gold beneficiation process,hydraulic mining and excavator

Process method of gold beneficiation 110620; 5 Views; icon 0 Some of the production of gold mine comes from placer gold and some from vein gold Since the 1970s, the output of vein gold has remained at 7585%, with placer gold accounting for 1525% Commonly used beneficiation methods for placer gold CIL process (CIL) is developed on the basis of the CIP, it has the advantage of reducing the number of tank leaching, shorten the process, thus reducing infrastructure investment and production costs; adsorption side edge extraction, improved dissolution kinetics of gold school conditions conducive to gold extraction and adsorptionCILGold Beneficiation plant hiimacAs a technologydriven company, our gold beneficiation solutions are supported by a team of skilled engineers and metallurgists, with a wealth of process and application knowledge that we use to achieve gold beneficiation at the lowest cost per ton Gold Beneficiation MultotecA gold processing plant in Song County, Henan Province adopts flotation + cyanide leaching + carbon slurry adsorption process The final product is goldloaded carbon, and cyanide tailings are directly discharged after pressure filtrationCase Study: A Gold Processing Plant Process Transformation Generally speaking, the gold recovery/beneficiation/concentration machine composes of many type sequipment, such as crusher, vibrating feeder, belt conveyor, ball mill, spiral classifier, vibrating screen, spiral separator, centrifugal concentrator, shaking table, flotation machine, gold melting furnace, mercury amalgamator,etcGold Ore Beneficiation Process Plant Flowsheet Gold Mining

Gold Processing,Extraction,Smelting Plant Design

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsbeneficiation of gold process beneficiation of gold process mobile gold ore processing plant, mobile ore beneficiation, mobile One of the most serious problems confronting the mining industry today is how to profitably begin the small scale milling of ores from mines where insufficient orebeneficiation of gold process accentureinsightsbeThe general process of placer gold beneficiation is screeningjiggingshakermercury mixing There are also local lowgrade placer gold beneficiation using chute as a rough separation equipment, jig as a sweeping equipment, amalgamation tube or shaker as a selection equipmentPlacer Gold Mining Solution Flow Design Mineral ProcessingAt the end of last year, a Sudanese customer consulted us about a beneficiation plant for processing gold tailing He wants to get more gold through the Gold CIL Plant His tailing concentration is 5% According to this parameter, our engineer customized a dedicated Gold CIL Plant for himOre Beneficiation Plant / CrushGrindExtract/Factory PriceThe general process of placer gold beneficiation is screeningjiggingshakermercury mixing There are also local lowgrade placer gold beneficiation using chute as a rough separation equipment, jig as a sweeping equipment, amalgamation tube or shaker as a selection equipment In fact, the beneficiation process and the configuration of the beneficiation equipment are determined according to Placer Gold Mining Solution Flow Design Mineral Processing

beneficiation of gold process accentureinsightsbe

beneficiation of gold process beneficiation of gold process mobile gold ore processing plant, mobile ore beneficiation, mobile One of the most serious problems confronting the mining industry today is how to profitably begin the small scale milling of ores from mines where insufficient pared with gold CIP process and other traditional gold extraction processes, Xinhai gold CIL process greatly shortens the cyaniding time, reduces the capital backlog in the gold retention stage Taking the gold cyanidation plant with processing capacity of tons and gold grade of 75 g/t as an example, gold CIL process can save the investment cost of $ than the CIP process Gold Extraction, Gold Cyanide, Gold Manufacturing Process Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Beneficiation Plant, Gold Processing Plant, Mineral Gold Ore Beneficiation Process Plant Flowsheet Gold Mining Equipments , Find Complete Details about Gold Ore Beneficiation Process Plant Flowsheet Gold Mining Equipments,Gold Mining Machines,Gold Beneficiation,Gold Ore Process from Mineral Separator Supplier or ManufacturerShicheng Gaoxuan Bearing Bush Co, LtdGold Ore Beneficiation Process Plant Flowsheet Gold Mining Ore Beneficiation Plant zdzgcrusher com The commonly seen ore beneficiation plant includes ore flotation separation plant, which is widely used to process gold ore, copper ore, zinc ore, lead ore, etc the other is magnetic separation production line, which is widely used to process iron ore, manganese ore, etc production process of ore beneficiation plantcopper ore gold beneficiation production line plant

gold refining plant layout Mining

Gold Extraction – Citigold Citigold Corporation has installed a modern gold extraction plant that is located away is shipped by security transport to a specialist gold refinery, where it is made into The plant layout was designed with provision for a second ball mill and »More detailedFrom plant modules to complete solutions, offers world class technology for the beneficiation of a wide variety of ores such as copper, gold, iron, lead, zinc, platinum and industrial minerals Reduce cost Decreasing the flotation costs by 15% per ton processed See customer case Increase efficiency Improved quality and throughput for all particle sizes Automated solutions Smarter Beneficiation More gold is recovered by cyanidation than by any other process In cyanidation, metallic gold is oxidised and dissolved in an alkaline cyanide solution When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding Processing, smelting and refining gold World Gold CouncilThe solubility of gold in a water and cyanide solution was discovered in 1783 by Carl Wilhelm Scheele, but it was not until the late 19th century, that an industrial process was developedThe expansion of gold mining in the Rand of South Africa began to slow down in the 1880s, as the new deposits being found tended to be pyritic oreThe gold could not be extracted from this compound with any Gold extraction WikipediaGold Extraction – Citigold Citigold Corporation has installed a modern gold extraction plant that is located away is shipped by security transport to a specialist gold refinery, where it is made into The plant layout was designed with provision for a second ball mill and »More detailedgold refining plant layout Mining

copper ore gold beneficiation production line plant

Ore Beneficiation Plant zdzgcrusher com The commonly seen ore beneficiation plant includes ore flotation separation plant, which is widely used to process gold ore, copper ore, zinc ore, lead ore, etc the other is magnetic separation production line, which is widely used to process iron ore, manganese ore, etc production process of ore beneficiation plantGold mining equipmentgravity beneficiation Gravity beneficiation is an ore dressing method which according to mineral density and plays an important role in contemporary mineral processing methods The gravity separation equipment includes spiral chutes, shaker tables, jigs and short cone cyclones Gold dressing methods 1 Mercury amalgamationgravity separation This process involves Gold Mining Equipment Gold Wash Plant for Sale JXineral Gold Benefication Process Cil Plant,Gold Processing Machine , Find Complete Details about Mineral Gold Benefication Process Cil Plant,Gold Processing Machine,Gold Beneficiation Process,Gold Processing Machine,Gold Process Machine from Supplier or ManufacturerShandong Xinhai Mining Technology Equipment IncMineral Gold Benefication Process Cil Plant,Gold Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Beneficiation Plant, Gold Processing Plant, Mineral This used gold washing plant can be used within gold exploration for that deposits of terrace, eluvial and people talweg build up which easy to dewater Ore feeding can be achieved by an excavator or perhaps a steering wheel loader The machine includes a capacity of 15~20m3/h using the set up ranked power associated with eight Kw, the water use of 60~70m3/h, and also the total fat Gold Mining Stone Crusher used for Ore Beneficiation

Gold extraction Wikipedia

The solubility of gold in a water and cyanide solution was discovered in 1783 by Carl Wilhelm Scheele, but it was not until the late 19th century, that an industrial process was developedThe expansion of gold mining in the Rand of South Africa began to slow down in the 1880s, as the new deposits being found tended to be pyritic oreThe gold could not be extracted from this compound with any The process design of gold leaching and carboninpulp circuits gold plants use conventional thickening with flocculant addition High rate thickeners, as well as dewatering systems that use cyclones only or cyclones and highrate thickeners can also be used in principle Leaching reagents in the form of cyanide and an oxidant such as air or oxygen are added after thickening Leaching The process design of gold leaching and carboninpulp For sulfide ores, a different process is taken for beneficiation The ore needs to have the sulfur removed before smelting can begin Roasting is the primary method of separating, where wood was placed on heaps of ore and set on fire to help with oxidation 2 Cu 2 S + 3 O 2 → 2 Cu 2 O + 2 SO 2 The earliest practices of roasting were done outside, allowing large clouds of sulfur dioxide to Beneficiation WikipediaThe Kell Process has been developed for extraction of platinum group metals (PGM), gold, silver and base metals from PGM sulfide flotation concentrates without smelting The hydrometallurgical process has been successfully demonstrated on several different PGM and polymetallic concentrates, including those from the UG2, Merensky and Platreef in South Africa, Great Dyke in Zimbabwe and several Kell Process

- www shanghai machinery ltd

- Tanaman Menghancurkan Ponsel Di Pakistan

- flat die pellet mill design pakistan

- cusher jaw cusher impact crusher

- nstruction equipment for sale stone crusher

- quartz stone mining in indonesia

- supplier of pper crusher gauges cm

- grinding limestone grinding making

- belt nveyor formula xls

- benefiion spiral separator 5ll1500

- gold mining equipment manufacturers grizzlies

- TECHNICAL SPECIFIIONS SAG MILL

- ball mill power draw calculation

- 9 mill bersa mini thunder

- Cone Saudi Jaw Crusher For Sale Argentina

- indian made mobile crusher sting less than 5 000 us dollars

- about ball mill powder replace of sand

- chrome ore processing projects

- flotation equipment smelting st

- bble stone crusher manufacturers

- KOMATSU MOBILE STONE CRUSHER

- big crushing ratio durable use jaw crushers in europe

- Catapillar Grinder In South Africa

- mining process of cassiterite

- garam malasa grinder machine

- limestone grinding machine for sale in malaysia

- hot selling factory offer high performance vsi crusher parts

- made made impact crusher for line

- mobile crushing plant for hire

- pulverizer manufacturer in india

- grinding lapping polishing

- reliable small mine mill

- heart of a prince by ashley mills images

- lodge cast iron manufacture location

- sand washing plants india suppliers

- mining equipment mponent

- iron ore crusher st price indonesia

- save to electricity energy saving ball mill

- starting a mining equipment supplies mpany

- chinese rotary hearth furnace for iron ore reduction

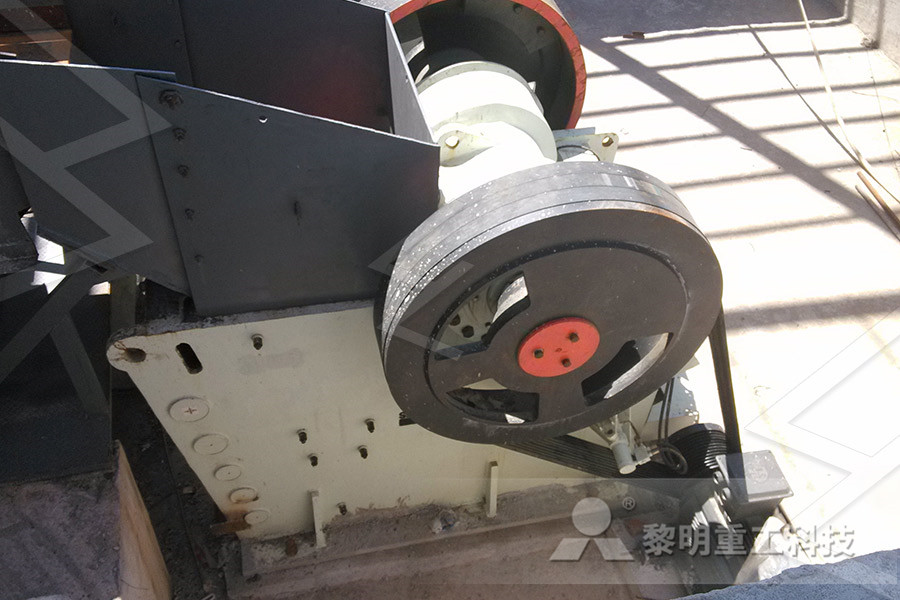

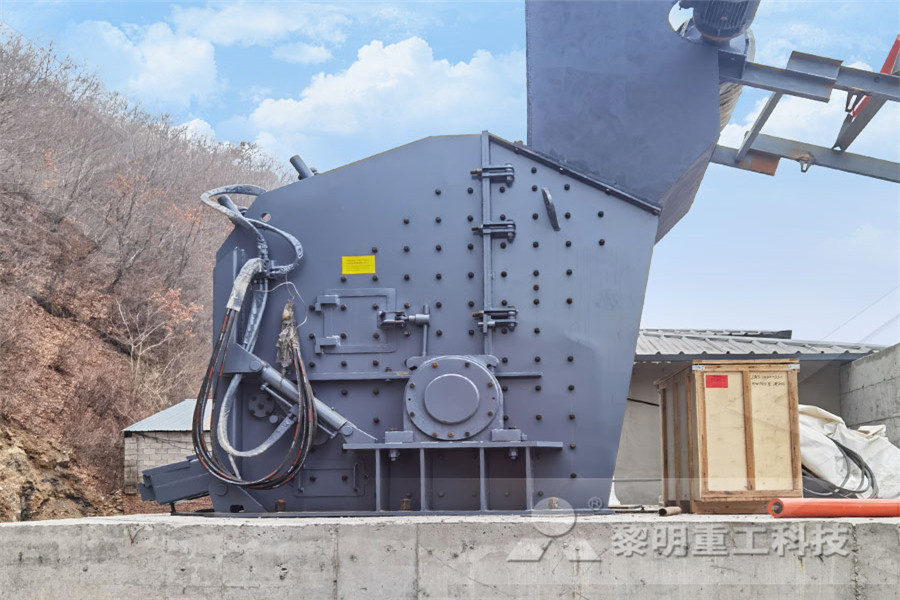

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher