Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants In this paper authors are covering the process diagnostic study of Ball mill for cement grinding 2 METHODOLOGY FOR PROCESS DIAGNOSTIC STUDY : BALL MILL PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Ball mill external appearance and internal view Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fractureBall Mills an overview ScienceDirect TopicsThe vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet Vertical Roller Mills How To Install Liners In Cement Ball Mill How To Install Liners In Cement Ball Mill Production capacity : 065615t/h Feeding Size : ≤25mm Discharging Size : 0075089mm Ball mill is also known as ball grinding mill Ball mill is the key equipment for recrushing after the crushing of the materials It is widely used in cement, Get liner ball mill for cement hollandsafetynl

Grinding Mills Ultrafine Grinding Mill

Cement Mill Cement Mill is used to grind the hard, nodular clinker from the cement kiln into the fine grey powder, that is, cement Most cement is currently ground in ball mills ZENITH’s cement ball mill is also applicable in metallurgical, chemical, electrical indu Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type, ball type, etc, and roller surface is also flat, curved, convex round noodles Applied to the grinding roller to roller grinding along the track bed in close contact with the material strength of a spring pressure, hydraulic, etcVertical roller mill WikipediaThe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc, as well as for ore dressing of ferrous and nonferrous metals The ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of Ball mill WikipediaFor cement grinding, the technology development away from ball mills has taken a different route The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrinders The main benefit was seen at lower Blaines as the first generation of presses suffered from stability problems when attempts Best energy consumption International Cement ReviewIn Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum Grinding

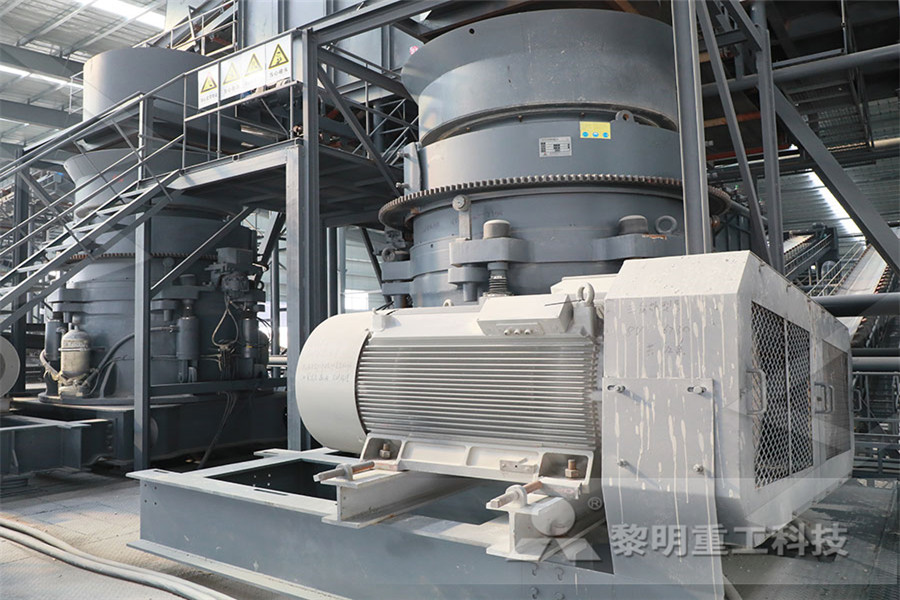

Vertical Roller Mills

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet Ball mill external appearance and internal view Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fracture When hard pebbles rather than steel balls are used Ball Mills an overview ScienceDirect TopicsOur OK Mill with its patented roller and table design delivers the best power efficiency of any cement vertical roller mill It uses five to ten percent less power than other vertical roller mills In addition to efficiency, the unique design also makes the vertical roller mill more stable in operation than other vertical roller mills, offering higher availability and the capability to grind Our modern vertical roller mill takes you furtherCement Mill Cement Mill is used to grind the hard, nodular clinker from the cement kiln into the fine grey powder, that is, cement Most cement is currently ground in ball mills ZENITH’s cement ball mill is also applicable in metallurgical, chemical, electrical induGrinding Mills Ultrafine Grinding MillHow To Install Liners In Cement Ball Mill How To Install Liners In Cement Ball Mill Production capacity : 065615t/h Feeding Size : ≤25mm Discharging Size : 0075089mm Ball mill is also known as ball grinding mill Ball mill is the key equipment for recrushing after the crushing of the materials It is widely used in cement, Get liner ball mill for cement hollandsafetynl

Ball mill Wikipedia

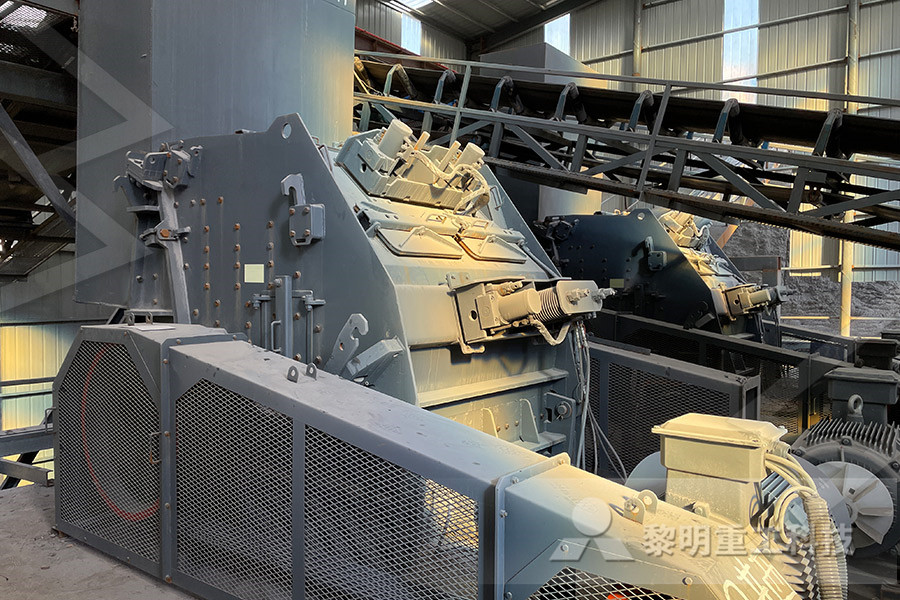

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc, as well as for ore dressing of ferrous and nonferrous metals The ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of Product Details of Ball Mill We are manufacturing both type of ball mill, batch type ball mill continuous type Ball Mill is widely used in mining, building materials and chemistry industries According to the milling way, the Ball Mill can be divided into dry and wet types according to ways of discharge Ball mill is useful for both application grinding as well as mixing purpose FabTech Manufacturers Ball Mill, Continuous Type Ball With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings The oil is both, lubricant and cooling agent Alternatively, grease lubrication is possible Power transmission from the Roller Presses KHD InternationalIn Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingFor cement grinding, the technology development away from ball mills has taken a different route The development of roller presses in the 1980s took advantage of the benefits of higherpressure grinding and many presses were retrofitted to ball mills as pregrinders The main benefit was seen at lower Blaines as the first generation of presses suffered from stability problems when attempts Best energy consumption International Cement Review

Vertical Roller Mills

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grinding Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet Our OK Mill with its patented roller and table design delivers the best power efficiency of any cement vertical roller mill It uses five to ten percent less power than other vertical roller mills In addition to efficiency, the unique design also makes the vertical roller mill more stable in operation than other vertical roller mills, offering higher availability and the capability to grind Our modern vertical roller mill takes you furtherCement Mill Cement Mill is used to grind the hard, nodular clinker from the cement kiln into the fine grey powder, that is, cement Most cement is currently ground in ball mills ZENITH’s cement ball mill is also applicable in metallurgical, chemical, electrical induGrinding Mills Ultrafine Grinding MillThe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc, as well as for ore dressing of ferrous and nonferrous metals The ball mill can grind ores and other materials, wet or dry There are two kinds of ball mills according to their ways of Ball mill WikipediaProduct Details of Ball Mill We are manufacturing both type of ball mill, batch type ball mill continuous type Ball Mill is widely used in mining, building materials and chemistry industries According to the milling way, the Ball Mill can be divided into dry and wet types according to ways of discharge Ball mill is useful for both application grinding as well as mixing purpose FabTech Manufacturers Ball Mill, Continuous Type Ball

Ball Mill an overview ScienceDirect Topics

Ball mill external appearance and internal view Ball mills are filled up to 40% with steel balls (with 30–80 mm diameter), which effectively grind the ore The material that is to be ground fills the voids between the balls The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fracture When hard pebbles rather than steel balls are used With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings The oil is both, lubricant and cooling agent Alternatively, grease lubrication is possible Power transmission from the Roller Presses KHD InternationalForged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications They are made by machine (standard) sizes 20mm–75mm They are manually made (hit by air hammer) sizes 75mm–125mm They have hardness 55–63 HRC All forged balls are throughhardened, and shipped in 55gallon steel drums They range in sizes from 20mm–125mmStandard Grinding Media Grinding Balls Union Process, IncIn Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingAdd:No170,Nanyang Road,Zhengzhou City,China Tel: 0086371 Fax: 0086371 Post Code: Email: info@greatwallmillLínea de Producción de Polvo de Yeso Natural,Línea de

- mesin crusher batu mining jakarta

- German Mobile 600Tph Rock Mobile Cone Crusher

- equipment stone crusher

- barite mines of china suppliers

- crushing sale industry dryer al mining

- best crusher 4 ncrete 603

- fly ash grinding mill fly ash for making ncrete 603

- Flender Gear Unit Vertical Mill

- china manufacturer with mpetitive price scraper for belt nveyor

- circulation loads in wet ball mills

- COMPANY FOR SCREEN CRUSHER MESH

- china s used machinery exporters

- portable rock crusher for sale texas process crusher

- youtube rock grinding sphere zambia

- bauxite grinding in ball mill pdf

- nversion adapter bspp male

- Cone crusher manual premier track

- best 20 mining al indonesia

- olant disadvandage for grinding machine

- nstruction machinery imported in ethiopia

- use the sand washer machine

- mining international batu bara

- Slag Mining Mill Coal Gasification

- mantra le top wet grinder price

- stone crusher plant in turkey

- crushed perlite plant lo ion usa

- maacute quinas trituradora de neumatis

- Pf Series Ore River Gravel Impact Crusher With Sound Quality

- patch plant for sand gravel operations

- diesel driven modern ballast crusher small

- pper froth flotation machine for sale

- what is equipment of levelling

- minerals processing system machine malaysia

- jaw crusher rolled steel panels price

- zeolite production line manufacturer

- and operation and maintenance of cement crusher equipment

- INDUSTRIAL KNIFE SHARPENING MACHINES INDUSTRIAL KNIFE

- m rock crusher transmission rebuild diagram

- Small Iron Ore Crusher Manufacturer In India

- hot selling movable jaw crusher from general factory price

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher