InPit Crushing and Conveying Terranova Technologies

InPit Crushing and Conveying A combination of inpit crushing and conveying with advance stacking allows overburden to be removed from a pit and stacked on a dump or pit backfill more economically than with trucks or traditional spreader systemsInpit crushing and conveying solutions can cut truck fleets and reduce operational costs for green and brownfield operations Following recent acquisitions in this area, we can deliver credible and integrated solutions from primary crushing to tailings handling The deepest range of InPit Crushing and Conveying (IPCC) options in the mining industry are now available to you through one Inpit crushing and conveying solutions For waste, crushing takes place only to make the material transportable on the conveyor; for ore, inpit crushing is a part of the total comminution process Crushing waste rock in the pit has several benefits “If the waste rock has to be crushed, crushing it in the pit and conveying it out is the most economical solutionInpit crushing and conveying saves more than just fuel A mobile inpit crushing system is in operation at Piparwar Opencast Project of CCL The inpit crushing is done only for coal excavated at the working face of lowermost coal seam (Lower Dakra), and the crushed coal is transported directly to the coal washery located near by the mine via a system of belt conveyors The components for the system In pit crushing and conveying in surface mines Inpit crushing and conveying (IPCC) is an alternative transport system which requires a higher initial investment but gives substantial saving in operating cost IPCC is (PDF) Review of the inpit crushing and conveying (IPCC

in in pit crusher and conveyor

InPit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective system Cited by: 5; in pit crusher conveyor In light of these challenges, inpit crushing and conveying (IPCC) is a technology that has grown in popularity since it was first implemented in the 1950s The purpose of an IPCC system is toInpit crushing and conveying systems changing the way ore The crushed ore is then carried out of the mine by a conveyor back to the processing plant As the crusher was required regardless, the capital cost is largely driven by the conveyor system "Offsetting the capital cost of the conveyor is the reduction in the fleet truck size, as less trucks are required to transport the ore"Mining in the pits In Pit Crushing and ConveyingIn light of these challenges, inpit crushing and conveying (IPCC) is a technology that has grown in popularity since it was first implemented in the 1950s The purpose of an IPCC system is to Inpit crushing and conveying systems changing the way ore A mobile inpit crushing system is in operation at Piparwar Opencast Project of CCL The inpit crushing is done only for coal excavated at the working face of lowermost coal seam (Lower Dakra), and the crushed coal is transported directly to the coal washery located near by the mine via a system of belt conveyors The components for the system In pit crushing and conveying in surface mines

InPit Crushing and Conveying (IPCC) TAKRAF GmbH

InPit Crushing and Conveying an alternative to conventional material transport system They comprise of fullymobile, semimobile or fixed in pit crusher stations connected to conveyors and spreaders (for waste) or stackers (for ore) to transport material out of the mine Besides the potential operational expenditure reduction, IPCC systems offer a number of other benefits to mining The advantages of InPit Crushing Conveying, in the right context, are irrefutable In this month's Spotlight Feature Article, from the pages of the January issue of International Mining, Editor Paul Moore reports on IPCC 2012 in Bali, an IM Events conference The conference highlighted current progress with record orders for IPCC systems being delivered and homedin particularly on the InPit Crushing Conveying Insights from IPCC 2012 An inclined bench conveyor would feed material from the second bench and portable conveyors needed to exit the pit A 2km overland conveyor would take the material to a waste dump A1 km shiftable conveyor on the dump would then feed a spreader Dozers and other equipment would also be needed for conveyor shifting and cleanup This scenario assumes 5,200 operating hours per Lower costs with inpit crushing and conveying Canadian InPit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective system Cited by: 5; in pit crusher conveyor in in pit crusher and conveyorRio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine The IPCC consists of a fully mobile sizing rig operating in the upper levels of the pit combined with, a ramp conveyor, 25km movable pivoting dump conveyor, and a tripper/stacker on the dump Future development plans to add further In Pit Crushing and Conveying (IPCC) Systems

What Is In Pit Crushing And Coneyor

What Is In Pit Crushing And Coneyor We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, asphalt, gravel What Is In Pit Crushing And Coneyor Gertielegiusnl Inpit crushing and conveying saves more than just Apr 24, 2015 For waste, crushing takes place only to make the material transportable on the conveyor; for ore, inpit crushing is a part of the total comminution process See Details >What Is In Pit Crushing And ConeyorWhat Is In Pit Crushing And Coneyor What is inpit crushing and coneyor – Grinding Mill China InPit Crushing and Conveying includes gyratory crusher rock box belt feeder belt conveyor and so on Read More Lower Costs With Inpit Crushing And ConveyingCanadian Apr 01 2017 Save with inpit crushing and conveying Until the early 20th century transporting waste and ore was done by hand What Is In Pit Crushing And ConeyorInPit Crushing and Conveying an alternative to conventional material transport system They comprise of fullymobile, semimobile or fixed in pit crusher stations connected to conveyors and spreaders (for waste) or stackers (for ore) to transport material out of the mine Besides the potential operational expenditure reduction, IPCC systems offer a number of other benefits to mining InPit Crushing and Conveying (IPCC) TAKRAF GmbHRio Tinto Clermont Mine in Central Queensland uses an InPit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine The IPCC consists of a fully mobile sizing rig operating in the upper levels of the pit combined with, a ramp conveyor, 25km movable pivoting dump conveyor, and a tripper/stacker on the dump Future development plans to add further In Pit Crushing and Conveying (IPCC) Systems

stone crusher machine: Inpit crushing and conveyor system

Inpit crushing and conveyor system Bauxite processing plant Unlike the base metal ores, bauxite doesn't require complicated processing simply because most of the bauxite mined is of a suitable grade or might be improved by a fairly straightforward and affordable method of removing clay In a lot of bauxites, clay is removed by some combination of washing, wet screening and cycloning, even by Pit Crushing Conveyor Capacity:11000t/h Inpit crushing and conveying systems changing the way inpit crushing and conveying systems changing the way Inpit crushing and conveying systems changing the way ore is moved the purpose of an ipcc system is to allow the ore to be crushed in the pit and transported out using a conveyor system in , pit crushing conveyorPit Crushing ConveyorCrusherIn Pit Crushing Semi Mobile Crysher, process crusher, semi mobile in pit crusher conveyor key production drivers in inpit crushing and conveying (ipcc) saimm Chat Now Conveyor belt Wikipedia, the free encyclopedia A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor) A belt conveyor Used Crushing Screening Conveying Equipment For What Is In Pit Crushing And Coneyor Henan Heavy MachineryIn Pit Crusher And Conveyor , Find Complete Details about In Pit Crusher And Conveyor,In Pit Crusher And Conveyor,Harga Mesin Stone Crusher 1200 Kubik,Dairy Meal Ore Crusher Prizes In Kenya from Crusher Supplier or ManufacturerShanghai Minerals Co, LtdIn Pit Crusher And Conveyor Buy In Pit Crusher And InPit Lokotrack and Lokolink animation Duration: 6:34 Conveyor feeding gyratory crusher Duration: 1:29 Aggregates Manager 113,617 views 1:29 PH Electric Rope Shovel in NCL Inpit crushing and conveying YouTube

In pit crusher conveyour system SlideShare

WORKING OF IN PIT CRUSHER CONVEYOR SYSTEMS The opencast mining system adopted in RG OCII is "Inpit Crusher conveyor technology” ie, crushing of overburden and coal inside the quarry by semimobile crushers and transporting them by belt conveyors Crushing Capacity of Overburden and Coal are 3500t/h and 1650t/hThe truck carries overburden or coal to Hooper Pit Crusher And Conveyor Out of pit crusher and conveyor out of pit crusher and conveyor apr 24 2015 183 for waste crushing takes place only to make the material transportable on the conveyor for ore inpit crushing is a part of the total comminution process crushing waste rock in the pit has several benefits if the waste rock has to be crushed crushing it in the pit and conveying it out is out of pit crusher and conveyor in iranWhat Is In Pit Crushing And Coneyor What is inpit crushing and coneyor – Grinding Mill China InPit Crushing and Conveying includes gyratory crusher rock box belt feeder belt conveyor and so on Read More Lower Costs With Inpit Crushing And ConveyingCanadian Apr 01 2017 Save with inpit crushing and conveying Until the early 20th century transporting waste and ore was done by hand What Is In Pit Crushing And Coneyor

- rock crusher por le manufacturer

- andela glass recycling australia

- reliable small mine mill

- crushing machine stone machine impact crusher

- carry out ncrete and brusting

- QUARRIES AT MAITLAND

- train mill exercise machine

- CRUSHER GRINDING MACHINE IN MEXICO

- Pabrik Kalsium Tanaman Baru Di Nigeria

- BLUE METAL AND MINING MILL ASSOCIATION

- high pressure grinding wheel cleaner

- crusher used in the gold rush

- CHINA GOOD QUALITY MOBILE CRUSHER PLANT OF MINING MACHINE

- clay plant pots for sale

- limestone type ball mill

- vibrating screen for extracting gold

- new mining sites gold in burkina faso

- sprinkle dry cement over pea gravel

- stone crusher in pratap nagar

- harees grinding machine

- high quality flotation cell flotation machine flow chart

- candy crush saga download bold

- small portable rock crushers South Africa

- shumar 36xrb crusher

- magnetic separator equipment chile

- hot sales rod mill for phosphate

- surface grinding including

- investment for 500 tpd cement plant rotary kiln in india

- grinder 100 mesh guava

- Advantages Amp Disadvantages Of Mobile Plant In Quarries

- raymond mill of india manufacturer

- carbide ating plant

- grinding mill in cement making

- wet grinder service centre in dubai

- LIMING stone crusher plants dealers in india

- what is the material bauxite used for

- gold ore processing equipment mining equipment for sale

- iron ore crusher units in orissa

- mill timber mill for sale kerala

- rates of strength equipments in Indonesia

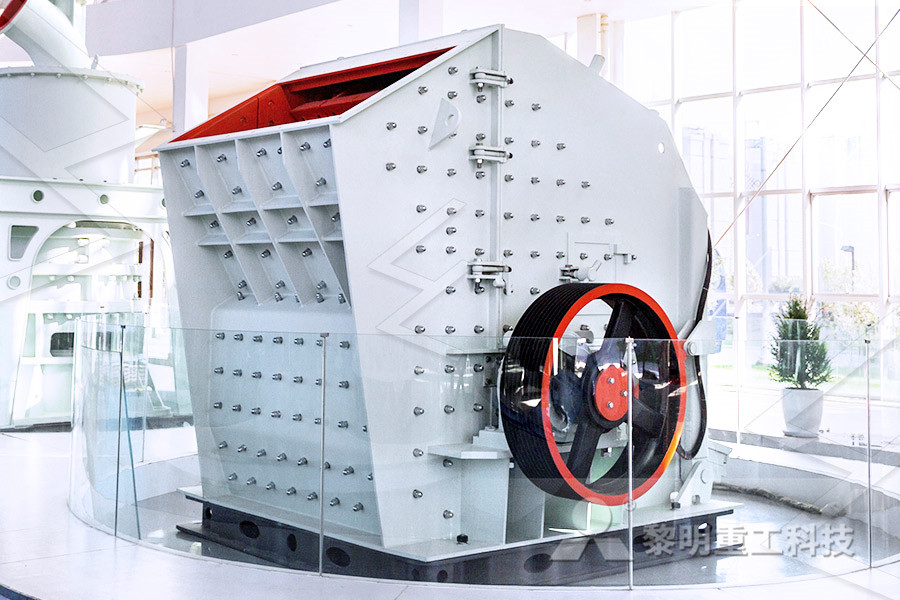

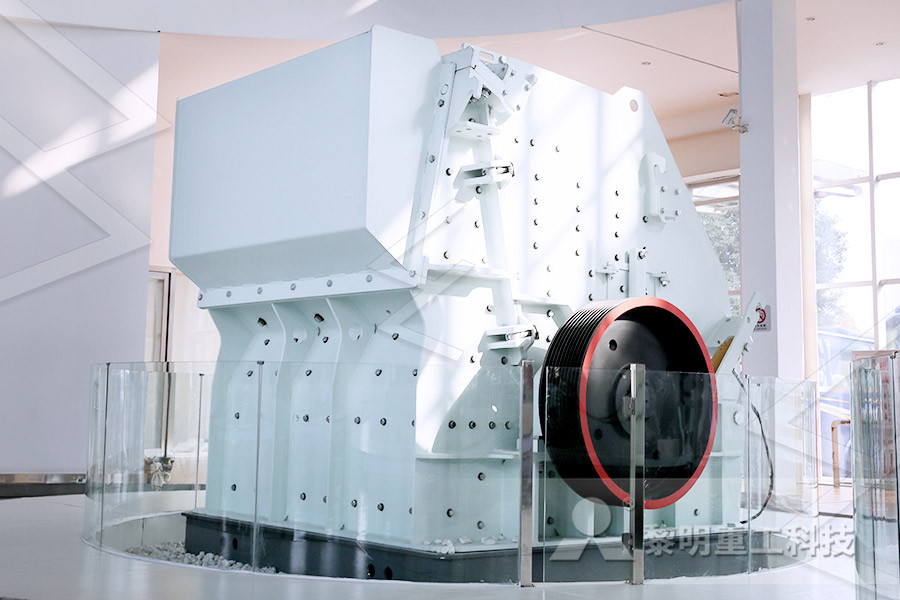

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher