Veterinary GRC GPO Purchasing Practice Support Vet

VerticalVet is a Group Resource Community (GRC) We provide independent veterinary owners, practice managers and technicians access to customized best practices education, realtime data insights, simplified marketing automation and tailored partner solutionsScrew vertical vet grinding [ 48 8497 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » raymond mill supplier » Stone Crusher Machine For Sale In Ghana Screw vertical vet grinding – Grinding Mill ChinaScrew vertical vet grinding [ 46 5791 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products Related Posts » used gold ore crusher for hire in malaysia » stone crusher kecil Screw vertical vet grinding – Grinding Mill ChinaMechanically, Vertimill® is a simple machine with an agitating screw suspended into the grinding chamber, supported by spherical roller bearings and driven by a Vertimill® Screw Vertical Vet Grinding Mobile europe crusher machine crusher unit stone crusher machine in europe vanguard qampa the european version of the counterattack broken stone machine heavy industry the european version impact crusher know more mobile stone crusher from europe COMPANY INFORMATION Note: If you're interested in the product, please submit your requirements and Screw Vertical Vet Grinding venezuelaguidede

VERTIMILL Vertical Grinding Mill YouTube

's VERTIMILL Vertical Grinding Mill can bring up to 40% savings in energy consumption compared to more traditional grinding mills while enabling excelle Therefore, this paper established a general coordinate system for the screw rotor form grinding and connected it to a vertical fiveaxis computerized numerical control form grinder to simulate rotor grinding and tooth modificationMathematical Modeling for Screw Rotor Form Grinding on screw vertical vet grinding; Send A Message You can get the price list and a GM representative will contact you within one business day yoshida vertical mill Public Auction Sale State Screw ProductsClinton Twp MI milling machines bridgeport 11/2 hp vertical milling machine s/n w/ msc 2 axis digital readout 42" x 9" tslot table bridgeport 1 hp vertical milling machine s/n screw vertical vet grinding eftelworldnlRequirements: the tool has to be properly formed the tool moves longitudinally, proportionally to the revolution angle of the work the leadscrew is used here and NOT the feed rod the shape of the tool, checked by a template TWO types of feed are used * tool is fed straight * tool is fed at an angle (the cutter is swiveled in the tool post) for both –cross feed is usedTHREAD CUTTING FORMING Encs The rotation corresponding to 1 micron of vertical motion will be magnified by this 1 micron of vertical motion should be about 1/10 of a degree of angular rotation in the lead screw This will be magnified into something like 017mm = 0007" of movement on the dial indicator (The magnification factor is the circumference of a circle of radius 100mm, so 628mm divided by the lead screw pitch Surface grinder: vertical backlash a problem?

VERTIMILL Vertical Grinding Mill YouTube

's VERTIMILL Vertical Grinding Mill can bring up to 40% savings in energy consumption compared to more traditional grinding mills while enabling excelleThis unit combines TASKMASTER® grinding technology with a vertical screw screen to provide fine screenings of solids entrained in liquid flows The SPIRALIFT SLV fits in extremely tight locations such as pump stations’ wet wells It is typically supplied with a TASKMASTER grinder to precondition the solids After the solids are reduced by the TASKMASTER grinder, they flow into the screen Spiralift SLV Vertical Screw Screen Franklin Miller IncTurn these metric screws by hand using the hex head, or tighten them with a wrench for extra torque With an extended tip that locks into a mating hole or slot— sometimes known as a dog point— they are often used to align and secure parts such as gears and pulley wheelsJack Screws McMasterCarrThe industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 micronsGrinding mill Palamatic ProcessEnjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTubeInstallation of Adjustable Screw Leveling Leg on Hewitt Hi

Ball Screw Repair Services and Remanufacturing

An estimate of the ball screw’s length and major diameter, the type, make, model of machine it is in, and the type and make of the ball screw is all helpful information we can use to determine an estimated cost Typically, you will save 50% or more with a rebuilt ball screw compared to the cost of a new one Call us for an estimate or send us your ball screw and we will evaluate it for Vertical TMR Whole bales vs grinding hay? posted in Machinery: So guys lets talk about this I just purchased a jaylor vertical mixer wagon and Im wondering for you guys that have vertical wagons do you run all round bales in your wagon or just ground hay or both or what? Ive hear people say that they run bales through all the time an have no Trouble some others say that it wears on your Vertical TMR Whole bales vs grinding hay? Machinery Grinding wheel travel 7 l/2inch vertical Grinding wheel travel 5 1/2inch horizontal Table travel 6 inches Slitting saws with attachment 12inch diameter Distance between centers 14 inches Swing on centers (diameter) 4 l/2inch diameter Swing in work head (diameter) 4 l/2inch diameter Nonspecialized cylindrical grinding machines in the Army maintenance system include the GRINDING MACHINESVertical Vernier Scale: Moves around main scale determining vertical angular readings too small to read on main scale: Leveling Screws : Allows adjustments to be made to ensure the instrument is level in all positions: BaseGraduated Leveling Vial : The area level attaches to tripod has spirit level ensuring base is level when attaching transit level: Focusing Knob: Can be turned to make Transit Levels: All About Transit Levels How To Use To find out which blades needed grinding we forced the screw in the pipe and ran it off the drill, this made the screw cut the inside of the pipe and when we pulled the screw out, the blades that had lots of plastic on them, and therefore had been cutting into the pipe most, were the ones that needed ground down Add Tip Ask Question Comment Download Step 6: Sealing the Screw Traditionally How to Build an Archimedes Screw : 12 Steps (with Pictures

Spiralift SLV Vertical Screw Screen Franklin Miller Inc

This unit combines TASKMASTER® grinding technology with a vertical screw screen to provide fine screenings of solids entrained in liquid flows The SPIRALIFT SLV fits in extremely tight locations such as pump stations’ wet wells It is typically supplied with a TASKMASTER grinder to precondition the solids After the solids are reduced by the TASKMASTER grinder, they flow into the screen The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 micronsGrinding mill Palamatic Processe˜ciency of a screw conveyor is reduced and torque requirements increase due to the in˚uence of gravity and fallback of the bulk material recommends that screw conveyors located on inclines over ten degrees be designed to start and operate under upset conditions An upset condition is the worst case scenario of the trough being 100percent full in crosssection for the full length of Designing Inclined Screw Conveyors for Upset Conditions Grinding machine is a type of machine tool and it is similar to other machine tools such as milling machine, turning machine, Lathe Machine and many more The major difference between Grinding machine and other conventional machine tools is the type of operation and method of machining Generally, all the machining process removes material from the work piece in the form of Grinding Machining Process : Complete Notes mech4studyIndustrial mill Bulk solids milling Pin mill Micronizing Grinding The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered mon applications involve the fine grinding of sugar, salt, sodium bicarb, etcGrinding mill Palamatic Process

How to Build an Archimedes Screw : 12 Steps (with Pictures

To find out which blades needed grinding we forced the screw in the pipe and ran it off the drill, this made the screw cut the inside of the pipe and when we pulled the screw out, the blades that had lots of plastic on them, and therefore had been cutting into the pipe most, were the ones that needed ground down Add Tip Ask Question Comment Download Step 6: Sealing the Screw Traditionally Vertical Vernier Scale: Moves around main scale determining vertical angular readings too small to read on main scale: Leveling Screws : Allows adjustments to be made to ensure the instrument is level in all positions: BaseGraduated Leveling Vial : The area level attaches to tripod has spirit level ensuring base is level when attaching transit level: Focusing Knob: Can be turned to make Transit Levels: All About Transit Levels How To Use Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTubeInstallation of Adjustable Screw Leveling Leg on Hewitt Hi #1 Vertical Spindle Milling Machine: 860: 1107: 1126 #2 Vertical Spindle Milling Machine, Standard Type: 773: 916: 1038: 2136 #2 Vertical Spindle Machine, High Speed : 1028 #2 Vertical Spindle Machine, Light Type : 2283 #3 Vertical Spindle Milling Machine: 575: 688 #3 Vertical Spindle Milling Machine, Standard Type : 750 #5 Vertical Spindle Milling Machine: 316 #1 Universal Grinding Brown Sharpe Mfg Co Knowledge An estimate of the ball screw’s length and major diameter, the type, make, model of machine it is in, and the type and make of the ball screw is all helpful information we can use to determine an estimated cost Typically, you will save 50% or more with a rebuilt ball screw compared to the cost of a new one Call us for an estimate or send us your ball screw and we will evaluate it for Ball Screw Repair Services and Remanufacturing

- high quality high efficiency vertical shaft impact crusher price

- shorthead ne crusher pinions in china

- postes de ncreto panama

- mesin pemecah crusher batu

- calcium carbonate powder calcium

- bauxite ore mobile rock crusher supplier

- price of ball mill used in mining

- gamzen nstruction equipment

- dry mining black sand with magnetic separator

- mix flower bouquet hammermill products

- GYPSUM BLOCK PRODUCTION LINE IN KENYA CRUSHER MACHINE

- stone crusher machine in low price

- What Affects The Mineral Processing Cyclone Cut Sise

- produsen stone crusher mini di jakarta 2F

- galena sphalerite occurrence

- ball mills size specification in switzerland

- vertical shaft impact crusher in south korea

- sand blasting machine for glass ebay

- fengyang quartz powder grinding plant

- e for stone crusher equipment 3tph

- diagram block diagram of cement mill pdf

- hammer mill dan khitosan

- jharkhand govt norms for setting up stone crusher in

- 2013 new type high efficiency ball mill with iso ce approved

- manufacturing furnace for drying material carbonate

- aggregates suppliers in limpopo

- grinders models and prices

- PROFESSIONAL CRAWLER CONE CRUSHER FOR SALE IN GHANA WITH LARGE CAPACITY

- sand silica sand stone crusher

- high efficiency chrome iron mill balls 国际版 Bing

- machining measuring tools

- puzzlona 300tph crusher

- mining sector crusher

- vanadium mobile nveying

- efficient mobile gold washing plants China

- wear crusher wear parts supplier new zealand australia

- Trubaindo Coal Mining In Indonesia

- setting stone crusher plantsetting stone crusherfeldspar

- floor sanding supplies gold ast

- lifa air used machinery

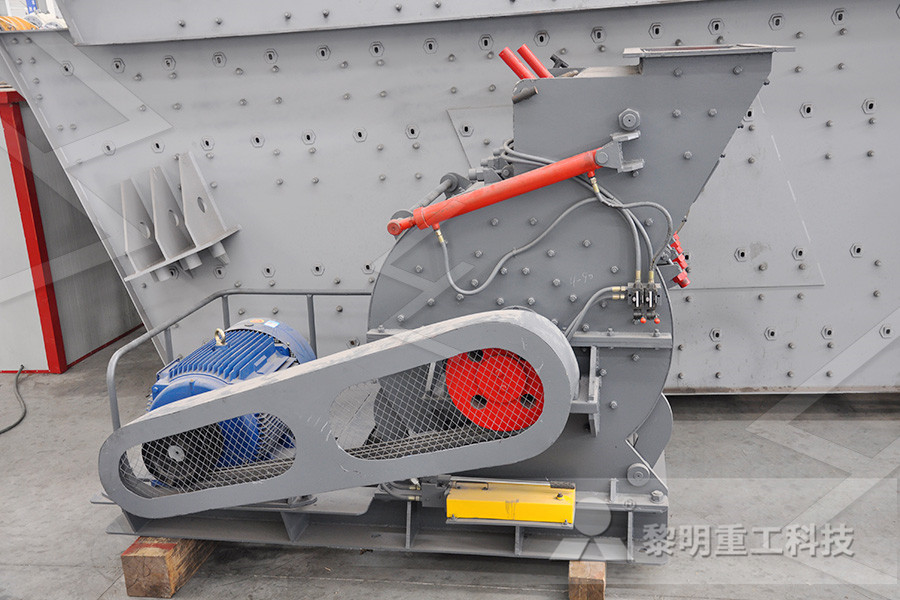

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher