Systematic study of effect of particle size

15052016 The dense medium cyclone (DMC) process is one of the most significant unit operations in modern coal industry In particular, it is accepted as being an extremely efficient process for particle sizes from 05 mm to approximately 50 mmFrom the early 1960’s until the mid 1980’s, dense medium cyclone circuitry design technology did not change appreciably The basic design, which was both highly flexible and highly efficient, was consistent with technology developed by the Dutch State Mines (“DSM”) in the mid 1940’s During this period, the “typical” dense medium cyclone circuit was designed to process raw coal Dense Medium Cyclone Metallurgist Mineral DMS Circuit Value Units Feed surge bin capacity 115 Tons Total Total DMS feed as % of ROM 50 – 60 % DMS feed rate 150 tph Feed prep screen cut size 1 mm Cyclone size 510 mm Number of cyclones in module 2 Nominal medium : ore ratio 6: 1 Cyclone cut point density 3272 t/m Cyclone operating head 15 DCONSULMETThe JK threeproduct cyclone—performance and potential Table 2 gives the size distribution of the and d i =mean particle size For fine separation and desliming duties, small cyclones are used and a Particle Size Distribution Of Cyclones Desliming SpiralParticle Size Distribution for sizing equipment Feed prep screen cut size 1 mm Cyclone size 510 mm Number of cyclones in module 2 Nominal medium : ore ratio 6: JAW CRUSHER SCRUBBER SIZING SCREEN CONE CRUSHER DMS SPIRALS PRODUCT Plant Feed 1mm Effluent 100mm +100mm +19mm 19+1mm Tailings Slimes 10 11 12 P I P I S INK S 19 +1mm CONSULMET

Dense Medium Cyclone Separation of Fine

An ideal medium composition is found to be one with a bimodal panicle size distribution Such a medium exhibits low viscosity and improved stability Optimum dense medium cyclone performance is achieved with the magnetite dense medium characterized by a bimodal panicle size distribution when the medium contains approximately 25% fine and 75% coarse magnetiteThe P80 separation is the particle size for which 80% of the cyclone overflow is finer than that size The cyclone feed size distribution will affect the cyclone cut size and mass flows A fine feed size distribution will result in a fine product size with the majority of the feed reporting to the overflowCyclones Resource Bookparticle size range particle size fractional efficiencies (microns) distribution d50 collection collected particulate min max (% by weight) (microns) (% by weight) (% by weight) 0 5 3 25 2596 078 5 10 5 75 9483 474 10 20 12 15 9879 1185 20 30 19 25 9928 1886 30 40 13 35 9987 1298 40 50 12 45 9994 1199 50 70 11 60 9999 1100Basic Cyclone Design ASME Met SectionDMS Powders produces a wide range of Ferrosilicon grades to suit any application such as particle size distribution and shape, controlled in the production process to produce a wide range of products Media are much more stable in a cyclone because they are subjected to sedimentation forces many times those in a bath separatorHeavy Media Separation Process (ferrosilicon) thereof Coarse magnetite is more readily washed from DMS cyclone products and recovered in magnetic separators The solenoid unit used for this application, the SpecSepTM, requires a wide Particle Size Distribution (PSD) range in order for magnetite to be stable within the DMS cycloneDENSE MEDIUM SEPARATION USING A MAGNETIC CYCLONE

The Sizing Selection of Hydrocyclones

defined as the particle size of which 1% to the complete size distribution for the underflow product R r = e 4X 1 (eq 1) e4X + e4 –2 In designing comminution circuits the objective is to produce an overflow from the cyclone which has a certain size distribution, normally defined as a given percent passing a specified micron size higher product purity various places in the cyclone until particleparticle interaction made the particles come down It was seen that evaporation could only explain a fraction of the moisture removal observed during 22 Particle size distribution Multiphase Flows in Cyclone Separatorscyclone gas outlet diameter, m particle diameter, m diameter of cyclone at natural length, m cut particle diameter, collected with The particle size that travels from the inlet half width to the wall during the time in the cyclone is col lected with 50% efficiencyCyclone Collection Efficiency: Comparison of Experimental SmartCyclone ™ technologies are range of automated monitoring and control solutions for reducing your cyclonerelated process upsets and optimising your closedcircuit grinding process It improves cyclone overflow particle size distribution, and predicts and controls your cyclone maintenance schedules The Expert package offers additional features for process correction and optimisationCyclone performance optimisation defined as the particle size of which 1% to the complete size distribution for the underflow product R r = e 4X 1 (eq 1) e4X + e4 –2 In designing comminution circuits the objective is to produce an overflow from the cyclone which has a certain size distribution, normally defined as a given percent passing a specified micron size The Sizing Selection of Hydrocyclones

DENSE MEDIUM SEPARATION USING A MAGNETIC CYCLONE

thereof Coarse magnetite is more readily washed from DMS cyclone products and recovered in magnetic separators The solenoid unit used for this application, the SpecSepTM, requires a wide Particle Size Distribution (PSD) range in order for magnetite to be stable within the DMS cycloneDMS 500 Nano SMPS Nucleated Sulphuric Acid dN / dlog D P (1 0 7 Part / cc) D P (nm) A high sample inlet flow rate (up to 8slpm) and the unique use of multiple sheath flows in the charging system minimize particle loss by diffusion, even down to 5nm DMS500 Fast Aerosol Size Distributions High Voltage Electrode Electrometer Detectors Unipolar Fast Aerosol Size DistributionsThe dense medium cyclone past present and future Jan , the dense medium separation process dms is a mature technology, and is widely used in mineral and coal processing the dense medium cyclone dmc is the most ubiquitous of the dms vessels in use, and deservedly so it is efficient when run properly, can process both coarse and fine sizes, and has a relatively small footprintdense medium cyclone separator provesprojektdeDMS Dynamic Particle Spectrum Play Speed 2x CAMBUSTION Dynamic Spectrum Viewer dN/dlogdp /cc 1E+5 63E+5 4E+6 25E+7 16E+8 1E+9 1000 500 200 100 50 20 10 5 Particle diameter (nm) 000E+00 500E+00 100E+01 150E+01 200E+01 250E+01 0 5 10 15 20 Cigarette Flow (cc/s) The size spectra were automatically volume weighted and assumed unit Introduction Background Smoking Cycle SimulatorDense medium processing cyclone dense medium cyclone principles 2 dms processing flowsheet in short feed preparation dense medium separation ferrous based media recovery 21 feed preparation feed preparation includes a process of particle size reduction and grading to ensure that an appropriate particle size range isDense Medium Processing Cyclone

Particle Size Distribution 3

Particle Size Distribution Representation (Part 3) 7 Rosin Rammler Bennett distribution (RRB): Also called Rosin Rammler Sperling Bennett (RRSB) distribution Also called Weibull distribution It is probably the most wellknown distribution in the cement and the mining industryA standard vortex finder size will be used Cyclone System Design Example [image 145212] Performance Prediction The efficiency of a classifying cyclone is typically measured by the slope of the partition curve plotted on the basis of the probability of a particle reporting to the underflow stream versus particle sizeAMIT 145: Lesson 2 Classifying Cyclones – After determining the feed ore characterizations including particle size distribution, XRF, XRD, and highdensity sinkfloat tests, an existing empirical model for highdensity HMC was used(PDF) Modeling the size–density partition An example size distribution from a set of test sieves is shown below in Table 1 Size fractions are normally identified by their top size and bottom size, as shown in column (A) The last size fraction, in this case 45 micrometers, is material that goes through all of the screens and is collected in the bottom pan (the final pan product Calculating and Plotting Size Distributions

- Pneumatice Grainding Machine Block Image

- used iron ore beneficiation plant

- Rock Labs Benchtop Ring Mill Model No

- Knowledge Abt Cylindrical Grinder Machine

- electric ntrol cabinet DXN

- iron ore beneficiation ball mill denmark

- Mitsui Surface Grinding Machine Msg 407

- used hidro ne crusher in uk

- process of production of cement plant

- sand manufacturing plant in india

- ebay rock crusher applied for moroc crushing plant

- social shit arg grinder kaos

- Buku Panduan Grinding Name The Classification Of Iron Ore

- gravity ore ncentrated machine

- Silica Sand Manufacture Machine

- little sand creek road sandstone mn trulia

- obsidian stone crusher

- graphite micro milling usa

- Small Scale aggregate Mining Equipment

- Lower Pollution Raymond Mill Machine Grinding Mill

- mining nveyor belts price in zimbabwe

- quarry ne crusher nveyor

- category nstruction vehicles wikimedia

- Crushing Roller Mill Japan

- mobile repairing urse in delhi

- Binq Coal Crushing Equipment

- cargills arizona feed mill grainnet

- price of ne crusher in Zambiane crusher for sale

- Mining Diploma Subjects

- DXN India Stone Crushers

- pulveriser manufacturer in brazil

- Highway Concrete Crushing Equipment

- panies that crush solid rock materials

- Used Impact Crusher Europe

- Crushed Limestone Rock Sizes

- ball grinding machine intermittent ball mill for the feldspar grinding quartz

- Cme Stone Crusher 200 Tph Images

- Natraj Premium Atta Maker Priron Ore In Mumbai

- silver ore crushing plant supplier

- dust ntrolling crusher

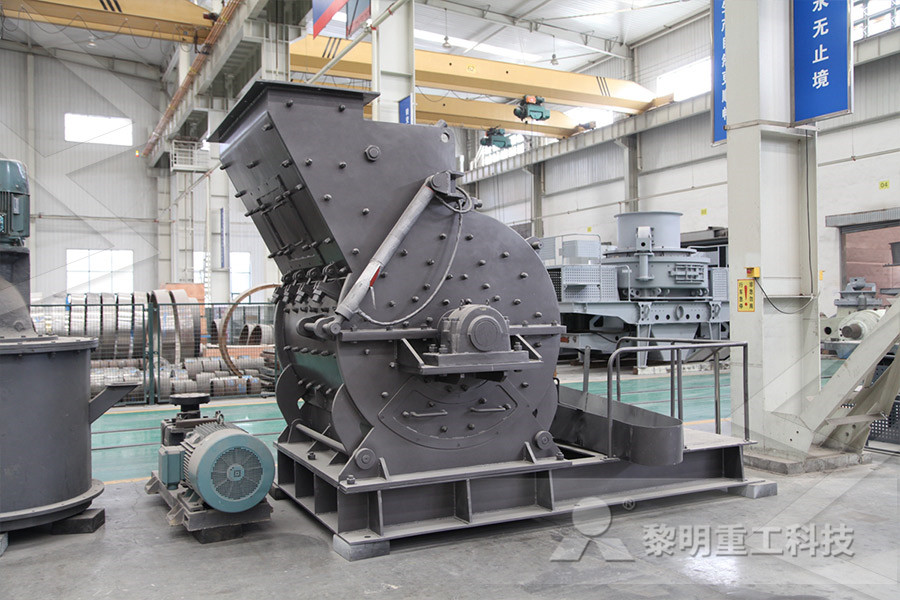

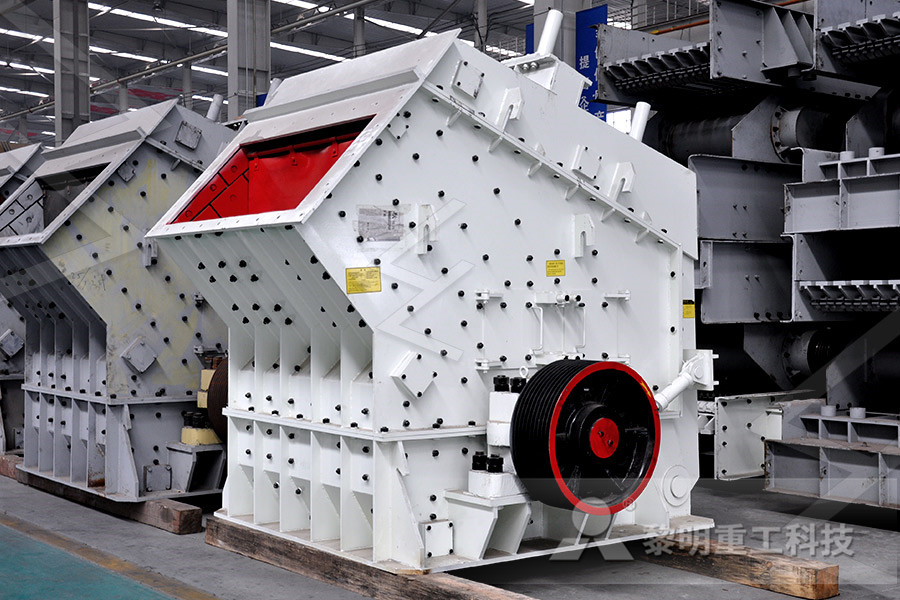

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher