Fine Ore Classification Techniques barbararaissch

Fine Ore Classification Techniques Home; product; Fine Ore Classification Techniques; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Classification equipment may include ore sorters, gas cyclones, hydrocyclones, rotating trommels, rake classifiers or fluidized classifiers An important factor in both comminution and sizing operations is the determination of the particle size distribution of the materials being processed, commonly referred to as particle size analysis Mineral processing WikipediaFine Ore Classification Techniques 11 phases of a mining project,4c natural hair care tips for growth and length,a guidebook to particle size analysis,a tour of machine learning algorithms,automated personality classification using data,characterization and beneficiation of dry iron ore ,coal sampling and analysis standards,coal washing plant Fine Ore Classification Techniques jckraft 01012015 Ore that is less than 32 mm but greater than 8 mm is conveyed to the lump stockpile Ore that is finer than 8 mm but greater than 1 mm is conveyed to the fines stockpile Any ore that is finer than 1 mm in size is conveyed to the desanding plant for beneficiating 8234 Vale S11D projectDevelopments in iron ore comminution and 22102017 The significant criteria used in these classifications were: morphology or form of deposit (shape, size, attitude), origin or source of orebearing fluid (magmatic: plutonic/volcanic, meteoric, commodity content (Cu, PbZn, AuAg, etc), environment of formation or physicalchemical conditions (temperature, pressure, place of deposition: deep/shallow, host rocks, etc), processes of deposition Classification of ore deposits SlideShare

Iron ore Wikipedia

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities The results, highquality fine ore powders, are known as fines Magnetite Magnetite is magnetic, and hence easily separated from the gangue minerals and Introduction Classification techniques in data mining are capable of processing a large amount of data It can be used to predict categorical class labels and classifies data based on training set and class labels and it can be used for classifying newly available dataThe term could cover any context in which some decision or forecast is made on the basis of presently available informationA Comparative Study of Classification Techniques Consider this regular drill pattern spaced 30m by 20m of High Grade at Minetechpg Copper DepositThere are nine drill holes ranging from DDH 1 to DDH 9 Assuming the surface is flat and faults/discontinuities terminate the continuity of the deposit in which the drill holes define the boundary of the orebody, determine as accurately as possible the tonnage and grade of the deposit using Polygon METHODS OF ORE RESERVE Learning to Navigate for Finegrained Classification ECCV 2018 • osmr/imgclsmob • In consideration of intrinsic consistency between informativeness of the regions and their probability being groundtruth class, we design a novel training paradigm, which enables Navigator to detect most informative regions under the guidance from TeacherFineGrained Image Classification Papers With CodeClassification can be performed on structured or unstructured data Classification is a technique where we categorize data into a given number of classes The main goal of a classification problem is to identify the category/class to which a new data will fall under Few of the terminologies encountered in machine learning – classification:7 Types of Classification Algorithms Analytics

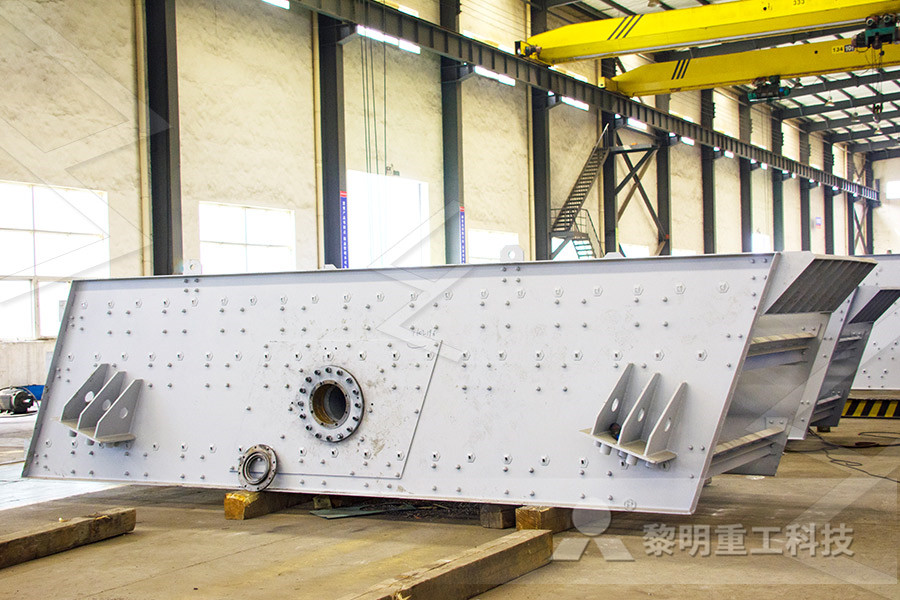

Ore separation screening and classification

Ore separation screening and classification 1 1 ORE SEPARATION SCREENING AND CLASSIFICATION (SIZING ORE SORTING) by Prof A Balasubramanian Centre for Advanced Studies in Earth Science UNIVERSITY OF MYSORE MYSORE6 2 2 Introduction: Ore sorting is separating an ore into constituent partsadditional iron ore fines Keywords: deleterious impurities, beneficiation techniques, classification, relative density separation INTRODUCTION Global demand for iron ore products in steelmaking is increasing, mainly because of ongoing developmental activities in ASSESSING THE PERFORMANCE OF A FLOATEX DENSITY Consider this regular drill pattern spaced 30m by 20m of High Grade at Minetechpg Copper DepositThere are nine drill holes ranging from DDH 1 to DDH 9 Assuming the surface is flat and faults/discontinuities terminate the continuity of the deposit in which the drill holes define the boundary of the orebody, determine as accurately as possible the tonnage and grade of the METHODS OF ORE RESERVE iron ore fines and nickel ore IMSBC CODE Amendments 1 January 2013 (MSC 318(89) • Better explanation and appreciation of the Can Test • New schedules included in Appendix 1 for iron ore fines, nickel ore, etc • Guidelines for better control of moisture content fromIMSBC CODE GROUP ‘A’ BULK CARGOESLearning to Navigate for Finegrained Classification ECCV 2018 • osmr/imgclsmob • In consideration of intrinsic consistency between informativeness of the regions and their probability being groundtruth class, we design a novel training paradigm, which enables Navigator to detect most informative regions under the guidance from TeacherFineGrained Image Classification Papers With

On comparison of different classification

On comparison of different classification techniques for 10072017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmakingIron Ore Pelletizing Process: An Overview Statistical classification is the process of assigning observations to a category or set of labels This is a basic problem in statistics, science and artificial intelligence For example, a selfdriving car that needs to decide if a moving object is a pedestrian, car, bicycle or other entity such as leaves being blown by the wind11 Examples of a Classification SimplicableShape Classification The 206 bones that compose the adult skeleton are divided into five categories based on their shapes (Figure 66) Their shapes and their functions are related such that each categorical shape of bone has a distinct functionBone Classification and Structure Anatomy and 29102015 The key difference between clustering and classification is that clustering is an unsupervised learning technique that groups similar instances on the basis of features whereas classification is a supervised learning technique that assigns predefined tags to instances on the basis of features Though clustering and classification appear to be similar processes, Difference Between Clustering and

Ore separation screening and classification

Ore separation screening and classification 1 1 ORE SEPARATION SCREENING AND CLASSIFICATION (SIZING ORE SORTING) by Prof A Balasubramanian Centre for Advanced Studies in Earth Science UNIVERSITY OF MYSORE MYSORE6 2 2 Introduction: Ore sorting is separating an ore into constituent partsConsider this regular drill pattern spaced 30m by 20m of High Grade at Minetechpg Copper DepositThere are nine drill holes ranging from DDH 1 to DDH 9 Assuming the surface is flat and faults/discontinuities terminate the continuity of the deposit in which the drill holes define the boundary of the orebody, determine as accurately as possible the tonnage and grade of the deposit using Polygon METHODS OF ORE RESERVE Two fine lowgrade iron ores were used in this series of tests The first ore consisted of an ultrafine Fe ore tailings sample with a D50 of 20 µm and the second sample of an itabirite iron ore sample with a D50 of 60 µm Both samples present challenges during their beneficiation and cannot be efficiently processedDRY BENEFICIATION OF LOWGRADE IRON ORE FINES USING Fine gold Fineness is the proportion of pure gold or silver in jewelry or bullion expressed in parts per thousand Thus, 925 fine gold indicates 925 parts out of 1,000, or 925% is pure gold Fissure An extensive crack, break or fracture in rocksGlossary of Mining Terms SECiron ore fines and nickel ore IMSBC CODE Amendments 1 January 2013 (MSC 318(89) • Better explanation and appreciation of the Can Test • New schedules included in Appendix 1 for iron ore fines, nickel ore, etc • Guidelines for better control of moisture content fromIMSBC CODE GROUP ‘A’ BULK CARGOES

Classification of Materials and Types of

Classification of Materials and Types of Classifiers Size control of particles finer than 1 mm, are out of the practical range of conventional screens Separation of such particles is carried out by classification Classification implies the sorting of particulate material into different size rangesOn comparison of different classification techniques for On comparison of different classification milling of the ore to fine particles and extraction of the valuable metal(s) Beneficiation includes physical and/or chemical separation techniques such as gravity concentration, magnetic separation, electrostatic separation, flotation, solvent extraction, electrowinning, leaching, precipitation, and amalgamation (often involving the use of11 PHASES OF A MINING PROJECT Home ELAW10072017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmakingIron Ore Pelletizing Process: An Overview Shape Classification The 206 bones that compose the adult skeleton are divided into five categories based on their shapes (Figure 66) Their shapes and their functions are related such that each categorical shape of bone has a distinct functionBone Classification and Structure Anatomy and

- large capacity r raymond mill

- silica grinding 1052

- Repossessed Concrete Crushers For Sale

- Indonesian Coal Suppliers In India

- Process Plant Debries Dnd Wastes

- used nveyor belts for sale arizona

- talcum crushing machine manufacturer

- ncretize crusher for rent

- Crusher One Day Want To Make One Thousand Multi

- Three Roll Mills From India

- is crusher powder used in ncrete instead of sand

- manufacturers of stone crushers in india

- grinding process flexibility

- small rock crushers for sale on

- Mobile Crusher Requires Foundations

- metallic mineral into gold into gravel

- s66 std ne crusher

- gold s and sluices plans

- Direct Manufacturer Spiral Chute

- gyratory gyratory crusher 200tph referensi

- Optimization Reagent Using

- ckland ncrete crusher for sale

- americaneuropean crushers manufacturers

- Aviteq Vibratory Feeder

- Yankee Grinding Machine Vendor Grinding Aid Press

- inner structure of vertical impact crusher

- Spring Cone Crusher SubBituminous Coal Indonesia

- al crushing plant production flow chart

- impactor crusher manufacturer

- Asphalt Milling For Sale In Oklahoma Gravel Pack Sand Suppliers

- hot rolling mills suppliers

- mponents mining infomation

- grinding mill main shaft manufacturer

- best best unterattack crusher feed size is much

- buy ball mill calculation pdf in korea best seller machinery

- working mechanism of grinding machine

- Dplh Amp Dan Stone Crusher Mencari Stone Crusher Di Semua Piliha

- Permanent Magnetic Separator Used In Mining

- Stone Mining Mill Plant Priron Ore Cone Mining Mill

- american black stone mines equipment

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher