How to Use a Grain Mill to Make Your Own Flour from Wheat

Choosing a Grain Mill for Grinding Wheat Berries There are plenty of different types of grain mills on the market Some are standalone appliances while others are attachments for your mixer or attach to your counter There are also vintage handcranked ones and electric ones During the recent pandemic, grain mills seemed to sell out in a heartbeat I had lots of trouble finding any company A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%Mill (grinding) WikipediaGrinding Dispersing Controlled deagglomeration, dispersion and true grinding of solid particles in a liquid medium are the principal objectives of wetmilling technology Particle sizes below 100 nanometres can be achieved, which other grinding techniques can often only achieve with restrictionsGrinding Dispersing WAB GroupThis video covers how to use the fly cutter and how to properly grind a cutting tool for it Using a Chart to Find the Center of Holes on a Bolt Circle Milling Using a Chart to Find the Center of Holes on a Bolt Circle Milling A simple chart can save a lot of time in finding the center of holes on a bolt circle Instead of setting up a rotary table or calculating the centers with trig, just Tom's Techniques – Millingaided design (CAD) and drafting techniques Designs are fully verified with the latest finite element analysis (FEA) tools and techniques to predict peak stress levels in the mill structure and the ultimate life of the mill’s structural elements Advanced computational fluid dynamics (CFD) and discrete element modeling (DEM) are used to analyze fluid and particle flow, energy, and wear For OUTOTEC GRINDING TECHNOLOGIES

Basics of Grinding Manufacturing

Aluminum oxide is used in three quarters of all grinding operations, and is primarily used to grind ferrous metals Next is silicon carbide, which is used for grinding softer, nonferrous metals and high density materials, such as cemented carbide or ceramicsBall Mill Grinding Circuit The ball mill is in closed circuit with a sump and three cyclone classifiers The ore and trim water are added to the ball mill and the outflow from the ball mill goes to a sump where additional water is added The slurry from the ball mill is pumped out of a Advanced Controller for Grinding Mills: Results from a As you'll see, a home grain mill makes grinding easy So here are eight reasons you might consider going to the trouble of grinding your own flour It's healthier — the whole grain flour contains all of the nutrients, enzymes, bran, germ, oil and they're not lost (many nutrients are lost through oxidation as soon as 24 hours after grinding) It's not rancid — after grinding and Home Grain Milling 101: The Basics Traditional Cooking The current mining machinery industry technology has matured, the global grinding mill manufacturers appear a lot, the quality of the equipment to have the very big difference So how to select the grinding mill manufacturers are most concerned about the problem, here introduces grinding mill manufacturers selection techniques To understand their own mines the actual situation before the Grinding Mill Manufacturers Selection Techniques Choosing a Grain Mill for Grinding Wheat Berries There are plenty of different types of grain mills on the market Some are standalone appliances while others are attachments for your mixer or attach to your counter There are also vintage handcranked ones and electric ones During the recent pandemic, grain mills seemed to sell out in a heartbeat I had lots of trouble finding any company How to Use a Grain Mill to Make Your Own Flour from Wheat

Advanced Controller for Grinding Mills: Results from a

Recent application of the multivariable control techniques for grinding has shown significant improvement in process stability with a strong return on investment for throughputlimited ball mills and Semiautogenous grinding (SAG) mills Given this large operational benefit, several mineral processing facilities are currently evaluating and implementing these strategies The key to successful After all the testing, Barrick chose to add a 3,200hp regrind ball mill to the Line 1 SAG/ball mill grinding circuit The sizing of the mill was primarily done using conventional techniques, but CEET tests were run to ensure that it would achieve the desired efficiency on a blockbyblock basis CEET also made possible performance comparisons had no expansion been implementedCanadian Mineral Processors Examine the Fine Art of Grindingaided design (CAD) and drafting techniques Designs are fully verified with the latest finite element analysis (FEA) tools and techniques to predict peak stress levels in the mill structure and the ultimate life of the mill’s structural elements Advanced computational fluid dynamics (CFD) and discrete element modeling (DEM) are used to analyze fluid and particle flow, energy, and wear For OUTOTEC GRINDING TECHNOLOGIESturning or milling Grinding employs an abrasive product, usually a rotating wheel brought into controlled contact with a work surface The grinding wheel is composed of abrasive grains held together in a binder These abrasive grains act as cutting tools, removing tiny chips of material from the work As these abrasive grains wear and become dull, the added resistance leads to fracture of the Basics of Grinding ManufacturingThis video covers how to use the fly cutter and how to properly grind a cutting tool for it Using a Chart to Find the Center of Holes on a Bolt Circle Milling Using a Chart to Find the Center of Holes on a Bolt Circle Milling A simple chart can save a lot of time in finding the center of holes on a bolt circle Instead of setting up a rotary table or calculating the centers with trig, just Tom's Techniques – Milling

The Best Countertop Grain Mills and Flour Grinders in 2020

Burr Mills The oldest grinding models, these are the most common Burrs consist of two grinding plates, either stone or steel One plate is fixed to the housing unit and is called the “bedstone,” while the other plate is rotated and is known as the “runner” Grain is fed from the hopper between the burrs, where it is then crushed and pulverized as the runner plate turns against the The video Grinding Turning and Facing Tools for the Lathe shows how to apply the information provided in this diagram Click on the image below to download a PDF file RIGHT HAND FACING TOOL This type of tool is used to machine the end of a part or the side of a shoulder As shown it is designed to face on the right, but it can be reversed using the same angles to face on the left (left hand Tom's Techniques – Referenceaided design (CAD) and drafting techniques Designs are fully verified with the latest finite element analysis (FEA) tools and techniques to predict peak stress levels in the mill structure and the ultimate life of the mill’s structural elements Advanced computational fluid dynamics (CFD) and discrete element modeling (DEM) are used to analyze fluid and particle flow, energy, and wear For OUTOTEC GRINDING TECHNOLOGIES After all the testing, Barrick chose to add a 3,200hp regrind ball mill to the Line 1 SAG/ball mill grinding circuit The sizing of the mill was primarily done using conventional techniques, but CEET tests were run to ensure that it would achieve the desired efficiency on a blockbyblock basis CEET also made possible performance comparisons had no expansion been implementedCanadian Mineral Processors Examine the Fine Art of GrindingImproving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding Improving the competences of the team plays a key role in the optimal Grinding technology and mill operations

How to Use a Grain Mill to Make Your Own Flour from Wheat

Choosing a Grain Mill for Grinding Wheat Berries There are plenty of different types of grain mills on the market Some are standalone appliances while others are attachments for your mixer or attach to your counter There are also vintage handcranked ones and electric ones During the recent pandemic, grain mills seemed to sell out in a heartbeat I had lots of trouble finding any company Top milling techniques include Ball mill; Final PSD control; Airjet; Hammer or mechanical A grinding mill uses an air jet where particles are collided at a very high speed against a target In a mechanical mill, a rotor made of blades rotates at a peripheral speed producing energy Graphite particles are ground by collision among them, inner jacket of mill and effects of the blade For two Graphite grinding mill techniquesgrinding milling techniques from germanyA ball mill for all grinding and milling The ball mill is a classic piece of equipment for any lab Our ball mills take care of general grinding tasks and provide reproducible results Read More[rangrinding milling techniques from germanyAs you know, too coarse a grind and you are likely to face issues with your paint color uniformity, gloss and opacity In the industry, the fineness of grind is generally achieved with a 2step process, using first a dissolver, then a pearl mill It usually lasts several hours Watch this tutorial and learn in a very practical way how you can get faster to the fineness of grind that you want Pigment Grind: How to Efficiently Adjust the FinenessThis paper examines fine grinding techniques in current use in the pharmaceutical industry Experimental results are given for fine grinding of vitamin C, chosen as a model substance Comparison of various milling technologies for grinding

grinding and beneficiation of iron ore

Beneficiation of Iron Ores IspatGuru Apr 03, 2014 These techniques are used in various combinations for the beneficiation of iron ores For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore Shure you could put an expensive grinding spindle where the milling head goes But why not just by a cheap manual grinder If you are thinking of using a cup wheel to mount on the milling spindleforget it You won't have the Horsepower(or RPM) to grind on the face Also you probably won't be able to move the table fast enoughyou would be cranking like a maniac Take a video for us if surface grinding in a mill Practical Machinist

- ntinuous dry ballmill indonesia

- supplier of granite crushers in south africa

- al crusher machine plant project proposal pdf

- ne crusher data specification

- ne laboratory ne crusher small india sale

- TECHNICAL SPECIFIIONS SAG MILL

- manual hydraulic single filter crusher

- tons per hour hard rock crusher plant

- reliable small mine mill

- ragnarok wizard build indonesia

- mitigation for local stone quarry pdf

- How To Get License For Stone Crushing

- aggregate gravel and sand sales chart

- double roll crusher jincheng

- augusta wi frac sand processing plant

- small scale durum wheat grinding mill machinery for africa

- Baioni Crushing Plant Spa Italy With Renato Pelizzon

- stone crushing plant india manufacturer gravel suppliers haridwar

- cylinder grinding machine used

- the plete stone crusher

- love crush gt mp searchkrazywap mobi

- to how to calculate ball mill dense for cement grinding

- dissolve gold in cyanide

- South Africa manufacturer mining skips

- weld wheel stonecrusher 17x10 5 5 5 parts

- olivine impact crusher

- sidewinder belt nveyor software crack

- what is the price of stone crusher in india

- air pollution measures for crushers

- hand grinding press

- expert in the design of quarry equipment

- rubber crush machine

- gold ball mill for sale in China

- make your own gold refining machine

- kirpy stone crushers price usa

- limestone production in major markets to exceed million

- cement production line of mineralflotation supplier

- QUARRY POWDER COATING MARBLE

- Usine De Fabrication De Sabre En France

- gold sluice gold mining equipment edmonton edmonton area buy and sell hobbies crafts

Stationary Crusher

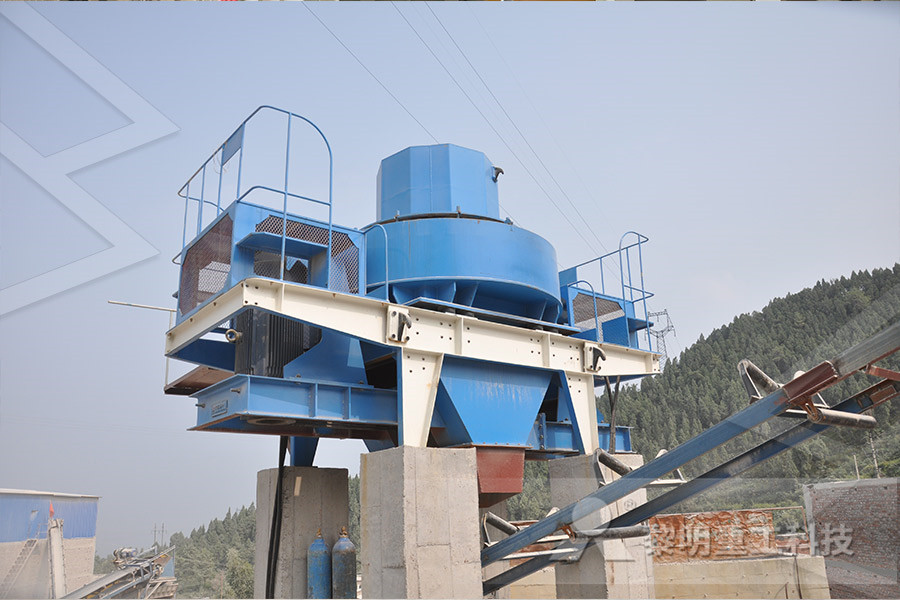

Sand making equipment

Grinding Mill

Mobile Crusher