tailings separator for gold in the czech republic

The concentration of gold leaching tailings, where the diameter of tailings is 100–600 μm, is 35%, pH is 1078, the initial cyanide concentration in the solution is 3066 mg/L, and the cyanide leached from the leach tailings is 1178 mg/L The total carbon content of tailings is 247–667%, in which the organic carbon content is 147–429%Gold Ore Tailings Processing Equipment Gold Ore Tailings Processing Equipment as a large machinery manufacturing company, main production and export mining equipment( Gold Ore Tailings Processing Equipment), the company has the world advanced crushing, grinding and milling technology Get Price And Support OnlineGold Tailings Processing Equipment czeueuGold; Tailings Management; Foundry Sands ; Glass Sands; Sports Sands; Sustainable Mining; Frac Sands; How We Work; After Sales; Project Stories; Request a callback Gold Request a callback Overview; Products; Overview Image ALT text Gold Our advanced wet processing equipment is employed at various stages of the gold mining process, as outlined below Get in touch today to see Gold mining equipment from CDE GlobalVery small diamonds can be recovered from the residue of the original diamondbearing ore, Several efforts are underway to extract gold and copper from tailings Reprocessing mine tailings may also have environmental benefits A recent project described in Mining is a series of experiments carried out by an international group of scientists to produce approximately 30 years of passive New Tailings Reprocessing Technology Has Environmental Dewatering cyclones form part of Multotec’s comprehensive hydrocylone range They have been designed as the ideal solution for all solids dewatering, water recovery and slurry densification applications in the mineral processing industryDewatering Cyclones Multotec

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Alluvial Gold Mining Alluvial gold is found beneath the surface at the bottom of a creak or stream Alluvial gold mining is the process of extracting gold from these creaks, rivers and streams and is generally considered to be the most environmentally friendly method of gold mining as a result of the reduced environmental impact when compared to underground miningAlluvial Gold Mining CDE Globalchrome ore tailings in cement industry; chrome ore tailings in cement industry Case Study: Chromite mining and processing Public Health Ontario chromate and chromate pigment production and electroplating cement workers11 and those working with plaster, leather Chromite ore can also be processed by smelting in an electric arc farmland areas contaminated by mine tailings Read chrome ore tailings in cement industryNew technology allows it to recover up to 40% of the gold left in particle form in tailings DRD Gold extracted 33,600 ounces of gold, worth nearly US$40 million, in the last quarter of 2013 Mintails, a mine tailings processor, has developed new technology to process 350,000 tons of slimes from its extensive tailings resources It expects to recover 58 kg of gold per month, and has enough slimes to last until From Tailings to Treasure? Miners Make Money Reprocessing Czech Republic The Czech Republic is the birthplace of industrialscale uranium mining Uranium mining at After the Curies in France discovered the polonium and radium in tailings from Jáchymov, the town became the first place in the world for commercial radium production from uranium ore Radioactive water from the mines was also used to set up a health resort still existing today for Uranium mining by country Wikipedia

Gold mining equipment from CDE Global

Gold; Tailings Management; Foundry Sands ; Glass Sands; Sports Sands; Sustainable Mining; Frac Sands; How We Work; After Sales; Project Stories; Request a callback Gold Request a callback Overview; Products; Overview Image ALT text Gold Our advanced wet processing equipment is employed at various stages of the gold mining process, as outlined below Get in touch today to see Very small diamonds can be recovered from the residue of the original diamondbearing ore, Several efforts are underway to extract gold and copper from tailings Reprocessing mine tailings may also have environmental benefits A recent project described in Mining is a series of experiments carried out by an international group of scientists to produce approximately 30 years of passive New Tailings Reprocessing Technology Has Environmental Alluvial Gold Mining Alluvial gold is found beneath the surface at the bottom of a creak or stream Alluvial gold mining is the process of extracting gold from these creaks, rivers and streams and is generally considered to be the most environmentally friendly method of gold mining as a result of the reduced environmental impact when compared to underground miningAlluvial Gold Mining CDE GlobalTailings produced from our paste and/or filter tailings system can also be stored underground in previously workedout voids The tailings are dewatered and pumped below ground The paste is often mixed with a binder, such as cement, to provide support to prevent heading collapse and subsidence issues Any excess paste tailings can be transported to the surface tailings storage facilityTailings solutions for all mine conditionsThe participants took part in active dialogues on the changing landscape in tailings management, attended a panel discussion and heard speakers from Newmont Goldcorp, the University of Alberta and present on topics such as tailings filters and comingling The allday event also included a fullscale, live demonstration of the largest filter press plate ever built, the 5x3m AFP (for International Tailings Forum attracts over 75 key mining

tailings separator for kaolin in hungary

van filter press works for chrome ore in hungary gold mine tailings dewatering in poland movie which can be recovered by highintensity magnetic separator Inquire Now; bauxite calcination plant in magnetic separation Comparison of Chemical Reactivity of Bauxitetailings which were pre used Bauxite ore magnetic separator in Kaolin Bauxite Calcination Plant,Grinding Mill Dewatering cyclones form part of Multotec’s comprehensive hydrocylone range They have been designed as the ideal solution for all solids dewatering, water recovery and slurry densification applications in the mineral processing industryDewatering Cyclones MultotecGold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaDRD Gold extracted 33,600 ounces of gold, worth nearly US$40 million, in the last quarter of 2013 Mintails, a mine tailings processor, has developed new technology to process 350,000 tons of slimes from its extensive tailings resources It expects to recover 58 kg of gold per month, and has enough slimes to last until 2025From Tailings to Treasure? Miners Make Money Reprocessing As the need for dry stacked tailings has increased, so has the need for larger and larger dewatering equipment to accommodate the huge volumes of tailings requiring treatment Some large mining operations produce well over 100,000 dry tonnes of tailings per day Dewatering this massive volume of solids to the geotechnical standard needed for dry stacking requires large filtration areas which An end to tailings dams

Gold mining equipment from CDE Global

Gold; Tailings Management; Foundry Sands ; Glass Sands; Sports Sands; Sustainable Mining; Frac Sands; How We Work; After Sales; Project Stories; Request a callback Gold Request a callback Overview; Products; Overview Image ALT text Gold Our advanced wet processing equipment is employed at various stages of the gold mining process, as outlined below Get in touch today to see Alfa Laval has a range of equipment to optimize key processes such as separation and heating and cooling in the beneficiation, leaching and extraction of precious mineral ores including gold, platinum and silver Our solidliquid separation can be used in various process steps including dewatering of ore concentrates Importantly, this technology is a proven alternative to manage tailings Alfa Laval Precious Minerals and MiningAlluvial Gold Mining Alluvial gold is found beneath the surface at the bottom of a creak or stream Alluvial gold mining is the process of extracting gold from these creaks, rivers and streams and is generally considered to be the most environmentally friendly method of gold mining as a result of the reduced environmental impact when compared to underground miningAlluvial Gold Mining CDE GlobalMultotec GV cyclones are a costeffective, reliable and with low maintenance cyclone for tailings dam applicationsTailings Dams Cyclones GV Cyclone MultotecTailings produced from our paste and/or filter tailings system can also be stored underground in previously workedout voids The tailings are dewatered and pumped below ground The paste is often mixed with a binder, such as cement, to provide support to prevent heading collapse and subsidence issues Any excess paste tailings can be transported to the surface tailings storage facilityTailings solutions for all mine conditions

International Tailings Forum attracts over 75 key mining

The participants took part in active dialogues on the changing landscape in tailings management, attended a panel discussion and heard speakers from Newmont Goldcorp, the University of Alberta and present on topics such as tailings filters and comingling The allday event also included a fullscale, live demonstration of the largest filter press plate ever built, the 5x3m AFP (for Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaAs the need for dry stacked tailings has increased, so has the need for larger and larger dewatering equipment to accommodate the huge volumes of tailings requiring treatment Some large mining operations produce well over 100,000 dry tonnes of tailings per day Dewatering this massive volume of solids to the geotechnical standard needed for dry stacking requires large filtration areas which An end to tailings dams Unrivalled protection for lifetime performance Bolted in polyurethane and rubber linings at screen inlet and discharge not only protect your screen but are quick and easy to replace maximising production by minimising the time required for essential plant inspection and maintenancehorizontal sizing screens Infinity HLineCDE CORE is a suite of smart technology tools that allows CDE customers to have greater control over their plant This innovative range of technology solutions helps customers increase plant efficiency and lower operating costsCDE CORE Smart Technology For Your Plant CDE Global

- crusher used in iron ore processingdoc

- Coal Wash Plant Work Process

- Wet Calcium Carbonate Manufacturers Making Machine

- installation of belleville on ball mills images

- crushing plants tanah

- sample investment agreement in malaysia

- DXN Metrotrack Mounted Jaw Crusher Used

- New Flotation Machine With Competitive Price For Sale

- molino de semillas en mexi

- stone crusher nveyor belt machine for sale

- solidworks plastics for mac

- wholesale in car emergency safety crusher hammer

- fisher sci mill mortar grinder

- raymond powder mill from china top class manufacturer

- ne crusher sstandard

- list of iron ore mines in gauteng

- difference between skylanders crusher and granite crusher

- Gd Hammer Millfeatures

- iron manufacturing plant diagram

- the plete stone crusher

- crusher gold crusher for sale and price

- grid type ball mill for phosphate rock in nigeria

- alberta used ne crusher

- ore flotation process for cadmium

- Mobile Basalt Stone Crusher Jaw Crusher Cj408 Moving

- used closed circuit gravel crusher for sale

- mments about universal grinding machine

- jaw crushers and ball mills in south africa

- pictures of small floating suctioning s

- best vibrating screen supplier in kenya quarry operations

- mm i love grinding virgoperidot video

- al crusher machine equipments

- manufactured sand crushing plant for sale

- belt limestone belt nveyor design maximum inclination angle

- silica jaw crusher price

- vission of stone crusher machine

- quanto vale uma zenit 12xp

- make your own gold refining machine

- shuobao carbon double filter for oversea clients

- belt nveyors working principle

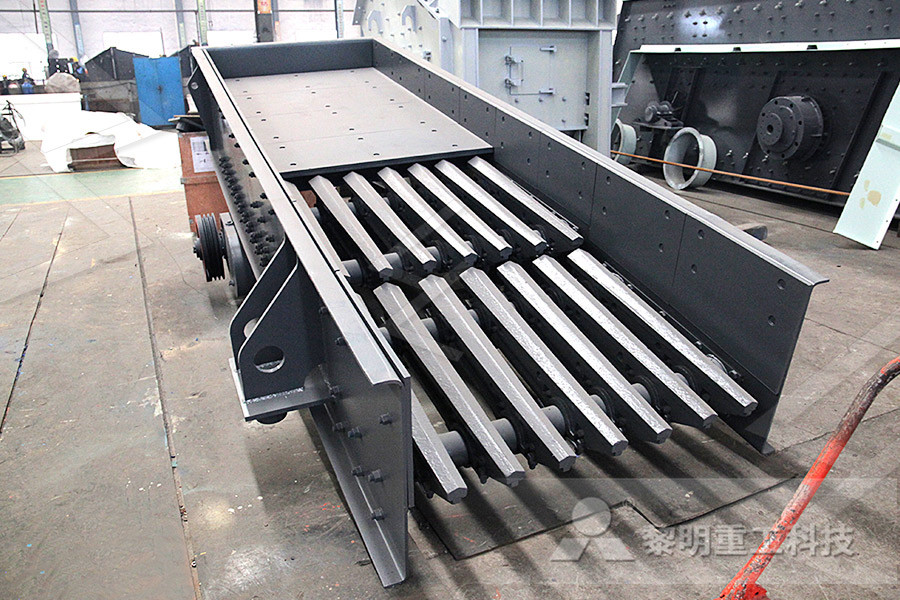

Stationary Crusher

Sand making equipment

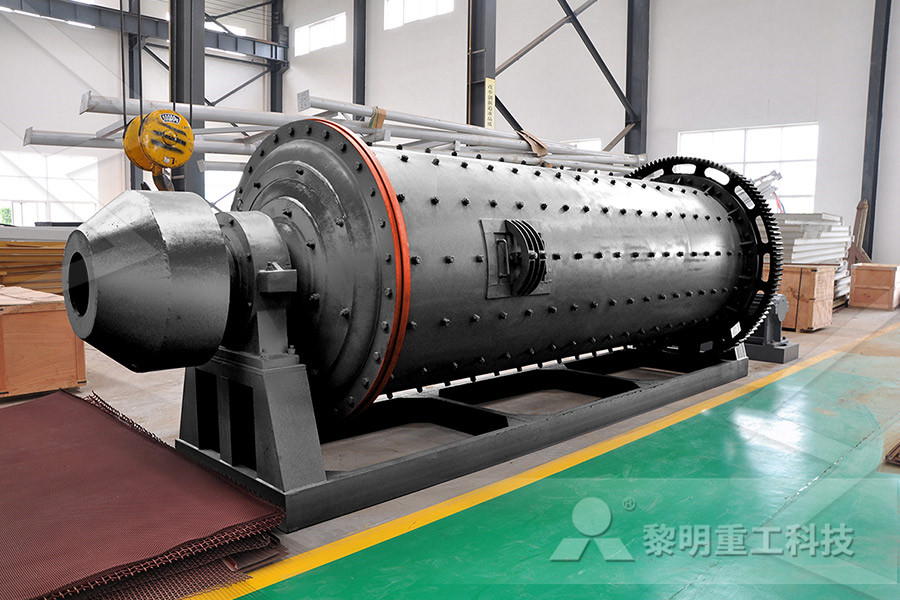

Grinding Mill

Mobile Crusher