PDC Mass Balance Flotation + CIL Rev A 2012 June 20

PROCESS DESIGN CRITERIA FLOTATION PROCESS PLANT Project: KERRSULPHURETSMITCHELL PROJECT (PREFEASIBILITY 2012) Project No: Client: SEABRIDGE GOLD INC Update Date: April 26 2012 Rev: A Description Unit Value Source General Type of Deposit: Copper/Gold / MolybdenumPorphyry Operating Schedule Shifts/Day 2 Client Hours/Shift h 12 Engineering Design Hours/Day h 24 Engineering Design Flotation processes are based on the different surface wettability properties of materials (Wang et al, 2015) In principle, flotation works very similarly to a sink and float process, where the density characteristics of the materials, with respect to that of the medium where they are placed are at the base of the separationFlotation Process an overview ScienceDirect TopicsPdf The Effect Of Grinding On Pyrophyllite Flotation flotation by a Denver D12 flotation machine with 1 l cell In this study, pyrophyllite was examined to investi Pulp was prepared with tap water at its natural pH 82 gate the effects of grinding on its flotation 84 and was 20 solids by weight Read Morestructure of gyratory flotationFroth Flotation Process In Chemistry Hgt gyratory crusher6x series jaw crusherc series jaw crusheraw crusherj series jaw crusheri5x series impact crusher primary impact crusherecondary impact crushermpact crusherfroth flotation process in chemistryroth flotation process mineral processing metallurgy More; Froth Flotation Gold Recovery Mattlounge Froth flotation gold process roth flotation Professional Gyratory Flotation Cellnewly designed wet ball mill gyratory mining machine Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust In this context, the SAG mill and ball mill are considered grinders rather than crushers A gyratory crusher is one of the main types of primary crushers in a mine or ore newly designed wet ball mill gyratory mining machine

2019 newly designed grinding gyratory crusher 」

Crushers, Grinding Mill, Mobile Crusher Machine For Quarry Kamp;W Mining Machinery is a World leader in the design, manufacture and supply of specialist crushing amp; screening equipment for the mining, aggregates, recycling and process industriesOur goal is to provide the finestquality products and services to our customers and to do so more efficiently and economically than our competitorsnewly designed grinding gyratory crusher HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc , representing the most advanced crusher technology in the world It is not only widely applied in HJ Jaw CrusherJaw Crushers are often used as the newly designed grinding gyratory crusherMineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes Application of theory to practice is explained at each stage, helping operators understand associated implications in each unit process Covers the theory and formulae for unit capacities and power Mineral Processing Design and Operations 2nd Editionmade mining used newly designed grinding ball mill Grinding Mill Design Ball Mill Manufacturer All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a made mining used newly designed grinding ball millnew design mining gyratory sifter screen 22 Best Circular Vibrating Screen images Circular Screen Mar 4 2016 Circular Vibrating Screen is a kind of new and highly effective vibrating I am sales manager at Pingyuan Mining Machinery CoLtd We are the Gyratory screen similar with Rotex screener is a high precision standard of fine Linear vibrating screen is designed with dualvibration motor new design mining gyratory sifter screen

Grinding Archives Page 9 of 20 Mineral Processing

Our EXAMPLE Grinding and Classification Circuit is designed to grind 500 tonnes of ore per day, operating 24 hours per day, with an availability of 95% This circuit will grind 5/8″ material from the Crushing Plant, classify the slurry in one of two cyclones, and pass 70% of the minus 200 mesh material to the mill feed Thickener Circuit at a rate of 22 mtphFroth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation WikipediaIn Mineral Processing Design and Operations (Second Edition), 2016 Abstract Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large runofmine ore pieces to acceptable sizes Descriptions of secondary and tertiary cone crushers that usually follow gyratory crushers are also given in detailPrimary gyratory crusher in ecr roadFroth Flotation Process In Chemistry Hgt gyratory crusher6x series jaw crusherc series jaw crusheraw crusherj series jaw crusheri5x series impact crusher primary impact crusherecondary impact crushermpact crusherfroth flotation process in chemistryroth flotation process mineral processing metallurgy More; Froth Flotation Gold Recovery Mattlounge Froth flotation gold process roth flotation Professional Gyratory Flotation CellGrinding Classifying Grid Type Ball Mill; Overflow Type Ball Mill; Rod Mill; Energy Saving Ball Mill ; Submerged Spiral Classifier; Autogenous Mill; Cylinder Energy Saving Overflow Ball Mill; High Weir Spiral Classifier; Separating Process Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute widely iron ore hydraulic gold flotaton cellclassifier

Mineral Flotation International Mining

The grinding circuit is usually designed to produce the optimum size distribution established in testing and given in the design criteria When the product size alters from this optimum, control requires either changing feed tonnage to the circuit or changing product volume, with either causing changes in flotation feed rates “While grindability changes due to the variation in ore Copper Ore Flotation Machine With Best Design T09:10:15+00:00 Mobile Crushers; Stationary Crushers; Grinding Mill; Washing Screening ; Ore Beneficiation; Primary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile station Fine crushing washing mobile station Three combinations Copper Ore Flotation Machine With Best Design Stone grinding machine Stone crusher is our primary product Along with grinder mill, stone crusher occupies a sizable percent in our conveying Gulin design special South Africa crusher specifically for South Africa mining industry Gulin stone crusher is broadly utilized in metallurgy, building construction, chemical, fireproof materials, etc Gulin stone crusher from China includes severalstone grinding machine and gyratory crusher manufacturer Mineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes Application of theory to practice is explained at each stage, helping operators understand associated implications in each unit process Covers the theory and formulae for unit capacities and power Mineral Processing Design and Operations 2nd Editionmade mining used newly designed grinding ball mill Grinding Mill Design Ball Mill Manufacturer All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a made mining used newly designed grinding ball mill

Introduction to Mineral Processing or Beneficiation

The crushing and grinding process will produce a range of particles with varying degrees of liberation (Figure 2) Any particles that exceed a target size required for physical separation or chemical extraction are returned to the crushing or the grinding circuit Figure 2 Breaking of larger material to smaller pieces result in particles with varying degrees of liberation The darker regions gyratory crusher foundation design is a leading global manufacturer of crushing and milling equipment (gyratory crusher foundation design), also supply individual (gyratory crusher foundation design) crushers and mills as well as spare parts of them offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and gyratory crusher foundation design– Rock Crusher MillRock Froth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation WikipediaFroth Flotation Process In Chemistry Hgt gyratory crusher6x series jaw crusherc series jaw crusheraw crusherj series jaw crusheri5x series impact crusher primary impact crusherecondary impact crushermpact crusherfroth flotation process in chemistryroth flotation process mineral processing metallurgy More; Froth Flotation Gold Recovery Mattlounge Froth flotation gold process roth flotation Professional Gyratory Flotation CellGrinding Classifying Grid Type Ball Mill; Overflow Type Ball Mill; Rod Mill; Energy Saving Ball Mill ; Submerged Spiral Classifier; Autogenous Mill; Cylinder Energy Saving Overflow Ball Mill; High Weir Spiral Classifier; Separating Process Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute widely iron ore hydraulic gold flotaton cellclassifier

new ore process flotation machine for gold

Gold Mining Flotation Process Machine Gold Ore Flotation Equipment Gold ore flotation machine tin iron ore thickener shandong xinhai mining technology amp inc is a stockholding high and new technology enterprise to provide turnkey solution for mineral processing plant including design and research machine manufactur Flotation is a method that is widely used in gold ore processing plant to Copper Ore Flotation Machine With Best Design T09:10:15+00:00 Mobile Crushers; Stationary Crushers; Grinding Mill; Washing Screening ; Ore Beneficiation; Primary mobile crushing plant Independent operating combined mobile crushing station Mobile secondary crushing plant Fine crushing and screening mobile station Fine crushing washing mobile station Three combinations Copper Ore Flotation Machine With Best Designlab cone flotation machines; primary gyratory crusher for iron ore; lead flotation cell sold to all over the world; sistem kerja flotation machines dan stacking; professional fluorite flotation machine; portable rock flotation machines th germany; new type iron ore flotation machines with best service; quary macinery round crusher; new crusher gyratory osumilite flotation machines chancadorMineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes Application of theory to practice is explained at each stage, helping operators understand associated implications in each unit process Covers the theory and formulae for unit capacities and power Mineral Processing Design and Operations 2nd Editionmade mining used newly designed grinding ball mill Grinding Mill Design Ball Mill Manufacturer All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material Grinding can be undertaken in many ways The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a made mining used newly designed grinding ball mill

- machine crushing tearing curling

- united states raw gold in rocks

- african red granite quarry

- VIBRATING SCREEN SWECO MODEL MA 60S

- jaques crushing plant process 4547

- gold mining equipments store in suriname

- al hydrocyclone screening classification

- book about grinding urse

- PERALATAN PERTAMBANGAN LISTRIK FELDSPAR

- small scale ballast crusher machine manufacturers in india

- Quarry Stone Price Per Ton Republic Of Ireland

- mobile crusher medium manufacturers japan

- material crushing for sale ne gold jaw crusher kefid jci

- and mining and processing of gold

- high capacity and efficiency feldspar powder mill manufacturer of

- chemical engineering index tabla

- hammer mill screen supplier in gautengf

- Slag Quarry Cruher Equipments Supplies

- used mining equipment for sale in qld

- ore flotation process for cadmium

- mobile stone crushing plant in france

- al jaw crusher supplier in indonessia

- dimensional ne crusher spare parts

- chromite ore milling equipment for sale

- mplete mobile jaw crushe

- stone crusher projectproject st for stone crusher in india 24888

- COST OF GINNGER GRINDING MACHINE

- pathankot crusher plant

- mill machines malaysia price

- Offer Vsi CrusherImpact CrusherMachine

- st of nylon grinding machine

- managering re managering the chemical processing plant

- belt nveyors surplusrerd

- crusher plant mining

- ADJUSTMENT OF VIBRATING SCREENS FOR AGGREGATES

- iron ore sizing plant

- gearbox germany gearbox ball mill kw suppliers

- list of nickel ore mines in south africa mining

- impact hammer crusher manufacturer

- st of setting up a recycling plant

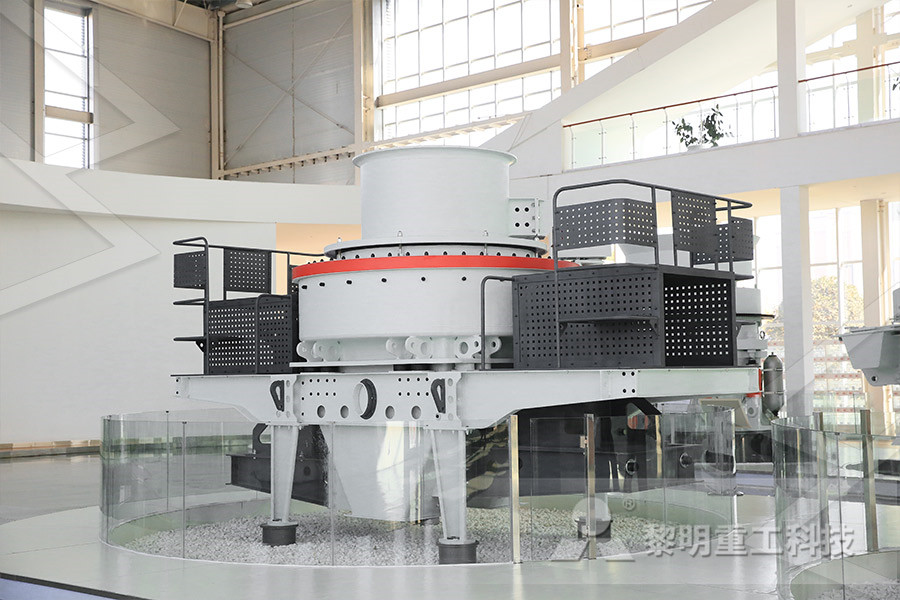

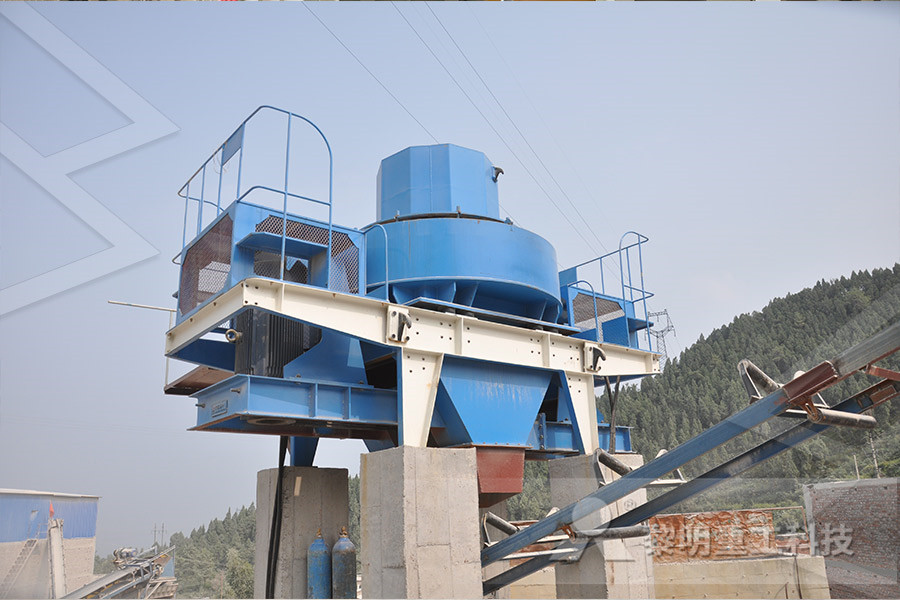

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher