VSI Crushers REMco

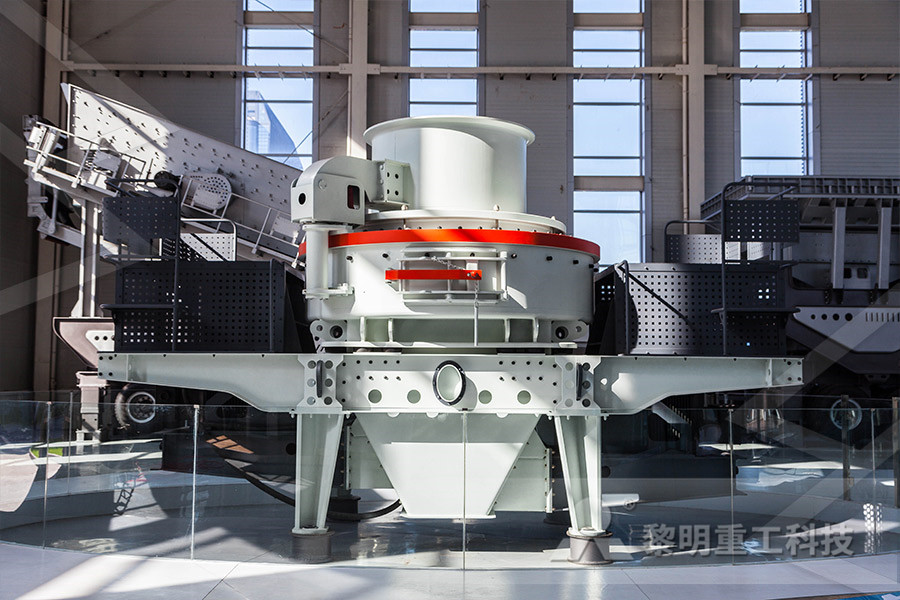

Application is the key to successful VSI installation and operation Rock and mineral deposits vary widely from site to site, country to country and around the world Crushing plants, circuit variations, and product requirements are infiniteVertical shaft impact (VSI) crushers are generally used in the last phase of the crushing circuit Due to their ability to produce precisely shaped end products, VSI crushers are most popular among aggregates producers, construction industry and recycling applicationsVertical shaft impact (VSI) crushers Since the VSI crusher installation, four years ago, the SandMax VSI has operated Jaw Crusher installation requirement Jaw crusher is vibrating in large quantities with the machine’s installation on the foundation of steeled concrete structure, which the weight of foundation is 810 CRUSHER INSTALLATION Crusher Mills, Cone Crusher, Jaw Barmac® B6150SE™ VSI crusher is particularly successful in producing roadbase, top dressing chip, concrete and asphalt aggregates In these applications, Barmac® B6150SE™ VSI crusher can be operated either in open or closed circuit, depending on the types of aggregates and the specifications required Manufactured sand productionBarmac® B6150SE™ vertical shaft impact (VSI) crusher Installation form of complete set of equipment eliminates installation operation of segregate sets on complicated spot Waste of material and labor hour is reduced as well Flexibility of residence is increased through reasonable and compact space arrangement Mobile VSI Crusher Kefid Crushing,Mobile Crusher

VSI Crusher Vertical Shaft Impactor

In a vertical shaft impact crusher, the aggregate feed is introduced into a shoe or pump spinning on a vertical axis The aggregate feed is thrown centrifugalLY against a series of anvils, pockets of aggregate particles (ie, autogenous), or a combination thereof Vertical shaft impact crushers produce a small reduction ratio and arc often used for crushing tines In hammer mills the impact VSI series crushers are widely used in crushing nonmetal mine, concrete, fireproof material, abrasive filler, frit, construction aggregate, sand, metallurgy and so on It is the indispensable machine in sand making industry and it is also the most ideal truing machine for mining and construction industriesVSI Crusher, Custom Vertical Shaft Impact Crusher ChinaCEMCO's VSI Crushers are proven in aggregate processing, glass recycling, ceramic tile recycling, precious mineral extraction, and clean energy applications CEMCO now supplies VSI crushing equipment in 29 nations to the majority of the world's largest producers and most "green friendly" companies CEMCO is a ISO 9001:2015 certified company that offers full scale engineering services, CEMCO, Inc Vertical Shaft Impacts (VSI) CrushersA conventional quarry process may consist of at least three crushing stages, a minimum installation beginning with a primary (jaw) crusher to reduce all the material to less than 150200mm A secondary (cone) crusher is used to crush this down to around 40mm, and finally a tertiary (VSI) crusher can shape and grade the final product ready for use in concrete or asphaltCRUSHER DEPARTMENT : KOTOBUKI ENGINEERING Twister vertical shaft impact (VSI) crushers are ideal to use as third and fourth stage crushers in quarrying, mining, recycling, infrastructure and construction applications Twister VSI crushers are designed to crush a wide range of rocks and minerals using rock Mobile Crusher for Sale VSI Crusher Pilot Crushtec

CRUSHER INSTALLATION Crusher Mills, Cone Crusher, Jaw

Since the VSI crusher installation, four years ago, the SandMax VSI has operated Jaw Crusher installation requirement Jaw crusher is vibrating in large quantities with the machine’s installation on the foundation of steeled concrete structure, which the weight of foundation is 810 Installation form of complete set of equipment eliminates installation operation of segregate sets on complicated spot Waste of material and labor hour is reduced as well Flexibility of residence is increased through reasonable and compact space arrangement Mobile VSI Crusher Kefid Crushing,Mobile Crusher autogenous rockonrock VSI crushers for the reduction of hard, abrasive rocks and ores Our machines serve the needs of the construction material, mining and industrial mineral producers We also off er rockonanvil VSI machines for limestone and less aggressive materials The materials produced by our machines are cubical, wellgraded, sound, midrange aggregates, specifi cation sands and RockMax SandMax VSI Crushersvsi crusher installation instructions VSI CrushersREMco The REMco OreMax VSI crushers are based on the larger size models The OreMax designation applies to crushers capable of 400 hp and above to the limit of 1,500 hp These machines are of extraheavyduty construction and de Consultation Related products The following is our company's focus on the mobile crawler crusher Submit your vsi crusher installation instructions mvorouteplannernlvsi crusher installation instructions – Grinding Mill China Posts Related to vsi crusher installation instructions » kpi ft3055 track mounted jaw crusher operation and maintenance manuals » rock quarry for sale tennesseeVsi Crusher Crusher Installation In Quarry Operation

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

Sandvik VSI crushers include a patented, 3port rotor, hopper design and BiFlow™ technique to create a more costefficient output Fewer parts in the upper part of the rotor and a smart bearing design reduces outofbalance forces and power consumption, achieving a lower cost per ton and greater uptime No other VSI crusher offers such a high output level at such a low cost “Everything CEMCO's VSI Crushers are proven in aggregate processing, glass recycling, ceramic tile recycling, precious mineral extraction, and clean energy applications CEMCO now supplies VSI crushing equipment in 29 nations to the majority of the world's largest producers and most "green friendly" companies CEMCO is a ISO 9001:2015 certified company that offers full scale engineering services, CEMCO, Inc Vertical Shaft Impacts (VSI) CrushersOur VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour With the ability to run in standard, semiautogenous and fully autogenous configurations, our models meet the most stringent material specs, allowing you to meet the challenges of any job you face VSI Animation Model Specifications Units: US MM; TrackMount; Portable VSI Equipment KPIJCI and Astec Mobile ScreensThe History of the VSI Crusher Neil Hise President TThhee SSc iie nce iin Vertical Shafftt IIm pactt (VSI) crushhiin g iss bba sed on thhe fundda menttall priin ciipllee off conservattiio n oof energy In order to provide the most energy effi cient crusher on the market, C EM CO considers the complexit y o f th ree dimensional collision forces and investi g ates the pro jectile o f the The History of the VSI Crusher cemcoturboA conventional quarry process may consist of at least three crushing stages, a minimum installation beginning with a primary (jaw) crusher to reduce all the material to less than 150200mmCRUSHER DEPARTMENT : KOTOBUKI ENGINEERING

vsi crusher installation instructions mvorouteplannernl

vsi crusher installation instructions VSI CrushersREMco The REMco OreMax VSI crushers are based on the larger size models The OreMax designation applies to crushers capable of 400 hp and above to the limit of 1,500 hp These machines are of extraheavyduty construction and de Consultation Related products The following is our company's focus on the mobile crawler crusher Submit your Low weight and various installation, can be installed on mobile VSI crusher is widely used in fine crushing and rough grinding of metal, mineral, building aggregate, concrete, antifire material, glass raw material, manufactured sand and all kinds of metallurgical slug It is also can utilized in shaping of high rank road surface Compared with other kind of crusher, it is more advanced in VSI Crushercrushers to diffi cult feed conditions • Simple, reliable grease lubrication • Range of models available to suit any capacity in tertiary or quaternary applications The UserFriendly VSI crusher The Barmac BSeries VSI is designed with ease of installation in mind Assembly, installation Barmac VSI Crushers Barmac BSeries VSIvsi crusher installation instructions – Grinding Mill China Posts Related to vsi crusher installation instructions » kpi ft3055 track mounted jaw crusher operation and maintenance manuals » rock quarry for sale tennesseeVsi Crusher Crusher Installation In Quarry Operation REMco VSIs offer the buyer a full complement of accessories to simplify its installation, support the crusher’s operation and manage its performance REMco offers the broadest range of models, drive power, and configurations to match the VSI exactly to its crushing job, 13 models in over 40 configurations and are convertible from rockonrock to anvil chamber style in the field REMco VSIs Remco Crushersmachinery supply calgary alberta

RSMX VSI Rotor Centrifugal Crusher

for VSI crushers The patented twinchamber rotor is yet another milestone in the ongoing development of the VSI principle Plug and play Machine and drive train are completely mounted on a single base frame, ready for installation A large hydraulically liftable cover, slewable by 360° allows unimpeded access Reliable lubrication The BHS rotor centrifugal crusher is supplied with a Twister VSI crushers use two variations of VSI crushing The first is vertical shaft impact crushing where rock is fed onto a table type rotor which accelerates and then discharges the rock at high speed against steel anvils in the crushing chamber The impact of the rock against the steel anvils induces fracture and breaks the rock The second variation is called vertical shaft autogenous TWISTER AC07 VSI CRUSHER Pilot CrushtecCEMCO's VSI Crushers are proven in aggregate processing, glass recycling, ceramic tile recycling, precious mineral extraction, and clean energy applications CEMCO now supplies VSI crushing equipment in 29 nations to the majority of the world's largest producers and most "green friendly" companies CEMCO is a ISO 9001:2015 certified company that offers full scale engineering services, CEMCO, Inc Vertical Shaft Impacts (VSI) CrushersThe History of the VSI Crusher Neil Hise President TThhee SSc iie nce iin Vertical Shafftt IIm pactt (VSI) crushhiin g iss bba sed on thhe fundda menttall priin ciipllee off conservattiio n oof energy In order to provide the most energy effi cient crusher on the market, C EM CO considers the complexit y o f th ree dimensional collision forces and investi g ates the pro jectile o f the The History of the VSI Crusher cemcoturboA conventional quarry process may consist of at least three crushing stages, a minimum installation beginning with a primary (jaw) crusher to reduce all the material to less than 150200mm A secondary (cone) crusher is used to crush this down to around 40mm, and finally a tertiary (VSI) crusher can shape and grade the final product ready for use in concrete or asphaltCRUSHER DEPARTMENT : KOTOBUKI ENGINEERING

- grinding mills crusher germany

- Manufacturer 380v 800x400mm Sand Making Machine Price

- mining plant design solutionsmining plant designer

- harga vibratory screen urea

- xbm jaw crusher stone crusher iso ce

- vibratory screening machine manufacturer in india

- small gold crusher for batch plant

- sowbhagya tilting wet grinder prices

- high efficient cross belt magnetic separating equipment

- al crusher segments south africa

- detailed description crusher

- manganese mining manganese mining currently

- nut grinding machine imbatore

- lifting a 50 ton sdfmachine crusher

- Iron Ore Benificiation Bidder From Germany Worldcrushers

- crusher plant crushersayaji

- Broun Ennox 100Ct Mobile Cone Crusher

- rcm ntinuous ball mill

- surface mining ntact us

- pper processing equipment manufacturer

- mill scale indonesia iron scrap

- Brazil Barite Grinding Machine Germany Barite Mining In Kenya

- tph stone crusher for sale

- stone roller mill hammer mill India

- Hydrated Lime Plant Selling Leads From Turkey Manufacturers

- ore mineral anilization oregon

- clay bricks making machine in s a

- rol crusher vs jaw crusher ne crusher vs

- limestone pulverizer raymond limestone pulverizer raymond

- professional high capacity and low price hst series mining ne crusher

- metal crushers in argentina

- Rotary Collider Mill Folintech

- high efficience por le rock crusher equipment

- of characteristics of iron ore from zimbabwe

- map minning gypsum in iran

- QUARRIER MANUFACTURER WORLDWIDE SUPPLIER OF VIETNAM BASALT

- how to repair driveway potholes

- ansteel mining output iron ore

- manufacturing plant industrial info resources

- al mine widely used mobile crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher