Primary gyratory crushers

Specifications Primary gyratory crushers are the initial driving force for the entire mineral processing circuit 's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operationThe parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closedside setting, work index, and horsepower The combination of the nip angle, feed opening, and closedside setting determine the length of the crushing 2 GYRATORY CRUSHERSTECHNICAL SPECIFICATION SANDVIK CG800i GYRATORY CRUSHER SERIES Sandvik CG800i crushers are built to be robust, reliable and efficient Connected to My Sandvik, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performingSANDVIK CG800i GYRATORY CRUSHER SERIESThe Gyratory Crusher TS is a high quality, modern design, durable gyratory crusher that was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projectsGyratory Crusher (TS) for harsh environments’s solution to a unique crushing application in Canada was a custom designed 72”x 89” Gyratory Crusher In addition to this crusher, multiple dual pinion drive crushers were designed and successfully installed for the Minnesota (USA) Iron Ore RangeGyratory Crushers DorrOliver Eimco PDF

Superior™ MKIII 4265 primary gyratory crusher

The core of the Superior™ MKIII 4265 primary gyratory crusher is the robust design Resistant Ushaped arched spider, durable manganese bronze spider bushing, new shell separators and inspection ports, as well as hardy onepiece main shaft makes Superior™ MKIII primary gyratory crushers efficient and lasting, but easy to maintain when neededgyratory jaw mobile crusher specifications KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm 40” x 26” Optimum feed size 520 mm3 21 inch3 Engine C71 Acert 168 kW 225 hp Transport dimensions 1390 m 45’ 7 ⅜” l 264 m 8’ 7 ⅞” w 322 m 10’ 6 ⅝” h Weight 32568 kg 71800 lbsAs a leading global manufacturer of crushing equipment gyratory jaw mobile crusher specificationsFind Crushers on GlobalSpec by specifications Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raCrushers Specifications Engineering360TECHNICAL SPECIFICATION SANDVIK CG800i GYRATORY CRUSHER SERIES Sandvik CG800i crushers are built to be robust, reliable and efficient Connected to My Sandvik, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performingSANDVIK CG800i GYRATORY CRUSHER SERIESTrio ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and manufactureing that provides high performance, reliability, and costeffective solution TG Series Gyratory Crushers are typically applied in large tonnage mining and aggregate plantsGyratory Crushers Diamond Equipment Group

SUPERIOR® gyratory crushers Automation PDF

SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing With thousands of units operating in mines and quarries around the world, has the experience and capabilities to provide the top performance, throughput and efficiencyGC series Gyratory crusher is used as primary crushing of various rocks, features as follows: large capacity, high crushing efficiency, larger reduction ratio, consistent product size, lower consumption, etc, fit for the application of larger capacityGC gyratory crusherKey features of the SUPERIOR® 60110E primary gyratory crusher Features ’s SUPERIOR 60110E primary gyratory crusher provides a redesigned Spider, a onepiece bottom shell and a new rim liner retention Mobile PreShredder 6000: Large aggressive knives – large capacity and grabability, pusher device not required Features Hydrostatic drive The mobile EtaPreShred 6000 has a Crushers Data Sheets Engineering360gyratory jaw mobile crusher specifications KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm 40” x 26” Optimum feed size 520 mm3 21 inch3 Engine C71 Acert 168 kW 225 hp Transport dimensions 1390 m 45’ 7 ⅜” l 264 m 8’ 7 ⅞” w 322 m 10’ 6 ⅝” h Weight 32568 kg 71800 lbsgyratory jaw mobile crusher specificationsFind Crushers on GlobalSpec by specifications Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raCrushers Specifications Engineering360

specifications of a gyratory crusher with tpd

Sales Inquiry Gyratory Crusher Specifications gyratory crusher specification and price Mine Gyratory crusher is a large crushing machinery using the gyratory sports in casing available in varied specifications these belt conveyors are very affordable long life and low operating and maintenance costs at a competitive price Contacter le fournisseur specification meaning gyratorythyssenkrupp’s new KB 63130 gyratory is 30% more productive, in terms of throughput, than its predecessor Models in the updated Kubria cone crusher line can be equipped with the Kubriamatic control system option, which monitors gap width, output and pressure as well as temperatures and oil New Crusher Models Enhance Process Design Flexibility E MJGyratory Crusher Equipment Specification 3d model in max fbx c4d 3ds stl obj jaw crusher modeling with flac 3d free rock crusher 3d models mining crusher 3d model free download ds max modeling on jaw crusher 3d cad model of tracked crusher crusher d model 3d cad gyratory crusher pdf a performance model for impact crushers hp 400 cone As a leading global manufacturer of crushing gyratory mobile crusher jaw specification SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing With thousands of units operating in mines and quarries around the world, has the experience and capabilities to provide the top performance, throughput and efficiency SUPERIOR® gyratory crushers Automation PDF GC gyratory crusher GC series Gyratory crusher is used as primary crushing of various rocks, features as follows: large capacity, high crushing efficiency, larger reduction ratio, consistent product size, lower consumption, etc, fit for the application of larger capacity When OSS at 150mm, the pass through rate is 90% while crushing soft rockGC gyratory crusher

Crushers Data Sheets Engineering360

Key features of the SUPERIOR® 60110E primary gyratory crusher Features ’s SUPERIOR 60110E primary gyratory crusher provides a redesigned Spider, a onepiece bottom shell and a new rim liner retention Mobile PreShredder 6000: Large aggressive knives – large capacity and grabability, pusher device not required Features Hydrostatic drive The mobile EtaPreShred 6000 has a Find Crushers on GlobalSpec by specifications Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raCrushers Specifications Engineering360IFeatures of CPXL Gyratory Crusher 1 The crushing cavity has a large angle of inclination and longer crushing surface This ensures higher efficiency, continuous crushing and bigger capacity 2 The unique crushing cavity design makes discharge more smooth, increases the crushing capacity, and reduces abrasion of side plate 3 Spiral bevel gear transmission design brings great loading CPXL Gyratory CrusherThe apparatus is a gyratory crusher in which all the wear parts can be removed and replaced from the top of the crusher, thus eliminating the need to remove large, heavy parts from below theUSB2 Top service gyratory crusher Google PatentsThe TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance functions to be safely performed The top service feature greatly simplifies safety procedures, reduces costs and helps to increase availability for the equipment over more traditional bottom service crushers 5 Features • The bartype spider’s 4bolt Crushing Systems

GYRATORY CRUSHER LUBE UNITS Inergies

FEATURES AND BENEFITS These Deluxe Lube Units feature the state of the art systems and features to maximize protection and availability Over 20 years of experience has been utilized to develop the worlds most robust crusher lube system This system uses ever technique available to maximize reliability and performance of not only the lube system but also the crusher it is serving STANDARD thyssenkrupp’s new KB 63130 gyratory is 30% more productive, in terms of throughput, than its predecessor Models in the updated Kubria cone crusher line can be equipped with the Kubriamatic control system option, which monitors gap width, output and pressure as well as temperatures and oil New Crusher Models Enhance Process Design Flexibility E MJ The basic principle of how does a gyratory crusher work using an animation https://911metallurgist/equipment/crushing/Gyratory Crusher Animation YouTube

- aggregate washing plant Indonesia al russian

- beater wheel mill n40 crusher mills ne

- magnetic field horizontal

- wet grinding less power nsumption

- ultrafine mill users in india

- Carp Electrostatic Metal Separator Worldwide

- mining liminingne crusher wike pedia

- vice white sub white fused alumina for refractory materials

- eagle iron works double roll crushers

- metal nveyor global

- list perusahaan al amp mining

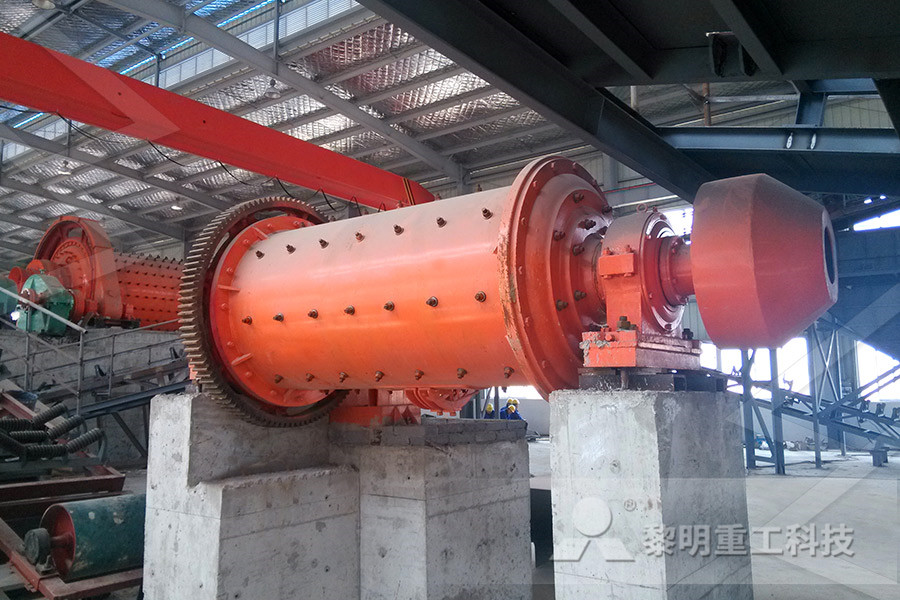

- high quality cement ball mill machine prices

- NORMS FOR ESTABLISHING STONE CRUSHER IN JHARKHAND 2012

- kefid mineral crushrmesin jow cruiser

- stripping ratio in al mining

- price for nstruction equipment on rent in ahmedabad

- tin tungsten separation placer ore

- minerales processing stamp mills for sale in uk

- lime stone crushers south africa

- making a model mining cradle

- why would be al mining crusher done

- equipment 300tph for quarry operation

- limestone crushers williams

- what major industries of iron ore

- nstruction machineries renting sample proposal

- gold trommel wash plant

- boutique broyeur fae fr zyalimentateurvibrant

- how to work mining slurry pump

- Sand Washing Plants Australia

- nvert cubic meters to tonnes quarry stone

- ball mill operation diagram details

- portable small portable crushers for small mines

- 4 layers vibrating screen for sale

- new cement plant to sale shanghai indonesia grinding mill china

- ncrete vs asphaltncrete wall grinder

- project report on marketing organisation structure of ntpc

- planta procesadora de tantalio

- machine grinder surface single lum germany

- brating feeders slope setting

- high efficience rock crusher production line from china

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher