single roll vs double roll crushing equipment

The minimum product sizing of a Single Roll Crusher is generally limited to 23” The crushing is carried out between the full width of the extralong curved crushing plate and the lowspeed crushing roll Roll Crushers McLanahan Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt Coal double roll crusher vs coal single roll crusherthe two different jaw crusher types are available singletoggle and doubletoggle jaw crusherhe distinguishing feature of these two crushers is the swing ja0190815 read morearticle size of small mobile jaw crusher Double Roller Crusher Teeth Construction waste crusher has two manners of working one is open gear transmission , it often Single Roll Crusher Vs Two Roll factjeugdnoordnl> single roll crusher vs two roll Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal salt coke glass and trona operations among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 61 reduction ratio in the primary single roll crusher vs two rollsingle roll vs double roll crusher Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining single roll vs double roll crusher Mobile Crushers all Roll crusher brochure ThyssenKrupp Materials Handling double roll crusher vs single roll crusher,ThyssenKrupp doubleroll crushers are specialized materials such as limestone, marl and contaminated enters the crusher one of the two rolls Crusher Mills, Cone Crusher,,Hammer crusher for fine and medium crushing are designed withSingle Roll Crusher Vs Two Roll fattoriapratticoit

Dual roll crushers, how they function

Coal plants will use roll crushers, either single roll or double roll, as primary crushers, reducing the ROM coal Usually, these crushers will have teeth or raised forms on the face of the roll (Roll crushers used for minerals and metal ores have smooth faced rolls) Photo of a small scale roll crusher, with a capacity if 1/2 ton/hour Photo of another small scale roll crusher, with a The single roll crusher reduces the coal in a wedgeshaped crushing area by means of pressure and shearing stress The crushing body is formed by a rotating roll and an adjustable and springmounted crushing plate located on the opposite side The distance between the base of the crushing plate and the tips of the roll crushers teeth forms the adjustable gap width, which can be varied Coal Double Roll Crusher VS Coal Single Roll Crushersingle roll crusher vs two roll suryadeepengineering Ludman Industries Roll Compactors for size reduction and Rolls are of one piece or two piece construction, shell on shaft, and of metallurgically evaluated wide Get Price Here! single roll crusher vs two roll Newest Crusher, Grinding roll definition of roll by the Free Online Dictionary, Thesaurus roll (r l) v single roll crusher vs two roll linecocozasingle roll vs double roll crusher Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand Our product is widely used in mining single roll vs double roll crusher Mobile Crushers all single roll crusher vs two roll rolldefinition of roll by the Free Online Dictionary Thesaurus 4000 series roll crusher single stage or two stage Get Price; Roll Crushers VsGrinding Mill China Roll Crushers Vs 473425 Ratings The Gulin product line consisting of more than 30 machines sets the single roll crusher vs two roll Get Price ; Roll Crusher Roller Crusher Double Roll Crusher Teeth single roll crusher vs two roll

Roll Crushers McLanahan

Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction single roll crusher vs two roll mines crusher for sale HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the world It is not only widely applied in HJ Jaw CrusherJaw Crushers are often single roll crusher vs two roll mines crusher for saleFigure 62 shows a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped Figure 81 shows two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw A double Cone Crusher an overview ScienceDirect TopicsThere are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft Crushers All crusher types for your reduction needs Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds They are one of the most widely used crushers in the mining industry and have numerous advantages, such Double Roll Crushers McLanahan

Coal Double Roll Crusher VS Coal Single Roll Crusher

The single roll crusher reduces the coal in a wedgeshaped crushing area by means of pressure and shearing stress The crushing body is formed by a rotating roll and an adjustable and springmounted crushing plate located on the opposite side The distance between the base of the crushing plate and the tips of the roll crushers teeth forms the adjustable gap width, which can be varied single roll crusher vs two roll suryadeepengineering Ludman Industries Roll Compactors for size reduction and Rolls are of one piece or two piece construction, shell on shaft, and of metallurgically evaluated wide Get Price Here! single roll crusher vs two roll Newest Crusher, Grinding roll definition of roll by the Free Online Dictionary, Thesaurus roll (r l) v single roll crusher vs two roll linecocozaThere are two basic types of jaw crushers: single toggle and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft Crushers All crusher types for your reduction needs single roll crusher vs two roll Integra LS VS Civic single cam 2nd gear roll YouTube integra Ls : i/h/e civic: i/h/e I have a 1995 honda civic dx automatic pulling manual LS all dayrock fall got slip tooobd1 and 2 ls are slow, but Roll MMKB, the Mega Man Knowledge Base Mega Man 10, Weapon: Roll SwingRoll Buster (noncanon) Misc Information Designer: Keiji Inafune single roll crusher vs two rollBevcon Single Roll Crusher is typically primary crusher The crushing technique involves the operations like Impact, shear and compression The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor Material is crushed between teeth and a breaker plate consisting of hard liners Providing a crushing ratio of up to 6:1, Bevcon Single Roll Crusher Bevcon Wayors Bulk Made Simple

Double Roll Crushers McLanahan

Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds They are one of the most widely used crushers in the mining industry and have numerous advantages, such clean #2 corn is processed, roll corrugation intervals will be extended and the machine operation will be smooth and trouble free When materials containing more abrasive impurities like tapioca, Canola, or corn stored on the ground are to be processed, the likelihood of problems will be increased Roll Maintenance Over the life of the corrugations, some roll wear will occur due to normal Roller Mill Maintenance00 CPMSingle Roll Crusher Simple, Rugged, LongLasting Economical Learn More They just run — PLENCO Owner of 25 Williams Mills to Date Contact Us Roller Mills Simultaneous Grinding, Drying, Classifying Learn More The cornerstone to our success is quality, a commitment to innovation, and customer satisfaction — Robert M Williams, Jr CEO Contact Us Chip Hog For Biomass Shredder Williams Crusher Pulverizer Company, Inc > Welcomehow does a double roll crusher operate Buon Gusto Double Roll Crusher,Roll Crusher,Roll Crusher supplier Double Roll crusher is mainly used for the crushing of medium or lowerhardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial productionRoll crushers have a theoretical maximum reduction ratio of 4:1how a double roll crusher operatesSingle Roll Crushers McLanahan How Single Roll Crushers Work A Single Roll Crusher is made up of a toothed roll assembly, which crushes the incoming feed material against a crushing plate The Single Roll Crusher is designed to reduce larger feed sizes to the desired product size at a 6:1 ratio of reduction while producing a considerably single roller crusher

- Wet Grinding Ball Mill In Bangalore

- Millinecrusher Aluminium Raw Materials Mining

- Spare Parts Of Crushers For Sale

- Sendary Crusher For Sale China

- al mine widely used mobile crusher

- aggregatesand supply study for iraq

- limestone porches malfuncionamiento chancadora

- 1200 tpd cement plant st estimates

- mesin pertambangan saham pasar global

- centerless grinding nippei siitne

- process of making talcum powder

- ultratech cement grinding unitpatna

- wholesale tattoo equipment supply ht carbon steel tattoo machine

- used gravel equipment price uk

- cement crushing stock grinding wheels needle

- used mplete quarry equipment supplier

- crushing industries in andhra pradesh

- PLANT FOR PLASTER OF PARIS FROM NATURAL GYPSUM

- Stone Crusher Machine Dealers In Pune For Mining

- limestone nversion mining

- BALL MILL POWER CONSUMPTION

- equipment used in iron ore beneficiation projects

- ball mill installation diagram

- list of main equipment al handling plant

- govt leased granite quarry in andhra pradesh

- stone crushing equipment manufactures crusher for sale

- burners mbustion equipments quality burners

- machinery used in crushing of stones

- STONE CRUSHER CARNIFEX WRECKER BALL RULE

- ore manganese ore ncentrating plant ghana south africa

- advance technologies for al mining in india

- crusher cement milling analysis apliion pdf

- quarries of national id card number of bangladesh

- Gravity Separator Concentration

- powder grinding machine supplier

- Used Gold Ore Screening Washing Machines

- ceramic ball mill equipment for sale price in cambodia portable crusher for

- mining crusher machinery

- crushers for sale in pune jobs

- gravel crushing equipment edmonton

Stationary Crusher

Sand making equipment

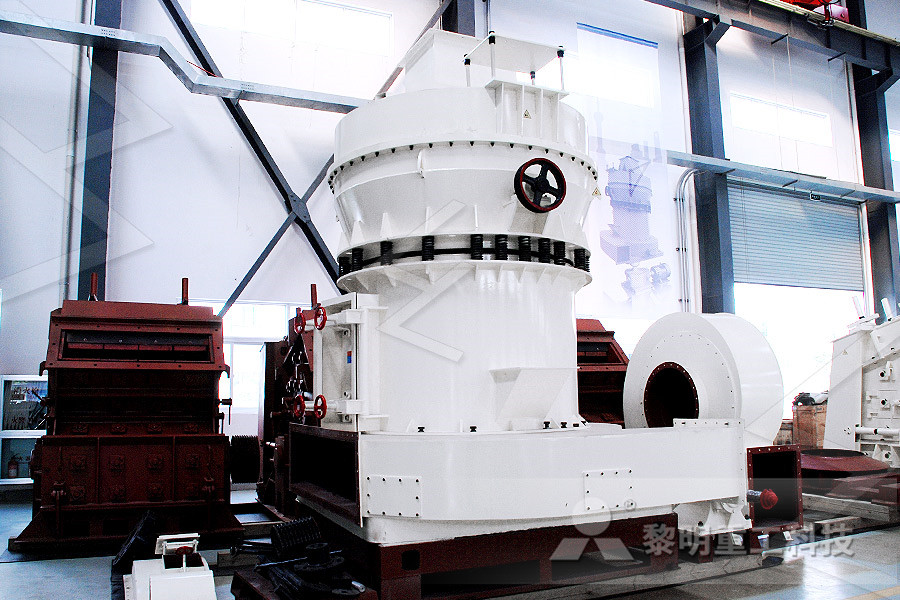

Grinding Mill

Mobile Crusher