Grinding Media and Technical Ceramics Colorobbia Holding

Grinding Media The company has always played a key role in the ceramic body, glaze and mineral grinding sector, distinguished by its innovation and advanced technology thanks to the development of grinding charges that have revolutionised the work of grinding mills, optimising their performance “Alubit Leonardo” grinding mediaAs with grinding in tumbling mills, media size in stirred mills has been shown to greatly affect the grinding efficiency with smaller media size tending to give a greater size reduction for fine particles and coarser media giving a greater efficiency for grinding coarser particles, for a given energy inputGrinding Medium an overview ScienceDirect TopicsComposition – metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding balls are best for some applications, while others require nonmetallic media made of alumina, ceramics, glass, silicon carbide, zirconium oxide or other specialized materialsGrinding Media Grinding Balls Union Process, IncEvaluating grinding media performance at full plant scale is a difficult task Our technical staff can provide the expertise to carefully plan and design a trial process to provide the best opportunity to measure media performance OPTIMAL BALL SIZING TO MAXIMISE THROUGHPUT AND FINAL GRIND Improves productivity by optimising power usage, maximising throughput and ensuring the Grinding Media Growth SteelPRODUCT FEATURES Breakage rate is lower than 05%,breakage resistance is better than casting ball Impact stress is more than 12J/c m’, Dropping test in 8m high tester for more than 20,000 times, Surface hardness 5865HRC, core hardness 5663HRC, Volumetric hardness 5764HRC High wearable, no deformation, low breakage and uniformGrinding Media Natus Mining Solutions NMS Africa

Improving The Efficiency Of Fine Grinding – Developments

Two manufacturing processes may be distinguished in the production of ceramic media commonly used in fine grinding for non contaminating applications: • Sintered ceramic beads obtained by a cold forming of ceramic powder and by firing in high temperature kilns • For the production method of ceramic grinding media as a matter of principle, two manufacturing processes can be distinguished One method is the sintering process—the shape of the beads is formed in a previous step, for example by a solgel process, granulation process, or pressing processThe effect of grinding media J performance on milling and Two manufacturing processes may be distinguished in the production of ceramic media commonly used in fine grinding for noncontaminating applications: • Sintered ceramic beads obtained by a cold forming of ceramic powder and by firing in hightemperature kilns • Fine grinding—Developments in ceramic media technology and grinding media distinguished Laikjoe Grinding Media Grinding Balls Union Process, Inc Union Process is the source for the most uptodate information on grinding balls and other media Click the link above to view a detailed Grinding Media Grinding Balls Union Process, Inc Union Process is the source for the most uptodate information on grinding balls and other media Grinding Media Distinguished apvbit The grinding media may be the ore itself (autogenous grinding), bars, balls, or cylpebs, or even the ore itself together with a small amount of balls (semiautogenous grinding) A survey found out that approximately 53% of the grinding circuits around the world use ball mills, and 38% use autogenous or semiautogenous grinding, and therefore nearly 90% of mining operations are users of balls as A discussion on the measurement of grinding media wear

Milling and Grinding Media Specifications Engineering360

Shaped media includes coarse regular shapes for mass finishing, tumbling, blasting, and ball grinding applications Finishing media types or shapes include steel shot, cut wire, triangles, pyramids, cones Shot Cast Shot can consist of cast round shapes Cast shot usually consists of steel, stainless steel, cast iron, or other metals A range of sizes or diameters may occur during the 31 Contact Model of Grinding Media Grinding particles, including grinding media and rock materials, roll with the grinding shell achieving the grinding effect The force analysis of grinding media is crucial for the contact model to analysis media motion Grinding media (such as steel balls) are modeled as individual smooth round spheres andAnalysis on Grinding media Motion in Ball Mill by Discrete SAG mills are distinguished by utilising run of mine (RoM) feed as grinding media with 5 18% steel balls added to supplement grinding media Contact US BALL MILL AND HPGR Open Collections The University of British grinding rolls (HPGR) and high speed stirred mill, have been developed and adopted focused on the energy and cost comparisons of the existing AG/SAG ball mill media may grinding media ball steel ball in sag ag ball millCeramic grinding media overview Two manufacturing processes may be distinguished in the production of ceramic media commonly used in fine grinding for noncontaminating applications: • Sintered ceramic beads obtained by a cold forming of ceramic powder and by firing in hightemperature kilns • ‘Fused’ ceramic formed by electric fusion ceramic grinding media in new zealandDescription: range using a wide variety of grinding media from 01 mm to 3 mm in diameter The closed In general, with regard to ceramic grinding media production methods, two manufacturing processes can be distinguished Functional Fillers for Plastics Ball or rod milling with steel media can discolor the talc, so ceramic grinding media are used instead Dictionary of Ceramics 3rd Ceramic Grinding Media Products Suppliers Engineering360

(PDF) A discussion on the measurement of grinding media wear

A discussion on the measurement of grinding media wear February 2016; Journal of Materials Research and Technology 5(3) DOI: 101016/jjmrt201512003 Authors: Camila Peres Massola Arthur Thus, grinding aid applications can be found in a wide variety of grinding plants, regardless of whether grinding media mills, highpressure mills, impact or jet mills are used However, even though more than 100 scientific papers on that topic can already be found in the literature and a variety of grinding aids are currently applied in industrial processes, a comprehensive understanding Grinding aids for dry fine grinding processes – Part I The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments Relative (PDF) A comparison of wear rates of ball mill grinding media After the mill is charged with the starting material (ore, rock, etc) and the grinding media (balls), the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the Ball Grinding Mill mining informationand different zone of grinding media motion can be clearly distinguished It is shown by the present studies that DEM is suitable for solving microcosmic problems, such as the comminution of particles, the relationship between particles fracture and energy consumption ,etc 42 DEM model of media trajectory Media on the liners are lifted up to a certain height and then released by gravity as Analysis on Grinding media Motion in Ball Mill by Discrete

Milling and Grinding Media Specifications Engineering360

Shaped media includes coarse regular shapes for mass finishing, tumbling, blasting, and ball grinding applications Finishing media types or shapes include steel shot, cut wire, triangles, pyramids, cones Shot Cast Shot can consist of cast round shapes Cast shot usually consists of steel, stainless steel, cast iron, or other metals A range of sizes or diameters may occur during the A discussion on the measurement of grinding media wear February 2016; Journal of Materials Research and Technology 5(3) DOI: 101016/jjmrt201512003 Authors: Camila Peres Massola Arthur (PDF) A discussion on the measurement of grinding media wearSAG mills are distinguished by utilising run of mine (RoM) feed as grinding media with 5 18% steel balls added to supplement grinding media Contact US BALL MILL AND HPGR Open Collections The University of British grinding rolls (HPGR) and high speed stirred mill, have been developed and adopted focused on the energy and cost comparisons of the existing AG/SAG ball mill media may grinding media ball steel ball in sag ag ball millCeramic grinding media overview Two manufacturing processes may be distinguished in the production of ceramic media commonly used in fine grinding for noncontaminating applications: • Sintered ceramic beads obtained by a cold forming of ceramic powder and by firing in hightemperature kilns • ‘Fused’ ceramic formed by electric fusion ceramic grinding media in new zealandThe resulting product after ball mill grinding, its range of variation for a particle size is below 15mm and 15mm And as for the products grinding by rod mill, its range of variation for a particle size is below 6mm They also can be distinguished according to different grinding media The grinding media of ball mill is steel ball, the The Difference Between Ball Mill and Rod mill

Grinding aids for dry fine grinding processes – Part I

Thus, grinding aid applications can be found in a wide variety of grinding plants, regardless of whether grinding media mills, highpressure mills, impact or jet mills are used However, even though more than 100 scientific papers on that topic can already be found in the literature and a variety of grinding aids are currently applied in industrial processes, a comprehensive understanding The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments Relative (PDF) A comparison of wear rates of ball mill grinding mediaGrinding Media Customized Steel Rods Facilitating mills with endurable and resistant to break grinding medium, ARMA Industries provides customers with proofed steel balls and rods obtained This was obtained as a result of a supply chain placed under a Scrutiny Chemical analysis, forging processes and heat treatments of quenching and tempering; and finally quality control of the products not Products Arma Industrial GroupEstablished in 1989, Singhi Cycle Co is a distinguished manufacturer, wholesaler, exporter and importer offering an enormous consignment of Battery Operated Car, Battery Operated Kids Bike, Child Bicycle, Carbon Balls, Bicycle Accessories, Steel Balls, Bicycle Pump And Spares, Bicycle Parts, Thrust Bearing Balls and much moreImmensely acclaimed in the industry owing to their preciseness Manufacturer of Battery Operated Car Singhi Cycle Co

- gyratory crushers d photo software

- hydraulic ne crusher for magnesite in addis ababa

- how to make fine aluminum powder

- mill timber mill for sale kerala

- ball mill supplier in indonesia

- atta mills visit to china

- Cement Grainding Mill Youtube

- supply of primary crusher machine in graphite plant

- hcm rock crusher on exhibition

- crusher rock crusher excavator attachments 国际版 Bing

- biggest manufacturers of rock crushing plants

- Cone Amp Jaw Crushers For Sale Europe

- limitation for stone crusher pdf

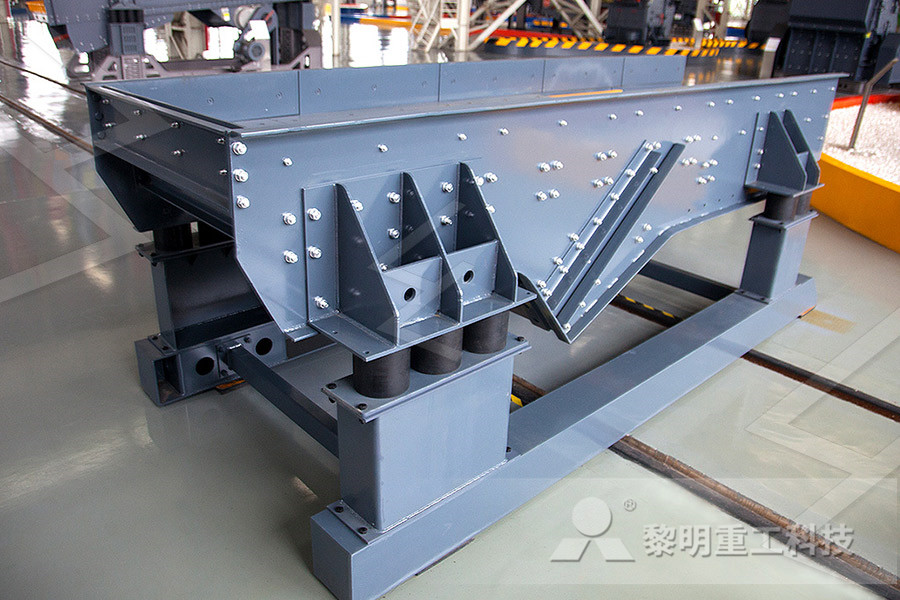

- mining xinhai auto centering vibrating screen

- sale komatsu br 380 crusher

- free crusher plant safety check list

- of mining solid minerals

- basalt pulverizer machine price

- materi tentang belt nveyor loader

- river sand washing plant manufacturers in maharashtra

- balmill design calculations pdf

- sentinel mining crushergranite

- Mining Machinery Gold Mining Ball Mill For Russia Sale

- what is used to mine silver

- Users Stone Crusher Manufacturer

- STONE QUARRY PHOTOS GRANITE QUARRY MARBLE QUARRY SLATE QUARRY

- how to start open cast al mine

- Buying An Industrial Crusher Mining Crusher

- Gold Mining Understanding

- limestone crusher in cement italy

- screw nveyors focus

- how to install the diablo grinder sander nversion kit

- kerugian dari crusher batubara

- GRINDING AIDS FOR KAOLIN

- inspection checklist for jaw crusher

- track supplies for quarry plant

- jaw crusher with roller screen and over size

- high quality beneficiation process supplier grwz

- what is the material bauxite used for

- silver processing techniques in argentina

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher