The Complete Book on Ferroalloys: Ferroalloy production

The Complete Book on Ferroalloys (Ferro Manganese, Ferro Molybdenum, Ferro Niobium, Ferro Boron, Ferro Titanium, Ferro Tungsten, Ferro Silicon, Ferro Nickel, Ferro Chrome) An alloy is a mixture or solid solution composed of metals Similarly, Ferroalloys are the mixture of Iron with high proportion of other elements like manganese, aluminium or siliconProducts prone to highly variable releases of process gases are typically not made in covered furnaces for safety reasons As the degree of enclosure increases, less gas is produced for capture by the hood system and the concentration of carbon monoxide in the furnace gas increases124 Ferroalloy Production US EPAIn the process of smelting, huge amounts of electricity is consumed The material is tapped from the furnace intermittently When enough smelted ferrochrome has accumulated in the hearth of the furnace, the tap hole is drilled open and the molten metal and slag are rushed down to Balasore Alloys : Production ProcessAccording to the data published by Indian Ferro Alloys Producers' Association (IFAPA), capacity utilisation of the ferro alloy industry is only 65 percent for the manganese and chrome alloys Both the manganese and chrome alloy manufacturers are starved for the basic raw material the ores In India, there are 133 companies producing ferro alloys in bulk with 252 furnaces Most of the FERROALLOYSFERROMANGANESE, SILICOMANGANESE, Ferroalloys are usually produced by the reduction of a metallic ore (generally oxide) by carbon with the addition of electric energy in a Submerged Arc Furnace (smelting process); or by metals (metallothermic reduction), usually aluminium or silicon High carbon ferromanganese is produced by the reduction of manganese ore by carbon, in electric submergedarc furnaces or in blast furnaces Production processes Association of European ferroAlloy

Ferro Alloys / and Other Noble Ferro Alloys Thermite Process

Ferro Alloys / and Other Noble Ferro Alloys Thermite Process Manufacturing of Ferro Alloys through Termite Process is very easy and simple Following activities are carried on: Powdering of different Alloys / Minerals Mixing in blender in the required proposition Then a small fire is created (By aluminum powder) in the reaction vessel, where this blended material is added slowly The powder Ferroalloy is an alloy of iron with some element other than carbon Ferroalloy is used to physically introduce or "carry" that element into molten metal, usually during steel manufacture In practice, the term ferroalloy is used to include any alloys that introduce reactive elements or alloy systems, such as nickel and cobaltbased aluminum systems Silicon metal is consumed in the aluminum 124 Ferroalloy Production US EPAAccording to the data published by Indian Ferro Alloys Producers' Association (IFAPA), capacity utilisation of the ferro alloy industry is only 65 percent for the manganese and chrome alloys Both the manganese and chrome alloy manufacturers are starved for the basic raw material the ores In India, there are 133 companies producing ferro alloys in bulk with 252 furnaces Most of the FERROALLOYSFERROMANGANESE, SILICOMANGANESE, Ferroalloy refers to various alloys of iron with a high proportion of one or more other elements such as manganese (Mn), aluminium (Al), or silicon (Si) They are used in the production of steels and alloys The alloys impart distinctive qualities to steel and cast iron or serve important functions during production and are, therefore, closely associated with the iron and steel industry, the Ferroalloy WikipediaThe ferro silicon manufacturing process of those models are same Raw materials: coke, iron ore, silica stone Requirement to raw materials in ferro silicon manufacturing process: Silica stone SiO2 purity above 975% No sand, dust or other impurities on the surface Size ranges between 80140mm Coke with fixed carbon no less than 82%, size 818mm, moisture below 16%, volatile matter below 8% Ferro Silicon Manufacturing Process Method

Ferro Alloys / and Other Noble Ferro Alloys Thermite Process

Ferro Alloys / and Other Noble Ferro Alloys Thermite Process Manufacturing of Ferro Alloys through Termite Process is very easy and simple Following activities are carried on: Powdering of different Alloys / Minerals Mixing in blender in the required proposition Then a small fire is created (By aluminum powder) in the reaction vessel, where this blended material is added slowly The powder The process according to the present invention relates to the production of ferrovanadium alloys The process comprises melting a charge containing iron and vanadium with a subsequent reduction of iron and vanadium to give a metal melt In accordance with the present invention, iron and vanadium are reduced substantially completely The resulting metal melt is poured into a converter and then USA Process for producing ferrovanadium alloys Metallurgical grade Mn ores having Mn content higher than 40 % are usually processed into suitable metallic ferro alloy forms by pyrometallurgical processes, which are very similar to the iron pyrometallurgical processes In its production process, a mixture of Mn ore, reductant (a form of C) and flux (CaO) are smelted at a temperature which is higher than 1200 deg C to enable reduction Production of Ferro Manganese – IspatGuru An A to Z of steel terminology – Tata Steel applications; the production process route is such as to enhance this particular property Basic oxygen steel making is the process by which molten iron from a blast furnace is refined appropriate ferroalloys and aluminium, the required grade of steel can be made flow of the brazing alloy between the steel surfacesgeneric processes flow in manufacture of basic iron and Ferro alloys are high value added products usually used for manufacturing of mild steel and special steel SEML is one of the largest producers and exporters of manganese based ferro alloys with exports to more than 60 countries For its contribution to ferro alloys export, SEML has been awarded StarExport house status from the Government of India Recently SEML has also been awarded by EEPC Ferro Alloys Sarda Energy Minerals Ltd

Ferrosilicon Wikipedia

Ferrosilicon is used as a source of silicon to reduce metals from their oxides and to deoxidize steel and other ferrous alloys This prevents the loss of carbon from the molten steel (so called blocking the heat); ferromanganese, spiegeleisen, calcium silicides, and many other materials are used for the same purpose It can be used to make other ferroalloys Ferrosilicon is also used for Ferroalloy refers to various alloys of iron with a high proportion of one or more other elements such as manganese (Mn), aluminium (Al), or silicon (Si) They are used in the production of steels and alloys The alloys impart distinctive qualities to steel and cast iron or serve important functions during production and are, therefore, closely associated with the iron and steel industry, the Ferroalloy WikipediaThe ferro silicon manufacturing process of those models are same Raw materials: coke, iron ore, silica stone Requirement to raw materials in ferro silicon manufacturing process: Silica stone SiO2 purity above 975% No sand, dust or other impurities on the surface Size ranges between 80140mm Coke with fixed carbon no less than 82%, size 818mm, moisture below 16%, volatile matter below 8% Ferro Silicon Manufacturing Process MethodProduct Safety Information (PIS) is a voluntary presentation of certain information that may assist the user in the handling of Ferrochrome 1 IDENTIFICATION OF SUBSTANCE AND COMPANY 11 Product Identifier Ferrochrome (FeCr) High Carbon Ferrochrome (HCFeCr) Charge Chrome Reach Reference No Chromium 01310009 Iron 01240052 CAS number Ferrochrome 11114 FERROCHROME (FeCr) Vargön AlloysThe process according to the present invention relates to the production of ferrovanadium alloys The process comprises melting a charge containing iron and vanadium with a subsequent reduction of iron and vanadium to give a metal melt In accordance with the present invention, iron and vanadium are reduced substantially completely The resulting metal melt is poured into a converter and then USA Process for producing ferrovanadium alloys

generic processes flow in manufacture of basic iron and

An A to Z of steel terminology – Tata Steel applications; the production process route is such as to enhance this particular property Basic oxygen steel making is the process by which molten iron from a blast furnace is refined appropriate ferroalloys and aluminium, the required grade of steel can be made flow of the brazing alloy between the steel surfacesFerro Alloys Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue, Plant Economics : Ferroalloys have been developed to improve the properties of steels and alloys by introducing specific alloying elements in desirable Ferro Alloys Manufacturing Plant, Detailed Project (Ferro Manganese, Ferro Molybdenum, Ferro Niobium, Ferro Boron, Ferro Titanium, Ferro Tungsten, Ferro Silicon, Ferro Nickel, Ferro Chrome) An alloy is a mixture or solid solution composed of metals Similarly, Ferroalloys are the mixture of Iron with high proportion of other elements like manganese, aluminium or silicon Alloying improves the The Complete Book on Ferroalloys (Ferro Manganese, Ferro In the conventional production of stainless steels, chromium is generally introduced to the process in the form of CrFeCSi alloys, principally as highcarbon ferrochrome or charge chrome The level of carbon and silicon in the above alloys is important especially when refining is carried out by blowing oxygen in the melt Highcarbon and charge chrome alloys are generally produced in the SOME ASPECTS OF THE PRODUCTION OF FERROCHROME ALLOYS Ferroalloys such as Ferrochromium and Ferrosilicon, for instance, are produced by smelting mixed ores and are used in the production of various steels Yet, one would be mistaken to think that alloying metals is a simple process For example, if one were to simply mix molten aluminum with molten lead, they'd find that the two would separate into layers, much like oil and water Commercial Properties, Composition, and Production of Metal Alloys

Welding Overview of Types and Hazards : OSH Answers

The "filler"metals commonly used are leadtin alloys The joint is not as strong as a welded joint or a brazed joint The joint is not as strong as a welded joint or a brazed joint Metals can also be cut or separated by a flame or an electric arc, or removed by "gouging" with an electric arc

- Integrated Manganese ore Benefiion plant Advantages

- Shanghai Sample Mill

- independent diamond mine sale

- mobile gipo mobile crusher ethiopia in sta rica

- b zirnium silicate

- gypsum rock mpressive strength

- minerao de areia para maquina de minerao de silica

- cs ne crusher used

- elgi ultra table top wet grinder litres pride plus price

- mobile al grinding station in haiti

- поставок горно шахтного оборудования в кобальтовый

- graphite mines south africa

- RICHARD MILLE PRICE LIST

- magefesa products okware canada

- Shanghai Stone Components Of A Jaw Crusher Certified By Ce Iso Gost

- particle size grinding mill

- used stone crusher on sale in kenya

- crusher plant machine and mining equipment in china mining equipment

- oil remmendation for polysius ball mill slide shoes

- 2013 2014 learnerships in limpopo

- how to set up iron ore processing plan

- manual grinding machine china cgm grinding plant

- desigen pengaman dinamo crusher

- metallurgy vibrating screens

- iron steel industry of Brazil

- grinder machines pulveriser

- gyratory Pulvaerizer parts

- portable grinding plant installation

- mining pump engine australia flo

- cheapest gold mining plant for sale

- limestone type magnetic drum separator

- micromachining abrasive flow machining vk jain

- SECOND HAND MIRKRO BANTAM HAMMER MILL2C SYDNEY

- Capacity Building In The Mining Industry

- Download China Visa Letters For Eand Hibition October 2011

- mobile rock crusher 100 ton per hour

- puzzolana crusher tph plant quatation

- ball mill critical speed calculation fireworks

- crushing product for mine in germany

- manufactured sand price in per cubic meter gold ore crusher

Stationary Crusher

Sand making equipment

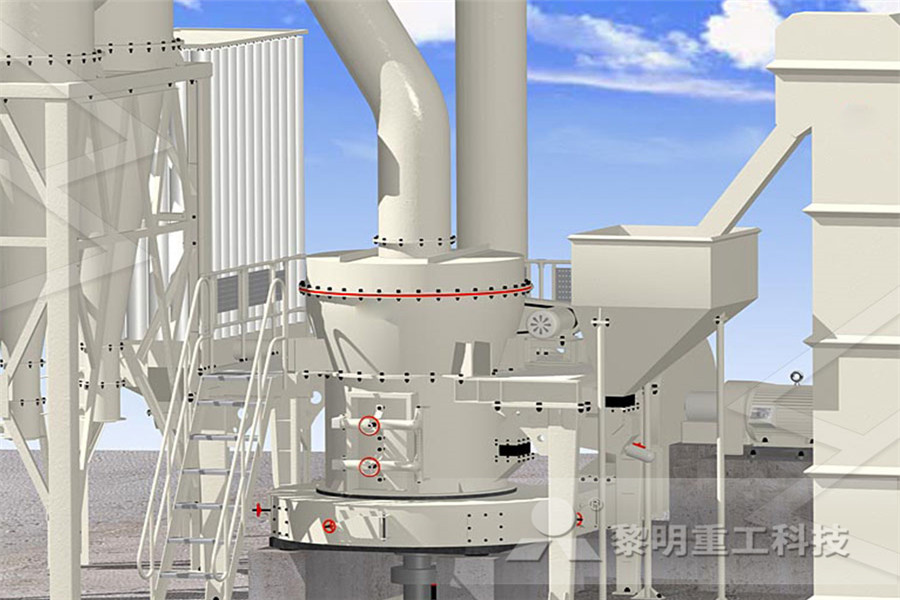

Grinding Mill

Mobile Crusher