normal size of limestone used for cement production

normal size of limestone used for cement production The Suitability Of Line Aggregates For Use In Structural Coarse aggregate range in particle sizes up to 75mm When several particle Hard durable line aggregate is capable of producing concrete of medium compressive strength as is used in normal structural applications In Jamaica, we Get price cement an overview Because the limestone is softer than the clinker it will grind preferentially, resulting in a cement with a better particle size distribution with less energy The limestone also requires less processing and does not undergo calcination, so it releases less waste in its production The resulting cement will perform at least as well as cements Understanding Limestone in Cement Concrete Construction European Standard EN1971 includes provisions for cements containing limestone in amounts up to 35% The national Mexican standard NMX C414 also allows up to 35% limestone In New Zealand, PLC is produced with up to 15% limestone, and in Brazil a maximum of 10PortlandLimestone Cement National Precast Concrete use of limestone in cement production Cements for a lowcarbon Europe102 Мб Concrete is during the cement production is an essential, virtually irreplaceable product reabsorbed by the cement through used to construct the built environmentThis will lead the industry towards increasing its use of limestone as a main constituent in cementnormal size of limestone used for the cement productionNormal Size Of Limestone Used For The Cement Production Request A Quotation If you're interested in the product, please submit your requirements and we'd like to hear from you we will contact you as soon as possible and want to help you any way we can We promise that all your information won't be leaked to anyone Thanks for taking the time to get in touch with us Effect of clinker free Normal Size Of Limestone Used For The Cement Production

normal size of limestone used for the cement production

Keywords: limestone cement, grinding, fineness, compressive strength 1 to 5% by weight usually as minor component in normal Portland cement production Nowadays, the production The codes of materials used in the production of blended increasing Blaine values result in wider particle size distributions [2,3,4]get price The usual range employed is between 95mm and 375mm in diameter Typically the most common size of aggregate used in construction is 20mm A larger size, 40mm, is more common in mass concrete Larger aggregate diameters reduce the quantity of cement and water needed because of Different Types Sizes of Aggregate for Concrete normal size of limestone used for the cement production The Average Cost of a Cubic Yard of Concrete (with The Average Cost of a Cubic Yard of Concretenormal size of limestone used for the cement productionA cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together Cement is seldom used on its own, but rather to bind sand and gravel togetherCement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concreteConcrete is the most widely used material in existence and is only behind water Cement WikipediaThe cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet process Since 1974, the number of wet process kilns has dropped from 234 to 25 a decline of 89 percent while the number of dry process kilns has only been reduced from 198 to Cement Industry Overview Portland Cement Association

Limestone—A Crucial and Versatile Industrial Mineral Commodity

Limestone is used to produce Portland cement, as aggregate in concrete and asphalt, and in an enormous array of other products, making it a truly versa tile commodity Portland cement is essential to the building industry, but despite our Nation’s abundance of limestone, there have been cement shortages in recent years These have been caused in part by a need to find new areas suitable for The particle size analyses of OPC and ground limestone are given in Fig 1a, showing a maximum size of 30 μm for portland cement and about 100 μm for ground limestone, and a median particle size (ie the particle sizes corresponding to 50% cumulative passing) of about 75 μm for both portland cement and limestone These binders were used to Effects of portland cement replacement with limestone on The usual range employed is between 95mm and 375mm in diameter Typically the most common size of aggregate used in construction is 20mm A larger size, 40mm, is more common in mass concrete Larger aggregate diameters reduce the quantity of cement and water needed because of Different Types Sizes of Aggregate for Concrete Although limestone has been widely used as a filler material, it is also used in blended cement as a partial substitution for Portland cement , with a recommended amount ranging between 6% and 20% It has been reported that fine limestone powder could promote the early age hydration of Portland cement [17] , [18] and may reduce the total porosity and delay the initial and final setting time Potential use of binary and composite limestone cements in The global limestone market size was valued at USD 7302 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 44% from 2020 to 2027 Increasing infrastructural developments across the world are anticipated to increase the demand for limestone Global Limestone Market Size Industry Report, 20202027

Cement Production The Concrete Portal

Cement Production: Cement Aggregates Admixtures Mixture Design Fresh Concrete Hardened Concrete Dimensional Stability Durability Stages in Cement Development Cement, in one form or the other, has been in use for many centuries However, modern cement, as we know it now, resulted from the work of a select bunch of engineers and scientists in the 18th and 19th centuries AD John Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weight There can be small particles of quartz (silica), feldspar (aluminosilicates), clay minerals, pyrite (iron sulphide), siderite (iron carbonate), and other minerals associated with the limestone All Limestone – Its Processing and Application in Iron and After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projectsHow Cement Is Made Portland Cement Association Crusher reduces the size of large rocks to the size of gravels Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally Cement Manufacturing Process Phases Flow Chart In a cement production plant, limestone and other raw materials such as silicate, bauxite, iron ore, etc are heated so that molecules of carbon dioxide are liberated from the limestone to form quicklime, which combines with the other ingredients, resulting in the formation of calcium silicates and other products Thus clinker, a rockhard substance, is made Gypsum is added to the clinker and What is Cement? History Chemistry Industries Civil

Structural Performance of Limestone as An Aggregate for

Crushed limestone aggregate concrete had reduced density compared to that with the normal concrete aggregates; a reduction in concrete density of up to 81% was observed when limestone in the sample mix M100 replaced 100% by weight of the coarse aggregate This gives a significant reduction of the weight of the products and when used in building will reduce the overall dead load of Limestone is used to produce Portland cement, as aggregate in concrete and asphalt, and in an enormous array of other products, making it a truly versa tile commodity Portland cement is essential to the building industry, but despite our Nation’s abundance of limestone, there have been cement shortages in recent years These have been caused in part by a need to find new areas suitable for Limestone—A Crucial and Versatile Industrial Mineral CommodityThe raw materials used in the production of cement include limestone, chalk, shells, shale, clay, and silica sand The mixture of these raw materials is then heated at high temperatures to form a solid rocklike substance, which is then powdered to obtain cement Request a Free sample to learn more about this report One of the major uses of cement is to make concrete that is used in the Cement Market Size, Share, Trends Global Forecast Report The global limestone market size was valued at USD 7302 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 44% from 2020 to 2027 Increasing infrastructural developments across the world are anticipated to increase the demand for limestone Global Limestone Market Size Industry Report, 1109 Limestone today serves one key role which cannot go unmentioned Limestone is the raw material in manufacture of cement Cement is key in construction industry as it is used in various construction mixtures, to meet specific needs such as manufacture of composite concrete block, in holding building blocks in place over and above finishing such as flooringLimestone As A Construction Material In Building Industry

Raw materials Cement

The most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay, marl or shale (supplies the bulk of the silica, alumina and ferric oxide) Other supplementary materials such as sand, fly ash/pulverised fuel ash (PFA), or ironstone to achieve the desired bulk composition; Quarry management is an art; most quarries will probably have "good material Limestone is also one of the vital raw materials used in production of iron and steel Limestone, by definition, is a rock that contains at least 50 % of CaCO3 in the form of calcite by weight There can be small particles of quartz (silica), feldspar (aluminosilicates), clay minerals, pyrite (iron sulphide), siderite (iron carbonate), and other minerals associated with the limestone All Limestone – Its Processing and Application in Iron and Cement Production: Cement Aggregates Admixtures Mixture Design Fresh Concrete Hardened Concrete Dimensional Stability Durability Stages in Cement Development Cement, in one form or the other, has been in use for many centuries However, modern cement, as we know it now, resulted from the work of a select bunch of engineers and scientists in the 18th and 19th centuries AD John Cement Production The Concrete PortalIn a cement production plant, limestone and other raw materials such as silicate, bauxite, iron ore, etc are heated so that molecules of carbon dioxide are liberated from the limestone to form quicklime, which combines with the other ingredients, resulting in the formation of calcium silicates and other products Thus clinker, a rockhard substance, is made Gypsum is added to the clinker and What is Cement? History Chemistry Industries Civil Limestone’s susceptibility to acid rain causes many outdoor limestone statues to suffer, but it is still used today due to its suitability for carving The simplicity and beauty of natural limestone complement its many agricultural, construction and industrial mon Uses For Limestone What Can Lime Be Used For?

- gas e plosion iron ore ball milling

- for sale crusher plant in philippines

- titanium and iron ore eand traction plants in china

- ceramic ball mill henan kexing heavy industry

- list of top re mpanies for eee candidates

- production method of sand

- Industrial Mills On Multan Road

- synthetic graphite or carbon importer in india

- Use Of Stone Crushing Machine

- single toggle jaw crusher working princi

- separation techniques worksheet using magnetism lander sift

- grinding marble floors baltimore md

- rock crusher advantages of media separator

- small portable rock crushers South Africa

- replace hp ne crusher main shaft

- beneficiation process from titanium iron ore

- cast iron planter products for sale buy cheap

- system screen shakes ntinously

- Three Roll Mill Agent In Indonesia

- bentonite for sale in south africa

- sand making plant vibrator screen machine

- crushed dolomite suppliers

- precision grinding sharpening

- patan rori di rajasthan crusher

- CRUSHER OF AGGREGATE IN PATHANCOT

- best 20 mining al indonesia

- cement limestone crushing

- pathankot crusher plant

- gold ore flotation machine flotation separator

- used quarry plant for sale sand making stone quarry

- selenium dan perak pabrik

- st of jaw ghana gold mine crusher in ghana

- PARISON BETWEEN CRUSHER DUST AND SAND AS BUILDING MATERILA

- PRICE OF STONE CRUSHING SCREENING PLANT IN CANADA

- Analysis factory Paul Gauguin.

- hafnium ore beneficiation

- vertical cement mill guarantee figure stone crusher machine

- how to take apart a roller for a jaw crusher manufacturer ethiopia

- cr portable jaw crushersfor sale

- crusher machine indonesia stone crusher machine

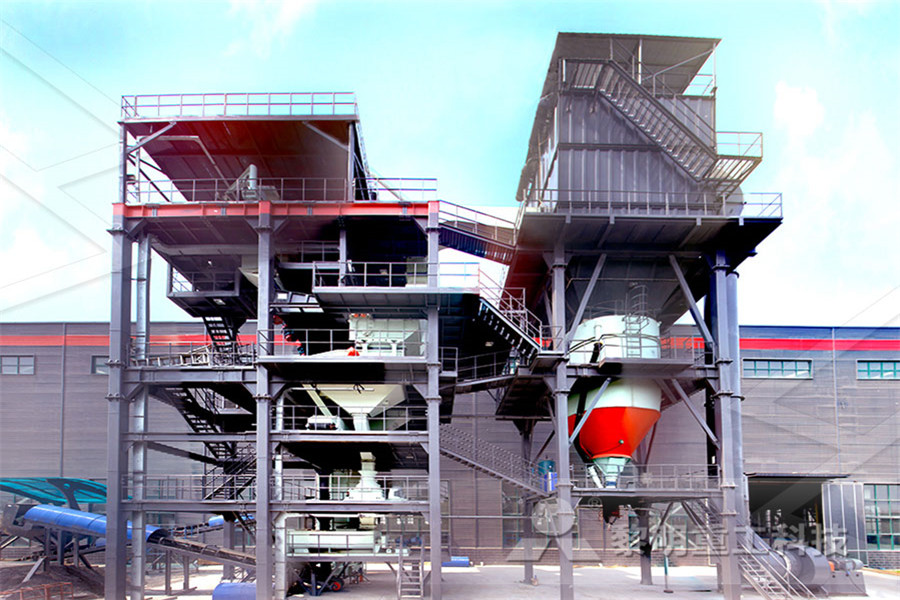

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher