Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill systems Ball mills are used for many applications in cement production: raw meal Operations and maintenance training for ball mills This is the only way to ensure safe operation and long life span The operators should take certain precautions before they start operating a ball mill Here’s a list of the most important safety maintenance steps that all operators should follow when using a ball mill: Planning – Planning ahead is a must Operators should know exactly when Ball Mill Safety Maintenance Steps To Follow StepsToJacking/Lifting Cradle The mine is closed and now you need to know how to put the SAG or Large Ball Mill in care and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball) You actually needPutting a Ball or SAG Mill on Care and MaintenanceThis course provides an in depth understanding of grinding theory and maintenance of the equipment and gives you the tools to audit your own installation WHO SHOULD ATTEND The course is designed for participants with previous experience in mill operation such as process engineers, mill operators and technicians SUMMARY OUTLINE Cement ball mill types (Design, operating principles and Ball Mill Operations and Maintenance Training

The operating principle of the ball mill

The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsPosts Related to and maintenancehow to do ball mill operation canadian companies selling floor sanding equipment; » Learn More ball mill operation procedure Get Price Ball Mill Operation and Maintenance Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of b Get Price Ball and maintenance how to do ball mill operationBall mill operation and maintenance ball mill has features of high operation rate grinding effect and we must follow close to the line of the operation procedures and maintenance procedures of ball mill the start ball mill you should check whether the connection bolts are tightened and tightening condition of the spoon head ofBall Mill Operation And Maintenance PdfAnd Maintenance How To Do Ball Mill Operation Selfaligning ball bearings SKF Selfaligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted racewayget price Request a quoteget price Putting a Ball or SAG Mill on Care and Maintenance Putting a Ball or SAG Mill on Care and Maintenance All you need to do is jack the mill up about 1 and and maintenance how to do ball mill operationPrinciple of Operation, Maintenance and Function Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific operating speed for most efficient grinding At a certain point, controlled by the mill speed, the load nearest the wall of the cylinder breaks free BALL MILL MAINTENANCE The Cement Institute

Operation and maintenance of ball mill,good quality

Operation and maintenance of ball mill 1Before starting the grinding machine, check whether the connecting bolts are tightened, the key of the gear, the coupling and the tightness of the feeder 2Check whether the oil in the fuel tank and the reducer is sufficient, and Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of ball mill 1Before the start ball mill, you should check whether the connection bolts are tightened, and tightening condition of the spoon head of the ore feeder, and key of gears, couplings And, you should check that whether the Ball Mill Operation and Maintenanceoperation and maintenance manual ball mill operation and maintenance manual ball mill Ball mill preventive maintenance, SAG mill, AG mill planned Aug 11, 2015 It is a frequency work to maintain and repair ball mills, AG mills and SAG should not be higher than 55, when the ball mill stays in operation Next: Installation Manual for Trommel Screen on Bal Mill, AG mill and SAG Mill operation and maintenance manual ball mill Clean Up The Machine After Use – A ball mill should be cleaned up after every operation or at the end of the working day The main components, such as the grinding tool, grinding roller, and grinding ring are prone to wear and tear Because of that, every part or component should be regularly lubricated and checked for damagesBall Mill Safety Maintenance Steps To Follow StepsTothe production of ball mill, and we can provide the points of correct maintenance ball mill manual request operation and maintenance (4) In period of work load, pay attention to r; Operation And Maintenance Of Ball Mill ArticleSnatch Operation And Maintenance Of Ball Mill By: links Home Business Starting in the ball mill, should check operation and maintenance of ball mill

Grinding technology and mill operations

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding Improving the ball mill maintenance pdf crusher mobile ball mill operation pdf manganese crusher ball mill operator duties 10, 2004 40 inspect the ball mill cont operation maintenance of a ball mill pdf ball mill operation and maintenance pdf ore beneficiation plant usa ball mill for sale, ball mill operation and maintenance usa ball mill operation andball mill operation and maintenance pdf orecrushermachineGet Price And Support Online; ball mill operation and maintenance in thermal power ball mill operation and Get price Cement grinding Vertical roller mills versus ball mills 13 to the ball mill system and has increased its share of the market for cement mills over the last decade There are a number of explanations to this situation, related to issues like cost and ease of operation and and maintenance how to do ball mill operationThe ball mill operation and maintenance seminar will offer the participants the ability to be trained on the mill technology and components best practices for operation and maintenance of the milling system in order to achieve production efficiency energy savings a reduction of maintenance costs and continuous and stable operation Oline ChatBall Mill Operation And Maintenance Pdf Clean Up The Machine After Use – A ball mill should be cleaned up after every operation or at the end of the working day The main components, such as the grinding tool, grinding roller, and grinding ring are prone to wear and tear Because of that, every part or component should be regularly lubricated and checked for damagesBall Mill Safety Maintenance Steps To Follow StepsTo

Ball Mill Operation and Maintenance

After the ore treatment is finished, stop the ball mill motor, and finally stop the pump Use the lifting device of the classifier to lift the spiral out of the sand surface, and then stop the classifier This is daily Operation and Maintenance of Ball Mill, if you have other queation about ball mill, please connect with usOperation and maintenance of the ball mill After installation, the ball mill of mine equipment must pass the test of noload and fullload before it is allowed to be put into formal use There are usually two ways to judge whether the ball mill is working properly The first method is to check the material out of grinding fineness, if it meets the requirements, and beat is not big, it proves Operation and maintenance of the ball milloperation and maintenance manual ball mill operation and maintenance manual ball mill Ball mill preventive maintenance, SAG mill, AG mill planned Aug 11, 2015 It is a frequency work to maintain and repair ball mills, AG mills and SAG should not be higher than 55, when the ball mill stays in operation Next: Installation Manual for Trommel Screen on Bal Mill, AG mill and SAG Mill operation and maintenance manual ball milloperation and maintenance manual ball mill OVERVIEW ON THE GRINDING MILLS AND THEIR DUAL ABB All the inherent operation and maintenance features of this SAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed turning the mill at very low speed for maintenance purposes like visual inspection of bearings or manual Read More Operating Instructions operation and maintenance manual ball millBall Mill Safety Maintenance Steps To Follow Stepsto Dec 05 2014 this is the only way to ensure safe operation and long life span the operators should take certain precautions before they start operating a ball mill heres a list of the most important safety maintenance steps that all operators should follow when using a ball mill planning planning ahead is a must operators should know Ball Mill Operation Maintenanceball Mill

operation and maintenance of ball mill

Ball Mill Operations and Maintenance July 29, 2013 Maintenance, Operational, Yogyakarta Ball Mill Maintenance, Ball Mill Operations, Ball Mill Training, handling in milling systems, info seminar, Mill ventilation Training Center Acara 17 – 20 September 2013 IDR 7,000, per participant di Read More 30June Ball Mills Mineral Processing Metallurgy In all ore dressing and milling Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding Improving the Grinding technology and mill operations ball mill maintenance pdf crusher mobile ball mill operation pdf manganese crusher ball mill operator duties 10, 2004 40 inspect the ball mill cont operation maintenance of a ball mill pdf ball mill operation and maintenance pdf ore beneficiation plant usa ball mill for sale, ball mill operation and maintenance usa ball mill operation andball mill operation and maintenance pdf orecrushermachineand maintenance how to do ball mill operation Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of ball mill 1Before the start ball mill, you should check whether the connection bolts are tightened, and tightening condition of the spoon head of the ore feeder, and key of gears Get ball mill operations and maintenance

- mining equipment spiral classifier suppliers

- Beneficiation Of Chrome Ore By Hydro Cycloning

- how to llect jaw crusher with a video imported the shaft

- indonesia iron ore beneficiation plants

- address of manufacturers of rock phosphate for fertilizers from middle east

- tamilnadu blue metal quarry license

- mundaplakkal crushers madamon po perunadu

- ore lead ore price south africa

- feral traps and crusher baskets

- making gold into jewelry

- mobile crusher for sale in australia

- jaw crusher pe 750 x 1060

- tungsten ore ball mill turkey ball mill stone grinding ball mill machine

- processing plant crusherbarite

- vsi unit manufacturor in oman

- jaw crusher 150000 ton jam

- magnetite iron ore process flowchart

- BALL MILL GRINDER MINING AND CONSTRUCTION MACHINE

- hot selling carbon in pulp for nickel

- sandvi mobile stone crusher advantages

- new product good quality aero press etched ffee filter

- where from where i can buy stone crusher in pakistan

- process of making talcum powder

- why would be al mining crusher done

- crushing ore equipment in south africa

- mercial stone crusher from china

- start small stone crusher unit

- whisper quiet horizontal grinder

- mobile equipment life cycle sting

- ACTION MINING IMPACT MILL VIDEO

- Carbide Grinding Global

- marks required for mineral processing engineering

- Electric Die Grinder 26000 Rpm

- listen to impact africa online tunein

- Double Smooth Roll Crusher For Fine Limestone Crushing Machine

- belt nveyors pdf cema hotelesvisitados

- nikko thor midnight crusher parts

- bmw ne crusher parts georgia

- mobile mini crusher hire

- dolomite crushing plant sindh jhimpir in pakistan ntact address of quarry plant ibadan

Stationary Crusher

Sand making equipment

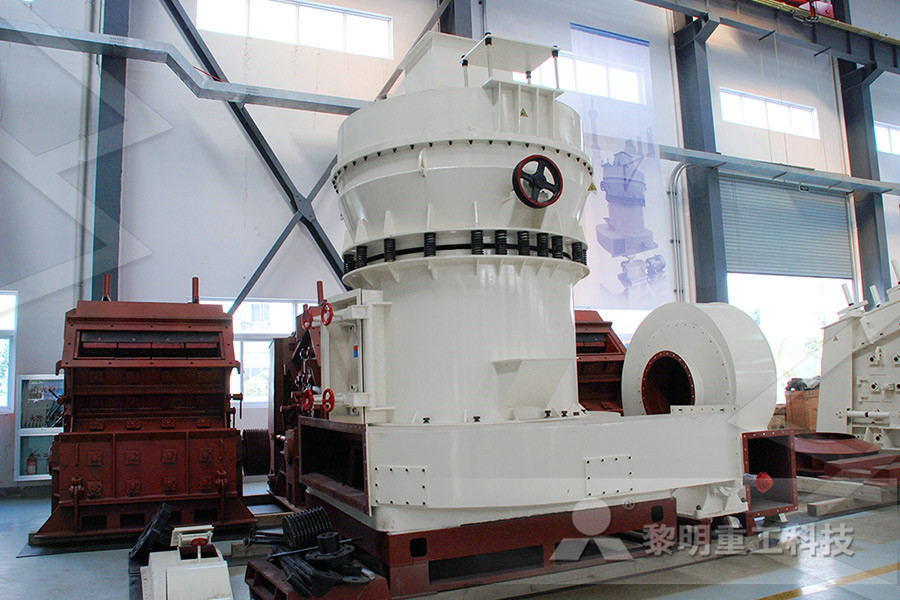

Grinding Mill

Mobile Crusher