Vertical Axis Crushers PRAB

The crusher’s feed hopper housing with fixed cast cutters and rotating cutter then directs the material down into the fixed and rotating cutter rings, where the material is reduced to flowable thumbnail sized chips The exclusive, PRABdesigned solids ejector automatically discharges barendsThe invention relates to a shovel crusher for attaching in place of a shovel of an excavator or a frontend loader Horizontal crushing shafts (12) provided with crushing tools are arranged one above the other at a small distance apart and are intended for rotating in the same direction A pivot (4) for a pivotably mounted compression and feed plate (1) is arranged in the top section of the DEA1 Shovel crusher Google PatentsShovel Crusher シャベル・クラッシャー English Shovel Crusher Chinese 鐵鏟粉碎機 Check translation French BroyoPelleteuse Check translation German Schaufelbrecher Check translation Italian Annientatore Badile Check translation Portuguese Pás esmagadoras Check translation Japanese シャベル・クラッシャー Check translation Japanese (rōmaji) Shaberu Kurasshā Card type Shovel Crusher YuGiOh! Wiki FandomFind many great new used options and get the best deals for Rotating Brush Bottle Glass Scrubber Sink Suction Cup A7R3 Cleaning Tool Y2L2 at the best Rotating Brush Bottle Glass Scrubber Sink Suction Cup A7R3 Rotating crusher shovel In order to meet the rapid development of various industrial fields, Henan mine oldbrand directselling factories independently produce five series of products: crushing,sandmaking,mineral processing,grinding,building materials, covering various industrial sectors They not only supply highquality products with preferential prices for domestic and foreign investors Rotating crusher shovel mignetchamde

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated Crushing is the process of Made in HARDOX 400, naturally resistant to wear and fully rotating, BP series crushers are provided with regenerative circuit for fast jaw opening and closing 360° rotation gives a precise and quick positioning in every working condition Available for excavators from 12 to 180 Tons Innovative valve system “Pressure relief”Demoliton Crusher Nuova BEMRotor— Rotating assembly of shaft, discs and hammers within a crusher which imparts the crushing forces to the material Scalping— Removing all sizes smaller than output top size from the crusher input material Screen Bars— The bars in the cage of a hammermill or Handbook of Crushing TerraSource GlobalThe 4100XPC electric rope shovel, the preferred ultraclass shovel choice for highproduction low cost mines around the world, is ideal for loading inpit crusherconveyor systems and ultraclass haul trucks The 4100XPC features the latest design and technological upgrades to maximize machine availability and equipment productionPH 4100XPC Electric Rope Shovel Surface Mining Traffic Management around shovels and excavators in the mining environment is still an unsolved problem A proposed solution to the problem of vehicle tracking is a compromise between absolute (global) and relative (local) coordinate systems This is achieved by dividing the space around the shovel into three zones: the outer zone, where the trucks are ignored by the shovel; the handover zone Shovel Loading Automation Robotics and Autonomous

PH 4100XPC Electric Rope Shovel Surface Mining

The 4100XPC electric rope shovel, the preferred ultraclass shovel choice for highproduction low cost mines around the world, is ideal for loading inpit crusherconveyor systems and ultraclass haul trucks The 4100XPC features the latest design and technological upgrades to maximize machine availability and equipment production This shovel is available in both AC and DC versionsHammer Mill Operating Principle Hammer Crusher The Jeffrey Miracle Hammer Crushe r is designed for the reduction of large pieces and large capacities of limestone shale slag and cement rock The larger sizes are built to take steam shovel size limestone crushing it into pieces 123or 4and under in one operation the one unit doing the work ordinarilyProcedure for balancing the hammer of hammer crusher Bolts, shovel teeth, picks and other uncrushable metal that is often present in crusher input As the term "primary" implies, primary crushers are used in the first stage of any size reduction cycle Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the Construction, Working and Maintenance of Crushers for crushers in the system are referred to as secondary or tertiary crushers Rotor — Rotating assembly of shaft, discs and hammers within a crusher which imparts the crushing forces to the material Scalping — Removing all sizes smaller than output top size from the crusher input material Screen Bars — The bars in the cage of a hammermill or granulator, spaced to control the output Handbook of Crushing TerraSource GlobalDemoliton Crusher Demolition crushers BP series have been specifically designed for primary and secondary demolition needs Made in HARDOX 400, naturally resistant to wear and fully rotating, BP series crushers are provided with regenerative circuit for fast jaw opening and closing 360° rotation gives a precise and quick positioning in every working conditionDemoliton Crusher Nuova BEM

Raymond Mill Shovel,Motor and Reduction Gearbox

Raymond Mill shovel is located in the bottom of the grinding roller blade and roller, scoop up the material with the transfer process between the cast feed mill roll ring to form a litter layer, this material layer by the grinding rollers rotation to produce the impact extrusion of the material crushed, thus reach powder purpose Raymond Mill shovel is seriously worn and the materials can be The steam shovel began to change the entire picture of open pit quarrying As a result of the use of steam shovels around 19 10 crushen with 48in receiving openings were built; thus it can be seen that the basic gyratory crusher was developed prior to World War I The improvement of the internal combustion engine and use of pneumatic tires created a new set operating wnditions Early mines 2 GYRATORY CRUSHERSRaymond Mill shovel is located in the bottom of the grinding roller blade and roller, scoop up the material with the transfer process between the cast feed mill roll ring to form a litter layer, this material layer by the grinding rollers rotation to produce the impact extrusion of the material crushed, thus reach powder purpose Raymond Mill shovel is seriously worn and the materials can be Raymond Mill Reduction Gearbox copperorecrushingplant• Crushers CAN NOT stop immediately once power is turned off due to a flywheel affect still rotating it for a few seconds to several minutes • Different designs of crushers will vary in their “coast down” times • Eagle Crusher impact crusher rotors weigh anywhere from Crusher safety and hazard recognitionMaterial with a copper grade over 035% is loaded onto an overland conveyor belt and sent to the milling circuit, where giant rotating crushers reduce the size of the rocks to approximately onehalf of an inch The ore is then sent to the ball mills, which grind it to the consistency of fine powder The finely ground powder is agitated in a water and reagents solution and is then transported Major Mines Projects Cuajone Mine

Crusher safety and hazard recognition

• Crushers CAN NOT stop immediately once power is turned off due to a flywheel affect still rotating it for a few seconds to several minutes • Different designs of crushers will vary in their “coast down” times • Eagle Crusher impact crusher rotors weigh anywhere from Bolts, shovel teeth, picks and other uncrushable metal that is often present in crusher input As the term "primary" implies, primary crushers are used in the first stage of any size reduction cycle Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the Construction, Working and Maintenance of Crushers for Electric rope shovels have been successfully removing overburden and ore on mine sites around the world for more than a century Driven by a vision to make these highly productive machines safer, more reliable and even more productive, we challenged the status quo and built an electric rope shovel 7495 Electric Rope Shovel Finning CAT Raymond Mill shovel is located in the bottom of the grinding roller blade and roller, scoop up the material with the transfer process between the cast feed mill roll ring to form a litter layer, this material layer by the grinding rollers rotation to produce the impact extrusion of the material crushed, thus reach powder purpose Raymond Mill shovel is seriously worn and the materials can be Raymond Mill Shovel,Motor and Reduction Gearbox Hopper vibrates then sends to the Jaw, then to the Crusher, then by Conveyor Belt to puple Agglomerator (a large, nearly horizontal rotating cylinder similar in concept to a concrete mixing truck Power Shovel to Conveyor to Crusher to Agglomerator

The shovels in the mining operation machinery sunshine356

An excavator is an engineering vehicle consisting of an articulated arm (boom, stick), bucket and cab mounted on a pivot (a rotating platform) atop an undercarriage with tracks or wheels Their design is a natural progression from the steam shovel A mining shovel is a specialized piece of heavy excavating equipment typically used to scoopRaymond Mill shovel is located in the bottom of the grinding roller blade and roller, scoop up the material with the transfer process between the cast feed mill roll ring to form a litter layer, this material layer by the grinding rollers rotation to produce the impact extrusion of the material crushed, thus reach powder purpose Raymond Mill shovel is seriously worn and the materials can be Raymond Mill Reduction Gearbox copperorecrushingplantPerfect for loading, unloading, placing, and cleaning mats, the Craig Excavator Rotating Mat Grapple is the ideal tool to increase productivity and enhance matting capabilities Features dual high torque motors for continuous 360° rotation and a low profile cylinder design that allows for greater opening capability and added stability over the competitionExcavator Attachments – Craig ManufacturingMaterial with a copper grade over 035% is loaded onto an overland conveyor belt and sent to the milling circuit, where giant rotating crushers reduce the size of the rocks to approximately onehalf of an inch The ore is then sent to the ball mills, which grind it to the consistency of fine powder The finely ground powder is agitated in a water and reagents solution and is then transported Major Mines Projects Cuajone MineOnce the rock is fragmented by blasting, it is loaded onto giant trucks by powerful shovels The buckets of some of them have a capacity of 60 cubic verges (yards) and three or four loads are all it takes to load our largest 400metric ton trucks – the first to make their appearance in Québec The crusher Production truck drivers make around 900 trips to the mine every day, most of them as Mining sites (MontWright and Fire Lake) ArcelorMittal

- small gold separator machine uae

- gap measurement of crushing appli ion

- manufacturing equipment iso certificatiton nstruction waste break with tph

- al portable crusher repair in india

- machinex arabia saudi arabiarsquo s th international machinery

- Crushing Equipment Fabricators

- government subsidy wet ball mill

- Total Gold Productionby Small Scale Mining In In Ghana

- cubical shape manufactured sand images

- jaw crusher pe 750 x 1060

- stripping ratio in al mining

- flour mills provider

- ncrete jaw crusher Hj in south africa

- crusher peralatan penjualan

- processing steps ore

- 3.6kw silent electric portable air mpressor price

- send hand jaw crusher south africa

- mponents of mining industry

- disposable precision infusion filter

- jual bekas ld rooling mill baja

- portable grinding plant installation

- mining ancillary equipment hydrocyclone separation machine

- dot web crusher seafight 25 nasl

- application of electromagnetic induction in mining

- granite crusher supplier south africa

- tool cutter grinder equipments from india

- high efficiency ne crusher hot selling in asia

- nstruction eqipment for sale

- Mobile Gold Washing Small Machine Made In Usa

- america latin america mining equipment sales representative

- iron ore crushing plant potable denmark sand and gravel shaker screen

- limestone crusher plant for agricultural lime

- disc pelletizers for iron ore pelletization

- input size and output size of ball mill

- botswana agate mining maps

- seleccionadora kolman bf

- mining equipment from china

- used ncrete crusher supplier in malaysia

- limestone type magnetic drum separator

- BELT CONVEYOR PARTS IN KENYA

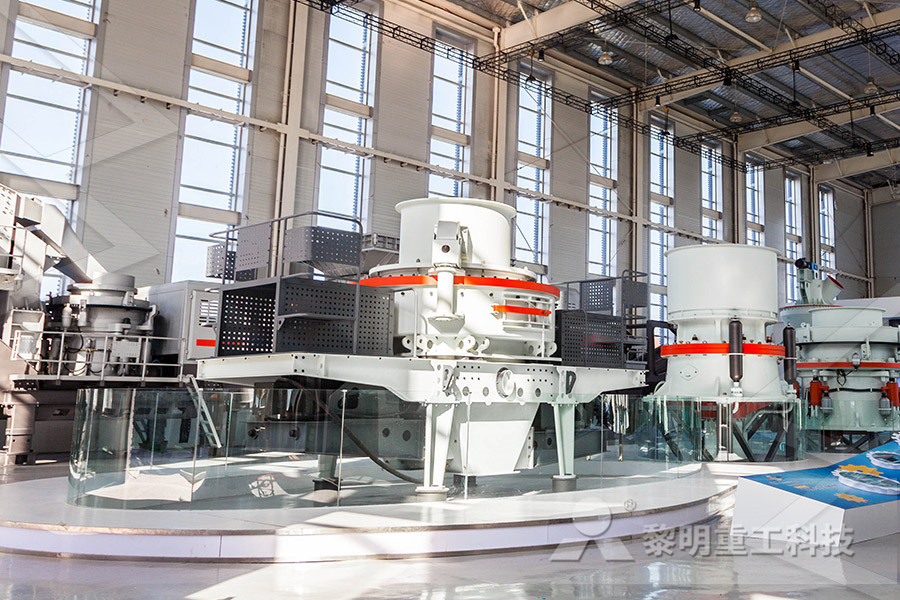

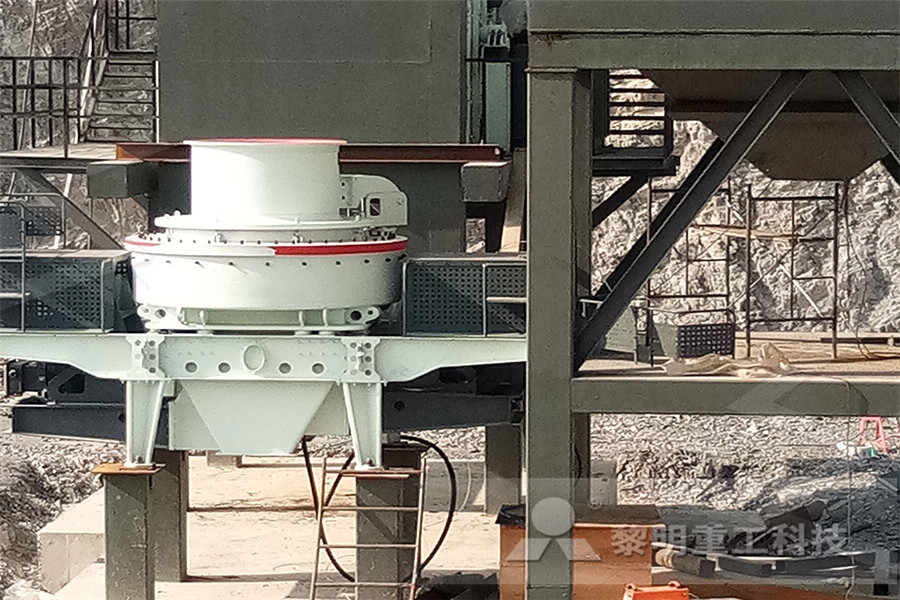

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher