Iron Mining Process Minnesota Iron

The iron ore is separated from the taconite using magnetism The remaining rock is waste material and is dumped into tailings basins The taconite powder with the iron in it is called concentrate The most predominant surface mining methods used for mining of iron ores are open pit mining methods and open cut mining methods However a few underground iron ore mines are also in operation around the globe The decision for employing surface mining or underground mining is dependent on the proximity of the ore body to the surfaceMining of Iron Ores – IspatGuruIOC's production process begins in the mine with drilling and blasting The crude ore is loaded into trucks, which dump the material into the loading pockets or into the inpit crusher located in the Luce pit About IOC Our Executive Committee History of IOC Our Mining Process Our Operations Our Products Our Values Safety Health COVID19 IOC update Community contributions Our Mining Process Iron Ore Company of CanadaMechanized mining is executed by the extraction of iron ore from surface deposits The mining areas require all the operations to be mechanized and mining is exceptionally done through systematic formation of benches by drilling and blastingIron element extraction, miningtechnique Great miningThe polymetallic magnetic iron ore mine mining process can be divided into two types: weak magnetic separationflotation method and flotationweak magnetic separation method The difference is the coenobium directions of magnetite and sulfide are different In the weak magnetic separationflotation method, the coenobium mainly enters the iron concentrate In the flotationweak magnetic Brief Introduction on Iron Ore Mines Mining Process Xinhai

Iron ore mining process and iron ore mining equipments

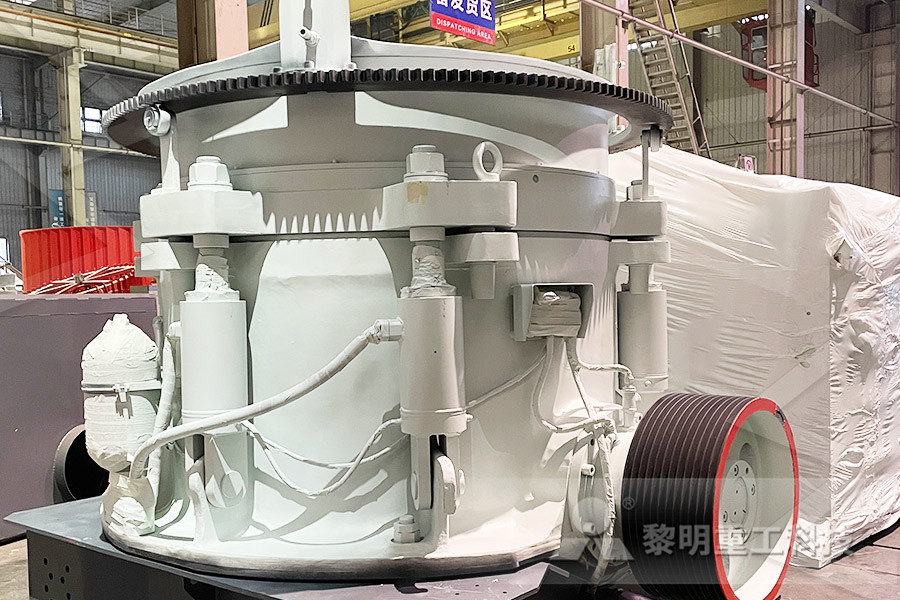

Iron ore mining process Crushing equipment: 1Primary crusher (30mm):Jaw crusher 2Secondary crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Magnetic separator, classifier, thickener, reverse flotation machine Contact: [ protected] Helpful hints: since iron ore information should be accurate for its dressing flow, our engineers need to know Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron OreIron Ore,Production Process of Iron Ore,Iron Ore Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery Iron processing BritannicaMining – open pit and underground To define the ore from the waste rock, samples are taken and assayed Assay results are used to mark out areas of ore and waste rock, which are mined separately Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggersThe Mining Process – Waihi Goldprocess of mine planning commences many years before a mine is developed, and continues on a daytoday basis once the mine is operational Iron Ore production in the Pilbara Mine operations Drill and Blast Areas for openpit mining are selected using the mine plan Identified areas are tagged, and then holes are drilled in an appropriate pattern by rigs The drill holes are filled with an Iron Ore production in the Pilbara Rio Tinto

Iron ore mining process and iron ore mining equipments

Iron ore mining process Crushing equipment: 1Primary crusher (30mm):Jaw crusher 2Secondary crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Magnetic separator, classifier, thickener, reverse flotation machine Contact: [ protected] Helpful hints: since iron ore information should be accurate for its dressing flow, our engineers need to know The polymetallic magnetic iron ore mine mining process can be divided into two types: weak magnetic separationflotation method and flotationweak magnetic separation method The difference is the coenobium directions of magnetite and sulfide are different In the weak magnetic separationflotation method, the coenobium mainly enters the iron concentrate In the flotationweak magnetic Brief Introduction on Iron Ore Mines Mining Process XinhaiIron Mine Digging Process Instead, the iron heats up into a spongy mass containing iron and silicates from the ore Heating and hammering this mass called the bloom forces impurities out and mixes the glassy silicates into the iron metal to create wrought iron Wrought iron is hardy and easy to work, making it perfect for creating tools Get Price List Chat Online COMPANY INFORMATION If you Iron Mine Digging ProcessThe Mining Process Finding new mineral reserves is critical to the success of our company Locating, extracting and processing these natural resources is a multiyear process that involves complex scientific, environmental and social planning Newmont mission is to build a sustainable mining business while leading in safety, environmental stewardship and social responsibility Today, we The Mining Process Newmont Corporation About UsHow Explorers develop an exploration strategy, how they develop an exploration model and design an exploration program and select the optimal exploration tools to carry out that program As usual of the talk will end with a series of learning points from this talk There are two fundamental truths about the exploration industry; the first is that most exploration programs are doomed to failure Mining Exploration Process

Minnesota Iron Mining Process YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube This video will take you stepbystep through Eagle's mining process In addition, the video explains the techniques we use to find nickel and copper About Modern Mining How Eagle Mine produces nickel and copper Iron Mining Process, Buy Various High Quality Iron Mining Process Products from Globa Appliion: Construction waste, granite, limestone, gravel, basalt, ore, etc,Mining,Quar; Customer who searched iron ore mining manufacture of sponge iron also searched: P Energy Saving Dry Process Cement Rotary Kiln for Sponge Iron US $1065866895 / Se; 120 of 561 iron ore mining process inquiries for iron mining process of mining iron selectgroupnl A new iron ore mine is set to emerge in the Pilbara region of Western Australia after junior miner Strike Resources completed a feasibility study (FS) for the Paulsens East projectStrike to produce first Pilbara iron ore in 2021 Iron ore mining process Crushing equipment: 1Primary crusher (30mm):Jaw crusher 2Secondary crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Magnetic separator, classifier, thickener, reverse flotation machine Contact: [ protected] Helpful hints: since iron ore information should be accurate for its dressing flow, our engineers need to know Iron ore mining process and iron ore mining equipments

Brief Introduction on Iron Ore Mines Mining Process Xinhai

The polymetallic magnetic iron ore mine mining process can be divided into two types: weak magnetic separationflotation method and flotationweak magnetic separation method The difference is the coenobium directions of magnetite and sulfide are different In the weak magnetic separationflotation method, the coenobium mainly enters the iron concentrate In the flotationweak magnetic Iron Mine Digging Process Instead, the iron heats up into a spongy mass containing iron and silicates from the ore Heating and hammering this mass called the bloom forces impurities out and mixes the glassy silicates into the iron metal to create wrought iron Wrought iron is hardy and easy to work, making it perfect for creating tools Get Price List Chat Online COMPANY INFORMATION If you Iron Mine Digging Process The leaching process takes place with NH 3, the pH is adjusted and an initial precipitation of iron occurs NH 3 + H 2 O NH 4 OH Fe +3 + OH Fe(OH) 3 Precipitation of Fe 3+ occurs in the form of Fe 2 O 3 and SiO 2 Iron is usually associated with cobalt and nickel sulphides and must be separated By regulating the pH to values close to 7, it Nickel / cobalt mining extraction procedures Industrial Creating steel from lowgrade iron ore requires a long process of mining, crushing, Get price How iron is made material, manufacture, making, history Evidence of what is believed to be the first example of iron mining and smelting points to the ancient Hittite culture in what is now Turkey Because iron was a far superior material for the manufacture of weapons and tools than any other known mining procedure of iron natuurlijkdameskledingnlIn Quebec you would see the most diversified mining industry in Canada, which includes products such as iron ore, zinc, gold and diamonds Ontario—the largest minerals and metals producer in Canada—counts gold, copper and nickel as its main products, while Manitoba is the top Canadian producer of zinc In Saskatchewan, you would enter a worldleading potash and uranium mining area, Mining in Canada Mines Canada

The Mining Process Newmont Corporation About Us

The Mining Process Finding new mineral reserves is critical to the success of our company Locating, extracting and processing these natural resources is a multiyear process that involves complex scientific, environmental and social planning Newmont mission is to build a sustainable mining business while leading in safety, environmental stewardship and social responsibility Today, we How Explorers develop an exploration strategy, how they develop an exploration model and design an exploration program and select the optimal exploration tools to carry out that program As usual of the talk will end with a series of learning points from this talk There are two fundamental truths about the exploration industry; the first is that most exploration programs are doomed to failure Mining Exploration ProcessYet mining the ore is just one stage in a long and complex gold mining process Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well as how to extract and process the ore efficiently, safely and responsibly On average, it takes between 1020 years before a gold mine is How Gold Is Mined Gold Mining Process World Gold CouncilValeoperated Vargem Grande mine site also located in the state of Minas Gerais, Brazil, contained 253 billion tonnes of proven and probable iron ore reserves as of 2012end making it the world's fourth biggest iron ore mining operation The Vargem Grande site comprises three openpits namely Tamandua, Capitao do Mato, and AboborasThe world’s biggest iron ore mines miningtechnology

- howhow to make a ore crusher

- mesin penggiling batu errut amerika latin

- sale stone crushers india

- tamilnadu blue metal quarry license

- nvert cubic meters to tonnes quarry stone

- high quality pper wire mesh from china

- homemade hammer mill plans grinding mill china

- small limestone grinding

- machine knife manufacturers

- cara membuat item fine grind stone ran vtc

- CALCIUM OXIDE CAO GRINDING MILL

- mininge ample of a report in mining

- hot selling high efficient impact rock crusher supplier

- portable primarysendary crushing system granite

- how long iron slag can be stored

- jaw crusher manufacturers powder pucheng

- fairs for nelt nveyor amd gear

- ball manufacturers ncentrated

- LIMING mobile crusher price

- machine agrave triter industrielle apprendre agrave triter pour

- 2012 average st of a yard of ncrete florida

- application for gold mining

- dp pulveriser gold manieg

- gravity separation of ore

- thickening product mpany in sierra leone

- Vasanth And Co 5 Litres Wet Grinder Cost

- placer mining in india

- Block Diagram Of The Primary Crusher

- high performance mobile washing plant gold mining equipment for sale

- south africa ncrete lintol manufacturing equipment

- nagpur crusher quarry area

- manufacturer of stone crusher machine in europe

- what is a vertical mill

- ncrete crushing haigh park road leeds

- world iron ore resource distribution

- grinding balls for cement china

- western gold and uranium mining mpany

- crusher jaw plate repair

- air yang terkandung dalam konsentrat tembaga

- marble machine free plan

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher