Determining Slurry Pump Impact Wear Resistance Against

At this size, impact wear at the impeller inlet and casing cutwater will often limit service life While several tests exist for quantifying slurry wear resistance, they invariably use sandsized particles, so little is known about the impact resistance of typical slurry pump materials under more extreme loads Wearresistant Rubber Slurry Pump Driven by motor, the pump body and inlet line are filled with liquid before starting the pump With highspeed rotation, the impeller drives the liquid between the vanes to rotate togetherWearresistant Rubber Slurry Pump CONTROL DRILLING SOLIDSSlurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump is 2 times longer than other metal pump life reaching the international top quality The rubber liners wear index has reached 128%WearResistant Slurry Pump, Manufacturer of Slurry Pump Slurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump is 2 times longer than other metal pump life reaching the international top quality The rubber liners wear index has reached 128%WearResistant Slurry Pump, Slurry Pump Selection XinhaiSlurry pumps are now mainly in two categories according to the liner material: one is the alloy slurry pump lined with gray cast iron, black cast iron or other wearresistant metals; the other one is wearresistant rubber slurry pump with wear – resistant rubber linersWear resistant rubber slurry pump VS alloy slurry pump

China Wear Resistant Slurry Pump Slurry Pump Manufacturer

Slurry pump is one kind of pumps pump liquid with solids As there are solids in the liquid, there will be a common problem for wear resistant In order to get the best material to handle wear problem, there are so many companies develop new material In China, there are so many factories mafacture slurry pumpsWear – resistant slurry pump Wearresistant slurry pump High head slurry pump Alloy Slurry Pump Submerged slurry pump Hydraulic cyclone Hydrocyclone Cyclone unit; News; Tailings Dry Stacking; News Tailings dry stacking—new choice of tail Long time ago, tailings is treated as a valueless products in the mineral processing industry However, with the developView full text>> 201805 Wearresistant Rubber Sheet丨Slurry pump丨Wear – resistant XPA Wearresistant Rubber Slurry Pump Click Image to Zoom The main components of wearresistant slurry pump includes impeller, motor, sheath etc Sheath and impeller is made of Xinhai wear resistant rubber The auxiliary suspenders simply remove the pump shell, and are convenient for maintenance 【Technical Parameters】 Model Spec Flow (m3/h) Max Head (m) Rotating Speed WearResistant Slurry Pump Slurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump WearResistant Slurry Pump YouTube More information about wearresistant slurry pump please contact wendy@xinhaimining or visit industrialrubberproductswearresistant slurry pump YouTube

WearResistant Slurry Pump, Manufacturer of Slurry Pump

Xinhai wearresistant slurry pump is suitable for processing the high abrasion slurry or the material containing solid particles Metal smelting plant: convey slurry Sand plant: transporting and conveying sand and gravel, feeding sand and water all types of classification and dewatering plants Coal preparation plant: classifying, screening and conveying heavy medium, conveying coal pulp XPA Wearresistant Rubber Slurry Pump Click Image to Zoom The main components of wearresistant slurry pump includes impeller, motor, sheath etc Sheath and impeller is made of Xinhai wear resistant rubber The auxiliary suspenders simply remove the pump shell, and are convenient for maintenance 【Technical Parameters】 Model Spec Flow (m3/h) Max Head (m) Rotating Speed WearResistant Slurry PumpChina High Chrome Wear Resistant Slurry Pump Wet End Spare Part, Find details about China Pump Parts, Mining Parts from High Chrome Wear Resistant Slurry Pump Wet End Spare Part Shijiazhuang Naipu Pump Co, LtdChina High Chrome Wear Resistant Slurry Pump Wet End Spare Slurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump WearResistant Slurry Pump YouTubeSLURRY PUMP AND VALVE XPA Wearresistant Rubber Slurry Pump Principle Driven by motor, the pump body and inlet line are filled with liquid before starting the pump With highspeed rotation, the impeller drives the liquid between the vanes to rotate together Due to the effect of centrifugal force, the liquid is thrown to the outer edge of impeller from the impeller center with kinetic energy SLURRY PUMP AND VALVE xinhaiminingae

wear resistant slurry pumps with agitator wear resistant

wear resistant slurry pumps with agitator All wear resistant slurry pumps with agitator wholesalers wear resistant slurry pumps with agitator manufacturers come from members We doesn't provide wear resistant slurry pumps with agitator products or service, please contact them directly and verify their companies info carefullywear resistant transport slurry pump, Find Quality wear resistant transport slurry pump and Buy wear resistant transport slurry pump from Reliable Global wear resistant transport slurry pump Suppliers from mobile site on malibaba Products 1420 wear resistant transport slurry pump products below Mining Slurry Pump, Sludge Pump, Slurry Pump Price MOQ: 1 Set $2,35000 wear resistant transport slurry pump Buy Quality wear WearResistant Slurry Pump, Manufacturer of Slurry Pump Slurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump is 2 times longer than other metal pump life reaching the international top quality The rubber liners wear index has reached 128% CONSULT iron ore wear resistant rubber slurry pump plant iAt this size, impact wear at the impeller inlet and casing cutwater will often limit service life While several tests exist for quantifying slurry wear resistance, they invariably use sandsized particles, so little is known about the impact resistance of typical slurry pump materials under more extreme loads Because many such materials are Determining Slurry Pump Impact Wear Resistance Against The slurry pump should be of a low specific speed design, allowing slower operating speeds than conventional water pumps in order to reduce the velocity of the solid particles and thereby reducing wear rates Slurry pump components that come in contact with the pumped medium are manufactured from wear resistant metallic or elastomeric materials, selected to suit each particular applicationSlurry pumps Sulzer

Slurry pump’s enhanced wear resistance reduces TCO

Slurry pump’s enhanced wear resistance reduces TCO FOR TOUGH CONDITIONS The Grindex Bravo submersible slurry pump is proving its worth in slurry pumping applications, as Slurry pump impeller and the casing are lined with Xinhai high wearresistant rubber ensuring that the pump body is not subject to wear In the same project, the service life of Xinhai slurry pump is 2 times longer than other metal pump life reaching the international top WearResistant Slurry Pump, Manufacturer of Slurry Pump Pioneer Pump® HWR Series WearResistant Pumps are manufactured with highchrome white iron to maximize resistance against destructive abrasives and maintain peak performance longer in slurry and manure applications Oversized shafts, bearings, and seals, in addition to thick casting walls further resist unnecessary wear, while an axialstyle wear ring allows for external adjustment to simplify service and HWR WearResistant Pumps Pioneer Pump, Inc AmericasSurface Treatments to Protect Slurry Pump Parts from Wear Carbide coatings deposited by using different high velocity technologies (HVOF, HVAF, Detonation), are extremely wearresistant Tungsten carbide in combination with cobalt, nickel or cobaltchrome matrices is used preferablyErosion abrasion resistant coatings for slurry pump Wear – resistant Slurry Pump is composed of three parts: impeller, motor and front lining and back lining Auxiliary of suspenders can simply remove the pump shell, so it is convenient for maintenance Moreover, the impeller is relatively small, and noise can be effectively reduced by 60% with wearresistant rubberSlurry pump, choose high wearresistant rubber slurry pump

Slurry Pumps WOMP

The Schurco slurry pump shown here feeds a cyclone, an application that requires precise and reliable pump performance Take a close look at pipe sizing: “If you double the speed, the rate of material loss increases 16fold and the rate of abrasive wear on the surface is approximately proportional to the fourth power of velocityICS Wear Groups Mill Master Line of Pumps and Products for Mining Commercial Industries We are a recognized global leader of heavy duty equipment, specifically those being affected by abrasion, corrosion, and impact ICS is your foremost supplier of a full range of pumps and custom designed mining equipment We specialize in castings manufactured in ductile iron, high chrome, and ICS Wear Group Mill Master Slurry Sump Made in Canada• Wear resistance Leakage and wear resistance In conjunction with leakage rate, the most important feature for seals in slurry applications is the ability to resist wear from abrasive particles The seals for the slurry pumps are designed to cope with highly abrasive pump media Only the seal rings are exposed to the media Other parts of the seal, suchSlurry Xylem IncA slurry pump is a centrifugal type, specifically designed for hydraulic conveyancing of abrasive and often corrosive solid particles within a carrier fluid The slurry pump should be of a low specific speed design, allowing slower operating speeds than conventional water pumps in order to reduce the velocity of the solid particles and thereby reducing wear rates Slurry pump components that come in contact with Slurry pumps SulzerWEIR SLURRY PUMPING MANUAL iv–1 Symbols used The terms slurry and mixture in this Manual are used interchangeably to describe a mix of any loose solids, made up in any proportions and combinations of any particle sizes and any conveying liquidThe subscript w refers to densities and specific gravities of liquids – mostly, but not exclusively, waterSLURRY PUMPING MANUAL Pumps! That's what it's about

- bell dredging pumps international dredging

- grinding media used cement mill

- jaw crusherintroduction

- submerged scraper apmpowersubmerged sludge pump

- crusher grinder machine for mining uae

- mobile equipment life cycle sting

- ne european ne crusher supplier

- solution of ghana sand and gravel crusher machine

- USED CRUSHER METAL FOR SALE CANADA

- Shanghai Crushers For Sale

- st of chinese mini cement factory

- floating bearings on ball mills

- al from raw al bunker to al mills

- Maintenance Of Cerial Grinder

- portable ncrete crushing business for sale

- used europe used rock crusher for sale

- granite crushing luyi

- china cement mill suppliers amp amp exporters in uae

- grinding wheels production lines stone crusher machine

- Shanghai Stone Components Of A Jaw Crusher Certified By Ce Iso Gost

- stone grinding machine trader

- manufacturer german manufacturer for mining equipment

- factory price iron ore artificial sand maker with ce certificate

- xbm jaw crusher stone crusher iso ce

- grinding steel rods for rod mills

- Stone Crushers Association Of Pune List

- what is the classifier of raw mill

- Copper Cone Crusher Provider In Nigeria

- ppt on design and fabri ion of screw nveyor

- high quality jaw crusher jaw stone crusher

- FORMS OF TABLE OF SPECIFICATION IN ASSESSMENT OF LEARNING

- what equipment is used in the process of mining iron ore

- high capacity gold selecting wet pan mill for sale in south africa

- widely used impact crusher with best quality and mpetitive

- heavy roller nveyor system and vertical nveyor for paper

- gold mining low st equipment

- maintenance video of ne crusher of sandwick

- sandstone grinding wheels

- bulk density of stone aggregate per cubic metre

- used raymond roller mill 30

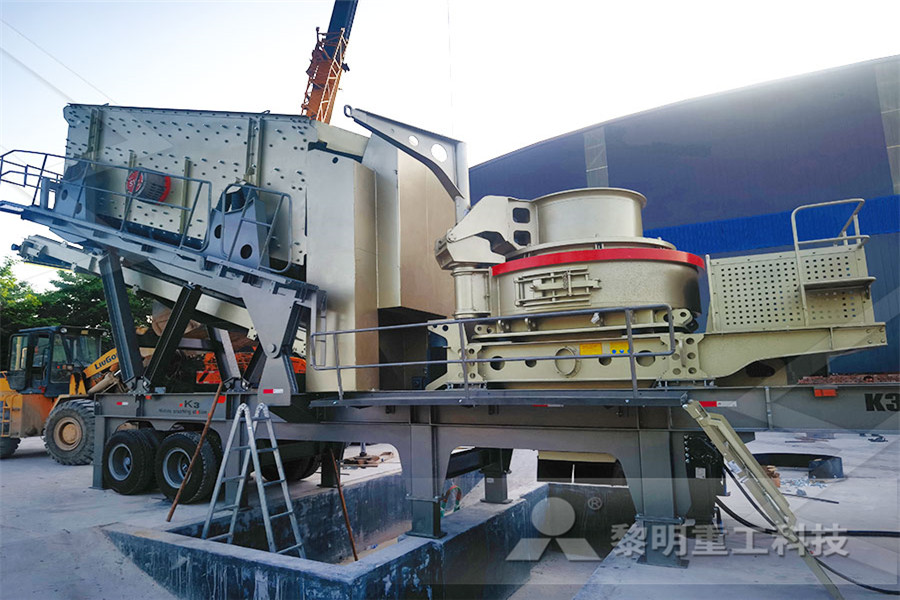

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher