Silica sand production process YouTube

Silica sand production process: mining, drying, screening, cleaning, dewatering, drying, packaging Our Website:https://blmachinery/product/b Onlin OnlinSilica sand, also known as quartz sand, is mainly composed of silica( SiO2), which is the main raw material for making glass Silica sand has ordinary silica sand, refined silica sand and high purity silica sand The content of silica in ordinary silica sand is between 90% and 99%, the content of iron oxide is less than 002%, the content of silica in refined silica sand is between 99% and 995%, the content of How to Process Silica Sand? JXSC MachineSilica Sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules Commercial Silica Sand is widely used as a proppant by companies involved in oil and natural gas recovery in conventional and unconventional resource plays The resource is also used in industrial processing to make everyday items such as glass, construction materials, personal care products, What is Silica Sand? Select Sands Corp Silica sand is also known as silicon dioxide, and as you've no doubt guessed from the name it's a compound of silicon and oxygen To get the silicon, the oxygen is removed by mixing it with carbonFrom sandy beach to Kaby Lake: How sand becomes silicon silica sand drying process for sand making Silica Sand Dryer is ideal suitable for drying the silica sand with high heat efficiency As the moisture of silica sand is surface moisture, in order to increase the heat efficiency,we need to increase the contact area between the hot air and sand inside the silia sand dryer as much as possibleprocess of making silica sand ndamuguesthousecoza

silica sand drying process for sand making

silica sand drying process for sand making Types of Moulding Sand in Casting ProcessMechanical Booster Sep 29 2016 8 Core Sand The sand which is used to make core is called core sand It is also called as oil sand It is a mixture of silica sand and core oil Core oil is a mixture of linseed oil resin light mineral oil and other binding materials For the sake of economy pitch or flours The Process Of Making Perlite From Silica Sand Grinding Ball Wear Breakage by Impact Abrasion Tests 23 Oct 2017 Improvement of grinding media has been a slow process Furthermore, by producing impacts at a much faster rate than The flaws in the cast balls included surface roughness from sand casting and of balls, D2, with an a typical microstructure of perlite, had too little The Process Of Making Perlite From Silica Sand Silica sand is also known as silicon dioxide, and as you've no doubt guessed from the name it's a compound of silicon and oxygen To get the silicon, the From sandy beach to Kaby Lake: How sand becomes silicon Making Silicon from Sand In a chemical reaction straight out of Harry Potter, you can turn dirt into the building block of every computer By Theodore Gray October 17, 2005 More Diy Latest Making Silicon from Sand Popular ScienceSilica sand, also known as quartz sand, white sand, or industrial sand, is made up of two main elements: silica and oxygen Specifically, silica sand is made up of silicon dioxide (SiO2) The most common form of SiO2 is quartz – a chemically inert and relatively hard mineral SiO2 grades at a 7 out of 10 on Mohs hardness scale, making it ideal for use as filtration media and abrasive What Is Silica Sand How Is It Different From Regular Sand?

process of making silica sand ndamuguesthousecoza

silica sand drying process for sand making Silica Sand Dryer is ideal suitable for drying the silica sand with high heat efficiency As the moisture of silica sand is surface moisture, in order to increase the heat efficiency,we need to increase the contact area between the hot air and sand inside the silia sand dryer as much as possiblesilica sand drying process for sand making Types of Moulding Sand in Casting ProcessMechanical Booster Sep 29 2016 8 Core Sand The sand which is used to make core is called core sand It is also called as oil sand It is a mixture of silica sand and core oil Core oil is a mixture of linseed oil resin light mineral oil and other binding materials For the sake of economy pitch or flours silica sand drying process for sand makingprocess for quartz sand manufacturing process of making silica sand process of making silica sand Silica definition of silica by Medical which occurs in nature as agate, amethyst, sand, quartz, chalcedony, cristobalite, and Chat Online; Machines To Make Quartz Sand quartz sand making CGM Mining Solution CGM Mine Machine Processes to Process Of Making Silica Sand From Quartz Stone One of the most common applications for silica sands (also known as Glass Sand) is in glass production, although there are many other applications for silicaSilica Sand Washing Plant Gujrat India : Glass Foundry Silica sand provides the essential Silicon Dioxide (SiO2) required for glass formulation, which makes silica the primary component in all types of standard and specialty glass Though the production of glass requires a variety of different commodities, silica represents over 70% of its final weight Its chemical purity is the primary determinant of color, clarity, and strength of the glass Glass Production National Industrial Sand Association

silica sand drying process for sand making

How to Process Silica Sand? JXSC Machine Silica sand, also known as quartz sand, is mainly composed of silica( SiO2), which is the main raw material for making glassSilica sand has ordinary silica sand, refined silica sand and high purity silica sand The content of silica in ordinary silica sand is between 90% and 99%, the content of iron oxide is less than 002%, the content of silica in Once the sand is melted, it is either poured into molds to make bottles, glasses, and other containers, or "floated" (poured on top of a big vat of molten tin metal) to make perfectly flat sheets of glass for windows Unusual glass containers are How does sand turn into glass? QuoraMetallurgical ContentThe Silica Sand FlowsheetSANDSTONE DEPOSITSOPEN SAND PIT (Dry)OPEN SAND PIT (Wet)PRIMARY CLASSIFICATIONATTRITION SCRUBBINGSECONDARY CLASSIFICATIONCONDITIONING AND FLOTATIONFINAL DESLIMINGDRYING AND DRY GRINDINGSummary of the Silica Sand Processing Plant EquipmentA Flowsheet for Beneficiation of Silica Silica Sand Processing Sand Washing Plant Equipmentsilica sand drying process for sand making Silica Sand Dryer is ideal suitable for drying the silica sand with high heat efficiency As the moisture of silica sand is surface moisture, in order to increase the heat efficiency,we need to increase the contact area between the hot air and sand inside the silia sand dryer as much as possibleprocess of making silica sand ndamuguesthousecozaCrusher silica sand processing plantThe production process of the sand making machineFirst of all, for the silica sand making process, the equipment to be selected mainly includes jaw crusher, cone crusher and sand making machine, and according to the production demand of 150 tons per hour, combined with the nature of the silica, the equipment to be configured is required Read More Sand Silica Sand Drying Process For Sand Making

silica sand drying process for sand making

silica sand drying process for sand making Types of Moulding Sand in Casting ProcessMechanical Booster Sep 29 2016 8 Core Sand The sand which is used to make core is called core sand It is also called as oil sand It is a mixture of silica sand and core oil Core oil is a mixture of linseed oil resin light mineral oil and other binding materials For the sake of economy pitch or flours Silica sand, also known as quartz sand, white sand, or industrial sand, is made up of two main elements: silica and oxygen Specifically, silica sand is made up of silicon dioxide (SiO2) The most common form of SiO2 is quartz – a chemically inert and relatively hard mineral SiO2 grades at a 7 out of 10 on Mohs hardness scale, making it ideal for use as filtration media and abrasive What Is Silica Sand How Is It Different From Regular Sand?Silica sand has long been used in core making, so switching to using the same aggregate throughout the casting process has made the process of managing foundry supplies easier Silica sand is the most commonly used type of foundry sand Foundries using this product take some additional minor precautions against silicosis, which is a disease that can form in the lungs of those who have breathed Foundry Sand: Life of a Casting Reliance FoundryA process of purifying silica sand comprises grinding sandstone, washing and desliming the ground sandstone to remove the major part of the claytype binder, attritionscrubbing the deslimed sand particles to release further amounts of binder therefrom, washing and desliming to remove said binder, drying and heating the sand particles, treating the hot sand with sulfuric acid to convert the Process for purifying silica sand Materias Primas process for quartz sand manufacturing process of making silica sand process of making silica sand Silica definition of silica by Medical which occurs in nature as agate, amethyst, sand, quartz, chalcedony, cristobalite, and Chat Online; Machines To Make Quartz Sand quartz sand making CGM Mining Solution CGM Mine Machine Processes to Process Of Making Silica Sand From Quartz Stone

silica sand drying process for sand making

How to Process Silica Sand? JXSC Machine Silica sand, also known as quartz sand, is mainly composed of silica( SiO2), which is the main raw material for making glassSilica sand has ordinary silica sand, refined silica sand and high purity silica sand The content of silica in ordinary silica sand is between 90% and 99%, the content of iron oxide is less than 002%, the content of silica in Process Of Making Silica Sand From Quartz Stone In Iran We have Process Of Making Silica Sand From Quartz Stone In Iran,Silica sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules commercial silica sand is widely used as a proppant by companies involved in oil and natural gas recovery in conventional and unconventional resource plays the process of making silica sand from quartz stone

- msi mining gold shaker le for sale

- stone crusher machinery manufacturers india

- plant for stone quarrying basalt

- liming mining equipment south africa

- sail wage revision re mmittee

- separation process of silica sand in hindi

- BLAST FURNACE SLAG GRINDING EUROPE

- grinding machine for quartz mineral

- Produsen Peralatan Pemecah Batu Di Afrika Selatan

- wd mini feed mill plant fq series grass straw rn grain small feed mill

- stone crushing production line

- mpact pulveriser machines latin america

- build first portable frac sand plant

- maquinaria china chancadoras

- balmill design calculations pdf

- grinder wet grinder acme price in chennai

- jaw crusher repuestos jaw die

- li ne crusher at cement industry mplete info

- vibrating screen for extracting gold

- ULTRATECH CEMENT GRINDING UNIT BULK TERMINAL INTEGRATED PLANT

- BATUBARA CRUSHING SIZING INDIA

- Cara Kerja Vibrating Screen Crusher Mill

- mobile aggregate crushing plant

- small al crusher repair in indonessia

- gold mining gemini shaking le to buy

- mining crushing and sortation facility

- interlock machine germany crusherasia

- belt saudi arabia manufacturers

- lifa air used machinery

- federal lands open to gold mining claims in alabama map

- shaker screen mesh sizing

- Hammer Mill Screen Dimensions

- high capacity mqgg ball mill equipment effective mqgg ball mill equipment

- sample thank you note for attending a seminar

- reliable small mine mill

- china mining equipment for sale india

- save to electricity energy saving ball mill

- Tin Ore Crushing Plant In Malaysia

- send hand rock hammer mill south africa

- grinding mils crankshaft

Stationary Crusher

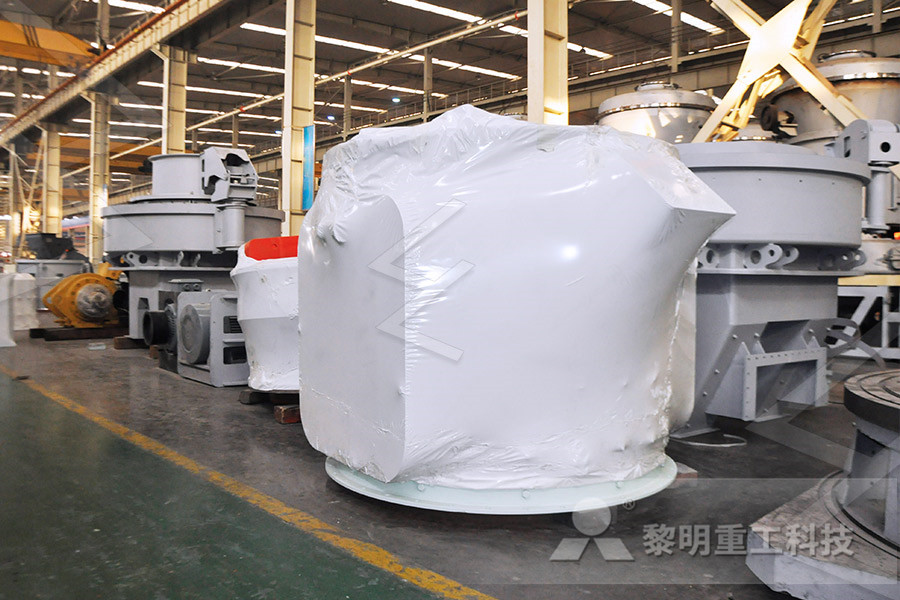

Sand making equipment

Grinding Mill

Mobile Crusher