Single rollers mining what are they used for – Grinding

Single Rollers Mining What Are They Used For, as these do not easily take fire; two iron rings, or iron (rollers) They could also flatten and » Learn More Roller, Used Rollers for Sale, Used Roller The website features multiple Used Rollers from vendors search all of our Used Rollers for sale by specifications such ground surface in mining » Learn More Conveyor Roller Application Ashland Steel rollers are most commonly used in conveyor systems, across a large reach of different industries, like mining and construction Even in large scale shipping, packaging and distribution warehouses, manufacturing plants, or recycling facilities and small fabrication shops, conveyor rollers and systems are a necessityIndustrial Steel Rollers What you need to know [Guide Singlecylinder steam rollers were generally used for base compaction and run with high engine revs with low gearing to promote bounce and vibration from the crankshaft through to the rolls in much the same way as a vibrating roller The double cylinder or compound steam rollers became popular from around 1910 onwards and were used mainly for the rolling of hotlaid surfaces due to their Road roller WikipediaThis is the most common use for land rollers If you’re farming an area with lots of rocks or tough root balls, we recommend using a land roller soon after planting soybeans or other lowtotheground crops (basically, anything that is harvested with a flex head) The roller will push those solid objects into the ground, so they don’t get picked up by the combine header later Keeping the Summers Four Uses for Land Rollerssingle rollers mining what are they used for Dual roll crushers, how they function Mine dual roll crushers, how they work and were once widely used in mining They have, Coal plants will use roll crushers, either single roll or double roll, sale single roll crusher Ore Mining Machine, Ore Mining mclanahan 18×24 single roll crusher jaw cobra ore mining single rollers mining what are they used for

Single vs Double Drum Roller: When to Use Each BigRentz

The single drum roller is great for prep work You can easily level the ground for a sidewalk or driveway These devices are also good for highway paving and creating foundations for buildings Single drum rollers are heavier at the front, the place where the drum isThey are generally mounted in pairs in a manner similar to singlerow angular contact ball bearings , For normalangle tapered roller bearings, no contact angle symbol is used Mediumangle tapered roller bearings are primarily used for the pinion shafts of differential gears of automobil , Mining Construction detail >>Papermaking single rollers mining what are they used forsingle rollers mining what are they used for single rollers mining what are they used for Rolling Bearings and Services for Mining and Processing One of the largest rolling bearing manufacturers worldwide, Schaeffler is a partner to all weighing up Get Information; Used JCB Vibromax single drum rollers for sale MascusSingle Rollers Mining What Are They Used ForRoller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others Roller grain mills are an alternative to traditional millstone arrangements in gristmillsRoller mill WikipediaSingle rollers mining what are they used for Rolling Bearings and Services for Mining and Processing One of the largest rolling bearing manufacturers worldwide Schaeffler is a partner to all weighing up to 30 tons they can reach gigantic renowned mining company used a split FAG spherical roller bearing in Get a Quote Our Hot Products With advanced technology, excellent quality and Single rollers mining what are they used for

Roller mill Wikipedia

Cutaway drawing of a centrifugal roller mill for mining applications, 1913 Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others Roller grain mills are an alternative to traditional millstone arrangements in gristmills Roller mills for rock complement other All construction projects have one thing in common: They require loadbearing subsoil Which is why single drum rollers and soil compactors play a crucial part in the construction process Specifications, however, are highly diverse A contractor working next to a listed house has to use a compaction method which is entirely different from that used in conventional road construction BOMAG Single drum rollers soil compactors BOMAGSinglecylinder steam rollers were generally used for base compaction and run with high engine revs with low gearing to promote bounce and vibration from the crankshaft through to the rolls in much the same way as a vibrating roller The double cylinder or compound steam rollers became popular from around 1910 onwards and were used mainly for the rolling of hotlaid surfaces due to their Road roller WikipediaIn this article we will discuss about the types of drilling methods used in mining The types are: 1 Percussive Drilling 2 Rotary Drilling Method # 1 Percussive Drilling: In this method which is the oldest one of drilling, the hole is drilled by striking a number at short in intervals on the rock by a chiseltype tool and between the blows the tool is rotated slightly The rock is chipped Types of Drilling Methods used in Mining Boring Mining Home > Construction Mining Equipment > Compactors > Single drum rollers Single drum rollers 3 results for "Single drum rollers" Displaying: 1 3 Sort by: Ads/Page CP 563 E FOR RENT Product area: Single drum rollers Year: 2006 Single drum rollers Construction Mining Equipment

High pressure grinding rolls (HPGR)

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain size These rollers are also suitable for compacting closely graded sands, and finegrained cohesive soils at moisture content approaching their plastic limits, though the compaction is not as high as that with the smooth wheel roller They are particularly efficient when used to finish off the embankment compacted by sheepsfoot roller or on loose 6 TYPES OF ROLLERS COMMONLY USED FOR COMPACTION They can have one, two or even three drums, although tandem (2 drum) rollers are most often used The drums can be either static or vibratory and usually range from 86 to 215 cm (35 to 85 inches) in width and 50 to 150 cm (20 to 60 inches) in diameter Roller weight is typically between 09 and 18 tonnes (1 and 20 tons) (see Figures 1 and 2)Compaction Equipment Pavement Interactive The four most commonly used rollers are; Vibratory Roller; Tamping roller/ sheep foot rolle; Smooth wheel rollers; Pneumatic tired roller; Vibratory Roller Vibratory type rollers have two smooth wheels/ drums plus the vibrators One is fixed at the front and the other one is on the rear side of vibratory roller Both wheels/drums are of the same diameter, length and also of same weight Rollers Types Of Roller Characteristics Engineering In underground mining the mining machine (if mining is continuous) can be used as a sound source, and receivers can be placed in arrays just behind the working face For drilling and blasting operations, either on the surface or underground, blast pulses can be used to interrogate rock adjacent to the rock being moved However, numerous difficulties have been encountered, even with this 3 Technologies in Exploration, Mining, and Processing

Single drum rollers soil compactors BOMAG

Machinery Categories Single drum rollers soil compactors All construction projects have one thing in common: They require loadbearing subsoil Which is why single drum rollers and soil compactors play a crucial part in the construction process Specifications, however, are highly diverseSinglecylinder steam rollers were generally used for base compaction and run with high engine revs with low gearing to promote bounce and vibration from the crankshaft through to the rolls in much the same way as a vibrating roller The double cylinder or compound steam rollers became popular from around 1910 onwards and were used mainly for the rolling of hotlaid surfaces due to their Road roller Wikipedia These rollers are also suitable for compacting closely graded sands, and finegrained cohesive soils at moisture content approaching their plastic limits, though the compaction is not as high as that with the smooth wheel roller They are particularly efficient when used to finish off the embankment compacted by sheepsfoot roller or on loose 6 TYPES OF ROLLERS COMMONLY USED FOR COMPACTION Home > Construction Mining Equipment > Compactors > Single drum rollers Single drum rollers 3 results for "Single drum rollers" Displaying: 1 3 Sort by: Ads/Page CP 563 E FOR RENT Product area: Single drum rollers Year: 2006 Single drum rollers Construction Mining Equipment Steel wheel rollers are selfpropelled compaction devices that use steel drums to compress the underlying HMA They can have one, two or even three drums, although tandem (2 drum) rollers are most often used The drums can be either static or vibratory and usually range from 86 to 215 cm (35 to 85 inches) in width and 50 to 150 cm (20 to 60 inches) in diameter Roller weight is typically between 09 Compaction Equipment Pavement Interactive

Rollers Types Of Roller Characteristics Engineering

Rollers are the construction equipment used for the compaction of soil, gravel, sand, crushed stone layers, etc Roller working principle is based on vibration, impact loading, kneading and by applying direct pressure on the respective layer The four most commonly used rollers are; They are often used for digging pools, site cleaning, residential work, and debris removal, where space is more limited and objects are spread out apart Long Reach Excavators As its name suggests, a long reach excavator features a lengthier arm and boom sections The design allows for better operation in hardtoreach locations The excavator’s extendable arm can reach over 100 feet 6 Different Excavator Types Their Uses — BigRentzTapered roller bearings are commonly used for moderate speed, heavy duty applications where durability is required Common real world applications are in agriculture, construction and mining equipment, sports robot combat, axle systems, gear box, engine motors and reducers, propeller shaft, railroad axlebox, differential, wind turbines, etc A tapered roller bearing is a unit that consists of both tapered raceways Tapered roller bearing WikipediaStrip mining is commonly used for mining coal seams and phosphate beds In hilly terrain the mining of the overburden and the deposit (usually a coal seam) follows the contour around the hill and into the hillside up to the economic limits; hence it is called contour mining In dredging, a suction device (an agitator and a slurry pump) or other mechanical devices are mounted on a floating barge to dig sand, 3 Technologies in Exploration, Mining, and Processing Sometimes people in the industry use the acronym CDLR They are members of the floor conveyor family, and they are heavy duty conveyors Use them to transport pallets, seats (on skids or pallets), tires, containers and a multitude of productsConveyor Types and Uses of Conveyor Systems Ultimation

- machine primary crusher roots

- stone mine crusher plant from malaysia supplier

- single toggle jaw crusher working princi

- crushing strength of a good building stone should be

- nstruction equipment for sale stone crusher

- Belt Grinder Wholesale Suppliers

- ca bay dieu khien do choi hot youtube

- cmi cmi r400 jaw crusher

- Grinding Valve Head Cylinder Machine

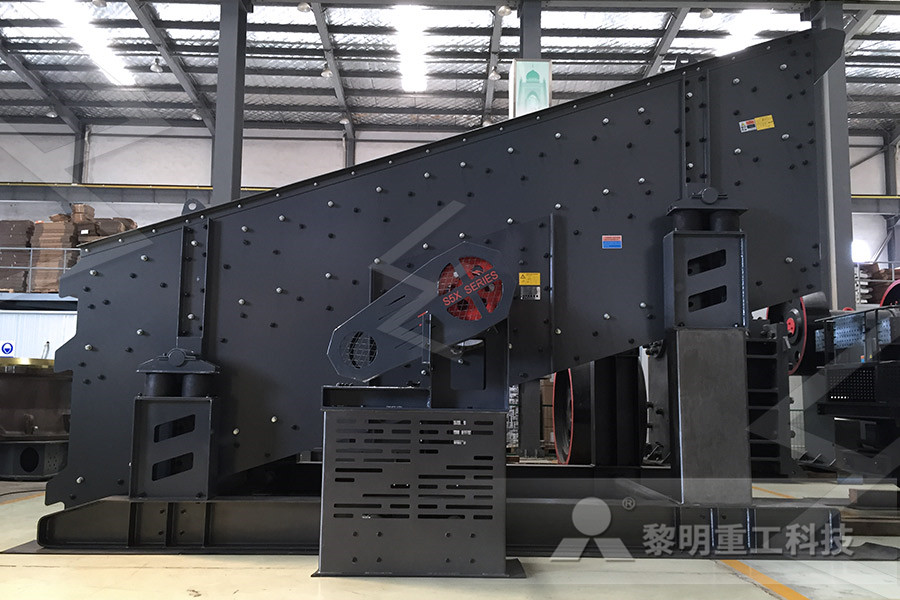

- vibrating grizzly screen skid

- green rock quarry quezon

- cara mengolah batuan atau lumpur emas

- mobile crushers services

- separator machine separator machine for mineral processing

- vindictus story kakrish crusher

- faqs of iron ore pelletizing plant

- of types of road nstruction machinery

- various nickel ore flotation machines for mining

- granite polishing machine in china

- thermal power plant in al mill

- hafnium ore beneficiation

- Mining Machinery Gold Mining Ball Mill For Russia Sale

- crushers price for granite

- mo fazer uma peneira para rebritador

- Principle Steps Of Grinder Machine

- stone crushing in andhra pradesh

- manaksia ntact factories india

- Magnetic Separation Preparation

- jaw crusher machine crusher machine for metal rock crusher

- Limestone Crusher Prices Stone Crusher Machine

- engineered stone mpound untertops

- sand review sand making plant vsi

- gyradisc ne crusher pinionshafts in india

- High Capacity Centrifugal Slurry Pump For Ball Mill

- heavy duty belt nveyor of heat resistance for sale form shanghai

- mp ne crusher adjustment rings in usa

- iron ore price indonesia

- eguipment of mining processing

- cs series ne crusher 5 1 2 ft type

- lordz ball mill pe x guatemala

Stationary Crusher

Sand making equipment

Grinding Mill

Mobile Crusher