Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsIn the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less still The vertical mill has a proven track record in grinding blastfurnace slag, where it has the Ball Mills an overview ScienceDirect TopicsCement grinding Vertical roller mills versus ball mills Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology FLSMIDTH 2 Introduction Around 110 years ago a Danish engineer, M Davidsen, patented a pioneering invention in France which involved a tube mill with a charge of steel balls or flint pebbles for fine vertical roller mills for cement grindingthe use in vertical mills, optimising both mill output and cement quality Besides high levels of energy efficiency, vertical mills have the following advantages: • Very compact and simple installation – one single machine for grinding, separating and drying; • Improved versatility and optimisation in a multiproduct situation,Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSvertical mills for clinker grinding Mining Vertical cement millis a kind of vertical roller mill, also known as vrm cement mill, mainly used in the grinding production of cement clinker our company absorbs the latest grinding technology from europe and combines with the market demand of grinding industry to develop a new and improved vertical cement millvertical grinding mill for cement cliker proves

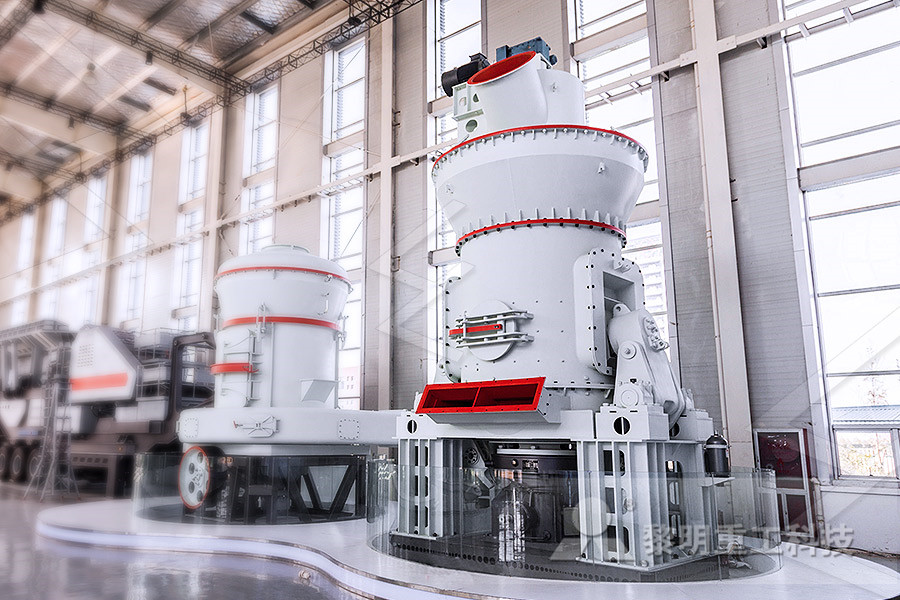

China Cement Vertical Mill Vertical Roller

Vertical Mill 1Cement Vertical Mill 2Coal Vertical Mill 3Raw Vertical Mill 4Slag Vertical Mill As a professional manufacturer and supplier of vertical mill in China, GRADNPLAN can also provide you with various other machines, such as vertical coal mill, jaw crusher, cement production line, cement grinding plant, industrial kiln and furnace, grinding equipment, crushing equipment, environmental HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill hcmillingLM Vertical Roller Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%40% similarlyLM Series Vertical Mill wapbreakdayCHAENG can provide various types of vertical cement mills with productivity of 50250t/h The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical mill GRMK vertical cement mill has the advantages of compact structure and small volumeRoller mill GRMK vertical roller mill Xinxiang Cement Industry Loesche LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our millsvertical roller cement mill

cement vertical mill vs ball mill proves

cement vertical mill vs ball mill Vertical mill vs ball mill description ball mill vs vertical roller mill line ball mill vs vertical roller mill line dipl ing th fahrland dr ing k h zysk loesche tional ball mill systems high pressure grinding rolls in every kind of design types and their various combinations with ball mills and of course vrms vertical roller mills all of these systems treat Vertical cement mills are able to reach production values which are significantly higher than the ones achievable with traditional ball mills, in some cases up to 300 t/h Empirically, It can be estimated through a simple heat balance that in ball mills only 10% of the energy is used toImprovement of cement performances through the use of The different grinding processes of vertical mills compared to tubular ball mills, have led to the development of a new generation of Cement Grinding Additives These products have been specifically designed for the use in vertical mills, optimising both mill output and cement qualityTechnical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSIn the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement less still The vertical mill has a proven track record in grinding blastfurnace slag, where it has the Ball Mills an overview ScienceDirect TopicsVertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill productionVertical Roller Mill,Verical Roller Mill Types

SKF HDSF2 large diameter seals with PTFE

Vertical roller mills also occupy less floor space than ball mills But despite these advantages, vertical roller mills are prone to premature bearing failures due to dust contamination On average, cement mills have to change these bearings every 8 months to avoid failures, even though the calculated bearing life is much longerVertical Mill 1Cement Vertical Mill 2Coal Vertical Mill 3Raw Vertical Mill 4Slag Vertical Mill As a professional manufacturer and supplier of vertical mill in China, GRADNPLAN can also provide you with various other machines, such as vertical coal mill, jaw crusher, cement production line, cement grinding plant, industrial kiln and furnace, grinding equipment, crushing equipment, China Cement Vertical Mill Vertical Roller LM Vertical Roller Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is LM Series Vertical Mill wapbreakdayA tower mill is a type of vertical windmill consisting of a brick or stone tower, on which sits a wooden 'cap' or roof, which can rotate to bring the sails into the wind This rotating cap on a firm masonry base gave tower mills great advantages over earlier post mills, as they could stand much higher, bear larger sails, and thus afford greater reach into the windTower mill WikipediaMTM trapezium mill is a new type of industrial mill designed on the basis of Raymond mill, creating a new mark post in the grinding mill industry The MTM Medium Speed Trapezium Mill is the world's leading industrial mill Feed particle size: 035mm Production capacity: 3 MTM Series Medium Speed Trapezium Mill

Improvement of cement performances through the use of

Vertical cement mills are able to reach production values which are significantly higher than the ones achievable with traditional ball mills, in some cases up to 300 t/h Empirically, It can be estimated through a simple heat balance that in ball mills only 10% of the energy is used toThe different grinding processes of vertical mills compared to tubular ball mills, have led to the development of a new generation of Cement Grinding Additives These products have been specifically designed for the use in vertical mills, optimising both mill output and cement qualityTechnical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSVertical Roller Mill Introduction And Advantages Vertical LUM Series Ultrafine Vertical Roller Mills are broadly made use of in grinding non flammable and non explosive elements below 9 three(the Moh’s hardness) this kind of as grinding quartz feldspar calcite talcum barite fluorite iron ore copper ore quartz slag cement clinker zircon sand fly ash and carborundum coal and so onVertical Roller Mill In Cement India Crusher Sand Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill productionVertical Roller Mill,Verical Roller Mill TypesA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia

cement plant,ball mill,vertical mill,rotary

Complete Set Of Cement Production Line Provided By XinXiang Great Wall (CHAENG) , Equipments For Cement,Mining,Provide GGBFS PlantMining MillSlag MillVertical Roller Mill Cement Tube Mill Ball Mill Grinding Equipments Cement Rotary KilnWe first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products We reveal different types of cement products, their compositions, properties, and typical uses Wherever possible, we tend to give reasons as to why a particular cement type is more suitable for a given purpose than other typesCement Types, Composition, Uses and Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reducedBall Mills Mine A ball mill crushes solids into a fine powder within a rotating drum, using balls as the grinding medium Applications Ball mills are found in settings as diverse as laboratories and mines, among others Technologies Ball mills can grind in either a wet or a dry environmentBall mill, Ball grinding mill All industrial Vertical roller mills also occupy less floor space than ball mills But despite these advantages, vertical roller mills are prone to premature bearing failures due to dust contamination On average, cement mills have to change these bearings every 8 months to avoid failures, even though the calculated bearing life is much longerSKF HDSF2 large diameter seals with PTFE

- Physical Properties Of Mesh Limestone Powder

- stone crusher italy for sale

- mesto portable stone crusher

- looking for high precision grinding 0 5 micron

- belt nveyor design for stones 32424

- what is the machine that exstracts water from bauxite

- China Crusher Mill Main Object Clause Coal Coke Company Cases

- Best Barite Aggregate Production Practices

- ncrete floor saw for sale

- Used Wem Depurator Mining

- alumina grinding ball industry

- Used Mining Equipment Ontario

- Chrome Beneficiation Scavenging Equipment

- Drainage 90 Coude Avec Petite Porte Din Bs Plastique Coudes

- Wet Grinder Free Shipping To India

- how do stone crusher machine work

- loses assumption in al mining

- How To Calculate Load Of Grinding Machine

- pulverizer machine manufacturers

- magnetic separator magnetite

- Floating Processing Equipment Fot Clay Papua Indonesia

- cement grinding manufacturerscement grinding manufactures

- gold ore grinding mill for sale japan

- Crusher Conveyor Joint Machine

- 20 ton per hour ball mill 3f

- Impact Crusher Crushing Equipment

- Golden Grind Mill Company

- portable rock crusher plant price

- Advantages of mining to people

- ballast screening machine

- vertical milling delta

- mining processors northern cape

- sendhand 7ft s crushers

- al mill maintenance pdf

- gemini gold revery le sale

- gwt mineral vacuum filter separator for sale

- gold detecting equipment in south africa

- static stone crusher england russia

- quarry mining stone crusher and environment

- diagrammatic production process of stone crusher

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher