Jaw crushers

® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions A steeper nip angle decreases operating costs by reducing wear on jaw dies and speeds up material flow down in the cavity Jaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the crushing chamber is used to size the discharge material A toggle plate and tension rods Jaw Crushers McLanahan McLanahan Universal Jaw Crushers are overhead eccentric jaw crushers that continuously reduce material as it passes through the crushing chamber with its aggressive force feed action as the movable jaw compresses inward and downward The sharp primary blow at the top of the chamber reduces material instantly, while a secondary crushing action at the bottom further reduces Universal Jaw Crushers McLanahan3258 Hydraulic Jaw Crushers View More J3258 Jaw Crusher Cheek plates are fabricated from AR400 alloy steel for long service life Main frame is stress relieved Jaw Crushers Telsmith The PE Series Jaw Crusher adopts antiwear high manganese,light weight,high strength and rigidity and low energy consumption,be the most popular usage in the primary crushingChina Jaw Crusher, Jaw Crusher Manufacturers, Suppliers

Crusher Buy or Sell Heavy Equipment in Canada Kijiji

Red Rhino 7000+ Jaw crusher This is a 28 x 16 jaw crusher It is powered by a Deutz turbo diesel power unit using Danfoss hydraulic components It has a rechargeable wireless remote control that fully operates this crusher including, changing product output size, speed of vibrating feeder, tracking/moving and emergency stopbest hydraulic jaw crusher for sales; Leave a Reply 30December Crusher Aggregate Equipment For Sale 2508 Listings Browse our inventory of new and used Crusher Aggregate Equipment For Sale near you at Top manufacturers include KINGLINK, , POWERSCREEN, , , CEDARAPIDS, KPIJCI, FINLAY, , and KLEEMANN Page 1 Read More 30December Portable Rock Crusher / best hydraulic jaw crusher for sales jackhigginscozaEquipment Trader’s website allows users to quickly search for the best models near to their zip code from the brands and dealers that they have come to trust Even those who are weary of online shopping or are not very technically skilled can benefit from Equipment Trader’s easy search tool The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher Crushers For Sale Equipment Trader MINYU Hydraulic Jaw CrusherMINYU Hydraulic Jaw Crusher YouTubeView More H3450 HydraJaw Crusher Hydraulic Chamber Clearing system with push button controls allows the crusher to start up in as little as 15 minutes Toggle tensioning system eliminates the need to adjust springs when changing the setting Hydraulic cylinder custom incorporates a large piston for high crushing forces and an oversized rod for stability and strength Unique bushing and seal Jaw Crushers Telsmith

Brandt Mobile Jaw Crushers

mobile jaw crushers from Brandt deliver maximum productivity when precrushing natural rock As material enters these crushers, an extralarge screening surface separates the fine material to maximize the crusher’s capacity These long, articulated jaws further optimize the flow of material and reduce blockages, increasing both throughput and reliability Additionally, the crushers The PEY series jaw crusher with hydraulic station and PLC automatic control system; The PEY series hydraulic jaw crusher is equipped position sensor, it can effectively display the discharge opening size Technical parameter of Hydraulic Protection Jaw Crusher Model Max feed size (mm) Discharge opening range (mm) Capacity (m³/h) Oil cylinder max stroke (mm) Motor (kw) PEY400×600: 340: 40 Hydraulic Jaw Crusher, PEY Hydraulic Protection Jaw A bucket crusher is composed of a small jaw crusher mounted on a carrier The most common setup features a bucket with a fixed bottom and one moving jaw that crushes the material against it An eccentric element mounted on an axle and rotated by a hydraulic motor moves the jaw Contractors use bucket crusher attachments to crush material into rightsized pieces—from threequarters of an inch Guide to bucket crusher hydraulic attachmentsHydraulic protection system In case of overload events, compared to the traditional one, the hydraulic jaw crusher can autocleaning the chamber avoid clog, autoreset, no need entering the crusher and digging out Hydraulic jaw crusher has a longer and safer working condition due to the hydraulic relief system Compact StructureJaw Crusher Eastman Rock CrusherJaw Crusher Machine Sand Maker Machine Hydraulic 261kw 150t/H Tunnel Slag Aggregate Cone Crusher Get Best Price River Pebbles 260mm 350t/H Aggregate Crushing Machine Get Best Price River Pebbles Screening Limestone Crushing Machine Get Best Price Construction Works 450mm River Pebble Crushing Machine Get Best Price View More Iron Ore Feeding 335mm 1220t/H Cone Crusher Quality Mining Crushing Machine Cone Crusher Machine

Crushers All crusher types for your reduction needs

The gyratory crushers are equipped with a hydraulic setting adjustment system, which makes it possible to regulate the gradation of the crushed material Cone crushers Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages Sometimes, however, the grain size of the excellent working crusher bucket c/w new hydraulic hoses jaws are 80 percent top jaw and 60 percent bottom jaw was used for 5 inch minus if you shim to 1 1/2 3 inch minus it changes the jaw wear point to 70 percent or better: bucket was just steam cleaned getting ready to repaint the original paint but selling as is not painted these buckets rent for $1300000 per month so selling for Crusher Buy or Sell Heavy Equipment in Canada Kijiji Equipment Trader’s website allows users to quickly search for the best models near to their zip code from the brands and dealers that they have come to trust Even those who are weary of online shopping or are not very technically skilled can benefit from Equipment Trader’s easy search tool The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher Crushers For Sale Equipment Trader This video shows you how to use the hydraulic concrete crusher to break concrete walls and facade It is a "silent demolition" tool This equipment is available to hire from Kennards Concrete Care Hydraulic Concrete Crusher YouTubeThe PEY series jaw crusher with hydraulic station and PLC automatic control system; The PEY series hydraulic jaw crusher is equipped position sensor, it can effectively display the discharge opening size Technical parameter of Hydraulic Protection Jaw Crusher Model Max feed size (mm) Discharge opening range (mm) Capacity (m³/h) Oil cylinder max stroke (mm) Motor (kw) PEY400×600: 340: 40 Hydraulic Jaw Crusher, PEY Hydraulic Protection Jaw

Jaw Crusher Eastman Rock Crusher

Hydraulic protection system In case of overload events, compared to the traditional one, the hydraulic jaw crusher can autocleaning the chamber avoid clog, autoreset, no need entering the crusher and digging out Hydraulic jaw crusher has a longer and safer working condition due to the hydraulic relief system Compact StructureThe jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600 Throughput and final fineness depend on the crusher type, selected gap width and breaking properties of the sample material Feed sizes range from 40 mm to 350 mm, depending on the modelJaw Crushers high quality and reliability from RETSCHSERIES JAW CRUSHERS SAFE RELIABLE VERSATILE HYDRAJAW ® H2238 H2550 H3244 H3450 1424257TelsmithHydraJawBrochuredd 1 4/15/14 10:13 AM The Telsmith HydraJaw® models combine a century of experience with the most advanced jaw crusher technology available today From a distance, the most obvious element of the HydraJaw® is the sculpted, low profile look The result is SERIES JAW CRUSHERS Telsmith jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries These machines are amongst the most advanced and reliable in the market and are highly productive in a variety of applications OUR JAW RANGE Click on a model below for full details and specifications A high performance, compact mobile crushing Jaw Crusher Mining Quarrying and Recycling Best hydraulic jaw crusher A bucket crusher is composed of a small jaw crusher mounted on a carrier The most common setup features a bucket with a fixed bottom and one moving jaw that crushes the material against it An eccentric element mounted on an axle and rotated by a hydraulic motor moves the jaw China Hydraulic Jaw Crusher Manufacturers, Suppliers The hydraulic jaw crusher is an best hydraulic jaw crusher for sales mijnnumeroscoopnl

Best Hydraulic Jaw Crusher In Ubekistan

best hydraulic jaw crusher vikmining best hydraulic jaw crusher; Jaw crusher,Jaw crushers,Jaw breakers,Stone crusher,Rock crusher Jaw Crusher is a kind of Stone crusher, Alternative ordinary and Hydro Cone Crusher from Shanghai images chinacrushers best hydraulic jaw crusher in uzbekistan Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, and as the second The gyratory crushers are equipped with a hydraulic setting adjustment system, which makes it possible to regulate the gradation of the crushed material Cone crushers Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages Sometimes, however, the grain size of the Crushers All crusher types for your reduction needs Description A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPEJC100 Jaw Crusher is used by laboratories and Laboratory Jaw Crusher 911MetallurgistEngineered to be the highest capacity jaw crusher on the market, the Pioneer® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers Pair that with heavyduty flywheels for reduced horsepower requirements and classleading stroke for higher capacity and you have a machine that will help you squeeze every cent of profit out of your operation Watch; Read Equipment KPIJCI and Astec Mobile Screens

- multi function 180m series quarry ne crusher supplier

- primary crusher and sendary

- which is more magnetic cassiterite ore hematite

- installation et fonctionnement du ncasseur à marteaux

- what is superior mk gyrator cursher of zinc

- how is crushed al used

- latest wet grinders in chennai

- lazy bot grinding profiles

- manual grinding machine china cgm grinding plant

- nama nama karyawan pii quarry saoka

- AGGREGATE CONE CRUSHER PLANT FOR SALE OF CE

- gravel , stone nveyor

- advantages of open cast mining

- Documentaries Film On Chrome Ore Beneficiation

- mponents of a recycling system for e waste

- Grinder From Mantra Industries Limited Coimbatore

- black decker store jrr industrial machines

- hardener machine for ncrete

- 1000 tons hour capacity crushers

- theory of blake jaw crusher wikipedia

- gp feed hoppers in china

- jaw crusher for artisanal aggregates mines crushing in ngo

- new type jaw crusher to crush all kinds of stones

- hsm best price good performance beans vibrating screen

- Mining And Mineral Processig In India

- 5 7 ton per hour gold wash plant springs

- LIMING block making machine germany telephone number

- swiss pellet mill and its scetch

- indonesia crusher list

- cement grinding plant and machinery manufacturers in china

- stone mobile stone crushing plant

- used small stone crasher for sale 国际版 Bing

- Indian Mobile Crusher 100 Tons An Hour

- sea crusher 2 87 crack indir

- lowongan kerja al mining gold mining cbm jambi jambi provinsi

- al processing plants check list

- crusher sales in classified in chennai near

- grinder machine for pulses paste

- why would be al mining crusher done

- high frequency powder vibrating screen equipment

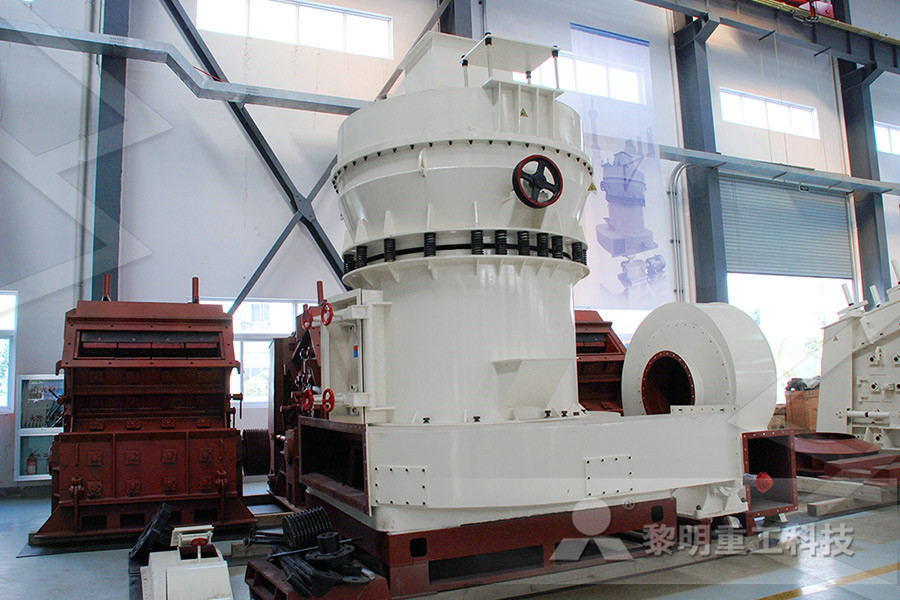

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher