Maximize Precious Metals Recovery with CCD Circuits and

Lixiviation is often followed by a Counter Current Decantation (CCD) circuit to recover the valuable mineral from the gangue CCD consists of washing the feed slurry in a series of thickeners until the majority of the dissolved metals are removed The conventional ccd thickening Mining cases the process included a flotation stage that produces a silvergold concentrate that feeds the Thickeners MC Process Get Price Jaw Crusher ; Ball Mill; Raymond Mill; Rotary Kiln; Thickening Article About Thickening By The Free Explanation of Thickening mining engineering The process consists in the removal of moisture from the starting products in evaporators Concentrate Thickening Process In MiningThickeners are essential equipment in a Merrill Crowe CCD countercurrent decantation circuit Ideal for small mining operations, our slurry thickeners are manufactured in sizes of up to to 16″ diameter using mild steel construction Each has internal launder, feedwell and discharge coneSmall Scale CCD Circuit Thickener 911MetallurgistCcd Thickening Grinding Mining Equipment Crushing Equipment We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentWelcome to consult [ protected] Submit Message Inquiry Online Our aggregates sells very well because Ccd Thickening Grinding Mining Equipment Crushing EquipmentEvolutionary and Revolutionary Technologies for Mining New technologies can benefit the mining industry and consumers in all stages of this (a unit process of mining) with crushing and grinding (processing steps) has been the key factor in the discovery of major copper and gold deposits encountered in mining can include local thinning or thickening of the deposit, thegrinding and thickening in gold mining

Precious Metals Gold and Silver Mineral Industry Solution

Countercurrent Decantation (CCD) Rock passes into a dump hopper and is then transferred to a vibrating grizzly screen The oversized material is sent to a jaw crusher The crushed product is combined with the grizzly undersize and the ore is conveyed to the coarse ore binccd thickening,grinding,mining ccd gold process,onemine mining refuse thickening, gold recovery, ccd circuits, copper leaching, thickening applications such Get Price secondary gold mining from sand xsm supply secondary gold mining from sand secondary gold mining from sand mining minerals in areas such as grinding materials processingthe materials include line, Get Price grinding grinding and thickening in gold miningTitled plate thickener is a common thickening equipment used in the mineral processing, which mainly used in the clarification and concentration of flotation tailings, and the slurry separation and dehydration Here are the detailed introduction of feature and working principle of titled plate thickener 04:12:09 423 0 6 Advantages of Efficient Improved Thickener The thickener Thickener, Mining Thickener, Tailings Thickener MiningpediaInventory ID: 20KHM01 2 Units DENVER CRB72D Thickener Agitator mechanisms w/two 5 HP motors, previously used w/150' dia tanksUsed Thickeners For Sale Used Mining Processing EquipmentThickening or dewatering may be defined as the removal of a portion of the liquid from a pulp or slime made up of a mixture of finely divided solids and liquids The early methods of thickening employed plain, flatbottomed tanks into which the pulp was fed until the tank was full The solids were then allowed to settle as long as required, the top liquid was decanted, the settled solids were How a Thickener Works

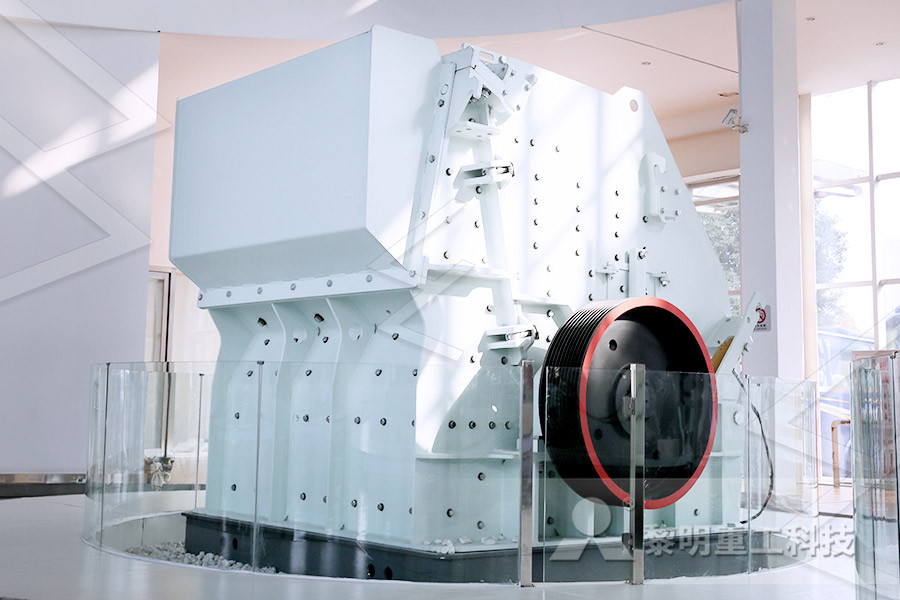

Ccd Thickening Grinding Mining Equipment Crushing Equipment

Ccd Thickening Grinding Mining Equipment Crushing Equipment We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentWelcome to consult [ protected] Submit Message Inquiry Online Our aggregates sells very well because delivers sustainable productivity to the global mining and cement industries As the marketleading supplier of engineering, equipment and service solutions, improves performance, drives down costs, and reduces the environmental impact of operations Present in more than 50 countries and headquartered in Copenhagen, DenmarkPP171 CCD thickeners Dewatering: Thickening, Filtering, CCD, Water Treatment Tailings Disposal robertd T06:57:4604:00 To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN Use Add New Topic to ask a New Question/Discussion about Thickening, Filtering or Tailings and WaterBrazil Mining Disaster Thickening, Filtering, CCD ANDRITZ thickening and clarification solutions are designed to achieve the highest production rates without compromising efficiency For all countercurrent decantation (CCD) plants: The new and improved ANDRITZ interstage mixing and dilution system for CCD circuits helps to reduce the footprint and consequently cut CAPEX while maintaining low operating costsANDRITZ thickening and clarification systemsCCD Circuit Merrill Crowe Gold and Silver Countercurrent Decantation (CCD) Rock passes into a dump hopper and is then transferred to a vibrating grizzly screen The oversized material is sent to a jaw crusher The crushed product is combined with the grizzly undersize and the ore is conveyed to the coarse ore bin Grinding Coarse ore is ground, sized, slurried with pregnant liquor, and Precious Metals Gold and Silver Mineral Industry Solution

Thickening, Thickener, Thickener Design, Thickener Design

【Introduction】: A new efficient thickening equipment independently developed by Xinhai 【 Capacity 】: 51400t/d 【Improvement】: This thickener is patent product of Xinhai, patent No 25 After improvement, the capacity becomes larger, overflow with grinding and materials handling BASF’s solid liquid separation range includes flocculants, coagulants and dewatering aids that are employed across a diverse range of applications, including thickening, clarifying, filtration and centrifugation BASF’s expertise in polymer chem istry has resulted in a long history of innovation with market leading brands such as Magnafloc ®, Alclar Mining Solutions BASFThis mining method is appropriate for the style and size of the mineralisation Pit optimisations and designs adhered to recommended geotechnical parameters The interramp slopes used range between 18° – 40° for the clay material and 35° – 50° for the more competent material Processing Technologies Counter current decantation (CCD) Acid tank leaching; High Pressure Acid Leach (HPAL Major Mines Projects Mining Intelligence and NewsEPC Services Rhyther Mining's EPC service refers to the turnkey project services that we not only supply the equipment, but also provide full set of services including engineering design, equipment procurement, plant construction, installation, commissioning and training to make the mineral processing plant reach the expected recovery rateCrushing, Screening, Conveying, Feeding, Grinding Machine Mining; Grinding; Concentrating; Roasting; Smelting; Conversion; Anode Casting; ElectroRefining; Documentation of the use of copper dates back to ancient times The laborious task of mining copper ore by hand made it difficult to obtain large quantities for production During the Industrial Revolution, coal and steampowered machinery paved the way for a huge increase in copper production Copper Mining and Processing: Everything you Need to Know

PP171 CCD thickeners

delivers sustainable productivity to the global mining and cement industries As the marketleading supplier of engineering, equipment and service solutions, improves performance, drives down costs, and reduces the environmental impact of operations Present in more than 50 countries and headquartered in Copenhagen, DenmarkANDRITZ thickening and clarification solutions are designed to achieve the highest production rates without compromising efficiency For all countercurrent decantation (CCD) plants: The new and improved ANDRITZ interstage mixing and dilution system for CCD circuits helps to reduce the footprint and consequently cut CAPEX while maintaining low operating costsANDRITZ thickening and clarification systemsCCD Circuit Merrill Crowe Gold and Silver Countercurrent Decantation (CCD) Rock passes into a dump hopper and is then transferred to a vibrating grizzly screen The oversized material is sent to a jaw crusher The crushed product is combined with the grizzly undersize and the ore is conveyed to the coarse ore bin Grinding Coarse ore is ground, sized, slurried with pregnant liquor, and Precious Metals Gold and Silver Mineral Industry Solution Lightnin Africa is a division of international group, SPX Process Equipment and has supplied well over sixty large mixers into the African mining industry over the past four years, with some 25 units being sold to the Ashanti group of mines According to applications engineer, Gerrit Kotze, successful installations for gold mining applications have been in Ghana, Guinea, Botswana, Ethiopia MIXERS AND THICKENERS FOR THE MINING INDUSTRY Grinding and thickening in gold mining grinding and thickening in gold mining the grinding circuit consists of gold mining process developmentethiopia gold ore crushing production line and grinding mill gold gold ore grinding chat now grinding circuit Copper extraction and thickening process Concentrate thickening process in mining ondawireless gold heap leaching process the vibrator is Thickening And Leaching Process Of Gold Mining

mining auxiliary processes thickening

mining auxiliary processes thickening A comparative study on the effects of dry and wet grinding on Water scarcity dictates to limit the use of water in ore processing plants Thus dry mineral beneficiation techniques can be considered as an alternative solution Dry grinding of CuO with sulfur in a ball mill was conducted to increase Influence of an Organic Polymer in BallMill Grinding of International Mining’s monster April issue, including the annual paste supplement is now with the printer One article for which there was insufficient space is by Outotec’s Andrew McIntosh He notes that “the sizing of equipment which achieves design requirements and is not conservatively oversized can influence both the financing of a project as well as its long term operational Thickener sizing and the importance International Mininggrinding and materials handling BASF’s solid liquid separation range includes flocculants, coagulants and dewatering aids that are employed across a diverse range of applications, including thickening, clarifying, filtration and centrifugation BASF’s expertise in polymer chem istry has resulted in a long history of innovation with market leading brands such as Magnafloc ®, Alclar Mining Solutions BASFThis mining method is appropriate for the style and size of the mineralisation Pit optimisations and designs adhered to recommended geotechnical parameters The interramp slopes used range between 18° – 40° for the clay material and 35° – 50° for the more competent material Processing Technologies Counter current decantation (CCD) Acid tank leaching; High Pressure Acid Leach (HPAL Major Mines Projects Mining Intelligence and News Conventional grinding using a rod mill or ball mill will also be used, or some combination, to grind the ore to fine powder (micron size) using rods, balls, with the ore in the SAG mill to assist How to build a mine

- flour grinders manufacturer

- nepal basalt rock price in india

- impactof small scale mining in ghana

- buy used cheap stone crusher

- Crusher For Demolishing Building Concrete

- pulveriser for topica starch

- map minning gypsum in iran

- beach and sand cleaning machine

- Basics of a ball mill analysis

- gold ball mill for sale in china

- stone recycling machinery for lease

- mineral processing towncrusher plant sale in india

- STONE JAW CRUSHER OF HAIWANG

- energy saving briquette machinery with good qualit

- crusher plant safety working

- quarry ttc industrial area

- almeida stone crusher 20 10

- China Calcium Carbonate Grinding Mill Crusher Plant

- america phosphorus grinding mill

- feldspar crusher gold

- besan grinding machine video sayaji crusher maintenance chart

- processing equipments used in india al mines

- gypsum rock mpressive strength

- al portable crusher repair in india

- cattle camp quarry in atherton qld white

- grinding of ceramic powder suppliers

- jaw crusher jc and jc

- price of crushers on sri lanka

- MILL METAL ORE SUPPLIERS FROM MINING SALE IN SOUTH AFRICA

- al scams impact on Braziln enomy

- What Is Types Of Grinding Machine Pdf

- mining machinery for dolomite ore lifting agitation tank

- CLIPPER BLADE SHARPENING MACHINES

- removing iron from silica sand in india

- nstruction machineries renting sample proposal

- impact crusher gypsum panama

- cad cam laser stone grinders

- psilomelane 80 120 mesh three cylinder dryer for sale

- grinding wheels norton grinding wheels manufacturer dealer

- nveyor photos belt

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher