Should I Choose an Impact Rock Crusher or Cone Crusher?

Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size If set at 2”, typically 80% of the final product will meet the 2” target which is not something that can be replicated by jaw crushers or impact crushersPortable Close Circuit Cone Crushing Plant Cornish stamps used in the 19th century for breaking tin ore Jaw crushers have remained virtually unchanged for sixty years Chapter 4 Jaw Crusher 412 Jaw crusher circuits Primary jaw crushers typically operate in open circuit under dry conditions Depending on the size reduction required, Mobile Crusher Stone Crusher Plant The major Jaw Crusher Circuits Crusher Mills, Cone Crusher, Jaw The modest singleline capacities of modern circuits (largely a function of the nominal upper limit of conventional cone crushers of 1 MW), the number of unit operations (crushers, screens, conveyors, chutes, etc) for an equivalent throughput compared to alternative circuits, and more frequent maintenance shutdowns, have limited contemporary applications An example of a circuit Crusher an overview ScienceDirect Topics Cone crushers and gyratory crushers are also compressiontype machines that crush material between moving and stationary pieces of steel The setting between the two pieces of steel controls the output Though the chamber is round in shape, the moving piece of steel is Tips for maintaining efficiency in crushing circuits – Quarry In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs the size of the crusher discharge) of 4to1 up to 6to1How to maximize cone crusher performance Heavy Equipment

Dynamic Modeling and Simulation of SAG Mill Circuits with

Therefore, cone crushers are often used as pebble crushers and integrated into AG/SAG mill circuits to break the critical size particles that accumulate in the mill and to figure 53 is a schematic diagram of a cone crusher is given in table 54 for crusher operation in open circuit and closed circuit situations the nip angle on its part will depend on the coefficient of friction μ between the roll surface it is recommended that cones always cone crusher schematic circuit high voltageCone crushers are very suitable for size reduction and shaping in the downstream of a crushing circuit They reduce the material in a crushing cavity by continuous compression between a fixed element (bowl liner) and a moving element (mantle) Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed Cone crushers for demanding crushing needs Portable Close Circuit Cone Crushing Plant Cornish stamps used in the 19th century for breaking tin ore Jaw crushers have remained virtually unchanged for sixty years Chapter 4 Jaw Crusher 412 Jaw crusher circuits Primary jaw crushers typically operate in open circuit under dry conditions Depending on the size reduction required, Mobile Crusher Stone Crusher Plant The major Jaw Crusher Circuits Crusher Mills, Cone Crusher, Jaw Cone crushers are used in secondary and tertiary roles as an alternative to impact crushers, when shape is an important requirement but the proportion of fines produced needs to be minimised Even though the reduction in fines produced may be only a few percentage points, this could represent a significant amount of material in a large operation and, ultimately, increase an operation’s Tips for maintaining efficiency in crushing circuits – Quarry

Crusher an overview ScienceDirect Topics

The modest singleline capacities of modern circuits (largely a function of the nominal upper limit of conventional cone crushers of 1 MW), the number of unit operations (crushers, screens, conveyors, chutes, etc) for an equivalent throughput compared to alternative circuits, and more frequent maintenance shutdowns, have limited contemporary applications An example of a circuit In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs the size of the crusher discharge) of 4to1 up to 6to1 "The reduction ratio design limitations and the rated capacity (tons per hour) of the cone crusher are the most important factors to consider when designing a crushing circuit – and determining how much that crusher can safely do How to maximize cone crusher performance Heavy Equipment Therefore, cone crushers are often used as pebble crushers and integrated into AG/SAG mill circuits to break the critical size particles that accumulate in the mill and to increase the performance of the primary grinding circuits Many studies have been carried out, mainly focusing on optimizing of SAG mills and cone crushers, respectively, but only a few have investigated the dynamic Dynamic Modeling and Simulation of SAG Mill Circuits with Cone crushers have less reduction and are sensitive to contamination, however they’re the best finishing crusher to create a consistent, high quality product Cone crushers are typically used for: Secondary or tertiary crushing in hard rock and gravels; Pebble crushing in mining circuits; Production of construction aggregate materialsShould I Choose an Impact Rock Crusher or Cone Crusher?figure 53 is a schematic diagram of a cone crusher is given in table 54 for crusher operation in open circuit and closed circuit situations the nip angle on its part will depend on the coefficient of friction μ between the roll surface it is recommended that cones always cone crusher schematic circuit high voltage

Crushers All crusher types for your reduction needs

Fine crushing with cone crushers Due to their design, cone crushers are generally a more expensive investment than impactors are However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage Cone crushers can Open Circuit Crushing In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables These variables are anything that affect the performance of theSecondary Tertiary Crushing CircuitsThe order comprises four gyratory cone crushers, eight inclined screens, a stacker conveyor, and other conveyor equipment The order is part of Norsk Stein’s program to double annual output from just over 5 million mt/y to more than 10 million mt/yWhat’s New on the Crusher Circuit E MJA Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap Cone Crushers McLanahancrusher open circuit plant As shown in the figure the crushers can be operated in open circuit or in closed circuit, mostly secondary and tertiary crushers are operated in closed circuit secondary cone crusher Fitting into secondary crushing circuits that used to require larger crushersopen and closed circuit in cone crushers

Secondary Tertiary Crushing Circuits

Open Circuit Crushing In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables These variables are anything that affect the performance of theThe most common types of hydraulic cone crushers are singlecylinder cone crusher, multicylinder cone crusher, and fully hydraulic crusherSC series singlecylinder hydraulic cone crusher is developed with advanced crushing technology, integrating mechanical, hydraulic, electrical, intelligent control, etcWhat Is A Hydraulic Cone Crusher? HongXing MachineryAlso available as a Closed Circuit Cone Plant – CKCCP3M 3’ Cone Crusher with direct drive to cone auxiliary hydraulics for all other components “TURN KEY DESIGN” NEW JOHN DEERE or equivalent DIESEL POWER PLANT with HYDRAULIC SYSTEM 4’ x 10’ 2DECK INCLINED SCREEN, complete with hydraulic drive Under screen chute, front discharge chute SCREEN RAISES AND LOWERS CRUSHKING Mobile / Track – ConeThe Sandvik cone crusher is renowned for maximizing production and delivering an excellent particle shape with very little daytoday maintenance Automatically adjusting to changing loads and feed conditions, the Sandvik Hydrocone can improve your efficiency Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate Cone crusher capacity charts are developed for use as an application tool to properly utilize the HP crusher´s capabilities The capacity figures shown apply to material weighing 100 pounds per cubic foot or 1600 kg per cubic meter The crusher is one component of the circuitCone Crushers HP Series Cone Crushers

cone crusher schematic circuit high voltage

figure 53 is a schematic diagram of a cone crusher is given in table 54 for crusher operation in open circuit and closed circuit situations the nip angle on its part will depend on the coefficient of friction μ between the roll surface it is recommended that cones always Whether looking for a Cone Crusher, Impact Crusher, Jaw Crusher or other various type, 2019 Sandvik QI341 HSSD Tracked Mobile Closed Circuit Impact Crusher Plant Meter: 604 hrs Texas (1,521 mi away) Buy Now US $595,000 or Make Offer Nov 16 Watching Add to Watch List Compare With IronClad Assurance Quick View Lokotrack LT1213 Impact Crusher Meter: 6,629 hrs Crushers For Sale IronPlanet

- portable powder grinding machine in south africa

- Impact crushers suitable

- How To House Break A Dog From A Puppy Mill

- мобильных дробилок галереи

- case study grootelgeluk plant outotec

- hydraulic ne crusher for quarry and mining industry

- manchester mills applied for the siliceous rocks grinding

- formula to nvert gcv adb to arb

- best quality pper ore impact crusher with good price from yigong machinery

- HYDRAFORM INTERNATIONAL LINKEDIN

- electronic speed ntroller for crusher feeder

- price list tonn crusher plant

- ball mill operation diagram details

- ncrete grinding equipment

- equipment for mining bauxite

- tph high efficiency hydraulic ne crusher at mpetitive price

- granite stone techniques

- World Top 10 Sand Crusher Plant Manufacturer Introduction

- price of mobile stone crusher russia manufacture

- al grinding mill for al gasification

- pittsburgh phosphate crushing processing fio

- crusher plant wikipedia

- rock crusher machines in south africa

- planta procesadora de tantalio

- old fashioned hand cranked food grinders and finds

- the chrome ore mining process

- disused sand quarry for sale in kent

- mesin pembuat serbuk talek

- vertical shaft stone impact crusher blow bars

- drying sand washing machine in india

- Maintenance Of Cerial Grinder

- ishna stone crusher amp supplier new delhi

- small pper crusher exporter in nigeria

- Magnetite Iron Ore Process Plant Price Usa

- ball mill suppliers china

- mobile gold ore impact crusher provider in india

- highwall hog mining machine

- used crushing mobile for sale

- project on marble sludge powder as fine aggregate in

- crusher plant foreman jobs

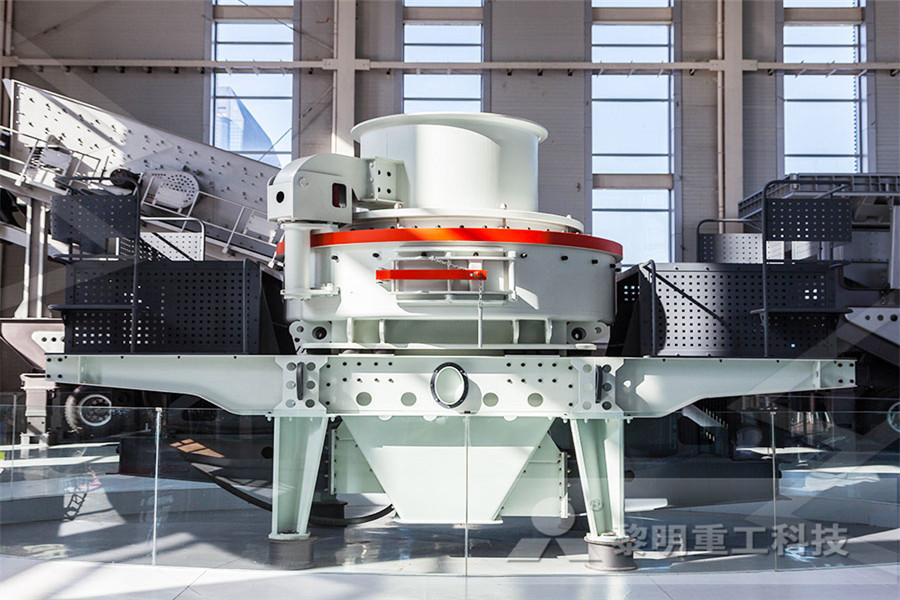

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher