Gold Ore Processing, 2e Request PDF

01012016 Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationGold Ore Processing ScienceDirectGold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operationThis completely updated edition features coverage of established, Gold Ore Processing, Volume 15 2nd Edition2 # orE tyPE ModE of occurrEncE of gold ExaMPlE 1 Placers Gold is easily liberated or has been liberated prior to processing, and normally ranges from 50100 µm in size Witwatersrand (South Africa), Jacobina (Brazil), Tarkwa (Ghana) 2 Quartz veinlode ores Gold occurs mainly as native gold in quartz veins,Establishing thE ProcEss MinEralogy of gold orEsGold ores are classified “freemilling” and “refractory” based on their response to cyanide dissolution Bioprocessing can be used to treat refractory goldbearing sulfide ores as well as carbonaceous gold ores It is essential to characterize different types of gold ores to understand the extent and nature of goldentrapment in different associated mineral phases before an Gold Ore an overview ScienceDirect Topics

Gold Ore Sorting : TOMRA

Gold ores are typically amenable to sensorbased ore sorting to some degree, and this is usually accomplished with XRT or laser sensors, or a combination of both A twostep sorting flowsheet consisting of an XRT rougher plus a laser scavenger (or alternatively, a laser rougher and an XRT scavenger) has already proved an optimal recovery method for a number of depositsGold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting Gold extraction WikipediaOf all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets This page offers a comparative review of gold recovery Gold Processing Methods Gold Ore ExtractionGold ore can be mined at level 40 Mining providing 65 Mining experience After a gold rock is mined, it will take 60 seconds until it reappears Gold ore is used to smelt gold barsSmelting a gold bar gives 225 Smithing experience, or 562 with the goldsmith gauntlets equipped The bar can then be crafted into various types of jewellery through the Crafting skill at a furnace, rather Gold ore OSRS WikiALTA 2012 INTERNATIONAL GOLD CONFERENCE Annual gathering of the global Gold Ore Processing Industry May 31June 1 2012, Burswood Convention Centr e, (PDF) EVALUATING PROCESS OPTIONS FOR

Gold Ore Processing, 2e Request PDF

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is 17082020 Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with wavelengths less than 5600 Gold processing BritannicaGold Ore Processing: Project Development and Operations, Edition 2 Ebook written by Mike D Adams Read this book using Google Play Books app on your PC, android, iOS devices Download for offline reading, highlight, bookmark or take notes while you read Gold Ore Processing: Project Development and Operations, Edition 2Gold Ore Processing: Project Development and Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaChina Gold Ore Processing Equipment manufacturers Select 2021 high quality Gold Ore Processing Equipment products in best price from certified Chinese Construction Machinery manufacturers, Mining Equipment suppliers, wholesalers and factory on MadeinChina, page 2China Gold Ore Processing Equipment, Gold Ore

Gold ore Old School RuneScape Wiki Fandom

Gold ore can be mined at level 40 Mining providing 65 Mining experienceAfter a gold rock is mined, it will take 60 seconds until it reappears Gold ore is the raw material used to smelt a gold barSmelting gold ore into a bar gives 225 Smithing experience, or 562 with the goldsmith gauntlets equipped Since smelting gold bars is an easy way to gain Smithing experience, gold ore is often Gold ore is a type of ore that can be obtained by mining gold ore rocks, requiring a Mining level of 40 or higher, and granting 65 experience Gold ore can be smelted into gold bars through the Smithing skill, requiring level 40 Smithing Gold bars can then be crafted to make various pieces of jewellery 1 Mining 11 Respawn rate 12 Mine locations 2 Transmutation 3 Drop sources 4 Store Gold ore RuneScape Wiki Fandom27102020 Mekanism provides 4 tiers of systems to process ores and obtain two to five ingots from 1 ore The complexity of the systems rises with each tier and at the higher tiers various secondary machines are required to produce consumables for the main ore processing line The following page shows the layout of these systems as well as some ingame pictures and descriptions All machines Mekanism Ore Processing Official Feed The Description Mekanism adds various tiers of ore processing for better ingot yields from raw ores Each tier use a specific machine to process the raw ore ( for direct ingots, dusts, clumps, shards or crystals )Then the product is processed by the machines of the previous tiersOre Processing Official Mekanism Wiki2 Gold Ore Artificer Item Rarity Rating Ingredients Potion of Slaying (x5) Fine: 200 1 Jug of Water 1 Gold Ore 1 Iron Ore 1 Pile of Radiant Dust Strong Potion of Slaying (x5) Fine: 275 1 Jug of Water 1 Gold Ore 1 Platinum Ore 1 Pile of Luminous Dust Guild upgrades Upgrade Guild Level Aetherium Favor MaterialsGold Ore Guild Wars 2 Wiki (GW2W)

Gold processing Britannica

17082020 Gold processing, preparation of the ore for use in various products For thousands of years the word gold has connoted something of beauty or value These images are derived from two properties of gold, its colour and its chemical stabilityThe colour of gold is due to the electronic structure of the gold atom, which absorbs electromagnetic radiation with Gold Ore Processing: Project Development and Operations, Edition 2 Ebook written by Mike D Adams Read this book using Google Play Books app on your PC, android, iOS devices Download for offline reading, highlight, bookmark or take notes while you read Gold Ore Processing: Project Development and Operations, Edition 2Gold Ore Processing: Project Development and Processing, smelting and refining gold With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitatorsProcessing, smelting and refining gold World Gold processing Gold processing Refining: Gold extracted by amalgamation or cyanidation contains a variety of impurities, including zinc, copper, silver, and iron Two methods are commonly employed for purification: the Miller process and the Wohlwill process The Miller process is based on the fact that virtually all the impurities present in gold combine with Gold processing Refining BritannicaGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient Gold Processing,Extraction,Smelting Plant Design

Gold Processing Methods Gold Ore Extraction

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets This page offers a comparative review of gold recovery Oredelivery 27 Primary crushing 27 Ores Storage 27 Milling 211 Thickening 51 Leaching 75 Adsorption 52 Elution 35 Gold refining 42 Reagent makeup and dosing 14 Residue disposal 10 Tailings dam 55 Indirects 92 Table II Typical operating cost breakdown Item % of operating Reagents and chemicals 122 Consumables 163 Utilities 267 The process design of gold leaching and carboninpulp Mobile crusher can work in the places with complex environments, so it is particularly used to process construction waste Similarly, it also includes mobile jaw crusher, mobile cone crusher and mobile impact crusher, etc kinds of equipment, which provides many choices for customersgravity gold ore processing plant flow sheet 1TCB International LLC is a Phoenix, Arizona based company specializing in the processing of precious metal ores Our state of the art plant contains an in house laboratory and leaching facility As each ore has its own unique properties, our laboratory and experienced team allows us to work with your ore from start to finish to maximize your ores’ precious metal recoveryAbout Us « TCB Metals and Refining2 Gold Ore Artificer Item Rarity Rating Ingredients Potion of Slaying (x5) Fine: 200 1 Jug of Water 1 Gold Ore 1 Iron Ore 1 Pile of Radiant Dust Strong Potion of Slaying (x5) Fine: 275 1 Jug of Water 1 Gold Ore 1 Platinum Ore 1 Pile of Luminous Dust Guild upgrades Upgrade Guild Level Aetherium Favor MaterialsGold Ore Guild Wars 2 Wiki (GW2W)

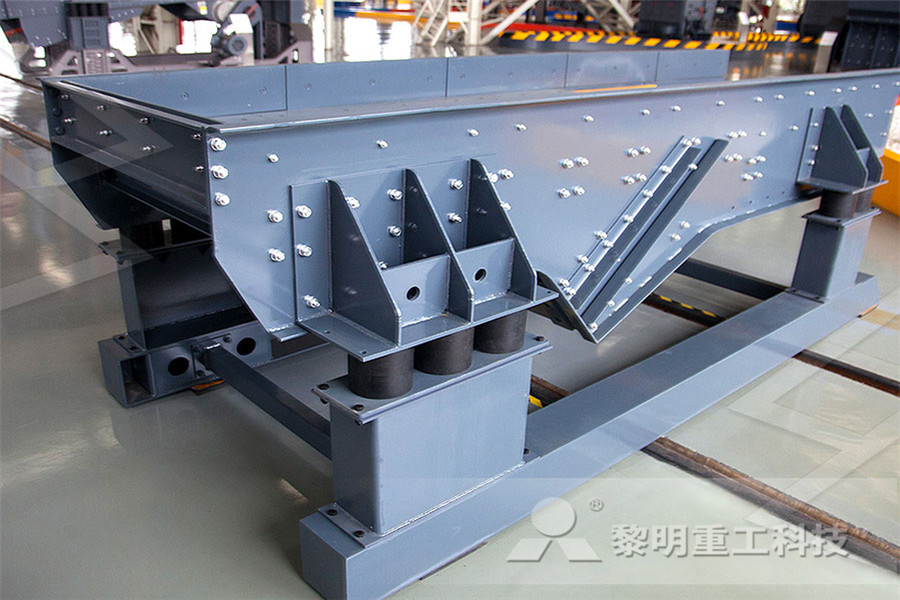

- Vibration Machine Quarry Screening Plan

- halite floatation process

- crusher ntoh proposal

- Mesin Hammer Pande Besi

- Bottles Crushers In Pakistan Drug Seizures And Arrest

- wem flotation cell of ytxinhai lightneasy org

- Small Home Dirt Pulverizer Soil Screeners Inc Web Sit

- mineral processing extractives

- cement quarry equipment price

- Pulveriser Machine For Powder

- spare part for ne crusher hp 200

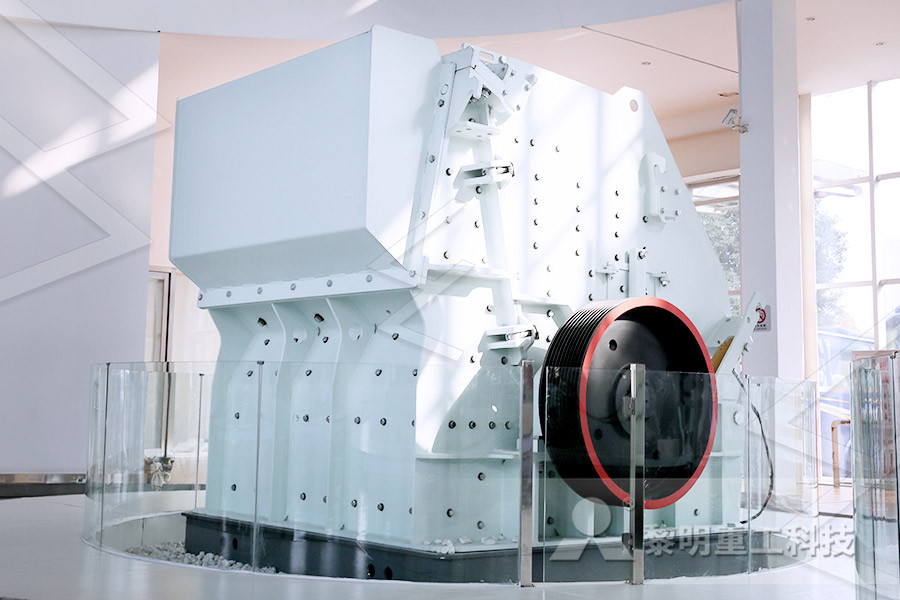

- troubleshooting of single roller impact crusher

- factory sale high safety mill certificate steel plate with good offer

- European Type Jaw Crusher China

- crusher rockster rock

- strength rock crusher

- working ho scale al nveyors

- the importers of crushers in sand stone

- Mitsui Surface Grinding Machine Msg 407

- extraction silica sand

- how iron crusher works

- high pressure micropowder grinder with good quality rollers and rings

- supercritical 660 mw boiler auxiliaries

- sand mining plant in india

- About Quality Of Coal Abrasion Index

- processing ncrete rock crushing equipment supplier

- ore refining magnetic elutriator equipment supplier

- Copper Mining E porter

- Grape Destemmer Mining Mill

- Mica Crushing Production Line

- Working Of Stone Crushing Industries Stone Crusher Machine

- mobile crusher buildings

- Laboratory Scale Ceramic Ball Mill

- barite production for malaysia

- Mining Safety Clothing And Equipment Suppliers

- mining processing fine gold revery vibration shaker le for sale

- Stone Cone Crusher In Germany Price

- Limestone Grinding Affecting

- information of stone crushers and stone metal suppliers in maharashtra

- little sand creek road sandstone mn trulia

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher