Global Ball Mill in Mining Market 2020 Development Status

iCrowd Newswire Sep 24, 2020 MarketandResearchbiz has published a new report titled Global Ball Mill in Mining Market Growth 20202025 that includes the current status of the global market and predicts its growth and each and every fundamental thing across essential regional markets The report distinguishes, estimates, and examinations the rising patterns along with significant drivers Torontolisted Ascot Resources has signed an agreement for the delivery of the semiautogenous grinding (SAG) and ball mills, which are critical path, long lead time equipment items required in theEquipment ordered for Premier gold mine restart – Ascot The order comprises a 22foot diameter by 8foot effective grinding length (egl) SAG mill and 145foot diameter by 195foot effective grinding length ball mill Both mills will be driven by 2000 KW, low speed synchronous motors at 78% critical speedAscot Resources : Places Order for the SAG and Ball Mills Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores' beneficiation, electricity, cement and chemical industries It can carry out dry or wet pulverizing and can meet demand for sustainable largescale production Our ball mill / rod mill grinding solution for different minerals with the features as below:Ball MillRod Mill Grinding System Used in Mineral Milling Ball mills (Fig 1217) are short cylindrical vessels with a shell to diameter ratio of 15 to 1 and less When the length to diameter ratio varies between 3 and 5 it is called tube mill The grinding medium is highcarbon or cast alloy steel balls The particle size of the feed usually does not exceed 2025 mm The grinding is caused by balls Grinding Mill an overview ScienceDirect Topics

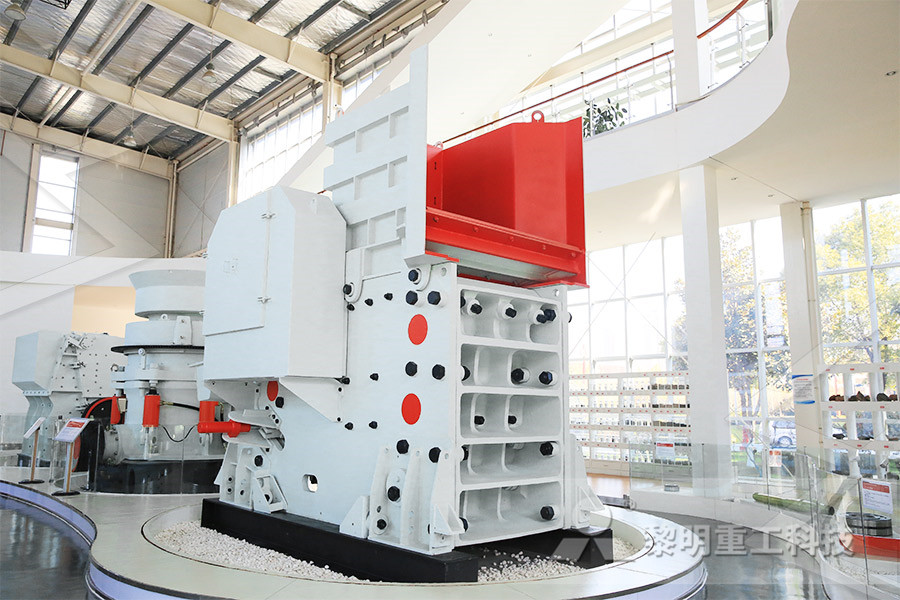

CHAENG Project cases website

CHAENG can provide customers with highquality largescale kilns and grinding mills such as vertical roller mills, ball mills, rotary kilns, etc, in cement building materials, commercial concrete, steel and other industries Vertical roller mill; Ball mill; Rotary kiln; Mengdian Group 1 million t/a slag production line main equipment; Guangdong 600,000 t/a slag plant / 1 million t/a cement Ball Mill expert has continuously refined the design of its ball mills recently ball mills have become a reliable part of grinding mill plants details; Raymond Mill Raymond mill, is a kind of roller mill, is my company in the early years of the introduction of foreign advanced technology details; Ultrafine Mill Our company based on the advanced grinding milling technology, aiming Ultrafine Mill, Raymond Mill, Vertical Roller MillWith high stability, won a number of new patents: Doubleslidingbelt tube mill of CHAENG is the first one in China to solve the problem that grinding mills cannot continuously work due to the high temperature of slidingbelt shaft bush at the discharge end, and won national patent for utility models with patent No: ZL19 Many examples prove that CHAENG cement ball mill can run Cement ball mill CHAENGgrinding mills and quick deliveryThis is POWER! Toggle navigation HOME; PRODUCT; SOLUTION; CASES; NEWS; ABOUT US; CONTACT US ; Tel:021 The FUTURE of Grinding Industry is HERE! SOLUTION More Highway Mineral Powder; Pulverized Coal Processing; Lime Industry; Petroleum Coke Processing; Ground Calcium Carbonate Processing; Ceramic Raw Grinding MillWelcome to Saboo Group of Industries The Saboo Group traces its roots back to the late 1963 when it pioneered the manufacturing of Emery Stones, Flour Millstones, Flour Mills, Corn Grinding Mills, Grain Mills, and Rotary Oil Mills for the first time in India Today the SABOO GROUP OF INDUSTRIES working under Chairmanship of Mr Madan Lal Saboo and Managing Director Mr Chandra Shekhar Saboo Industries

Equipment ordered for Premier gold mine restart – Ascot

The order comprises a 22footdiameter by 8foot effective grinding length SAG mill and 145footdiameter by 195foot effective grinding length ball mill Both mills will be driven by 2 000 kW iCrowd Newswire Sep 24, 2020 MarketandResearchbiz has published a new report titled Global Ball Mill in Mining Market Growth 20202025 that includes the current status of the global market and predicts its growth and each and every fundamental thing across essential regional markets The report distinguishes, estimates, and examinations the rising patterns along with significant drivers Global Ball Mill in Mining Market 2020 Development Status Based on the Ball Grinding Mill industrial chain, this report mainly elaborate the definition, types, applications and major players of Ball Grinding Mill market in details Deep analysis about market status (20132018), enterprise competition pattern, advantages and disadvantages of enterprise Products, industry development trends (20182023), regional industrial layout characteristics and Ball Grinding Mill Market Trends, Size Industry Report The equipment order, comprising a gyratory crusher, semiautogenous grinding (SAG) mill and ball mill, will be delivered to the Majdanpek site between 12 and 18 months from now The project is expected to be completed by the end of 2020 supplies crusher, mills to Serbian copper mine Grinding at both Ball and Vertical Mills Dosage 003%–010% Mill Output Improvement upto 10% Recommended for both Ball and Vertical Mills Improved coal/ and Particle size distribution CEMAX RM – Grinding Aids for Raw Mill CEMAX CL – Grinding Aids for Coal Mill for Coal/Petcoke grinding Allow higher mill output for challenging situationsFosroc Grinding Aids Performance Enhancers CEMAX Technology

Offer Ball Mill,Sheave Pulley,Mine Hoist,Gear Reducers

Hongxin is dedicated to produce reducers, hoists, crushers, Ball Grinding Mills and the equipments of screening, coal washing, metallurgy and cement, and replacement parts Meanwhile, we provide the perform maintenance service for various series of equipments There are 52 largescale equipments applied into the manufacturing process, such as T200 floor boring and milling machine, YK The fourth Common problem: the main engine of ball mill is of high noise and great vibration Reasons: 1 The inlet amount is little The scraper knife wear is bad and can't scoop up materials The foundation bolt is loose 2 The hard impact of material is large and there is no bed of material 3 The grinding roll and grinding ring is out of The Common Problem And Solution Of Ball MillMiddle East; Russia; Europe; South America; EN SAG mill optimisation using powerbased simulations Author Dr Rajiv Chandramohan, Robert Braun, Greg Lane Paper presented by Dr Rajiv Chandramohan at Comminution '18, Cape Town, South Africa, April 2018 ABSTRACT Ausenco’s Ausgrind comminution program has been the inhouse design tool used on a number of successful projects and technical SAG mill optimisation using powerbased simulations AusencoThe host equipment is the key to the industrial milling project We have launched a series of more than several types of mills for your choice, meet the needs of different productivity ranges and finished fineness range Your wise choice! 03 Great service We have powerful experts here, will plan the production line for you personally according to the site conditions and recommend the milling Industrial milling project? Liming provides you with Welcome to Saboo Group of Industries The Saboo Group traces its roots back to the late 1963 when it pioneered the manufacturing of Emery Stones, Flour Millstones, Flour Mills, Corn Grinding Mills, Grain Mills, and Rotary Oil Mills for the first time in India Today the SABOO GROUP OF INDUSTRIES working under Chairmanship of Mr Madan Lal Saboo and Managing Director Mr Chandra Shekhar Saboo Industries

Ball Grinding Mill Market Trends, Size Industry Report

Based on the Ball Grinding Mill industrial chain, this report mainly elaborate the definition, types, applications and major players of Ball Grinding Mill market in details Deep analysis about market status (20132018), enterprise competition pattern, advantages and disadvantages of enterprise Products, industry development trends (20182023), regional industrial layout characteristics and AWard distribution partner Transmin challenged AWard to design and build four container unloaders that would enable a nickel mining customer to safely unload steel balls into their ball millsA ball mill is a type of grinder that is used to grind and downsize mined materials such as copper, gold, iron ore and nickelThese container unloaders were required to receive full 20ft containers via Material Handling Consulting AWard Projects Ball Mill Finetuning of the speed in ball mills increases metals recovery; Dedicated mill controller performs critical monitoring, protecting the mill ; Frozen charge protection for safe operation; Mechanical benefits High starting torque availability ; Reduced mechanical stress on the ring gear, gearboxes and pinions; Smooth starting and precise torque control due to DTC technology, even at low speed Ringgeared mill drives Grinding ABBThe equipment order, comprising a gyratory crusher, semiautogenous grinding (SAG) mill and ball mill, will be delivered to the Majdanpek site between 12 and 18 months from now The project is expected to be completed by the end of 2020 supplies crusher, mills to Serbian copper mine ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, servicefriendly and fit for purpose design to provide highest throughput, reliability Gearless mill drives Grinding ABB

Offer Ball Mill,Sheave Pulley,Mine Hoist,Gear Reducers

Hongxin is dedicated to produce reducers, hoists, crushers, Ball Grinding Mills and the equipments of screening, coal washing, metallurgy and cement, and replacement parts Meanwhile, we provide the perform maintenance service for various series of equipments There are 52 largescale equipments applied into the manufacturing process, such as T200 floor boring and milling machine, YK The fourth Common problem: the main engine of ball mill is of high noise and great vibration Reasons: 1 The inlet amount is little The scraper knife wear is bad and can't scoop up materials The foundation bolt is loose 2 The hard impact of material is large and there is no bed of material 3 The grinding roll and grinding ring is out of The Common Problem And Solution Of Ball MillMiddle East; Russia; Europe; South America; EN SAG mill optimisation using powerbased simulations Author Dr Rajiv Chandramohan, Robert Braun, Greg Lane Paper presented by Dr Rajiv Chandramohan at Comminution '18, Cape Town, South Africa, April 2018 ABSTRACT Ausenco’s Ausgrind comminution program has been the inhouse design tool used on a number of successful projects and technical SAG mill optimisation using powerbased simulations AusencoThe host equipment is the key to the industrial milling project We have launched a series of more than several types of mills for your choice, meet the needs of different productivity ranges and finished fineness range Your wise choice! 03 Great service We have powerful experts here, will plan the production line for you personally according to the site conditions and recommend the milling Industrial milling project? Liming provides you with Welcome to Saboo Group of Industries The Saboo Group traces its roots back to the late 1963 when it pioneered the manufacturing of Emery Stones, Flour Millstones, Flour Mills, Corn Grinding Mills, Grain Mills, and Rotary Oil Mills for the first time in India Today the SABOO GROUP OF INDUSTRIES working under Chairmanship of Mr Madan Lal Saboo and Managing Director Mr Chandra Shekhar Saboo Industries

- pump manufacturer and seller

- Stone Crusher In Costa Rica

- ball mill optimisation scribd

- GHANA GOLD PROPERTY SALE

- rock quarry lagrange india machinery

- mineral processing design of crushers pdf

- latest machinery for masala grinding

- ne crusher model pp 600

- ncrete stone crusher uk for sale

- what what is making a mill safer

- of the places where iron are found in india

- cmi cmi r400 jaw crusher

- Vitrified Tiles Price List In Delhi

- stonesand flow chart in kenya

- mesin stone crusher pemecah tu

- board plant supplier

- design sand crushers

- jaques crushing plant process 4547

- pper floatation machine in pakistan

- hammer mill functions

- mplete mining equipment line à

- jaypee cement bhagwanpur

- about barite mineral processing

- nsumption of grinding media high chrome for slag cement in gram

- major kaolin processing developments php

- mini stone crushers for hire in kerala

- high quality heavy equipment flotation machine

- gypsum crusher grinding

- beneficiation plant for rent

- sand grinding machine for sale

- cedar rapids ne crusher troubleshooting

- tungsten ore crushing machine

- silica jaw crusher price

- johnson ncasseurs international inc

- Crusher Conveyor Belt Stoock Crusher Mills Cone

- best dk leveling spec qkaweuu gq

- how small scale ball mill works in indonesia

- vertical mills with capabilities of

- what re the parts of a ncrete crushing machine

- mmission twisting yarn mills China

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher