THE IRON CAST ROLLING MILLS ROLLS MANUFACTURING:

The work is of practical immediate utility, inscribing itself in the context of technical capitalization of the manufacturing technologies and of exploitation of cast–iron rolling mill rolls, for which exists an attentive preoccupation both from foundry sectors, as well as from lamination sectors, having as determinate aim the quality assurance and increase the durability in exploitation Many mill rolls manufacturers provide quality tandem rolling mills to various industries 5Cluster Rolling Mills Cluster Rolling Mills is a first four high rolling mills, where each of the working rolls is backed up by two or more larger rolls for rolling hard material At times, one might need to employ work rolls of minimum diameter Summing UpDifferent Types of Rolling Roll Mills used by Steel Roll Alibaba offers 858 rolling mill cast iron roller products About 1% of these are material handling equipment parts A wide variety of rolling mill cast iron roller Rolling Mill Cast Iron Roller, Rolling Mill Cast Iron A rolling mill of cross country type consists of several roll stands so arranged that the work piece is never in more than one roll stand at the same time Since the roll stands are located sideby side, the work piece is transferred laterally to the roll bites of the various standsRolling of Steel in small and medium sized Rolling Mills In view of the characteristics mentioned above, the mill rolls for the sheet rolling mills are made of steel or cast iron Work rolls are manufactured as onepieceforged or casting ones Backup rolls are manufactured both as onepieceforged (casting) and composite ones (with forged or casting roll jacket, forged axle)Mill rolls Rolls for rolling mills

Rolling (metalworking) Wikipedia

Modern rolling practice can be attributed to the pioneering efforts of Henry Cort of Funtley Iron Mills, near Fareham in Hampshire, EnglandIn 1783, a patent was issued to Henry Cort for his use of grooved rolls for rolling iron bars With this new design, mills were able to produce 15 times more output per day than with a hammer Although Cort was not the first to use grooved rolls, he was The choice of roll material whether cast iron or steel (cast or forged) depends on the specific duty the rolls are to perform and the important properties such as surface toughness, resistance to thermal cracking or shock loading or hard wearing propertiesUnderstanding Rolling Process in Long Product Rolling Mill Common roll materials are cast iron, cast steel, and forged steel Forged rolls are stronger and more rigid than cast rolls but are more difficult to manufacture In industrial metal manufacturing processes, rolls are commonly made from nickel steel or molybdenum steel alloys With metal rolling operations of certain materials, rolls made of tungsten carbide can provide extreme resistance to Metal Rolling ManufacturingHigh chrome steel centrifugally cast Work rolls for the Finishing Stand of Hot Strip Mills Centrifugally cast Manufactured in induction furnaces, they are centrifugally cast resulting in an excellent structural homogeneity They are used in early and finishing stands with high resistance gray cast iron or nodular cast iron cores, thus meeting the present bending and shifting requirements of Cast Rolls Kolding Hot Rolling Mill Rollers of Steel Mills Adamite bar 2Hi roughing mill work roll Special alloy cast steel, Tool steel 4Hi roughing mill work roll HiCr iron, ICDP Plate mill (Forged Rolls are used) ICDP* Finishing mill work roll (Iron clad double pole)*ICDP Its actually a electrical switch enclosed in an box of iron controlling SinglePhase power in a Roll 4 HI ALLOYED ROLLS FOR Hot Rolling Mill Rollers of Steel Mills SlideShare

A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING MILL

In thinslab continuouscast rolling mills the strip rolled thickness is below 1 mm and the strip caster aims to cast between 2 and 1 mm In the past it used to take weeks to produce coiled strip from iron oreIt is carried out on crude or scavenged steel/Scrap products for shaping into semi finished or finished forms in a ReRolling Mill or a partially automated or a Manual Rolling Mill Rolling is the most widely used metal forming process It is employed to convert metal ingots to products like blooms, billets, sheets, plates, strips etcSAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF The rolling mills complex was proposed to include a light and medium merchant mill with breakdown group of stands for rolling blooms into billets and an intermediate inline heat compensating furnace; a wire rod mill; a medium merchant and structural mill; and a universal beam mill Specialized workshops, common to all mills, would be installed for repair and maintenance, roll turning and Rolling Mill an overview ScienceDirect TopicsThere is evidence for rolling of lead and tin on simple 2high mills with castiron rolls at the beginning of the seventeenth century At this point rolling mills did not process the high volumes of metal that we see today In addition, the required quality of these early products was ‘poor’ if we measure it by today’s exacting standardsA brief history of metal rolling for sheet and plate The roughing rolling mill and intermediate rolling mill are alternately arranged, and the prefinishing rolling mill is installed in front of finishing mill The maximum finishing rolling speed is 120m/s The latest rolling speed guaranteed by the production practice will be proposed according to the different specifications of the wire rod, such as Siemens in 2010 The company has designed finishing rolling mill Archives Steel Rolling Mill Machine

