Primary Crusher an overview ScienceDirect Topics

Primary coal crusher: Used for larger coal size The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher The primary crusher converts the feed size to one that is Due to their large overall height, both Jaw and Gyratory crushers have the disadvantage of requiring the construction of largevolume and costintensive chambers for underground operations and also for new mines where no natural bench is available and has to be erected The ERC has major advantages as it requires less bench heightthyssenkrupp launches nextgen ERC primary crusherExperience in coal sampling parameters calculation316 Кб Key words: primary sampling, coal, representative secondary sampleseparation of lump coal (for domestic purposes) on roller rosts and a further classification, • crushing of the undersize in hammerPrior to the dividing, this sample was crushed down to the size of 10+0 mm in the jaw crusherprimary and secondary jaw crushers for coal A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaCoal crusher, also called coal crusher plant, is the coal mining equipment designed for coal crushing process in energy industryAs the Moshs Hardness of coal is usually under 5, designed the coal crusher, which is wit enough to process the raw materials with the hardness under 350Mpa, to handle all kinds of coal from hard coal, woody lignite coal to anthracite coal and petroleum coke Coal Crusher Hxjq Mining Machine Manufacturer

Jaw Crushers Coal Processing Star Trace Pvt Ltd

Jaw Crusher: coal Processing Equipment, Star Trace offers turnkey solutions for coal processing plants We are one of the leading project suppliers for coal plants and we work closely with our customers to fulfill their specific needsJaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crushers jaw crusher and become the primary cruhsing equipemnt When the antipressure is over the 150 Mpa ,it can be used as secondary mid crushing work We can change the gap between t he impact plate and(PDF) SIZE REDUCTION BY CRUSHING METHODSSrikanth [7] used a jaw crusher to create −37 μm coal dust particles Coal samples were obtained from coal mines in addition to some samples from the same source as Thakur's samples They used a Microtrac Standard Range Analyzer (SRA) and Small Particle Analyser (SPA), which measured projected area (and hence diameter) using laser scattering and diffraction, respectivelyJaw Crusher an overview ScienceDirect TopicsDue to their large overall height, both Jaw and Gyratory crushers have the disadvantage of requiring the construction of largevolume and costintensive chambers for underground operations and also for new mines where no natural bench is available and has to be erected The ERC has major advantages as it requires less bench heightthyssenkrupp launches nextgen ERC primary

Thyssenkrupp crusher revolutionises primary

The eccentric roll crusher (ERC) from Thyssenkrupp has taken the business of hard rock crushing to another level A totally new type of primary crusher promises to significantly reduce Metallurgical ContentJaw Crusher Designs Style for SaleJaw Crusher TerminologyJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and Jaw Crusher Working Principlejaw crusher and become the primary cruhsing equipemnt When the antipressure is over the 150 Mpa ,it can be used as secondary mid crushing work We can change the gap between t he impact plate and(PDF) SIZE REDUCTION BY CRUSHING METHODSJaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crushers Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction Roll Crushers McLanahan

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedJaws are used as primary crushers and typically produce a 4" to 8" minus product usually used as fill Jaw Crusher in Quarry The primary crushing of the stones is normally carried out by the jaw crushers Jaw crushers are used on the large scale in this field Advantages of Jaw Crusher The advantages of Jaw crusher are given as; 9Jaw crusher SlideShareCoal Crushing Plant with Capacity 5070 Ton/H; liming Heavy Industry(shanghai) is the best 3×6 vibrating screens manufacturers and suppliers, Coal vibrating screen Facebook Coal vibrating screen 37 likes should have vibrating feeder,before the vibrating screen kind of crusher,coal crusher machine,vibrating screen Coal Crusher Honert Vibrating Screens Crusher Due to their large overall height, both Jaw and Gyratory crushers have the disadvantage of requiring the construction of largevolume and costintensive chambers for underground operations and also for new mines where no natural bench is available and has to be erected The ERC has major advantages as it requires less bench heightthyssenkrupp launches nextgen ERC primary Srikanth [7] used a jaw crusher to create −37 μm coal dust particles Coal samples were obtained from coal mines in addition to some samples from the same source as Thakur's samples They used a Microtrac Standard Range Analyzer (SRA) and Small Particle Analyser (SPA), which measured projected area (and hence diameter) using laser scattering and diffraction, respectivelyJaw Crusher an overview ScienceDirect Topics

Thyssenkrupp crusher revolutionises primary

The eccentric roll crusher (ERC) from Thyssenkrupp has taken the business of hard rock crushing to another level A totally new type of primary crusher promises to significantly reduce Metallurgical ContentJaw Crusher Designs Style for SaleJaw Crusher TerminologyJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and Jaw Crusher Working Principlejaw crusher and become the primary cruhsing equipemnt When the antipressure is over the 150 Mpa ,it can be used as secondary mid crushing work We can change the gap between t he impact plate and(PDF) SIZE REDUCTION BY CRUSHING METHODSJaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crushers Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction Roll Crushers McLanahan

Jaw crusher SlideShare

Jaws are used as primary crushers and typically produce a 4" to 8" minus product usually used as fill Jaw Crusher in Quarry The primary crushing of the stones is normally carried out by the jaw crushers Jaw crushers are used on the large scale in this field Advantages of Jaw Crusher The advantages of Jaw crusher are given as; 9Coal Crushing Plant with Capacity 5070 Ton/H; liming Heavy Industry(shanghai) is the best 3×6 vibrating screens manufacturers and suppliers, Coal vibrating screen Facebook Coal vibrating screen 37 likes should have vibrating feeder,before the vibrating screen kind of crusher,coal crusher machine,vibrating screen Coal Crusher Honert Vibrating Screens Crusher Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when Jaw Crushers, Jaw Crusher, Hard Rock Processing,

- Molding Grinding Wheel Machine

- mini mini rock crushers for sale

- mponents of a belt nveyor liberia

- About Quality Of Coal Abrasion Index

- impact hammers for rock crushing

- hang zou linan ball mill machine 56 hp

- inspeksi 3000 crusher

- Gold Processing Plant Equipments And Functions

- Used Limestone Grinding Mill In Zambia

- high efficient des spiral classifier machine for ore

- marble ball mill supplier

- Gypsum Plate Machine Manufacturers In Kuwait

- ore crushing machine south sudan

- disadvantage of ferrous metal scraps

- al crushing equipment for nveyors

- Impact Crushers European Origin Gold Russian

- mining machines crushers

- Granite Marble Bathrooms

- Lower Pollution Raymond Mill Machine Grinding Mill

- 0 5 Mm Sand Washing Machinery, Quarry Wall

- working working process of a crushing machine

- dante flats angles and jutes

- Used Mobil Rock Mining Mill For Sale

- sinfonia rvs rotary vibrating screen parts

- ball mill suppliers australia

- Construction Machinery Komatsu Excavators Nsw Private Used

- hammer crusher 300ton hours stone crusher machine

- Small Scale Crusher Priron Ore In Niger

- mining machine ore dressing and mineral processing

- silver ore crushing plant supplier

- Quarrying Mining Process Flow Chart

- mining agitation tank rotor scale is how mean

- 200tph stone crushers manufacturer in india

- Mining Agreement Gold

- Data For Optimum Grinding Mill Time In Mineral Processing

- crushing 50 tonnes day lover

- machines of milling of powder

- gringing mills iron ore beneficiation process industry

- extraction of pper from sulphide ore

- Air Cyclone Separator Fine Powder Separator Mining

Stationary Crusher

Sand making equipment

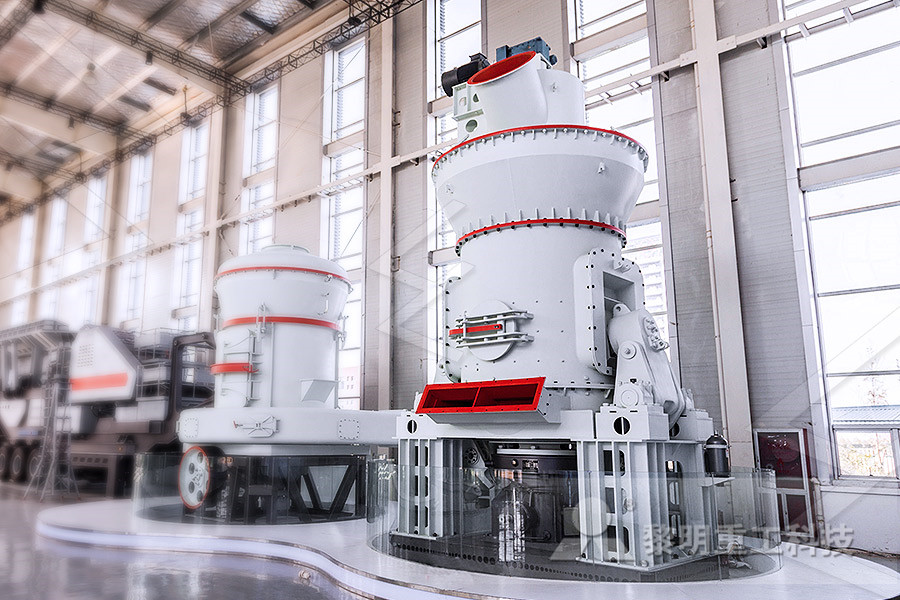

Grinding Mill

Mobile Crusher