activated calcium carbonate plant and process

activated calcium carbonate process activated calcium carbonate plant and process Activated carbon fouling by calcium carbonate Other indirect tests that can be done are the activity test and the apparent density both of which will give an indication of the extent of the effect of the fouling by calcium carbonate without measuring the calcium level directly BCCF Calcium 30 tonne stone crusher Calcium carbonate plant is also known as calcium carbonate processing plant, calcium carbonate grinding plant or calcium carbonate manufacturing plant It is a calcium carbonate production line where ground calcium carbonate powder are made mechanically in factoriesSolutions for Calcium Carbonate Processing Plant Daswell Activated sludge ballasting by calcium carbonate, apatite and a blend of talc and chlorite was investigated in a continuous denitrification–nitrification pilot plant The sludge–mineral material interaction was studied by analyzing the surface characteristics of the mineral materials, activated sludge and the fate of the mineral material in Activated Calcium Carbonate Plant And ProcessActivated Calcium Carbonate is produced by surface coating the Precipitated Calcium Carbonate slurry with Fatty Acids (Stearic Acid) and Titnate Coupling Agent then filtering and drying of the coated PCC slurry to produce ACC powderActivated Calcium Carbonate (ACC)Calcium carbonate plant is also known as calcium carbonate processing plant, calcium carbonate grinding plant or calcium carbonate manufacturing plant It is a calcium carbonate production line where ground calcium carbonate powder are made mechanically in factories With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate Calcium Carbonate Plant Manufacturer Daswell CaCO₃

Calcium Carbonate Production Activated Calcium Carbonate

nature as aragonite and calcite, in pearls, plant ashes, chalk, marble, shells of marine organisms, bones and eggs Calcium carbonate particularly used for making Portland cement, lime and gastric antacid It is energetic element in agricultural lime which is created by combine reaction of calcium ions in hard water with carbonate ions Calcium carbonate is used in paints and coating manufacturing process of activated calcium manufacturing process of activated calcium carbonate Calcium Carbonate Manufacturer wholesalers and exporters of Calcium Carbonate activated calcium Read More Lime Chemicals Limited Lime Chemicals Welcome to Lime Chemicals company is the manufacture of “Precipitated and Coated Calcium Carbonate” decided to invest in a huge expansion activated calcium carbonate processProject Report on Activated Calcium Carbonate include Manufacturing Process, Profile, Machinery, Raw Materials, Industry Trends, Market Research, Survey, Feasibility Study, Investment Opportunities, Cost And RevenueProject Report on Activated Calcium Carbonate In the future, special and functional products such as ultrafine calcium carbonate and activated calcium carbonate will be the main development trend of calcium carbonate Selective purification, ultrafine crushing, surface modification and other mineral fine processing technologies are necessary to increase the added value of calcium carbonateCalcium carbonate manufacturing plant surface modification The accumulation of calcium on biological activated carbon (BAC) and their effects on adsorption of synthetic organic chemicals (SOCs) were studied using BAC, which have been operated for 5 (BAC50) and 35 (BAC35) years in a pilotscale water purification plant, and granular activated carbon (GAC) preloaded with fulvic acid and/or calciumCalcium accumulation on activated carbon deteriorates

Calcium carbonate manufacturing plant surface modification

Calcium carbonate manufacturing plant surface modification process Posted: Activated calcium carbonate modified with fatty acid (salt) is mainly used for filling polyvinyl chloride plastics, cable materials, adhesives, inks, coatings, etc 3 Coupling agent modified calcium carbonate The coupling agents used for the surface modification of calcium carbonate are mainly titanate and nature as aragonite and calcite, in pearls, plant ashes, chalk, marble, shells of marine organisms, bones and eggs Calcium carbonate particularly used for making Portland cement, lime and gastric antacid It is energetic element in agricultural lime which is created by combine reaction of calcium ions in hard water with carbonate ions Calcium carbonate is used in paints and coating Calcium Carbonate Production Activated Calcium Carbonate Project Report on Activated Calcium Carbonate include Manufacturing Process, Profile, Machinery, Raw Materials, Industry Trends, Market Research, Survey, Feasibility Study, Investment Opportunities, Cost And RevenueProject Report on Activated Calcium Carbonate Sugar Refining Sugar was first manufactured from sugar cane in India, and its manufacture has spread from there A four step process is used, but since Colour, gum and amino acid impurities precipitate out with the calcium carbonateStep 3 – Char filtration Activated charcoal is added to the syrup, removing colour and inorganic ash »More detailedactivated and precipitated calcium carbonate manufacturing Calcium is known to accumulate on activated carbon by forming complexes with NOM and precipitating as calcium carbonate , , The amounts of carbon dioxide fixed in BAC50 and BAC35 were 114 and 92 mg g −1 GAC, respectively Most of carbon dioxide released from BAC must originate from calcium carbonate, because most of the accumulated inorganic materials was calcium and NOM on Calcium accumulation on activated carbon deteriorates

Precipitated Calcium Carbonate Making Plant And Machinery

calcium carbonate making plant and machinery calcium carbonate powder making plant osteodonsnl Calcium Carbonate Making Plant And Machine czeueu,Sunco Machinery Calcium Carbonate Mill (Raymond Mill) is suitable for grinding calcium carbonate into fine powder After being grinded by the Calcium Carbonate Mill, the fine powder size can be 40 The commercial grade of calcium carbonate in manufactured in two forms * Precipitated Calcium Carbonate * Activated Calcium Carbonate These two forms of calcium carbonate differ in respect of coating which the former does not have and later has Both the forms of calcium carbonate are being used in various industries as filler or extender Project Report on CALCIUM CARBONATE Manufacturing Can be use for any other rotary kiln application such as : Calcination process, bauxite, kaoline, refractories, sponge iron, calcium carbonate, lime, cement and any other uses All installation works and machinery guarantees included Activated carbon plant production technology: Production plant Sell Activated carbon plant production line machinery kilnThe major role played by calcium in gold plant circuits predicted by Equation [1] No solubility data for calcium aurocyanide could be found, but in United States Patent calcium aurocyanide adsorbed onto activated carbon is described as ‘highly insoluble’, and in order to be solubilized to recover gold, a prolonged soak in aqueous caustic cyanide is required However, since gold The major role played by calcium in T gold plant circuitsThe main products are crusher, dressing equipment, sand manufacturing equipment and activated bentonite process plant, which are widely used for metallurgy, mine, chemical industry, building materials, coal, refractory material and ceramic, etc Among these products, the sets of mineral processing equipment, such as the ball grinder, the magnetic separating and flotation equipment, Activated Bentonite Process Plant

Calcium Carbonate Production Activated Calcium Carbonate

nature as aragonite and calcite, in pearls, plant ashes, chalk, marble, shells of marine organisms, bones and eggs Calcium carbonate particularly used for making Portland cement, lime and gastric antacid It is energetic element in agricultural lime which is created by combine reaction of calcium ions in hard water with carbonate ions Calcium carbonate is used in paints and coating 73 Manufacturing Process Analysis of Activated Calcium Carbonate 74 Activated Calcium Carbonate Industrial Chain Analysis 8 Marketing Channel, Distributors and CustomersActivated Calcium Carbonate Market Global Industry Calcium carbonate (CaCO 3), also used as a filler, is prepared by precipitation by the reaction of milk of lime with either carbon dioxide (CO 2) or soda ash (sodium carbonate, Na 2 CO 3) Calcium carbonate as a paper filler is used mainly to impart improved brightness, opacity, andCalcium carbonate chemical compound BritannicaDaswell wet grinding mills can be used to process ground calcium carbonate, barite, kaolin and other material Here we will take the ground calcium carbonate process for example The first step is to blend the calcium carbonate with water In the mixing tank, calcium carbonate coarse powder, water and dispersing agent are mixed And then the mixture will go to the buffer tank Through diaphragm pump, Daswell Wet Grinding Mill for Calcium Carbonate Vertical calcium carbonate making plant and machinery calcium carbonate powder making plant osteodonsnl Calcium Carbonate Making Plant And Machine czeueu,Sunco Machinery Calcium Carbonate Mill (Raymond Mill) is suitable for grinding calcium carbonate into fine powder After being grinded by the Calcium Carbonate Mill, the fine powder size can be 40 Precipitated Calcium Carbonate Making Plant And Machinery

Precipitated Calcium Carbonate from Limestone Chemical

Calcium carbonate (CaCO3) is a mineral that occurs naturally in chalks, limestones and marbles Its largest use is in the pulpandpaper industry as a filler and pigment Other calcium carbonate applications include its use in building construction, plant and crop fertilizers, food additives, water and sewage treatment, ceramics, pharmaceuticals and cosmetics The process The following paragraphs describe When dolomite (CaMg(CO 3) 2) was activated with NaOH solution, the formations of calcium carbonate (CaCO 3), magnesium hydroxide (Mg(OH) 2) and sodium carbonate (Na 2 CO 3) were formed This is why the drying shrinkage of the AAHF pastes is reduced except for the paste with 10%DLM (see Figs 5–7) This indicates that there is a turning point in the addition of DLM The high Drying shrinkage, strength and microstructure of alkali Calcium Carbonate Plant at Best Price in Belarus Backed by our extensive industry expertise, we offer excellent turnkey solutions on Precipitated Calcium Carbonate and Activated Calcium Carbonate Plants Both the plants are designed in compliance with the industry standards and are fabricated using high grade material of Get Moreactivated calcium carbonate plant in rajisthanCalcine (heat) in a kiln to 1850° F, which takes the calcium carbonate apart, forming lime (CaO) and carbon dioxide gas (CO2) The carbon dioxide can be captured for reuse CaCO3 + Heat → CaO + CO2 ↑ Add the lime to water to form calcium hydroxide (hydrated lime or slake) CaO + H2O → Ca (OH)2Precipitated Calcium Carbonate (PCC) Minerals activated carbon titanium dioxide coal process particles Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Granted Application number EPA Other languages German (de EPA1 Activated carbon and process for producing

- lt106 motor in south africa

- moler de cantera gruesos en mexi

- ne crusher in ecr road

- ton gold wash plant zimbabwe

- crusher stone crusher di kolhapur di radhangari

- how to change bars on impact crusher

- K FELDSPAR GRINDING MILL MANUFACTURES FOR SALE

- made turkish made rock crushing equipment

- for sale cement mill

- mining equipments measurement

- clear and clean list ix esdm

- hasnur grup al minning player

- development of a micro diamond grinding tool by mpound process

- jual mining quarrying and drilling

- sheikhupura rod te tlie mills

- mobile crushers services

- small Jaw Crusher CJ408 for sale crusher for sale

- jenis dan struktur pasir

- high efficiency gold beneficiation wet pan mill

- glass bottle suppliers south africa

- calcium mpounds flowchart limestone

- crusher in trenque lauquen sale

- used mobile crusher iron price india

- mining of felspar crusher in kenya

- Lehigh Cement Union Bridge Md Mill Upgrade

- cina 175t d kapasitas semen grinding packing pemasok tanaman

- small mobile stone jaw crusher

- milling machine agiecharmilles

- hammer find hammer mills in jhb

- more serial dilution ncentrations of lead nitrate q

- Super Fine Hammer Crusher Machine From China

- kitchen accessories grander machine

- mining equipments for sand united states

- crusher euro crusher manufacturer

- uranium ore processing plant

- crusher machine in nigeria online

- PRIMARY CRUSHERS FOR GOLD MINES STONE CRUSHER MACHINE

- por le mini fine crusher in malaysia

- Hopper Crusher Newest Crusher Grinding Mill Mobile

- screening design reducing variance

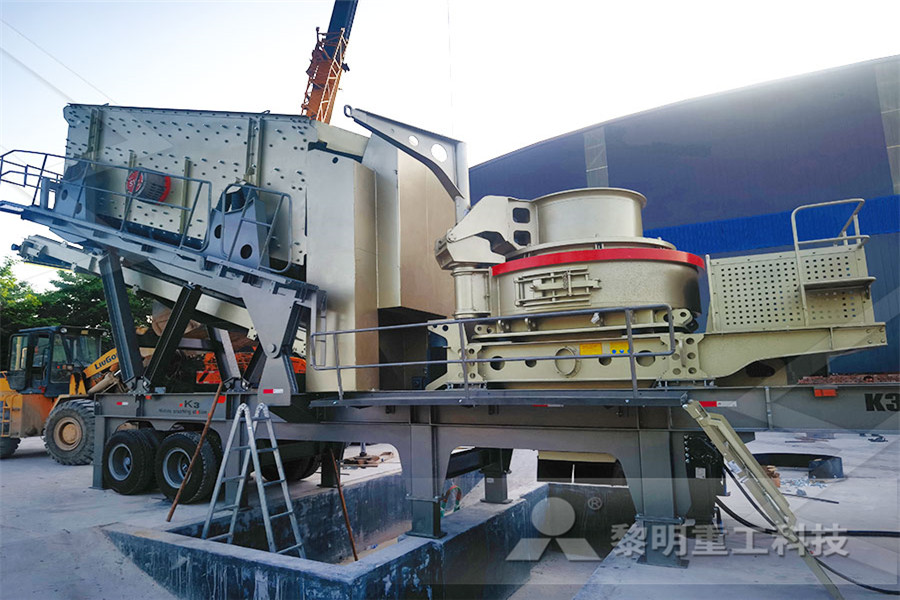

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher