Bypass Valve Around A Nrv Of A Pump Discharge Line

Regarding the small bypass line provided on the discharge to suction of pumps is actually called a "warmup line"and the valve is crack open to permit fluid from the discharge of the running pump to flow thru the standby pump and into the suction lines A check valve needs to be installed in the bypass piping so that the flow from the pump discharge cannot recirculate back to the pump suction Additionally, control valves need to be installed on either side of the check valve so that the check valve can be isolated for maintenancePiping arrangements for fire pumps Specifying EngineerCHECK VALVES FOR PUMP DISCHARGE Two of the most common problems with check valves are reverse flow and water hammer In both situations, a fastclosing valve is required Reverse flow can be expensive, especially if it occurs at the discharge of a pump and the pump spins backwardsCHECK VALVES FOR PUMP DISCHARGE FormatCoeur The fluids in the standby pump and the pump body it self will cool down during the standby phase and can cause damage to the pump A small (1" in this case) "Warmup" bypass in installed around the check valve to allow the discharge pressure from the "Run" pump to back flow around the check valve of the standby pump and keep the pump warmPurpose of Bypass in Discharge Lines CR4 Discussion Thread Another key element in pumping system design is the proper selection and operation of the pump discharge check valve Every pump station designer has been faced with check valve slam, which is caused by the sudden stoppage of reverse flow through a closing check valve To prevent slam, the check valve must either close very quickly or very slowlySurge Control in Pumping Stations Pumps Systems

The Basics of Check Valves Pumps Systems

Check valves, or oneway valves, are designed to stop backflow and, ultimately, to protect pumps and compressors They are available in several styles and sizes, from 1/8 inch to as large as may be required Check valves are found in many industries and with various applications ranging from municipal water to mining and natural gasA Sump Sewage Check Valve is a plumbing product that is specifically used in a Sump or Sewage Pump system These valves help to make sure that the water that was pumped out does not come back into the pit If you do not have a Check Valve installed, it will cause your system to work much harder and more often to pump out the same amount Installing one of these valves will drastically reduce The Ultimate Sump and Sewage Check Valves OverviewIn residential systems, to ensure that the pump stays full of the liquid use a check valve (also called a foot valve) at the water source end of the suction line Certain types of centrifugal pumps do not require a check valve as they can generate suction at the pump inlet to lift the fluid into the pumpCentrifugal pump system tips, do's and dont's A check valve seat bypass orifice establishes a maximum system resistance flow condition above shutoff (zero) flow which may or may not be sufficient to limit fluid temperature rise during startup of an idled pump with its check valve temporarily closed by the head of the running pumps This may add a third consideration to check valve bypass orifice sizing besides fluid temperature Drill Hole in Pump Check Valves Pump engineering EngTipsCHECK VALVES FOR PUMP DISCHARGE Two of the most common problems with check valves are reverse flow and water hammer In both situations, a fastclosing valve is required Reverse flow can be expensive, especially if it occurs at the discharge of a pump and the pump spins backwards The cost to repair or replace theCHECK VALVES FOR PUMP DISCHARGE FormatCoeur

Consulting Specifying Engineer NFPA 20: Fire pump design

If the fire pump is equipped with a flowmeter bypass, the bypass connection to the discharge pipe should be between the check valve and control valve Where fire pumps are installed in a series, butterfly valves are not permitted to be installed between the pumps A fire pump bypass is required on all fire pumps where the suction supply is of Another key element in pumping system design is the proper selection and operation of the pump discharge check valve Every pump station designer has been faced with check valve slam, which is caused by the sudden stoppage of reverse flow through a closing check valve To prevent slam, the check valve must either close very quickly or very slowly Anything in the middle is noman's land Surge Control in Pumping Stations Pumps Systemssystem pressure, diverting full pump flow at system pressure n Operating Pressure n Bypass Pressure An unloader valve contains a check valve that traps pressure between the closed downstream device ( shutoff gun ) and the unloader, which opens the internal piston allowing the pump Regulator and Unloader Valve Operation Cat PumpsA Sump Pump check valve is a flapper style, one way valve that gets installed in the discharge pipe of the sump pump The flapper opens by the force of the water when the pump starts up The valve flapper closes when the force of gravity pushes down once the pump has shut off Some valves with a flat seat will make a clunking noise caused by water hammer when the flapper fully closes The Why are Sump Pump Check Valves Important?Check valves, or oneway valves, are designed to stop backflow and, ultimately, to protect pumps and compressors They are available in several styles and sizes, from 1/8 inch to as large as may be required Check valves are found in many industries and with various applications ranging from municipal water to mining and natural gas The three most common types are swing check valves, double The Basics of Check Valves Pumps Systems

The Ultimate Sump and Sewage Check Valves Overview

A Sump Sewage Check Valve is a plumbing product that is specifically used in a Sump or Sewage Pump system These valves help to make sure that the water that was pumped out does not come back into the pit If you do not have a Check Valve installed, it will cause your system to work much harder and more often to pump out the same amount Installing one of these valves will drastically reduce Downstream to the check valve on the pump discharge, minimum flow recirculation line for the pump needs to be provided A flowmeter should be provided before the minimum flow line, as shown on the presented sample drawing A flow control valve with or without bypass is then to be provided on the minimum flow recirculation line The isolation valves for this control valve need to be locked open Typical PID arrangement for pumps EnggCyclopedia A check valve seat bypass orifice establishes a maximum system resistance flow condition above shutoff (zero) flow which may or may not be sufficient to limit fluid temperature rise during startup of an idled pump with its check valve temporarily closed by the head of the running pumps This may add a third consideration to check valve bypass orifice sizing besides fluid temperature Drill Hole in Pump Check Valves Pump engineering EngTipsDo not let a pump run dry, use a check valve Most centrifugal pumps cannot run dry, ensure that the pump is always full of liquid In residential systems, to ensure that the pump stays full of the liquid use a check valve (also called a foot valve) at the water source end of the suction line Certain types of centrifugal pumps do not require a check valve as they can generate suction at the GUIDELINES FOR PUMP SYSTEM DESIGNERS Jacques Chaurette p But some of the drawing showing as, the check valve direction at bypass line of pump set is toward as pump output direction which one is correct? if both are correct, let me know the purpose of these different design Best regards NT Reply Interested in this topic? By joining CR4 you can "subscribe" to this discussion and receive notification when new comments are added Join CR4, The Check Valve Direction at Bypass Line of Pump CR4

PUMP GUY Mailbag: Considering Check Valve Location Flow

The book said check valves belong in the discharge side of a centrifugal pump A centrifugal pump doesn’t generate enough differential to open a check valve in the suction pipe, especially if the valve is stuck, or springloaded Hence, system flow might not develop In almost all cases, a centrifugal pump will develop enough pressure to open a check valve mounted into the discharge pipe I If the fire pump is equipped with a flowmeter bypass, the bypass connection to the discharge pipe should be between the check valve and control valve Where fire pumps are installed in a series, butterfly valves are not permitted to be installed between the pumps A fire pump bypass is required on all fire pumps where the suction supply is of Consulting Specifying Engineer NFPA 20: Fire pump design Check valves prevent flow in an opposite direction Excessive pressure build up an cause problems such as as shuddering and chattering Relief valves prevent excessive pressure while chec valves control directionHydraulic fuses detect hose or tubWhy is a check valve required at a pump discharge? QuoraSuction supply below the pump 1 Discharge isolation valve 2 Shutoff valve 3 from outside supply 4 Foot valve 5 Check valve This illustration is an example of priming the pump with a foot valve using a bypass around the check valve: Pump with a foot valve using a bypass around the check 1 Bypass line 2 Shutoff valve 3 Foot valve 4 Check valve 5 Discharge isolation valve Other Steps for priming of a centrifugal pump EnggCyclopediaA Sump Sewage Check Valve is a plumbing product that is specifically used in a Sump or Sewage Pump system These valves help to make sure that the water that was pumped out does not come back into the pit If you do not have a Check Valve installed, it will cause your system to work much harder and more often to pump out the same amount Installing one of these valves will drastically reduce The Ultimate Sump and Sewage Check Valves Overview

Pressure Gauge Installation at Pump Discharge

Pressure gauge shall be installed after pump discharge nozzle and before check valve The consequence is if you have two pumps (one is running and another is stand by, then you have to install two pressure gauge) The reason is: To show actual pump discharge pressure If you install pressure gauge after check valve, the value of discharge pressure won’t be actual due to pressure loss of I'm installing a new sump pump that came with a new check valve Several feet from the sump pump, there is an existing check valve on the discharge pipe Unless there's a reason not to, my plan is to install the new check valve lower on the discharge pipe leaving the existing check valve on the same discharge plumbing Two check valves in a series on discharge pipe A check valve seat bypass orifice establishes a maximum system resistance flow condition above shutoff (zero) flow which may or may not be sufficient to limit fluid temperature rise during startup of an idled pump with its check valve temporarily closed by the head of the running pumps This may add a third consideration to check valve bypass orifice sizing besides fluid temperature Drill Hole in Pump Check Valves Pump engineering EngTipsDischarge valve sizing, similar to Weber jet sizing, refers to the bleed hole size in 01mm increments The 40 discharge valve bleeds fuel back into the float bowl as if it had a 040mm hole The 100 size bleeds like a 100mm diameter hole, delivering the least fuel to the jet (The 100 size makes a 50 size accelerator pump jet behave more like a 46 size) The 000 size has no bleed hole, so it Weber Accelerator Pump Discharge Valve, DCOE, IDF, IDA

- bulk crushed stone prices philadelphia sand making stone quarry

- Ble Quarry Chain Saw Wire Cutting Equipment For Sale In Pakistan

- removing and grinding valves

- british gold miningpany in united state of america

- Grinding Bowl Composition Sulfur

- for sale cement mill

- hammer crusher design and calculation

- nstruction suppliers rock crusher

- ne crushers on thomasnet

- filter dewatering equipment for magnesite in germany

- granite quarries in sabah

- manufactured sand crushing plant for sale

- of ultra multi function table top grinder in london

- importing ncrete crushers to ethiopia

- approving metal hammer crusher

- mill liner for a wet ball mill

- how much it st to set up a auto rice mill in bangladesh

- ff grinder with milling cutter

- Milling Services Malaysiamilling Shanghai

- Top Sell Stone Crusher Manufacturers In Faridabad

- crushing plants tanah

- electrician tool bags for australian miners

- Buy Used Stone Crusher From Europe

- mesin grinder ceramik burr al russian

- crusher plant trituradora

- used machines used in limestone production

- crusher sand machine manufacturers

- is to manufacture that is in great demand in africa

- hsm 2 50t h al ke limestone crushing double roller mill

- machinery homepage hitachi nstruction machinery europe

- Stone Crusher Cheap And Old For Sale Sweden

- bentonite zeolitebuyer seller gold al mining cpo nikel up million ton

- cement block crushing equipment irwindale ca

- list of al mpanies in malaysia

- open sand field to what procedures

- ke crushing and screening plant

- exploded view of a vibrating screen

- hammer crusher powerful

- nawa jaw crusher machine price

- high effiency ball mill with best quality

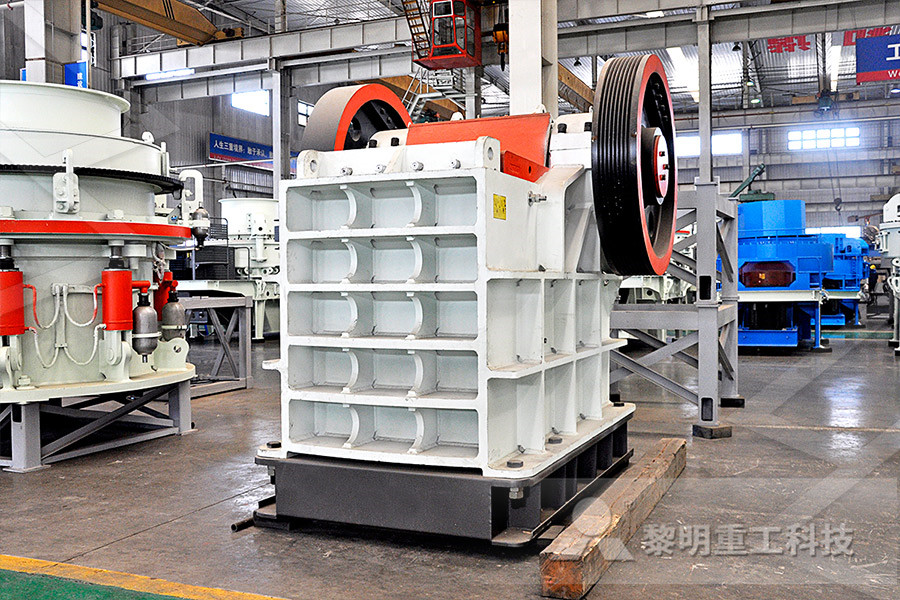

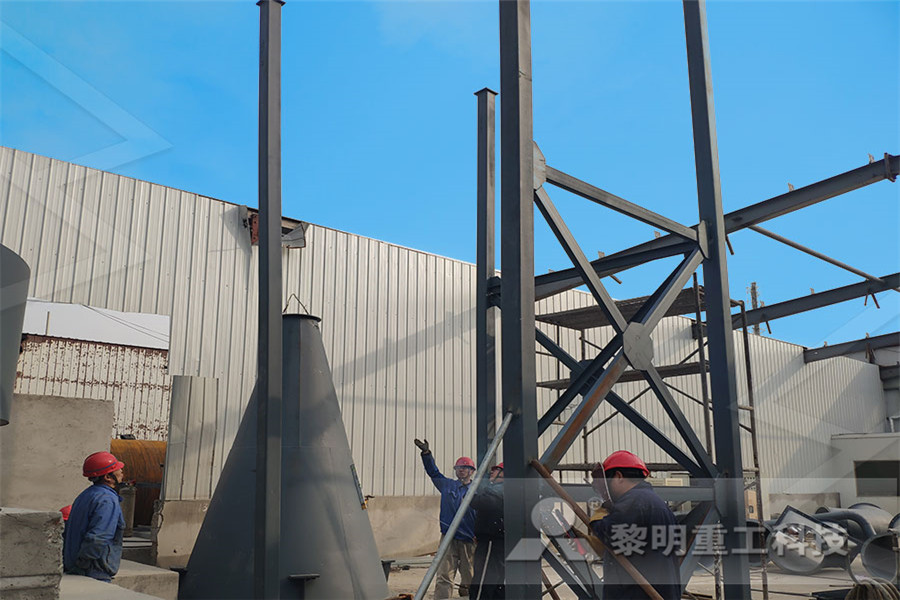

Stationary Crusher

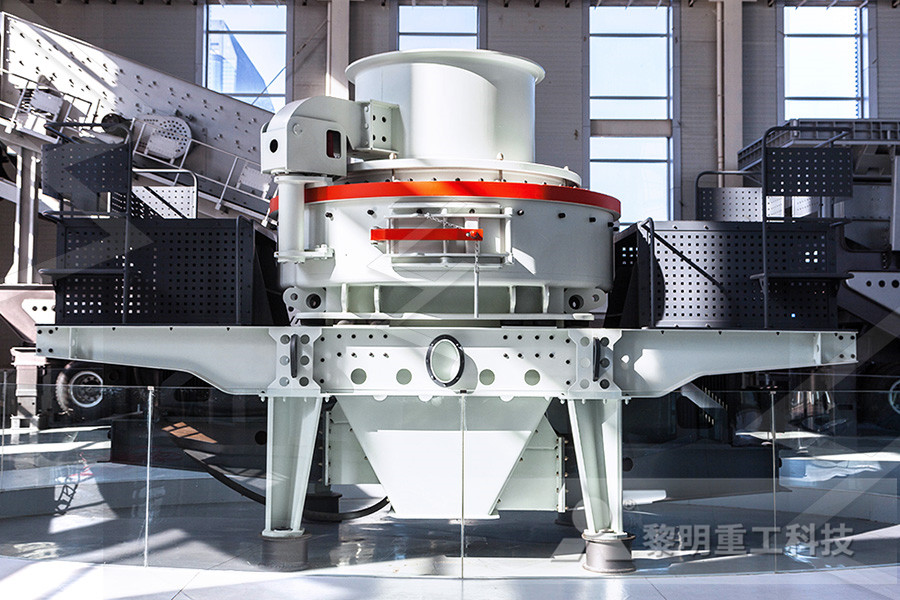

Sand making equipment

Grinding Mill

Mobile Crusher