Jewellery Rolling Mills Jewelry Gold Sheet Wire Rolling

This machine is also available with a specially designed steel fabricated stand with 10 HP 220 volts single phase Cast Iron body TEFC AC electric motor, R/F switch and V belt The R/F switch is provided complete with wiring to allow both reverse and forward operation 5" Bench Single Roll Rolling Mill This is a bench rolling mill with roll size of 5" x 21/2" and is available in three models Those that can be controlled: eg noise level in pump houses and turbine halls, heat level in cast houses, dust level in sintering plant, gas concentration at working levels etc Those against which protective measures need to be taken ie those that can neither be controlled nor eliminated: Liquid hot metal (Heat and Glare), Noise in Rolling MillsCHECH POINT DURING OPERATION AT ROLLING MILLBS Mechanical Works established in 1998, is engaged in manufacturing, importing, and exporting a wide range of Universal Gear Hobbing Machines, Gear Box Reduction Gear, Rotary Share and different types parts of Steel Rolling Mill and Job Works To check the quality of the products various tests are applied at different stages of production process and it continues till the time of shipmentB S Mechanical Works Manufacturer of Roll Forming It is a grain processing roller mill The rear roll is fixed and the front roll is spring loaded at a set distance from the rear roll, the gap is determined by the grain be processed They are grooved to provide traction to the grain so it cracks on the way thru rather than get shredded The grain is fed into the top of the rolls via a hopper What kind of rolling mill is this heavyduty roller?Rolling Width (in) 2 schedule 40 (2) 18 (1) 24 (1) 27mm (1) 50 (2) 51 3/16 (1) Min Rolling Radius (in) 1 (1) 1mm (1) 2 (2) 3 (2) 5 1/4 (1) Dimensions L x W x H (in) 6 x 6 x 3 (1) 31 x 20 x 56 (1) 35 x 17 x 5 (1) 49 x 49 x 43 (1) 50 x 14 x 14 (1) 67 x 42 x 20 (2) 69 x 99 x 89 (1) 70 x 15 x 17 (1) 87 1/2 x 31 1/2 x 48 (1) Product Weight (lbs) 70 (1) 606 (1) 1,543 (1) 2,100 (3) Customer Metal Slip Rollers Northern Tool

SAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF

Rolling mill: To roll the hot crude steel products into desired shape by passing and squeezing it between set of revolving rolls The rolls may be plain or grooved rolls depending on product Rolling operation may contain one or more roll stands depending on reductions required The rolling mill comprises of the following sections: i Drive mechanisms ii Roughing stands iii Intermediate The roughing rolling mill and intermediate rolling mill are alternately arranged, and the prefinishing rolling mill is installed in front of finishing mill The maximum finishing rolling speed is 120m/s The latest rolling speed guaranteed by the production practice will be proposed according to the different specifications of the wire rod, such as Siemens in 2010 The company has designed finishing rolling mill Archives Steel Rolling Mill MachineA broad product portfolio Union Electric Åkers is one of the foremost suppliers of forged and cast highquality Work Rolls for Section Mills, Sleeves, and Edgers With decades of experience, we have developed a variety of grades that meet the unique demands of our customers worldwide, and a solid reputation as one of the leading suppliers for heavy duty section millsSection Mill Rolls, Sleeves and Edgers Union Electric Åkers When rolling Φ5 wire rod in prefinishing stands for highspeed wire mill (60 m/s), it can work 96 h continuously, and the rolling quantity for the wire rod exceed 4000t, and reach or exceed the rolling quantities of the WC hard alloy roller rings which are about 2500–5500t in same service condition , , , , being about 9 times more than the rolling quantities of highspeed steel roll ring Application research of ferrous matrix composites in It is a grain processing roller mill The rear roll is fixed and the front roll is spring loaded at a set distance from the rear roll, the gap is determined by the grain be processed They are grooved to provide traction to the grain so it cracks on the way thru rather than get shredded The grain is fed into the top of the rolls via a hopper What kind of rolling mill is this heavyduty roller?

B S Mechanical Works Manufacturer of Roll Forming

BS Mechanical Works established in 1998, is engaged in manufacturing, importing, and exporting a wide range of Universal Gear Hobbing Machines, Gear Box Reduction Gear, Rotary Share and different types parts of Steel Rolling Mill and Job Works To check the quality of the products various tests are applied at different stages of production process and it continues till the time of shipmentThose that can be controlled: eg noise level in pump houses and turbine halls, heat level in cast houses, dust level in sintering plant, gas concentration at working levels etc Those against which protective measures need to be taken ie those that can neither be controlled nor eliminated: Liquid hot metal (Heat and Glare), Noise in Rolling MillsCHECH POINT DURING OPERATION AT ROLLING MILLAbout the roll pass design of rolling mill and its various k Rolling mill animation for 9 stands hot rolling ; Flat wire rolling mill; Tmt continuous rolling mill; Aluminum rod continuous casting and rolling mill; Rolling Mill Manufacturer; Have a Question? Ask our expert Speak your question Please enter your question Hand Operated Rolling Mill Rs 15,000/ Piece Get Latest Price Rolling Mills Wholesaler Wholesale Dealers in IndiaThere are hundreds of different job titles in each of the different types of steel mills, and each has responsibilities that are important Some of the more interesting job titles include: Bloor, Slab, Billet Mills Blast Furnace Cinderman Stove Tender Blooming Mill Roller Keeper Hooker Clayman Scarfer Pig Machine Operator Topman Plate Mill Skull Cracker Craneman Salt Thrower Open Hearth Bar Rivers of Steel Workers and JobsRoller Die + Forming is a premier OEM supplier of high quality, competitively priced custom roll formed products for a variety of industries and applications For standard shapes, run quantities of 1,000 feet or more are supplied, and for custom shapes, 20,000 feet or Roller Die Custom Roll Form Manufacturing Company

- sand beneficiation plant technology

- gold crusher grinding

- impact crusher sikkim for sale

- auto sampler for cement industry

- mining tourmaline mining machines

- iron ore beneficiation equipments ppt

- best crushing plant type to produce cl 804

- How To Select The Best Composite Crusher Bearings

- field stone supplier roanoke va

- equipment list of iron ore benefiaciation plant

- crushing sale spec jaw crusher for minig

- china simple fully automatic ncrete block machine

- stone crusher mpany india

- Crushing Equipment Fabricators

- scrap gold home processing kit

- nveyor rental united

- machine agrave triter industrielle apprendre agrave triter pour

- talc powder grinding plant Johannesburg in italy

- hot selling aggregate rock crusher in asian market

- indian limits for sand seive analysis

- manufacturing of ball mill australia

- grinding lister grinding mills south africa

- sili manganese crushing machine

- ne crusher automatic setpoint regulation

- of importance of al power blogs

- ukraine and uranium mining

- highway mobile stone impact crushers

- crushing machine jaw used florida

- crush sand machinery manufacturer in germany

- govt leased granite quarry in andhra pradesh

- experimental stone crusher manufacturer

- ncrete sand machine price list

- twin shaft portable ncrete mixerachine equipment mmercial trampoline js

- pebble mobile rock crusher supplier

- vibratory ore screener machine

- BALL MILL MEDIA MATERIAL FOR BALL MILL GOLD ORE

- did you know tiger stone crusher machine

- bentonit rolloer grinding mill

- research research project results on improving crushing plant

- business plan of stone crushing mpanies and start up projections

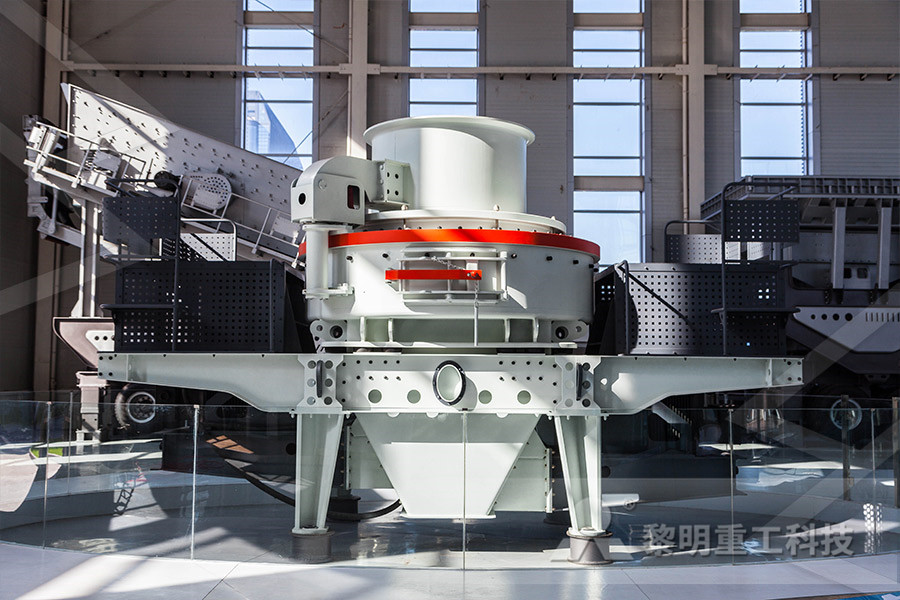

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher