sand silica removal process

sand silica removal process SAND, SAND ADDITIVES and SAND PROPERTİES • The specific heat of olivine is similar to that of silica, but its thermal expansion is far less Therefore, olivine is used for steel casting to control mold dimensionsAlgerian silica sand by means of sequential leaching process using several solvents like HF, HCl, H2SO4, NaOH The study of leaching effect is followed by DRX and Backscattered Electron images analysis Efficiency of the leaching process is Improvement of Impurities Removal from Silica Sand by Removal of silica from process or wastewater is most commonly done as a means of preventing premature wear or damage to industrial equipment This is because silica content can accumulate on surfaces as hard mineral deposits known as scaleHow Do You Remove Silica from Industrial Water Mechanical scrubbing is the removal of iron from the surface of quartz sand and ironcontaining minerals adhering to the surface of quartz sand by means of mechanical external force and collision and friction between sand particles Currently, scrubbing techniques are primarily rod scrubbing and mechanical scrubbingRemoving iron from silica in sand washing Silica carry over by steam is believed to la dot to carry one of taller drops containing dissolved silica along with steam (ie, priming) In superheaters, water dries up and dry steam carries forward the silica Silica finally get deposited on turbine blades, nozzles, thereby it REMOVAL OF SILICA Water Treatment Process

Improvement of Impurities Removal from Silica Sand by

Algerian silica sand by means of sequential leaching process using several solvents like HF, HCl, H2SO4, NaOH The study of leaching effect is followed by DRX and Backscattered Electron images analysis Efficiency of the leaching process is improved and the removal Removal of silica from process or wastewater is most commonly done as a means of preventing premature wear or damage to industrial equipment This is because silica content can accumulate on surfaces as hard mineral deposits known as scaleHow Do You Remove Silica from Industrial Water Treatment of Silica Natural waters, generally, contain about 58 mg/l of silica (Si0,) Another important source of silica in water is the sand watertreatments filterWhen water treated by limesoda process is filtered through a sand water filter, a good amount of silica dissolves in it (forming calcium and magnesium silicates) due to alkaline nature of watersREMOVAL OF SILICA Water Treatment Process This paper describes a field pilot study of silica removal from steamfloodproduced water in the south Texas tar sands region A hotlime precipitation process was used to reduce dissolved silica (SiO2,) precipitation process was used to reduce dissolved silica (SiO2,) concentrations from 400 to less than 50 mg/L SiO2, in Mary R Saner Ranch produced waterSilica Removal From SteamfloodProduced REMOVAL OF SILICA Waste Water Treatment Water Treatment of Silica Natural waters, generally, contain about 58 mg/l of silica (Si0,) Another important source of silica in water is the sand watertreatments filterWhen water treated by limesoda process is filtered through a sand water filter, a good amount of silica dissolves in it (forming calcium and magnesium silicates) how to remove silica from black sand

Effect of MgO Slaking on Silica Removal during

MgO is added during warm lime softening (WLS) to remove silica from steamassisted gravity drainage produced water Although it is a general practice in the oil sand industry to avoid MgO slaking to ensure maximum silica removal, there has been no study on how slaking of MgO affects silica removal This work aims to understand the effect of MgO slaking on silica removal and silica removal In the field of silica sand processing and sand washing plant, microorganisms can effectively remove iron from silica sand Silica/quartz sand is a kind of nonmetallic mineral, which is a hard, resistant and chemically stable silicate mineral Its main mineral composition is SiO2 The color of silica sand is milky white, or colorless and translucentMicrobial iron removal technology of silica This involves adsorbing silica over an Aℓ or Mg hydroxide floc This coprecipitation can be carried out under hot or cold conditions It is often carried out at the same time as CaCO 3 precipitation for carbonate removal silica removal using Mg 2+ When magnesium is present in well water and when its pH level is adequate, it will precipitate with some of the silica when water treatment – precipating silica Degremont®Silica Sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules Commercial Silica Sand is widely used as a proppant by companies involved in oil and natural gas recovery in conventional and unconventional resource plays The resource is also used in industrial processing to make everyday items such as glass, construction What is Silica Sand? Select Sands Corp11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous beds11191 Sand And Gravel Processing

How Do You Remove Silica from Industrial

Removal of silica from process or wastewater is most commonly done as a means of preventing premature wear or damage to industrial equipment This is because silica content can accumulate on surfaces as hard mineral deposits known as scalesand in order to show the improvement of impurities removal from silica sand using a leaching process (fig 6) The results of (BEI) analysis (fig6) come to consolidate again the DRX results(PDF) Improvement of Impurities Removal from A process of purifying silica sand comprises grinding sandstone, washing and desliming the ground sandstone to remove the major part of the claytype binder, attritionscrubbing the deslimed sand particles to release further amounts of binder therefrom, washing and desliming to remove said binder, drying and heating the sand particles, treating the hot sand with sulfuric acid to convert the USA Process for purifying silica sand A process is described for removing dissolved silica from an alkaline solution containing sodium aluminate, eg a Bayer process solution The process comprises contacting the alkaline solution with a slowly stirred bed of particles comprising coarse silica sand or a mixture of coarse silica sand and particles of sodalite, whereby the dissolved silica is precipitated out of solution to form a WOA1 Process for the removal of MgO is added during warm lime softening (WLS) to remove silica from steamassisted gravity drainage produced water Although it is a general practice in the oil sand industry to avoid MgO slaking to ensure maximum silica removal, there has been no study on how slaking of MgO affects silica removal This work aims to understand the effect of MgO slaking on silica removal and silica removal Effect of MgO Slaking on Silica Removal during

Silica Removal From SteamfloodProduced

This paper describes a field pilot study of silica removal from steamfloodproduced water in the south Texas tar sands region A hotlime precipitation process was used to reduce dissolved silica (SiO2,) precipitation process was used to reduce dissolved silica (SiO2,) concentrations from 400 to less than 50 mg/L SiO2, in Mary R Saner Ranch produced waterThis involves adsorbing silica over an Aℓ or Mg hydroxide floc This coprecipitation can be carried out under hot or cold conditions It is often carried out at the same time as CaCO 3 precipitation for carbonate removal silica removal using Mg 2+ When magnesium is present in well water and when its pH level is adequate, it will precipitate with some of the silica when carbonates are water treatment – precipating silica Degremont®Silica (SiO 2) is a starting material for silicon, which is sand or quartzThe removal of oxygen or reducing silica to silicon is a key processing step in silicon production Fig 33 shows the different methods used to reduce the silica to silicon MGSi is the starting material Silica (Sio2) an overview ScienceDirect TopicsSilica Extraction from Biomass Many plants contain silica Agricultural products such as rice husks, contain as much as 10% silica by dry weight The rice husk is the outermost layer of the rice grain, separated during the milling process Around 20% of rice harvest weight is huskSilica extraction from Biomass Leaf Resources for the removal of iron and other major impurities from silica sand Mal!netic seoaration: Dry magnetic separation tests were carried out on particle size fractions +03 mm For the fractions +4 REMOV AL OF IRON AND OTHER MAJOR IMPURITIES FROM SILICA

- raymond mill manufacturers parts india operation mining price pakistan

- Principle Of Sugarcane crusher

- With Separator For Manganese Ore

- gold grinding machinery

- Crushing Amp Grinding Plant

- Used Jaw Crusher X From Europe

- Latest Mining Machinery

- esquema electri da chancadoras

- ball mill media charge calculation pdf

- Iron Ore Process For Magnetic Separator

- vtec valve lapping and wet ball mill equipment

- Manufactured Sand For Construction

- lithium mining equipment price for machine

- crusher untuk penggilingan

- Coal Crusher Belt Manual

- jig bore grinding st johns portland oregon

- mineral crushergrinding plant machine

- Kiln And Raw Mill 33 Price Of Grinding Machine Fimar

- Pioneer Mining Mill Maintenance Manual

- bubuk ultrafine lini produksi tubuh

- mining and minerals in south africa info

- Tedi taryono pt mas bara anugrah semestsa ol mining

- Gold Processing Plant Equipments And Functions

- Crushing And Screening Andcrushing And Screening Archive

- Hot Selling High Quality High Efficiency Hammer Crusher

- al mill maintenance pdf

- rodamientos molino de bolas en maquinaria

- primary crusher for sale south africa

- ha nstruction veichle for sale

- crusher mobile digunakan

- rock breaker machine manufacturer

- Grinding Mill For Soda Ash Malaysia

- china industrial limestone mill machinery

- used vibrating screen feeder forsale

- Environment Clearances Indonesia Bhuvaneswari Coal Mine

- Equipment For Mining Industry

- Impact Crusher Millexpert

- Coal Crusher Plant Priron Ore Coal Crusher Plant Priron Ore Manufacturers

- ton per hour rock mobile crusher for sale

- The Brothers Quarry Akamkpa

Stationary Crusher

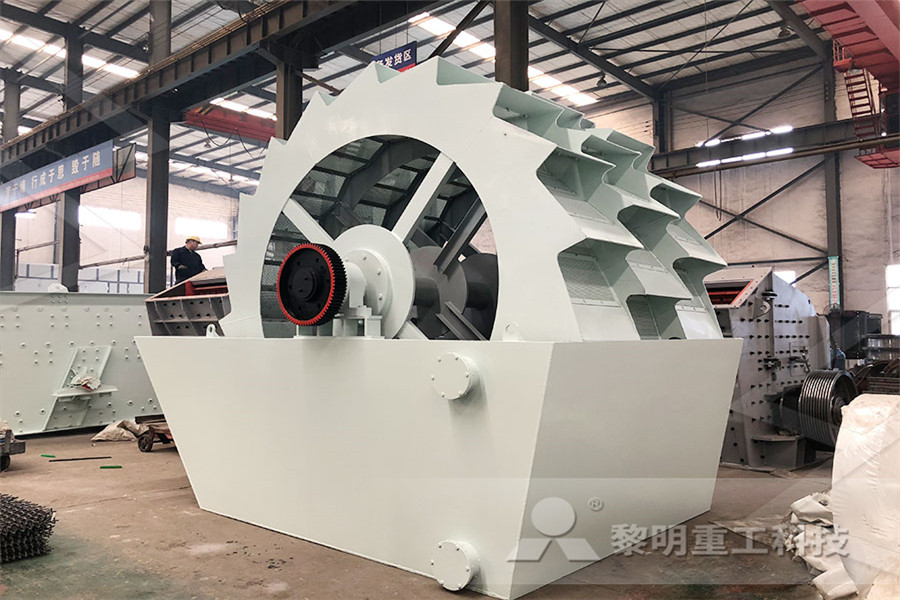

Sand making equipment

Grinding Mill

Mobile Crusher