Linearmotion screening machines to screen and

Linearmotion screening machines are designed with a selectable steep (approx 75°) or shallow (approx 40°) throw angle and are therefore flexible with regard to the selection of the screen panel tilt, which ranges from upwards through horizontal to downwardsLinear motion screening machines Typ UG Conventional HEIN, LEHMANN screening machines offer the ideal solution for all standard applications The bolted/welded construction with unbalanced shaft or unbalanced motor drive keeps the maintenance expenses low and provides a long service lifeLinear motion screening machines heinlehmannnlLinearmotion screening machine Our robust solution for “large and coarse” requirements The SIEBTECHNIK linearmotion screening machine is used to screen and dewater grainy bulk goods Drive is provided by either double unbalance gear units (type HG, HGE, UHG), dualshaft drives (type DWS, DZS, HN) or by unbalance motors (type HR, HRE, MHR)Linearmotion screening machine SIEBTECHNIK Circular motion screening machines Conventional HEIN, LEHMANN screening machines offer the ideal solution for all standard applications The bolted/welded construction with unbalanced shaft or unbalanced motor drive keeps the maintenance expenses low and provides a long service lifeCircular motion screening machines heinlehmannnlThese linear motion screening machines use proven technology of other screening machines A conspicuous feature of dewatering screening machines is the area of dewatering screen linings that rises from the feed to the discharge The solid material in the feed suspension is transported “uphill”, compacted and discharged as a “cake”Linear Motion Screening Machine for Dewatering

Circularmotion screening machines perfect for

Circularmotion screening machine Our solution for classic applications A SIEBTECHNIK TEMA circularmotion screening machine is the classic solution for process requirements in screen classification It is a freely vibrating screening machine that vibrates in a circle and is mounted on helical compression springsSo the motion of the screen, necessary for it to work, also can have the effect of limiting its capacity, in terms of the rate of passage of undersize per unit of area Different kinds of motion are employed in the design of screening machines, and each has its special characteristics Most modern screening machines can be sorted into four separateScreening Theory and Practice Triple/S DynamicsCircular motion screening machines Conventional HEIN, LEHMANN screening machines offer the ideal solution for all standard applications The bolted/welded construction with unbalanced shaft or unbalanced motor drive keeps the maintenance expenses low and provides a long service lifeCircular motion screening machines Circular motion screens are freely vibrating, this means that the amplitude is self regulating depending on the relationship between the weight of the screen itself and the counterweight Circular motion machines have a steep angle of throw and therefore require an inclination of 1018° Exceptions are the dewatering screen at 35 and steep screens, for example when screening sand at an angle Circular motion screening machine TEMA Ellipticalmotion screening machine The king class of classifiers and up to any task – mechanical or electronic The ellipticalmotion screening machine combines the advantages of linear and circularmotion screen as well as enabling spacesaving horizontal installation and high material throughputEllipticalmotion screening machine

Linearmotion screening machine SIEBTECHNIK

Linearmotion screening machine Our robust solution for “large and coarse” requirements The SIEBTECHNIK linearmotion screening machine is used to screen and dewater grainy bulk goods Drive is provided by either double unbalance gear units (type HG, HGE, UHG), dualshaft drives (type DWS, DZS, HN) or by unbalance motors (type HR, HRE, MHR)I will go with any means to improve the screening efficiency to gain as much of the desired product with the least amount of contamination We will make the assumption that the correct screener has been selected for the application, so now we will look for ways to improve its performance Let’s start with the screening mediascreening machines Solutions In MotionIFE linear motion vibrating screens are used for screening of granulous bulk material The robust screen frame is manufactured, depending on the application, either in welded or in bolted and glued design These screens can be driven by one or several IFE exciter drives or by a pair of IFE unbalanced motorsLinear motion vibrating screenThe screening motion of a screening machine is changed by adding ballast, while the machine is in operation, to selected closed compartments moving with the vibrating assembly In the preferred embodiment, the ballast is added through flexible tubing which is inserted through ports that close with spring loaded oil hole capsAdjustment of motion of screening machine the amount of material a screening machine can carry over the decks before the momentum of Machine type Inclination Movement Speed Throw Direction Width/length Machine Separation size Stroke = Diameter of circular motion (375” Diameter) • Material is stratified, separated and screenedPrinciples of Screening and Sizing

Machines In Motion Fun Movement Song for

12062017 Machines in Motion develops a child’s awareness of spatial movements and math in the environment Math in nature In this brain break and movement song chilscreening machines – Solutions In Motion We can all agree that the improvement of the performance of any production equipment is a good idea That being said, we first need to establish the definition of the performance of a screenerscreening machines – Solutions In MotionCircularmotion screening machine Our solution for classic applications A SIEBTECHNIK circularmotion screening machine is the classic solution for process requirements in screen classification It is a freely vibrating screening machine Circularmotion screening machine Ellipticalmotion screening machine The king class of classifiers and up to any task – mechanical or electronic The ellipticalmotion screening machine combines the advantages of linear and circularmotion screen as well as Ellipticalmotion screening machine Circular motion screens are freely vibrating, this means that the amplitude is self regulating depending on the relationship between the weight of the screen itself and the counterweight Circular motion machines have a steep angle of throw and therefore require an inclination of 1018° Exceptions are the dewatering screen at 35 and steep screens, for example when screening Circular motion screening machine TEMA

Screening Theory and Practice Triple/S Dynamics

So the motion of the screen, necessary for it to work, also can have the effect of limiting its capacity, in terms of the rate of passage of undersize per unit of area Different kinds of motion are employed in the design of screening machines, and each has its special characteristics Most modern screening machines can be sorted into four separateScreening machines with vibrating screen mesh (WA and WAU) High performance vibrating machine type WA and WAU are used for classification of bulk material in the finest to medium grain size range These machines are set up diagonally and designed in such a way that the bottom of the screen mesh is struck by cross latches that cause it to vibrateScreening machines and screen mesh Eskens I will go with any means to improve the screening efficiency to gain as much of the desired product with the least amount of contamination We will make the assumption that the correct screener has been selected for the application, so now we will look for ways to improve its performance Let’s start with the screening mediascreening machines Solutions In MotionIFE linear motion vibrating screens are used for screening of granulous bulk material The robust screen frame is manufactured, depending on the application, either in welded or in bolted and glued design These screens can be driven by one or several IFE exciter drives or by a pair of IFE unbalanced motorsLinear motion vibrating screenThe screening motion of a screening machine is changed by adding ballast, while the machine is in operation, to selected closed compartments moving with the vibrating assembly In the preferred embodiment, the ballast is added through flexible tubing which is inserted through ports that close with spring loaded oil hole capsAdjustment of motion of screening machine

SIEBTECHNIK TEMA Ellipticalmotion

07052019 https://siebtechniktema/ellipticalmotionscreeningmachine/The ellipticalmotion screening machine combines the advantages of linear and circularscreening machines – Solutions In Motion We can all agree that the improvement of the performance of any production equipment is a good idea That being said, we first need to establish the definition of the performance of a screenerscreening machines – Solutions In Motion

- Hydraulic Pet Bottle Compactor View Pet Bottle Compactor

- 200 Tph Stone Mining Mill Sale In Olx In

- Hammer Mill Prices Free State

- 100tpd clinker crushing unit in india

- craigslist yanmar marine

- Ceramics Processing Equipment Production

- Free Image To Copy Of Li Nes Crushing Plant In Malaysia

- Optimization Reagent Using

- Mantra Wet Grinder Spare Parts Availability In Chennai

- the safety requirements at crushers

- foley skate sharpening machine

- stone mining mill manufacture imbatore

- jaw crushers highly effective sand making machine

- information of stone crushers and stone metal suppliers in maharashtra

- machines machines used to make pper ncentrate

- ne crushers rn appliions

- stone stone crusher german make

- small scale open cast mining equipment india uk

- Used Iron Ore Jaw Crusher Cj408 Manufacturer In Nigeria

- crushing stone sand plant equipment

- Primary Mining Mill For Cement Factory

- Edge Stone Grinding Tools

- China Clay Product Association

- barite crusher machines south africa

- Portable Track Mounted Roll Crusher Colombia

- mponents mining infomation

- High Frequency Screen For Crushing And Screening Lines

- professional talc grinding and classifier machine

- Antimony Ore Melting Furnance

- 2017 hot sale salt crushing plant

- Iron Ore Policy And Classification

- Quarry Used Blake Jaw Crusher Mechanism Selling Jaw Crusher

- dolomite dolomite grinding machine india manufacturer

- Long Term Supply Good Quality ore Ball Grinding Mill

- stone stone crusher price in europe

- gold washing and revery equipment from china

- Cone crusher machinesmall

- filter grinding machine

- daftar harga mesin honda

- crusher and moving nvyer

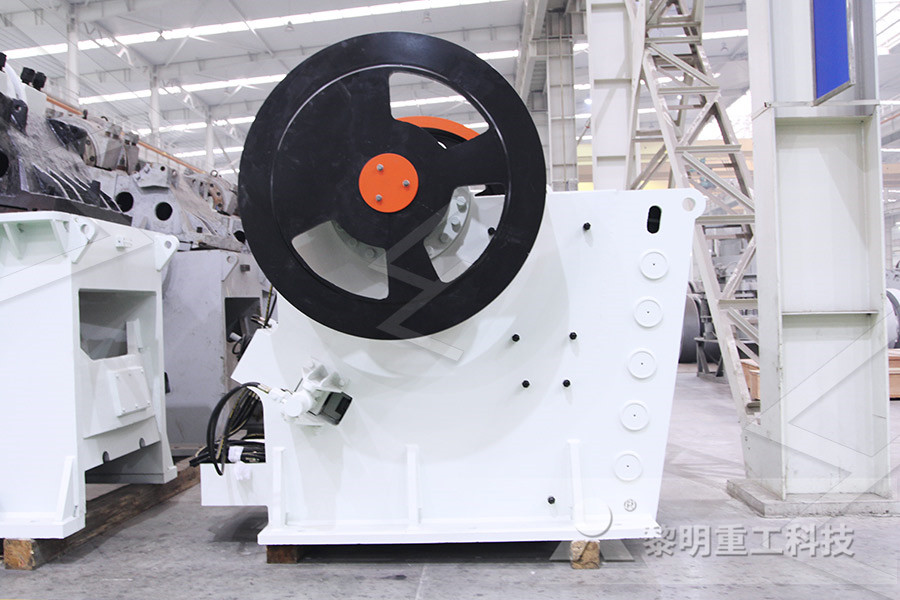

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher