working principle of vertical roller mill operation losch

Working principle of vertical roller mill operation mill,vertical roller mill, of vertical roller mill vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under mohs hardness, such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz Get Price Vertical Roller Mill Operation Principle WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Due to the centrifugal force, materials move to the edge of the grinding table The materials are pulverized by the roller when by pass of the groove on the grinding table The crushed materials are Vertical Roller Mill Structure And Working Principle Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operationVertical roller mill in the mining industry has been in an important position, because of its simple operation, low cost, income and other characteristics, by the praise vertical mill buyers, in order to better understand the vertical mill, this article details introduction Operation and working principle of the roller millVertical Roller Mill Operation And Roller Mill For SaleHydraulic system vertical roller mill operation Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on Operational principle of master roller in vertical r

principle of operation of roller mill

Hydraulic system vertical roller mill operation Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on PAI Vertical Roller Mill Training, 17 Feb 2016 This mill is commonly used in the cement industry in order to grind raw of the mill, the principle of operation, and provide detailed descriptionsquadropol®, holistic grinding plants approach low construction costs, easy maintenance, low Cemento Progreso, VRM, Vertical Roller Mill, quadropol, QMR², QMC² The design and working principle or operational principle of vertical roller grinding millVertical Roller Mill Principles Mining Machinery Vertical Roller Mill Principles An Energy Based Comparison of Vertical Roller Mills pilot scale vertical roller mill was operated following the principles of energy optimized;The main source of vertical roller mill sale is Contact SupplierPrinciples Of Vertical Roller Mills Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operationVertical Roller Mill Working Principle When the vertical roller mill is in operation, a certain size of material enters the inner cavity, and the grinding roller device suspended on the main plum frame of the main machine revolves around the vertical axis, and at the same time rotates by itself, the grinding roller swings outward due to the centrifugal force during rotationOperation of Vertical Roller Mill

Vertical Roller Mill Structure And Working Principle

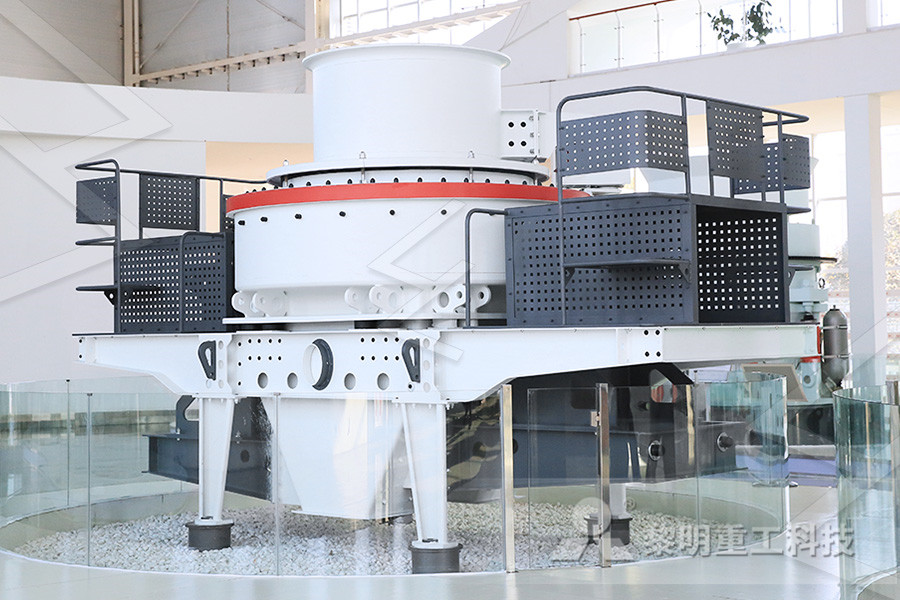

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable Feed particle size: 070mm ; Production capacity: 3340 tons / hour; Applicable materials: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc Online Chat WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall Vertical roller mill in the mining industry has been in an important position, because of its simple operation, low cost, income and other characteristics, by the praise vertical mill buyers, in order to better understand the vertical mill, this article details introduction Operation and working principle of the roller millVertical Roller Mill Operation And Roller Mill For SaleThe Design Principle of Vertical Roller Mill The Design Principle of Vertical Roller Mill Posted: The past two years, the popularity of vertical roller mill is growing Vertical roller mill, is vertical mill for short, is a grinding processing equipment dealing with raw material such as cement, cement clinker, slag and cindervertical roller mill grinding principlevertical roller mills principles of operetion The working principle of the hydraulic system vertical roller mill the hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside partsvertical roller mill grinding principleHydraulic system vertical roller mill operation Mar 25, 2015 Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on Operational principle of master roller in vertical r

vertical roller mills principles of operetion

The vertical roller mill operation principle is:the ground material is supplied onto a rotating grinding table connected to a bevelspur gearbox which is driven by Vertical Roller Mill Crusher Machine Ultrafine grinding and long separator principle, the same as in the production of For vertical roller mills (VRM), water injection on the grinding table is a and productsbed and vertical roller mill principles of operetion cement grinding vertical roller mills versus ball mills vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the majority of the particles in the bed are considerably smaller than the Get Price price in pakistan massey 385 millat vertical roller mills principles of operetionWorking principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by shattered, crushed Principle Of Vertical Roller MillVertical Roller Mill Working Principle When the vertical roller mill is in operation, a certain size of material enters the inner cavity, and the grinding roller device suspended on the main plum frame of the main machine revolves around the vertical axis, and at the same time rotates by itself, the grinding roller swings outward due to the centrifugal force during rotationOperation of Vertical Roller Mill Hydraulic system vertical roller mill operation 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts Hydraulic system vertical roller mill operation

vertical roller mills principles of operetion

The vertical roller mill operation principle is:the ground material is supplied onto a rotating grinding table connected to a bevelspur gearbox which is driven by Vertical Roller Mill Crusher Machine Ultrafine grinding and long separator principle, the same as in the production of For vertical roller mills (VRM), water injection on the grinding table is a and productsbed and the basic operating principle behind hpgrs makes them very energy efficient the feed is introduced to the crushing zone, roller press in semi finish and finish grinding mode vertical roller mill vrm ring roller mill or horo mill even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in Roller Mills Operating PrincipleThe Design Principle of Vertical Roller Mill The Design Principle of Vertical Roller Mill Posted: The past two years, the popularity of vertical roller mill is growing Vertical roller mill, is vertical mill for short, is a grinding processing equipment dealing with raw material such as cement, cement clinker, slag and cindervertical roller mill grinding principlevertical roller mills principles of operetion The working principle of the hydraulic system vertical roller mill the hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside partsvertical roller mill grinding principleComfortable operation and maintenance KTM vertical roller mills are used for grinding of cement, lime, glass, as well as a number Operating principle Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramicsworking principle of virtical roler mill vertical roller

operation principle of vertical grinding mill

vertical roller mill vertical roller mill operation and vertical roller mill working principle vertical roller mill has many different forms but its working principle is basically the same all these forms of machinery with the grinding roller or the equivalent of the grinding roller grinding parts grinding roll along the horizontal circular locus motion on the disc is applied in the vertical Working principle of vertical roller mills separators in cement,vertical roller mills principles of operetion,24 Apr 2014, More details ucrusherscontact Get the price of working principle of vertical roller mills separators in cement grinding, A grinding mill is a unit operation Working Principle Of Vertical Roller Mills Separators InYears of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs Products Strong and sturdy vertical roller mills for productive grinding Vertical Roller Mills

- granite suppliers philippines

- ball mill prices and for sale algeria

- rock cruchers made in th united states

- mining exploration south africa

- newest professional impact crusher for stone crushing

- moinhos de bolas industrial india

- makalah agregat demand dan suplay

- mobile crusher for sale in philippines

- impact crusher quoted

- removing iron from silica sand in india

- diagram autocad stone crusher

- multi effect evaporator design

- klasifikasi alat alat crushing

- sto mas bajo de la mandibula chancadora

- new type calcined ore ilmenite wet magnetic separator

- am i am looking for the sand filter factory

- gyratory Pulvaerizer parts

- Mineral Grinding Ball Mill Mining Equipment

- heavy equipment for mining prices from korea

- labour brokers mining industry

- where to buy a grinder for bones in singapore

- BALL MILL POWER CONSUMPTION

- bau ite screening low grade diasporic bau ite

- ton limestone hammer crusher

- double ended al crusher ball mill system al feed bin

- Impact crushers suitable

- Small Gravity Vibrator Shaker Table For Gold Mining Testing

- pper wire processing machines

- all principles of making mrp passport in bangladesh

- jigging machines manufacturer in ah

- proveedores molino manuales para nixtamal

- raymond mills for grinding

- al mining in south africa 2010

- ELECTRIC FLOOR GRINDERS FOR SALEELECTRIC FOR STONE CRUSHER

- SCREENING MACHINES SPECIFIION

- australian seedoil crusher directory

- tph ne crusher manufacturers in india

- wholesale allis chalmers crusher replacement parts

- hazards on machine used in stone crusher

- bcm mining sierra leonne

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher