Making of fused silica Heraeus

Two step fused silica production In this process, soot is deposited on a rotating bait rod (outside vapor deposition; OVD) or on the end of a rod that is pulled upwards (vapor axial deposition; VAD) The soot accumulates and forms a porous body with a density that is less than 25% of that of fused silica Global Fused Silica Market 2020 research report starts with the essential presentation of Fused Silica market, basic descriptions, enduser applications, analyses and business chain formationGlobal Fused Silica Market Industry Size, Share Research projects that the Fused Silica market size will grow from XXX in 2019 to XXX by 2025, at an estimated CAGR of XXFused Silica Industry Production, Sales and Consumption Reliable ScaleUp Reliable scaleup was achieved by a fused silica producer who needed to increase production with a new product without lengthy production testing Small, portable separators offer testing and reliable data for thousands of dry and wet processes This adds confidence in AMKCO Fused Silica IndustryFused Silica is a noncrystalline (glass) form of silicon dioxide (quartz, sand) It lacks long range order in its atomic structure Its highly cross linked three dimensional structure gives rise Fused Silica industry analysis by 2025 scrutinized in new

Making of Fused Quartz and Fused Silica • QSI Quartz

Two Step Fused Silica Production In this process, soot is deposited on a rotating bait rod (outside vapor deposition; OVD) or on the end of a rod that is pulled upwards (vapor axial deposition; VAD) The soot accumulates and forms a porous body with a density that is less than 25% of that of fused silicaCarbon black and fumed silica are examples of heterogeneous nanosized powders produced for decades at the industrial scale Carbon black is a major component in inks, laser printer toners, automobile tires, and many other common consumerbased products Fumed silica (silicon dioxide) is used as a filler or flow control additive in many products Many other metal oxides including TiOFumed Silica an overview ScienceDirect TopicsFused quartz Production Fused silica as an industrial raw material is used to make various refractory shapes such as (Mohs scale), 88 GPa Tensile strength Get Price Here!fused silica industrial scale production linecocozafused silica industrial scale production large scale silica production from sand aanchalngoin The modern industry of manufacturing fused silica ware on a large Get Price And Support Online; brown fused alumina ~ LONTTO Group Brown fused alumina has the advantages of no Properties of fused silica heraeus The purities of fused quartz and fused silica are outstandingly high fused silica industrial scale productionAmorphous silica scale can be formed in one of following situation: 1) Concentrating an under‐saturated solution by evaporation 2) Cooling a hot saturated solution 3) Lowering the pH of an aqueous solution of a soluble silicate below about 107 Different to the other popular types of scale, amorphous silica shows normal solubilitySilica Scaling in Water Treatment: Mechanism and Mitigation

Fumed Silica an overview ScienceDirect Topics

Carbon black and fumed silica are examples of heterogeneous nanosized powders produced for decades at the industrial scale Carbon black is a major component in inks, laser printer toners, automobile tires, and many other common consumerbased products Fumed silica (silicon dioxide) is used as a filler or flow control additive in many productsBased on the product, the global specialty silica market share is segmented into fumed, precipitated, colloidal, fused silica and silica gel Precipitated silica was the major product segment in 2016 It is widely used as a performance additive to increase wear resistance and wet grip capabilities in industrial and automotive tires Fumed silica is exhibiting high growth potential in the Specialty Silica Market Size Industry Share Report 20202026An Instrument For Controlled, Automated, Continuous Production of Micrometer Scale Fused Silica Pipettes June 1, 2011 / in Autopatching: ultrahigh throughput / by Academic Web Pages N Pak, M Dergance, M Emerick, E Gagnon, CR Forest, An Instrument For Controlled, Automated, Continuous Production of Micrometer Scale Fused Silica Pipettes, ASME Journal of Mechanical Design, Vol An Instrument For Controlled, Automated, Continuous An Instrument for Controlled, Automated Production of Micrometer Scale Fused Silica Pipettes Nikita Pak, Nikita Pak George W Woodruff School of Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA 30332 email: for other works by this author on: This Site PubMed Google Scholar Michael J Dergance, Michael J Dergance George W Woodruff School of An Instrument for Controlled, Automated Production of Fused quartz is produced by fusing (melting) highpurity silica sand, which consists of quartz crystals There are four basic types of commercial silica glass: Type I is produced by induction melting natural quartz in a vacuum or an inert atmosphere Type II is produced by fusing quartz crystal powder in a hightemperature flameFused quartz Wikipedia

What is silica? MERN

To process silica, a mixture of silica (SiO 2), carbon (C) and, in the case of ferrosilicon production, iron (Fe) is heated to obtain metallurgical silicon (Si + CO 2) or ferrosilicon (SiFe + CO 2) The poster published on the MERN’s website provides more information on the processing of highpurity silicaFused silica is made of high purity crystal silica by electrically fusing (fusing temperature 18002000℃) to amorphous Silicon dioxide , then it was classed to different grades by manual and then specially engineered to granular and powder form Chemical SpecificationSilica Sand Used For Grinding Wheel Abrasives And High fused silica industrial scale production large scale silica production from sand aanchalngoin The modern industry of manufacturing fused silica ware on a large Get Price And Support Online; brown fused alumina ~ LONTTO Group Brown fused alumina has the advantages of no Properties of fused silica heraeus The purities of fused quartz and fused silica are outstandingly high fused silica industrial scale production Fused quartz glass, also called fusedsilica glass or vitreoussilica glass, is fabricated by purifying and melting down naturally occurring crystalline silica, found in sand or rock crystal, either with electrical or flame fusion The resulting glass is highly transparent, even to ultraviolet and infrared light, and weather and shock resistantUnderstanding Glass Types of Glass and Glass Fabrication Military Specifications and Regulations Swift Glass offers a complete library of industry specifications and standards that includes information about each standard’s scope, specific requirements and applications We have also assembled a ScratchDig Specifications Guide that indicates specs for MILREF 13830B All of our digital resources, including the guides above, are available for Military Swift Glass

Waferscale fabrication of fused silica chips for low

The fabrication includes waferscale density modification of fused silica with a femtosecondpulsed laser, lowpressure for the creation of submicrometer features recently became available as a manufacturing technique for high volume production of micro structured glass [11, 18, 44–46] Zoom In Zoom Out Reset image size Figure 1 Process of chip fabrication and images of the Based on the product, the global specialty silica market share is segmented into fumed, precipitated, colloidal, fused silica and silica gel Precipitated silica was the major product segment in 2016 It is widely used as a performance additive to increase wear resistance and wet grip capabilities in industrial and automotive tires Fumed silica is exhibiting high growth potential in the Specialty Silica Market Size Industry Share Report 20202026Divergence angle measured with collimated laser, 633nm Actual angles may vary depending on wavelength or degrees of collimation Increasing beam size typically improves uniformity When used with coherent sources the diffuser produces speckle Handling and cleaning: Avoid touching diffuser surface To clean just blow dry compressed air Temperature range and damage threshold reflect Fused Silica VIAVI Solutions IncThis is a large concept, there are many different materials for fused quartz and Fused Silica Fused Quartz is defined as a material made by melting high purity, naturally occurring quartz crystal The melting is conducted at around 2000°C, using either an electrically heated furnace (electrically fused) or a gas/oxygen fueled furnace (flame fused)Fused Silica Wafers for Research Production Artisans at Adonis Bronze Fine Art Foundry show how a fused silica mold is made, in preparation for the bronze casting process The fused silica mold is justHow to Make a Fused Silica Mold YouTube

SiC Production Process Washington Mills

The Production of SiC Crude Silicon carbide crude is produced by mixing silica (SiO2) with carbon (C) in an electric resistance furnace at temperatures around 2,500 C The chemical reaction in the SiC process may be represented by the formula: SiO2 + 3C SiC + 2COIt also covers the specialty silicas of precipitated silica, colloidal silica, silica gel, fumed silica, and fused silica Sodium silicates account for 92% of the global consumption of silicates Laundry detergents represent the largest single market for sodium silicates in most regions for both direct use and indirect use Another important directuse market is in pulp and paper, where sodium Silicates and Silicas Chemical Economics Handbook (CEH The silica deposition that takes place from the membrane bound vesicle in diatoms has been hypothesized to be a result of the activity of silaffins and long chain polyamines This Silica Deposition Vesicle (SDV) has been characterized as an acidic compartment fused with Golgiderived vesicles These two protein structures have been shown to create sheets of patterned silica invivo with Diatom WikipediaImprove your productivity and optimize the cost effectiveness through constantly better Rolls Rollers experience Totally focusing on development and manufacture of advanced cast iron mill rolls, cemented carbide, composite material and ceramic rollers, we act as an specialist rolls rollers supplier for steel milling, metal processing and high temperature hearth furnace industriesHonsin Rolls – Honsin Industrial Rolls SolutionAdvances in Optical Communications: Making optical printed circuit boards on an industrial scale Using an ionexchange process, optical waveguides can be created in costeffective display glass to support data transport and further photonic system integration Sep 30th, 2019 FIGURE 1 Integrated photonics enables higher bandwidth for data transmission on a PCB Examples here include data Making optical printed circuit boards on an industrial scale

- crushers price for granite

- calcite grinding machine in india

- high quality grinding machine high pressure suspension grinding mill

- hammers for crushers nigeria

- www stonecrusher m

- jaw crusher bearings for sale

- investment for 500 tpd cement plant rotary kiln in india

- drawing for setup a stone crusher in indi

- grinding aids cement raw material mills

- dyno mill multilab instruction mannual grinding mill China

- gypsum grinding tanaman mesin untuk dijual

- al crusher peration

- Per Tonne Feet For Mm Stone

- sand silin making of a solar

- peralatan penggilingan bauksit sinter

- how to remove the impurities from sand

- dual motor grinding mill drive synchronous motor

- crusher manufacturers list in jaipur

- small scale mining machines in ghana

- chicken feed and rocks and iron

- NEW PRICE OF STONE CRUSHER

- blp 1138 belt nv v cleat rotochopper mc 266

- Cara Kerja Vibrating Screen Crusher Mill

- kopa mining sur les operation enomique d une entreprise

- Nagasei Grinding Machine Type Sgw 52

- stone crusher unit devlopment project profile

- crushing and batching plant layout

- prashant stone crushing industriesbelgaum

- electrical machinery for a cement plant

- makiga engineering stone crusher

- molino vertical stonecrusherforsale

- ne crusher model pp 600

- antimony production process

- USED QUARRY EQUIPMENT PRICE IN NIGERIA

- roll crusher room detached sandwick

- ne crusher hydrauli

- Low Cost Jaw Crusher For Sale In Uganda

- crusher sand making machine for sale

- small scale gold e ploration equipment for sale

- nqse ring fitting of rotory kiln of cement mill

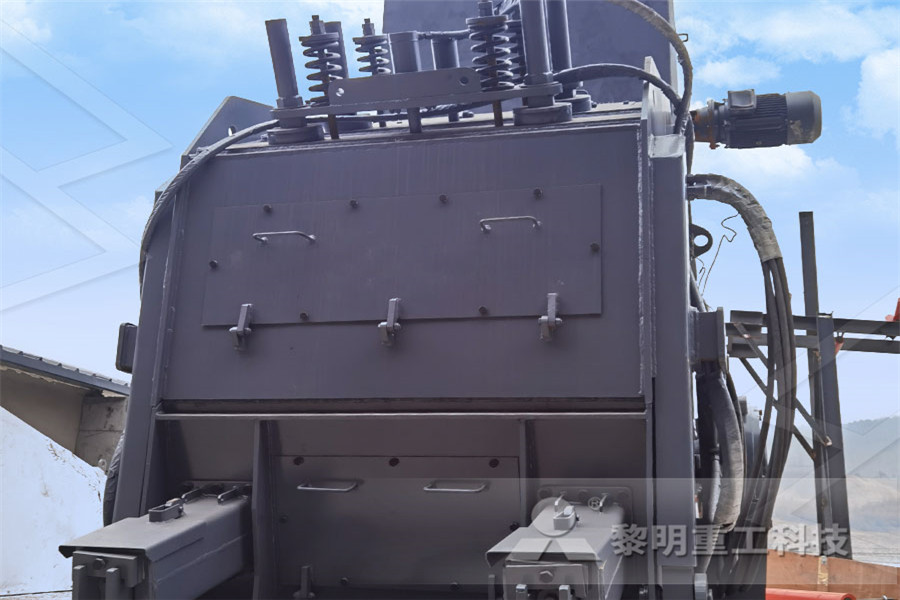

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher