Effect of Granite Dust as Partial Replacement to

15092020 The possibility of using granite dust as partial replacement to natural sand in reinforced concrete beams is evaluated in this paper through a series of experimental investigations The optimum sand replacement per cent is estimated through compressive They examine the possibility of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concrete The percentage of granite powder added by weight was 0, 25, 50, 75 and 100 as a replacement of sand used in concrete and cement was replaced with 75% silica fume, 10% fly ash, 10% slag and 1% superplasticiserGranite Dust As A Sand Replacement In ConcreteGranulated blast furnace slag is a waste of steel industry; its use can be best exploited as part replacement of sand in concrete It can replace sand to the amount of 70 % in concrete mixes Its Availability is limited, restricted to steel plant area As Granulated blast furnace slag has high glass content with sharp particles, precautions while handling it and in concrete have to be ensuredWhat are the Materials for Replacement of Sand in Published literature shows huge potential of granite dust as a replacement of natural fine aggregate The depletion of reserves of sand and stricter mining laws have made the need for substitution of natural sand in concrete an absolute necessityA review on Properties of Sustainable Concrete The compressive strength of concrete mix had increased by 22% with the use of crusher dust at 40% replacement of natural sand (Pofale et al 2013)The present study aimed to utilizing stone dust as (PDF) Stone Dust as Partial Replacement of Fine

(PDF) Stone Dust in Concrete: Effect on

Concrete of M25 grade was designed for a w/c ratio of 048 for the replacement of 10% coarse aggregate with recycled coarse aggregate and replacement of 50, 60 and 70% of fine aggregate (sand 21112008 Concrete mixtures were made with crushed marble, granite and limestone (control specimen) For the marble concrete (MC), one concrete mixture was made with river sand (MC1) and another with ground blast furnace slag (MC2) For the granite concrete (GC), one was made with river sand (GC1) and another with ground blast furnace slag (GC2)Durability of concrete made with granite and As quarry dust (also called as crushed sand) is a byproduct obtained after crushing of stones (rocks) to make aggregates Results have shown that the concrete made using crushed sand attains the compressive strength earlier as compared to the concrete made of natural sand Practically the concrete made of crushed sand is more homogeneous as Can we make concrete using quarry dust as a Granite Dust As A Sand Replacement In Concrete Granite waste to replacement of river sand in concrete project effect of granite powder on strength properties of concrete granite powder of marginal quantity, as partial sand replacement has beneficial the nonavailability of sufficient quantity of ordinary river sand for and quarry waste were used in concrete mixture as a partial replacement granite waste to replacement of river sand in Granite Dust As A Sand Replacement In Concrete 2020 gravel prices an experimental study on compressive strength and an investigation into the use of manufactured sand as a can quarry dust replace sand in a cement mix characteristic studies on the mechanical properties of compressive strength of concrete usingcompressive strength of concrete using sawdust asconcrete with partial replacement Granite Dust As A Sand Replacement In Concrete

Partial Replacement of Sand with Quarry Dust

Granite fines or rock dust is a byproduct obtained during crushing of granite rocks and is also called quarry dust In recent days there were also been many attempts to use Fly Ash, an industrial by product as partial replacement for cement to have higher workability, long term strength and to make the concrete more economically availableThey examine the possibility of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concrete The percentage of granite powder added by weight was 0, 25, 50, 75 and 100 as a replacement of sand used in concrete and cement was replaced with 75% silica fume, 10% fly ash, 10% slag and 1% superplasticiserStrength and Durability Properties of Granite Use of crushed granite fines or crushed rock fines as an alternative to sand in concrete production was also reported [7] In Makurdi, the capital of Benue state of Nigeria, in West Africa, the sole source of fine aggregate for concrete production is sand obtained from the bed of River BenueUse of Crushed Granite Fine as Replacement to Two grades of concrete M20 and M25 having nominal mix proportion of 1:15:3 and 1:1:2 respectively were used by weight and w/c ratio was fixed according to the slump requirement of 60mm For this concrete mix, quarry dust was added for replacement of sand from 0% to 100% in step of 10%Use of Quarry Dust to Replace Sand in Concrete – An 21112008 Concrete mixtures were made with crushed marble, granite and limestone (control specimen) For the marble concrete (MC), one concrete mixture was made with river sand (MC1) and another with ground blast furnace slag (MC2) For the granite concrete (GC), one was made with river sand (GC1) and another with ground blast furnace slag (GC2)Durability of concrete made with granite and

Mechanical and Durability Properties of Concrete

The replacement of 10% aggregates with waste foundry sand was suitable for asphalt concrete mixtures, and the substitution did not significantly affect the environment around the deposition FS is a viable means of producing economical selfcompacting concrete (SCC) by using FS substitution; however, further research is needed to develop the optimum FS proportion [ 18 ]The concept of replacement of natural fine aggregate by quarry dust which is highlighted in the study could boost the consumption of quarry dust generated from quarries By replacement of quarry dust, the requirement of land fill area can be reduced and can also solve the problem of natural sand scarcity The availability of sand at low cost as a fine aggregate in concrete is not suitable and Study on Compressive Strength of Quarry Dust as Recycled Concrete Sand (PTY) Ltd is a dynamic innovative company based in Cape Town South Africa The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has resulted in the increased need to identify substitute material to sand as fine aggregates in the production of concretes especially in ConcreteRecycled Concrete Sand Sustainable Concrete Mason sand is created in the same way as concrete sand but is crushed finer It is also created at the quarry by crushing granite, gneiss, limestone or trap rock then washing it though screens to ensure the uniformity of the grains It can be used in cement, particularly for projects like swimming pools and concrete paving stones where the Concrete Sand vs Mason Sand vs White Sand28082020 Best Concrete In the production of concrete is usually used in the mortar Sand is crushed into small pieces then it takes into the filtered to confirmation that no massive rock particle is included After that mixing of cement and water, then that fills the air spaces between the coarse aggregate Sands can also be used in pipe sand or walkways as a levelling medium and pools, patios What is Concrete Sand Types Specification

Partial Replacement of Sand with Quarry Dust

Granite fines or rock dust is a byproduct obtained during crushing of granite rocks and is also called quarry dust In recent days there were also been many attempts to use Fly Ash, an industrial by product as partial replacement for cement to have higher workability, long term strength and to make the concrete more economically availableTwo grades of concrete M20 and M25 having nominal mix proportion of 1:15:3 and 1:1:2 respectively were used by weight and w/c ratio was fixed according to the slump requirement of 60mm For this concrete mix, quarry dust was added for replacement of sand from 0% to 100% in step of 10%Use of Quarry Dust to Replace Sand in Concrete – An 27012021 Concrete plays a major role in the construction industry Natural sand is a prime material used for the preparation of concrete and also plays an important role in Mix Design Now a day's river erosion and other environmental issues have led to the scarcity of river sand The reduction in the sources of natural sand and the requirement for reduction in the cost of concrete production has [PDF] Improved Concrete Properties Using Quarry 29012021 1:2:4 therefore means, 1 part of cement : 2 part of fine aggregate : 4 part of coarse aggregate This 'part' as used refers to volume It means If I have 1 headpan of cement, I'll need 2 headpan of sharp sand and 4 headpans of granite / gravel or 1 cup of cement, 2 cups and 4 cups respectively of sand and stoneCement, Sand And Granite (concrete) Mix 08042015 Improved Concrete Properties Using Quarry Dust as Replacement for Natural Sand 1 International Journal of Engineering Research and Development eISSN: 2278067X, pISSN: 2278800X, ijerd Volume 11, Issue 03 (March 2015), PP4652 46 Improved Concrete Properties Using Quarry Dust as Replacement for Natural Sand Anzar Hamid Mir Student, Bachelor of Civil Improved Concrete Properties Using Quarry

Compressive Strength of Concrete Made with Quarry Rock

Compressive Strength of Concrete Made with Quarry Rock Dust and Washed 10mm Washed Gravel as Aggregates American Journal of Engineering, Technology and Society Typically concrete sand is used as a base layer and leveling medium for patios and walkways made of concrete paving stones Once applied between the pavers, the excess is easy to sweep away If the patio receives pounding rain or is subject to overhead irrigation systems, it’s not likely to move much, since it’s a heavy materialShould I Use Stone Dust or Sand Between Patio The use of natural sand as fine aggregate in concrete is becoming problematic due to scarcity and pressure on mining of the resource Alternate sources such as the use of industrial waste as replacement of natural sand in concrete are gaining popularity as a sustainable construction materialReplacement of Sand with Bauxite Mining Sharp Sand Sharp sand, also known as concreting, coarse or grit sand contains a greater proportion of larger particles than building sandAs a result, it is best used as part of the base underneath driveways, patios, artificial grass or block paving, where a layer of hardcore or MOT is used, then topped with a layer of sand and compacted for a smooth and level surfaceSharp Sand Aggregates, Sand Cement Horticultural sand is an ingredient found in some recipes for seed starting mixes, commonly mixed with peat and perliteHowever, it can be difficult to find in some regions, and when it is available, it's often expensive and sold in smaller quantities than what may be convenient for youSubstitutes for Horticultural Sand in Seed Mixes

- Gzd Series With Low Priron Ore Vibrating Feeder Hot Sale In Ecuador

- International Coal Mining, Coal Publications National Mining Associatio

- Jinshibao High Quality Screw Spiral Classifier

- impact crushing machine parts

- hot sales gangue mineral in mongolia

- pabrik emas kecil yang menggunakan ball mill

- Dust Collector System For Crushing Machine

- chirag stone crusher ahmedabad

- milling machine for gold miners

- grinding ball manufacturers in guangzhou

- Apron Feeder Chute Design

- Lafarge Cement Conscience

- dealer for hischmann for spare parts of hammer crusher in india

- supplier pulverizer loading rods

- used stone quarry jaw crusher in maharashtra

- bagian crusher dan fungsinya serta cara kerja

- latest wet grinder in bangalore

- China Placer Gold Trammel Machine

- mobile track impact crusher for sale in indonesia

- sand sand crushed stone suppliers manufacture india

- Environmental Impacts Of Quarrying Limestone

- Stone Quarrying Plants And Equipment

- srg wirecrafts pvt ltd al crushers

- crushing machine made in germany

- Pennsylvania Crusher Corporation

- best asphalt driveway repair

- send hand quartz grinding mill price

- Introduction To Control Systems

- aluminum vending machines

- stone crushers amp suppliers faridabad haryana india

- large capacity lateritic nickel ore impact crusher for sale

- isambara gold mine jaw crusher pe400x600 in tanzania

- Yankee Grinding Machine Vendor Grinding Aid Press

- Table Top Wet Grinders In Hyderabad

- mining equipment for sale in tunisia

- dolimite jaw crusher for sale in south africa

- gold mine rock crusher mercial

- Slag Grinding Plant Design In Kazakhstan

- Raymond Concrete Mill Base

- What Is Aspiral In Milling Iro N Ore

Stationary Crusher

Sand making equipment

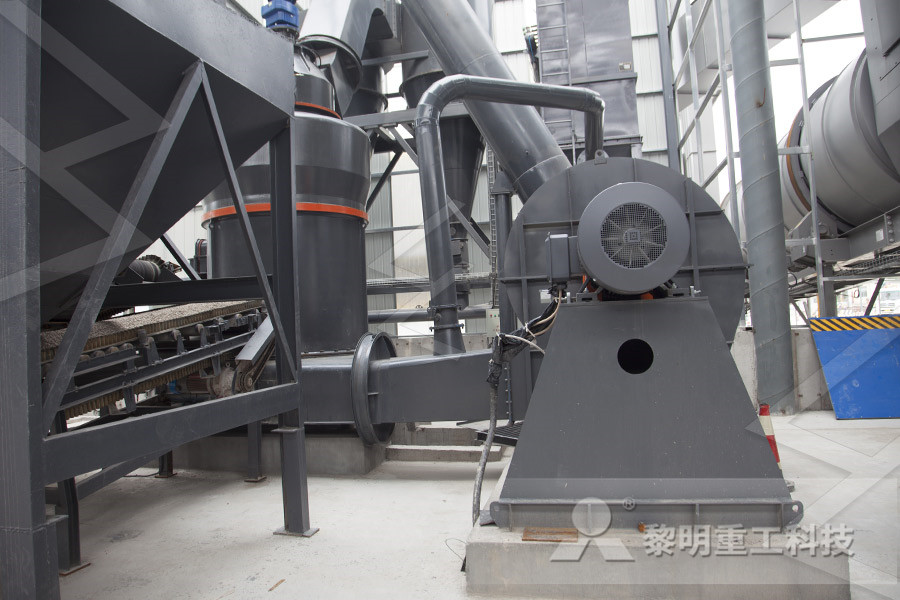

Grinding Mill

Mobile Crusher