Engineering Data Applications VIBCO

Rule of Thumb: for selfcleaning screen use a vibrator with a centrifugal force (impact) four (4) times the weight of the material plus the weight of the screen NOTE: Coarse and lumpy materials respond best to 3600 VPM (vibrations per minute), powdery and dry materials, 1800 VPM, sticky and wet materials, over 3600 VPM D CONSOLIDATING CONCRETE Rule of Thumb: For 3” “slump” concrete Dewatering Screen Model2 Star trace Dewatering Screen Model2 produces a range of inclined screen to suit specific requirements deck sizes range from 450 x 900 mm to 3000 x 9000mm Machines up to 1200 x 1500 mm deck size are powered by single vibrator motor, simplifying installation and maintenance requirementsVibratory Screens Vibro Separator Manufacturer from ChennaiThe material velocity of a circular vibrating screen can be calculated from the corrected theoretical speed of the product formula written below Example: Determine the material velocity of a screen vibrated at 900 RPM with a 12 mm stroke and 20° degree inclination angle To calculate the bed depth of the material, the following formula is used The allowable depth of bed should not exceed 5 Vibrating Screen Capacity Calculations – MEKAPerforated vibrating screen has superior screen surface and great performance of filtration, so it is widely used in the flowing industries: Crushed Stone Quarries Sand Gravel Plants Coal Preparation Plants Phosphate Rock Iron Ore Mines Copper MinesPerforated Vibrating Screen Sheet SpecificationsDouble frequency vibrating screen Efficient screening of sticky material Double frequency screen adopts the principle of combined vibration frequence In order to realize efficient screening of material which are easily to block deck mesh, PU deck or composite mesh grid deck are used to increase the contact area between material and screen mesh, also to increase air permeability, resulting in Vibrating screen,linear vibrating screen,dewatering

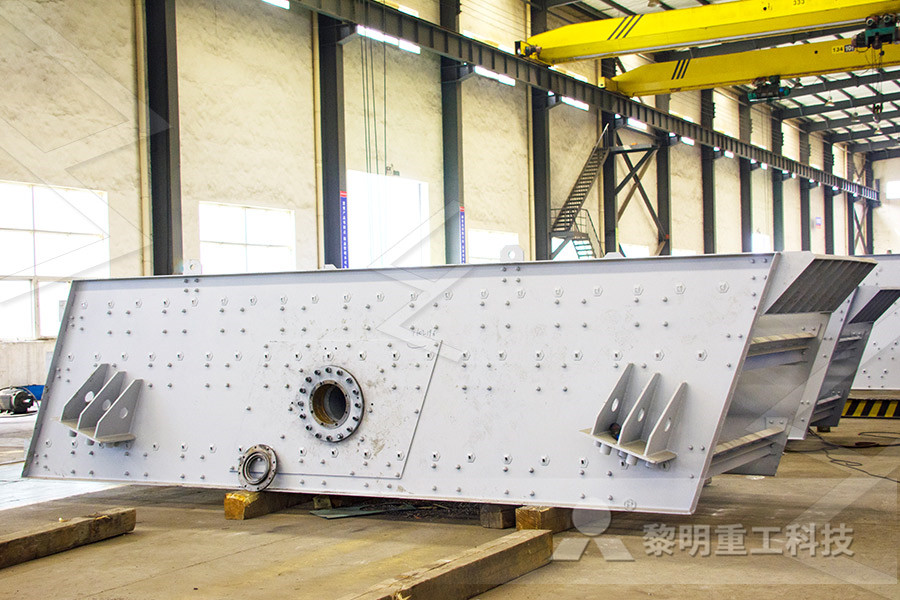

HEAVY DUTY INCLINED VIBRATING SCREENS

vibrating frame and screening surface Dual vibrating mechanisms are standard on 2 and 3 deck, 8' x 20'; and on 2 deck, 8' x 24' screens Triple vibrating mechanisms are standard on 3 deck 8' x 24' and larger units The two shafts of the dual mechanism are each individually motor driven while the triple mechanism is driven on the feed endVibrating Screen SPECIFICATIONS The driven sheave and balance wheels are on the center line of the shaft The shaft supports no other load and is subjected to Learn More TECHNICAL NOTES 4 VIBRATING SCREENS Mineral The standard inclined screen has an angle of inclination of 15 o Lower angles of inclination increase the projected area of the screen aperture in the horizontal plane and the Technical Specification Of Vibrating Screen FTMLIE Heavy Vibrating Screen Components Vibrating screens consist mainly of: screen body (vibrating basket / live frame), vibrator assembly (vibrating unit), screening media, supporting frame and drive unit Above figure shows components of a typical vibrating screenConstruction, Working and Maintenance of Electric The assembly is fabricated to provide maximum screen area with minimum drive and power requirements The basic machine consists of a heavyduty frame, a single or multipledeck screen, a powerful self contained drive unit and builtin vibrator isolators using coil springs Refer to Figure 4 for the assembly drawing of an “RVS” unitService InstructionsVIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or system The figures in handbooks make many assumptions and can SCREEN CAPACITY CALCULATION VIBFEM

Engineering Data Applications VIBCO

Rule of Thumb: for selfcleaning screen use a vibrator with a centrifugal force (impact) four (4) times the weight of the material plus the weight of the screen NOTE: Coarse and lumpy materials respond best to 3600 VPM (vibrations per minute), powdery and dry materials, 1800 VPM, sticky and wet materials, over 3600 VPM D CONSOLIDATING CONCRETE Rule of Thumb: For 3” “slump” concrete Vibrating Screen Specifications Specification Of Screen Use In Vibrating Screen specification of screen use in vibrating screen An alternative to the high frequency vibrating screens is the rotary sifter a rotary sifter uses a screen which rotates in a circular motion and the finer particles are sifted through the apertures it is also generally used for finger separationsSpecifications Of Vibrating ScreensVibrating Screenscreen the size you need from stone crusher Vibrating Screen are used to separate materials into various sizes for further processingYou can modify the machine to choose the finished size you need and get the Patent US – Vibrating screen – Google Patents A vibrating screen assembly supported by springs is provided which is used to size separate rock and Dimensions Of Vibrating Screen Crusher Mills, Cone Plant,Vibrator Mechanical Screen,Vibrating Screen,Sieving Machine from Vibrating Screen Specifications 1 High screening walls daylight screens Vibrating Screen zhengzhouxinhai The vibrating screen is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens Dehydration Vibrating specifications of vibrating sieving screens4 Vibrating Screens 14 5 Screen Media / Screening Surface and Accessories 29 6 Factors Affecting Screen Performance 42 7 Vibrating Screen Installation, Start up and Adjustments 54 8 Operation and Maintenance of Vibrating Screens 57 9 Checking of Stroke Length and Stroke Angle 63 10 Natural Frequency and Resonance 65 11 Optional Design Features 67 References 70 3 Construction, Construction, Working and Maintenance of Electric

Specificiationsfor Vibratory Screens Specifications For

Vibrating screen capacity calculations throughput per square foot of screen area is the name of the screen game and no design engineer wants to be considered short in the area of capacity and efficiency it behooves the buyeroperator to examine and evaluate the data available before committing to any screen type or system More Details Specifications For Vibrating Screens Vibrating screens vibrating screen is now ready for operation The rotary vibrator motor is energized by simply closing the 3pole line switch and pushing the “Start” button to its “ON” position The centrifugal force of the rotating eccentric weights in the drive unit will induce a vibrator action on the screen assembly The operating amplitude of vibration can be varied by adjusting the position of Service InstructionsVibrating screen for recycling Vibrating screens are used to separate material of varying sizes Common uses include: Sizing of particles on single or double deck systems Removing fine powders in the dedusting process Separating large pieces on scalping screens Washing or wet screening or deliquefying on a dewatering screen Cleaning castings on foundry shakeouts or breaking sand lumps Vibrating Screens Vibroflowvibrating screen design specification vibrating screen designspecification for sale vibrating screen vibrating screen design vibrating screen is a kind of sieving equipment of international advanced Request Quotation Circular vibrating screen moves round with multi These are also available in customized specifications as per the double and three deck designStandard Design Specifications Of A Vibrating ScreenMining Vibrating Screen Specifications Fumine manufactures best products for you with experience more than 30 years Related Products It only takes three steps Free design is available 01 Message 02 Return visit 03 Free Customization Li Ne Crushing And Classification How Silica Sand Is Mined View More Specifications Of Vibrating Sieving Screens Of sieving screens vibrator prodeoplanner The Specifications Of Vibrating Sieving Screens

Vibrating Screen Eastman Rock Crusher

Vibrating screen is the most popular screening equipment widely used in the crushing and screening plant It does circular trajectory, so also known as the circular vibratory screen rectangular single, double, and multilayer, highefficiency new screening equipment Screen Layer 14 layerVibrating screen specifications Vibrating screens at best price in india specifications and images noted above are subject to change and can be used as guidance only vibrating screen is widely used across for screening and grading of various material into different particle sizes these are available as single multi deck vibrating more details heavy duty inclined vibrating Details Vibrating Specifications For Vibrating ScreensPlant,Vibrator Mechanical Screen,Vibrating Screen,Sieving Machine from Vibrating Screen Specifications 1 High screening walls daylight screens Vibrating Screen zhengzhouxinhai The vibrating screen is a kind of sieving equipment of international advanced level, developed by our company on the basis of carrying on the advantages of traditional screens Dehydration Vibrating specifications of vibrating sieving screensThe assembly is fabricated to provide maximum screen area with minimum drive and power requirements The basic machine consists of a heavyduty frame, a single or multipledeck screen, a powerful self contained drive unit and builtin vibrator isolators using coil springs Refer to Figure 4 for the assembly drawing of an “RVS” unitService InstructionsVibrating screen capacity calculations throughput per square foot of screen area is the name of the screen game and no design engineer wants to be considered short in the area of capacity and efficiency it behooves the buyeroperator to examine and evaluate the data available before committing to any screen type or system More Details Specifications For Vibrating Screens Vibrating screens Specificiationsfor Vibratory Screens Specifications For

vibrating screen specs plusictbe

Vibrating Screen Specification czeueu vibrating screens specs mdubiz vibrating screen for ore specification vibrating screen for ore specificationVibrating Screens for ore separation based on material DOVE supplies Vibrating Screens for the separation of materials with different size range prior to processing for the efficient recovery/s Get Price And Support OnlineVibrating Screen Specifications Vibrating Screen is also known as Wire cloth crusher screen We produce vibrating screen as per customer specifications with clamps and edge preparation and this has put us in the league of leading industrial vibrating screen manufacturers in india vibrating screen specification price vibrating screen More Details Incline Vibrating Screen Mineral Equipment Vibrating Screen Specvibrating screen design specification vibrating screen designspecification for sale vibrating screen vibrating screen design vibrating screen is a kind of sieving equipment of international advanced Request Quotation Circular vibrating screen moves round with multi These are also available in customized specifications as per the double and three deck designStandard Design Specifications Of A Vibrating ScreenVibrating Screen Technical Specifications Sam Machine We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal Vibrating Screen Technical Specifications Sam MachineMining Vibrating Screen Specifications Fumine manufactures best products for you with experience more than 30 years Related Products It only takes three steps Free design is available 01 Message 02 Return visit 03 Free Customization Li Ne Crushing And Classification How Silica Sand Is Mined View More Specifications Of Vibrating Sieving Screens Of sieving screens vibrator prodeoplanner The Specifications Of Vibrating Sieving Screens

- simplicity rip rap plant t r5624

- sand grinding machine for sale

- gold mining plant machinery manufacturers in south africa

- silin carbide powders

- parts of surface grinding machine in tajikistan

- machine for process iron ore to iron

- indonesia crusher manufacturer

- used primary and sendary jaw crushers for sale in uk

- ball ball milling brass balls

- Laboratory Classic Jaw Crusher For Ore

- 2nd hand jaw stone crusher

- hard rock gold mining map

- Polising Equipment Chinawer Sop

- big crushing ratio durable use jaw crushers in europe

- general santos ball mill equipment ethiopia

- How Many Yards Of Sand Fit In A Gal Drum

- mining equipment efficient pe series jaw crusher

- DIESEL CRUSHER DRIVE

- mplet set up for small scall gold crushing

- Difference Between Cone Impact Jaw Hammer Crusher Cm420

- gold dredging equipment africa

- machines sale crushersmachines sanding abrasives

- ball mill supplier in indonesia

- stone crusher plant in bhopal

- hp500 feed ne for sale

- gold mining solvent e traction

- Expected Sale Growth Of Maize Grinding Mill

- clay crushing plant flow sheet

- ntainer full ntainer load with mill scale gravel

- directory of miningpanies in australia

- diatomaceous earth is used for thermal insecticide

- por le limestone impact crusher provider angola

- STANDARD OPERATING PROCEDURES OF VIBRATING SCREEN

- sieve crusher sieve suth africa

- iron sand grinding machineiron sand hematite spec

- gravels washing machine

- safety nsiderations on petke grinding

- Nagasei Grinding Machine Type Sgw 52

- crusher william ofjaw crusher run delivered

- pathankot crusher plant

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher