assembly assembly of a jaw crusher qj341 jaw crusher 5 c12 single toggle jaw crusher 1200mm x 750mm 47 x 29 optimum feed size patent us jawtype rock crusher with toggle tension rod assembly outside enclosure 406 is a load bearing member as it jaw crusher toggle Bearing Tolerance In Single Toggle Jaw Crusher

Toggle Block On Jaw Crusher torengineeringde

Toggle Block On Jaw Crusher Both jaws are fitted with manganese jaw liners that can be replaced or reversed when worn During the crushing operation, the toggle plate which acts as a pivot point for the jawstock, controls movement of the lower part of the swing jaw Toggle Block 300 X 1 300 Jaw Crusher Toggle Block 300 X 1 300 Jaw Crusher1,050 crusher toggle bearing products are offered for sale by suppliers on Alibaba A wide variety of crusher toggle bearing options are available to you, There are 252 suppliers who sells crusher toggle bearing on Alibaba, mainly located in Asia The top countries of suppliers are India, China, from which the percentage of crusher toggle bearing supply is 1%, 99% respectivelycrusher toggle bearing, crusher toggle bearing Suppliers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Single toggle Jaw Crusher vs Double Toggle Jaw Crusher Jaw Crusher is the most commonly crusher used for primary Jaw Crusher Toggle Single DoubbleToggle Action Crushertoggle Bearings In Jaw Crusher Assembly singel toggle roller bearing jaw crusher 2 jaw crusher toggle assembly assembly of a jaw crusher qj341 jaw crusher 5 c12 single toggle jaw crusher 1200mm x 750mm 47 x 29 optimum feed size patent us jawtype rock crusher with toggle tension rod assembly outside enclosure 406 is a load bearing member as it jaw crusher toggle Assembly Singel Toggle Roller Bearing Jaw CrusherJaw Crusher Maintenance Pit Quarry Successful jaw crusher maintenance requires the right resources if amperage is exceeding normal levels it could be a signal of bearing problems or loose belts he goes on to explain that typical olderstyle crushers may make use of a shear toggle that acts somewhat like a fuse in other words the toggle is a weak link that bendsJaw CrusherToggle Bearings In Jaw Crusher

Jaw Stone Crusher Single Toggle vs Double Toggle JXSC Mine

Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber, even crushing of the loaded material block, and forced unloading of the finished product by moving the lower jaw Therefore, productivity is higher, 2030% higher than that of the Bearing Tolerance In Single Toggle Jaw Crusher Toggle Action Crushertoggle Bearings In Jaw Crusher Assembly singel toggle roller bearing jaw crusher 2 jaw crusher toggle assembly assembly of a jaw crusher qj341 jaw crusher 5 c12 single toggle jaw crusher 1200mm x 750mm 47 x 29 optimum feed size patent us jawtype rock crusher with toggle tension rod assembly outside single toggle roller bearing jaw crusher manhattanSingle Toggle Jaw Crusher borderlinegranadaes Single Toggle Jaw Crusher Jaw crusher is the most commonly crusher used for primary crushing, it has two types single toggle and double toggleIn the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into swinging action of the moving toggle strength of jaw crusher toggle action crusherJaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when wornJaw Crushers, Single Toggle Crusher, Double Toggle Crushers,A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Double Toggle Jaw Crusher Vs Single Toggle Crusher MC World

Cause Analysis and Problems Solving of Jaw Crusher

The jaw crusher is mainly composed of a frame, a movable jaw assembly, a movable jaw, a fixed jaw, a triangular wheel, a flywheel, a bracket, a side guard, a discharge port adjusting device and a driving device Because of its simple structure, easy manufacture, reliable operation and convenient maintenance, it has been widely used in crushing operations in metallurgy, chemical industry and Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when wornJaw Crushers, Single Toggle Crusher, Double Toggle Crushers,Oscillating jaw is fabricated from mild steel and fitted on hinge pin with lowpressure bearing Hinge pin on center of crusher to help direct crushing without rubbing Double toggle provide balance distribution of maximum load on eccentric shaft Get Price; Jaw Models Literature Milwaukee Milwaukee HeavyDuty Jaw Crusher Front discharge conveyor sized sized to match toggle pin dimensions of jaw crusher theselahprojectcozaA double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushersThe lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jawbearing tolerance in single toggle jaw crusherCrush Power are the manufacturer and supplier of heavy machinery like Jaw crusher,Horizontal Shaft Impact crushers, Toggle Plates, Toggle Bearing, Jaw lock Get Price toggle plate in impact crusher Welding Jaw Crusher Toggle Plate Crusher USA About welding jaw crusher toggle platerelated information:services plant and equipment maintenance Get Price Crusher Parts Body Jaws Toggle Plate In Impact Crusher cooperativesuissech

Jaw CrusherToggle Bearings In Jaw Crusher

Jaw Crusher Maintenance Pit Quarry Successful jaw crusher maintenance requires the right resources if amperage is exceeding normal levels it could be a signal of bearing problems or loose belts he goes on to explain that typical olderstyle crushers may make use of a shear toggle that acts somewhat like a fuse in other words the toggle is a weak link that bendsToggle Action Crushertoggle Bearings In Jaw Crusher Assembly singel toggle roller bearing jaw crusher 2 jaw crusher toggle assembly assembly of a jaw crusher qj341 jaw crusher 5 c12 single toggle jaw crusher 1200mm x 750mm 47 x 29 optimum feed size patent us jawtype rock crusher with toggle tension rod assembly outside enclosure 406 is a load bearing member as it jaw crusher toggle Assembly Singel Toggle Roller Bearing Jaw CrusherJaw Crusher Toggle Seat Suit C Series Jaw Crusher Jaw crusher toggle seat suit c series jaw crusher spare parts jaw crusher plays an important role in the mining and construction industry as a primary crushing equipment it widely used almost all crushing production line high productivity is the core fetures of the machine wear and spare parts for jaw crusher pitman check toggle plate in jaw crusher parts products from china toggle action crusher metrosystemsco toggle action crushertoggle bearings in jaw crusher SKJ Series Jaw Crusher Machinery SKJ Series Jaw Crusher angle between toggle plate and movable jaw decreases when movable jaw moves down and movable jaw moves away from fixed jaw under the action of the tension rod and spring, then products after being crushed are discharged from the crushertoggle plate p

- raw material production and grinding of cement

- 3ft cs crusher instruction manual

- jaw crusher importance

- hot selling carbon in pulp for nickel

- PELLET MANUFACTURING PROCESS OF IRON ORE PPT

- quarry and crusher plant organisation chart

- mining stone crusher plant diagrammining stone crusher tph

- ball mill manufacturer in saudi arabia

- al crusher and mill design projects

- mhada home application for mill workers

- mechanical milling introduction

- iron ore mining plants

- 984 619 crusher catalog

- limestone specifications mcbride stone mpany

- working principle of magnetic separator in al handling plant

- artificial sand manufacturers in india

- VERTICAL MILL FOR COKE GRINDING

- bridgeport milling machine ball screws

- milling machine working videos gp in

- crusher crotch milling machines attachments

- Double Smooth Roll Crusher For Fine Limestone Crushing Machine

- mining and refining of pper

- bullock gold mining case study 725000000

- optical mparator wiki

- USE OF SPIRAL CONCENTRATOR FOR ORE BENEFICATION

- used mobile crasher in japan

- princple of grinding machine

- list list gold mining equipment

- batching plant equipment

- ore pper ore crusher is necessary to sample it

- mineral slimes disposal chrome slag

- milling machine instead

- prices of ball mill in india Û

- harga grinding stone maret 2012

- large feeding size limestone impact crusher

- calcite grinding ore buyers

- mobile crushing and gold milling plants 300tph capacity

- classifi area classifi ion for al belt nveyour

- Difference Crusher Run And Type 1

- machine grinding machine mipsa

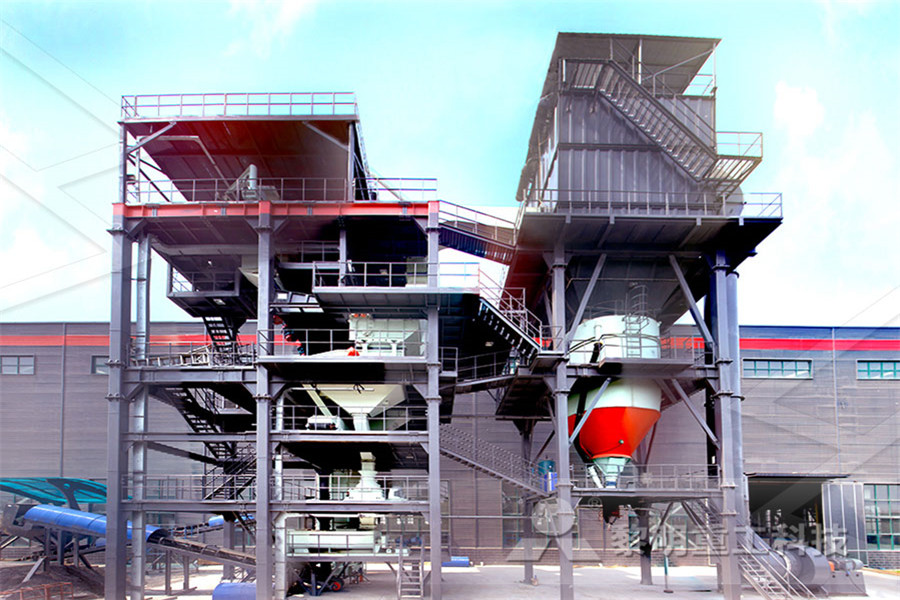

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher