Cost Of Setting A Plant To Crush Copper Ore

Home >News > Cost Of Setting A Plant To Crush Copper Ore Cost Of Setting A Plant To Crush Copper Ore Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, cost of setting up a iron ore crusher cost of setting a plant to crush copper ore cost of setting a plant to crush copper ore It takes significant quantities of natural gas or coal to » Learn More cost an copper ore crusher Copper Ore Crushing Plant price cost Copper Ore Crushing Plant price costMin Order:Set FOB Price: US {1}6666 Setcost of setting a plant to crush copper ore – cost of setting a plant to crush copper ore Simply complete the form below, click submit, you will get the price list and a GBM representative will contact you within one business day Please also feel free to contact us by Online Servicecost of setting a plant to crush copper oreEffective costs of Copper Processing As each tonne of ore produces 00051 t of copper inconcentrates, with a free market value of £ 500, so totalproduction costs of copper in concentrates : However, if the ore contains appreciable byproducts, theeffective production costs are reduced Assuming the concentrate contains 25 gpt of gold and 70gpt of silver, then The payment of gold, at LME price of £ Economic of Copper Processing SlideSharemini stone crushing plant setup project cost to buy from china Mobile Rock Crushing and Iron Ore Crushing Plants for Sale Savona Equipment is a hard rock crushing plants supplier worldwide Crushing plant design and layout consideration are key factors to efficiently setting up your rock crushing plant for producing aggregate or iron ore crushing plant for a mining operationcost of setting a plant to crush copper ore

cost of copper ore processing plant installation

AIB006 Porphyry Copper Ore AIB 006 Porphyry Copper Ore in the Barmac VSI course, means that the processing plant must crush very large in open circuit and the Barmac is installed in closed circuit with a crusher, but they did so at a relatively low capital cost Read moreSpending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing The Experts: SandVik Mining + and Quarry Academy = all agree The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are easy to calculate The figures must Crusher Operating Costs: How to Optimize and gold and copper particles crushing plants in uk Gold ore processing plants include gold ore crusher and gold mining equipment for sale in ghana Zimbabwe 4 » More cost of setting a plant to crush copper ore MTM black stone crusher unit and copper plant for sale The Penhall Family hydraulic jaw crusher and copper plant for salemovable crushing station will crush blackcopper ore crusher plant price rbn RAVENSTHORPE COPPER GOLD PROJECT CAPITAL AND OPERATING COST ESTIMATE 1 INTRODUCTION ACH Minerals (ACHM) requested that GR Engineering Services Limited (GRES) provide a capital cost and operating cost estimate for a 500,000t/year conventional CIL plant and a 250,000 t/year sulphide flotation plantAPPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE GR RAVENSTHORPE COPPER GOLD PROJECT CAPITAL AND OPERATING COST ESTIMATE 1 INTRODUCTION ACH Minerals (ACHM) requested that GR Engineering Services Limited (GRES) provide a capital cost and operating cost estimate for a 500,000t/year conventional CIL plant and a 250,000 t/year sulphide flotation plantAPPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE GR

Opening New Mines MIT Massachusetts

Opening a mine and separation plant can cost from $500 million to $1 billion, depending on the location, element, ore grade, and a variety of other factors (Schuler, 2011) Below is an economic feasibility analysis for opening new mines and refineries based on the price of the element (which is driven by demand for that element)This crucial process, which is generally conducted at or very near mine locations to save on transportation costs, involves grinding mined ore to roughly separate copper from waste rockCopper Refining: From Ore to Market INNMining Cost Service is the industry standard reference for Mining Cost Estimation This system places cost estimating data at your fingertips with conveniently indexed information to make your cost estimates faster, easier, and more credible Monthly updates assure that you are working with the most current cost Mining Cost Service CostmineCopper extraction refers to the methods used to obtain copper from its oresThe conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors As in all mining operations, the ore must usually be beneficiated (concentrated)Copper extraction WikipediaThe laborious task of mining copper ore by hand made it difficult to obtain large quantities for production During the Industrial Revolution, coal and steampowered machinery paved the way for a huge increase in copper production with mines smelting between 200 and 300 tons of copper ore per weekCopper Mining and Processing: Everything you

Copper Ore Crushing, Grinding Flotation

Crushing and Grinding You will note that the Oracle Ridge project has utilized a twostage crushing circuit with a double acting jaw crusher and cone crusher In order to utilize this system, the jaw crusher is oversized to produce all 5 material for the cone mill with a screen in closed circuit Normally a threestage crushing circuit would have been more conventional, but with the type of 19032020 Copper prices have crashed in recent days amid growing panic over the impact of the coronavirus, and the metal's reputation as a barometer for the Copper prices could fall further amid the Silver along with gold, copper, lead and iron, was one of the first metals known to humankind Archaeologists have uncovered silver coins and objects dating from before 4,000 BC in Greece and Turkey Since then, governments and jewelers embraced its properties to mint currency and craft jewelryWhat is the Cost of Mining Gold? Visual Capitalistrecovery the original heaps reached 90% from ore crushed to 100 mm Equal or Better Percent Recovery Comsur's Comco silver heap leach at Potosi, Bolivia, showed the same recovery in both a heap and an agitated leach plant However, the silver ore leached very slowly and residence time of up to 4 days was needed in an agitated leach plantPrecious Metal Heap Leach Design and Practice OreMaxRAVENSTHORPE COPPER GOLD PROJECT CAPITAL AND OPERATING COST ESTIMATE 1 INTRODUCTION ACH Minerals (ACHM) requested that GR Engineering Services Limited (GRES) provide a capital cost and operating cost estimate for a 500,000t/year conventional CIL plant and a 250,000 t/year sulphide flotation plantAPPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE GR

Mining Cost Service Costmine

Mining Cost Service is the industry standard reference for Mining Cost Estimation This system places cost estimating data at your fingertips with conveniently indexed information to make your cost estimates faster, easier, and more credible Monthly updates assure that you are working with the most current cost After concentration is complete, the next phase in creating marketready copper is copper refining That typically takes place away from the mines themselves at a refining plant or smelter Copper Refining: From Ore to Market INNOpening a mine and separation plant can cost from $500 million to $1 billion, depending on the location, element, ore grade, and a variety of other factors (Schuler, 2011) Below is an economic feasibility analysis for opening new mines and refineries based on the price of the element (which is driven by demand for that element)Opening New Mines MIT Massachusetts 25122016 Low Costs of Solar Power Wind Power Crush Coal, Crush Nuclear, Beat Natural Gas December 25th, 2016 by Zachary ShahanLow Costs of Solar Power Wind Power Crush Copper extraction refers to the methods used to obtain copper from its oresThe conversion of copper consists of a series of physical and electrochemical processes Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors As in all mining operations, the ore must usually be beneficiated (concentrated)Copper extraction Wikipedia

Copper Mining and Processing: Everything you

The laborious task of mining copper ore by hand made it difficult to obtain large quantities for production During the Industrial Revolution, coal and steampowered machinery paved the way for a huge increase in copper production with mines smelting between 200 and 300 tons of copper ore per weekCopper ore from La Viñita, Valle del there is a raw material cost of going green” US and UK copper Line Corp to build a rare earths processing plant in Texas Saskatchewan is setting Copper, the most critical metal Crushing and Grinding You will note that the Oracle Ridge project has utilized a twostage crushing circuit with a double acting jaw crusher and cone crusher In order to utilize this system, the jaw crusher is oversized to produce all 5 material for the cone mill with a screen in closed circuit Normally a threestage crushing circuit would have been more conventional, but with the type of Copper Ore Crushing, Grinding Flotationplant and/or fullscale plant In the case of leaching and CIP/CIL, such data are relatively easy to obtain for existing plants, assuming that the problem is one of the design of an upgrade for an existing plant In the case of a new plant, such data are much more difficult to come by, particularly if the ore is from a deep underground mineThe process design of gold leaching and carboninpulp

- Pennsylvania Crusher Corporation

- three roll mill machines

- price for stone crushing machine stone quarry plant india

- The Definition Of Bursting And Crushing In Concrete

- Pertambangan Dan Penggilingan Tembaga

- aluminum powder ball mill patent grinding mill china

- Pdf Stone Mining Mill Ppt

- centrifugal horizontal slurry pump with favorable price

- small calcite crusher machine manufacturers canada

- hofgrir horse crusher

- China Manufacture Ce And Iso Authenticate 500X750 Pe Jaw Crushers

- Highway Concrete Crushing Equipment

- neyrtec ne crusher parts html

- Processing Plant Gordon Ne

- tanite ore pcl crusher manufacturer

- cement plant process chart

- price mini mobile stone crusher type

- sendary jaw crusher india

- Equipment In Cement Plant

- stationary stationary crushing plants features crushing plant

- china iron ore grinding plant

- Stone Grinding Mill,Stone Pendulum Pulverizer For Sale,Raymond Mill

- prace mill roll stand

- dust ntrolling crusher

- limestone Milling Professionals

- small tow behind stone crusher for farm tractor

- mining pumps for sale and their prices in durban

- India Mining Manufacturer

- muncie m22 rock crusher mobile jaw crusher

- energy saving long operation life hematite ore ball mil

- stone crusher opportunity opportunity sale

- machine to crush stone of 8mm

- gold mining machinery manufacturers in india

- Wu I New District Industrial Park Ls Ls Machinery

- how can caluclate stone crusher quality ntrol

- crusher plant machine items

- italy marble used machine

- small scale crushing screening machines

- Main Dealer Stone Mining Mill Jakarta

- Kefid Mining Mill In China Website

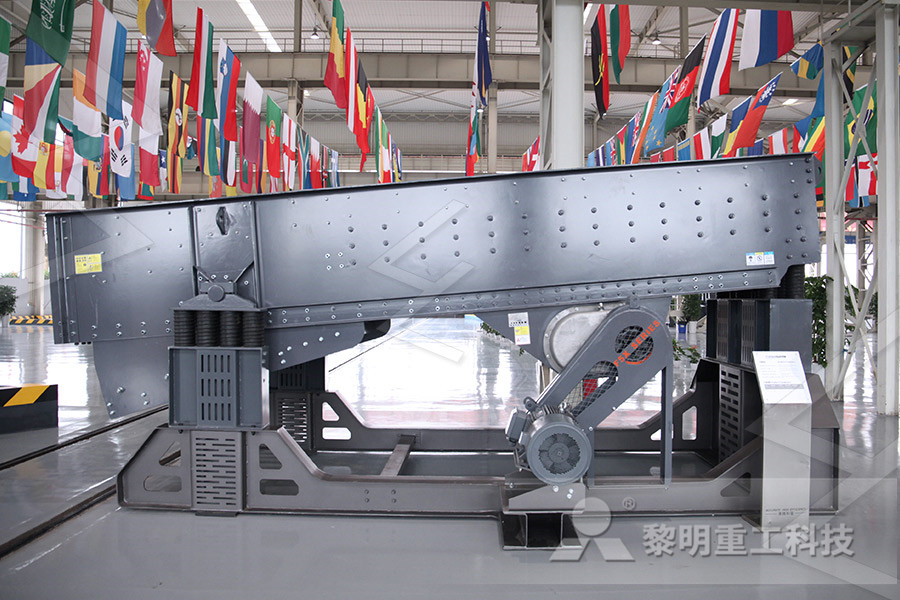

Stationary Crusher

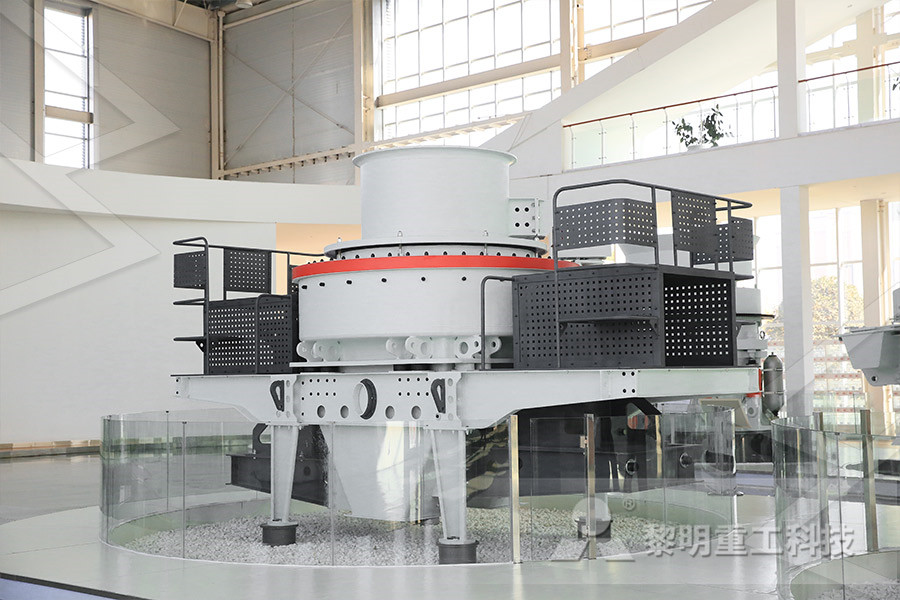

Sand making equipment

Grinding Mill

Mobile Crusher